OBS 7.3 Fuel System Diagram: Troubleshooting & Repair

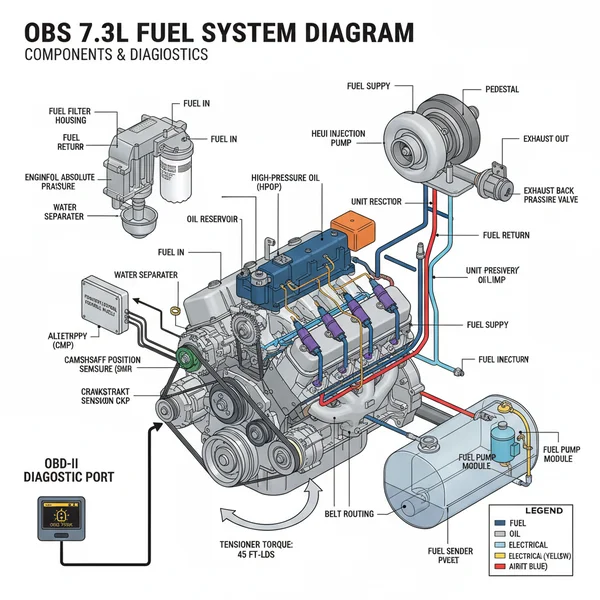

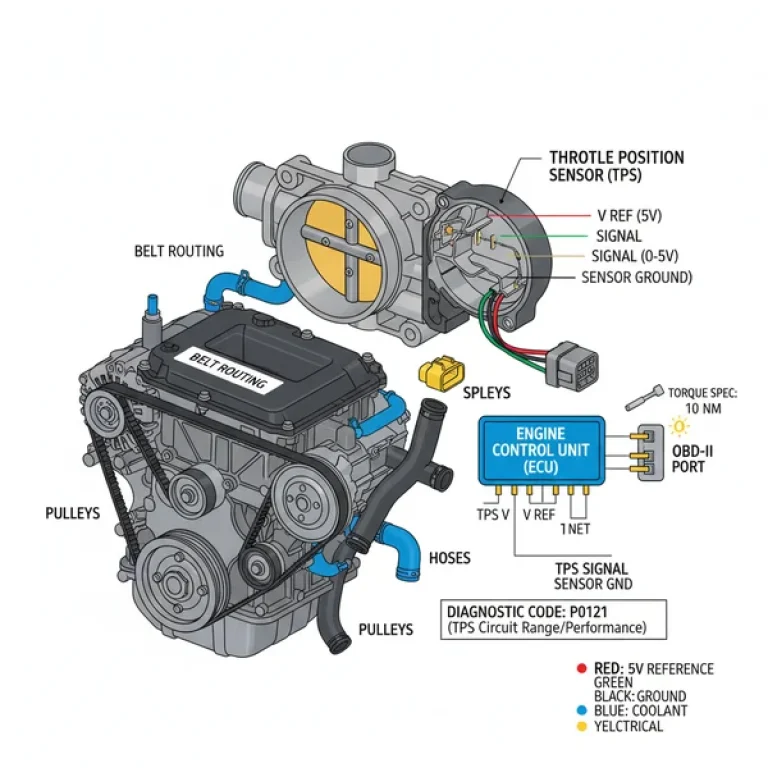

The OBS 7.3 fuel system diagram illustrates the flow from the tanks through the mechanical lift pump to the fuel bowl and injectors. Understanding this layout is crucial for diagnosing a check engine light or interpreting a diagnostic code via the OBD-II port, ensuring every component meets the required torque spec during repairs.

📌 Key Takeaways

- Visualizes fuel flow from dual tanks to the fuel injectors

- Identify the mechanical lift pump and fuel filter bowl assembly

- Ensure all fuel lines meet the specific torque spec to prevent leaks

- Use for diagnosing air intrusion or fuel delivery failures

- Essential when converting to an electric fuel system

Owning a classic Ford Powerstroke requires a deep understanding of its mechanical nuances, and nothing is more central to its performance than the obs 7.3 fuel system diagram. Whether you are dealing with a “crank but no start” condition or a mysterious puddle of diesel in the engine valley, having a clear roadmap of the fuel flow is indispensable. This article provides a comprehensive breakdown of the fuel delivery architecture, from the dual tanks to the fuel injectors. By the end of this guide, you will be able to identify every major component, understand the pressure requirements, and perform your own diagnostics with confidence, ensuring your legendary diesel engine remains reliable on the road.

Understanding the OBS 7.3 Fuel System Layout

The fuel system in the Old Body Style (OBS) 7.3L Powerstroke is unique because it utilizes a cam-driven mechanical fuel pump located in the engine’s valley. Unlike later models that shifted to electric pumps, the OBS system relies on physical engine rotation to move fuel. The obs 7.3 fuel system diagram typically illustrates a “dead-head” design where fuel is pumped into the cylinder heads and has no continuous loop back to the tank from the heads themselves, though a return line exists at the fuel bowl.

Key components within the diagram include the dual fuel tanks, the frame-mounted selector valve, the mechanical lift pump, and the fuel filter housing (commonly called the fuel bowl). The system begins at the pickup tubes in the tanks, travels through the selector valve, and moves toward the engine. The mechanical pump is a two-stage unit; the first stage pulls fuel from the tanks at low pressure, and the second stage pushes it into the fuel bowl and then to the cylinder heads at approximately 40 to 70 PSI.

Visualizing the diagram, you will notice the fuel bowl sits prominently at the front of the engine valley. It acts as a central hub, containing the fuel filter, the fuel heater, and the Fuel Pressure Regulator (FPR). The FPR is a critical point on the diagram, as it maintains the necessary backpressure to ensure the injectors are properly fed. Variations in the diagram may occur depending on whether the truck has been modified with an “e-fuel” (electric fuel) conversion, which replaces the mechanical pump with an electric equivalent, but the factory configuration remains the standard for most purists and restorers.

[DIAGRAM_PLACEHOLDER: A detailed schematic showing the flow from the rear and mid-ship fuel tanks, through the frame-mounted selector valve, up to the mechanical pump in the engine valley, into the fuel bowl assembly, and finally through the stainless steel lines into the rear of the cylinder heads. Labels indicate the Fuel Pressure Regulator (FPR), the fuel heater element, and the return lines to the tanks.]

Step-by-Step Guide to Interpreting and Servicing the System

Reading an obs 7.3 fuel system diagram is the first step, but applying that knowledge to physical maintenance requires a systematic approach. Follow these steps to trace, inspect, and service your fuel delivery system.

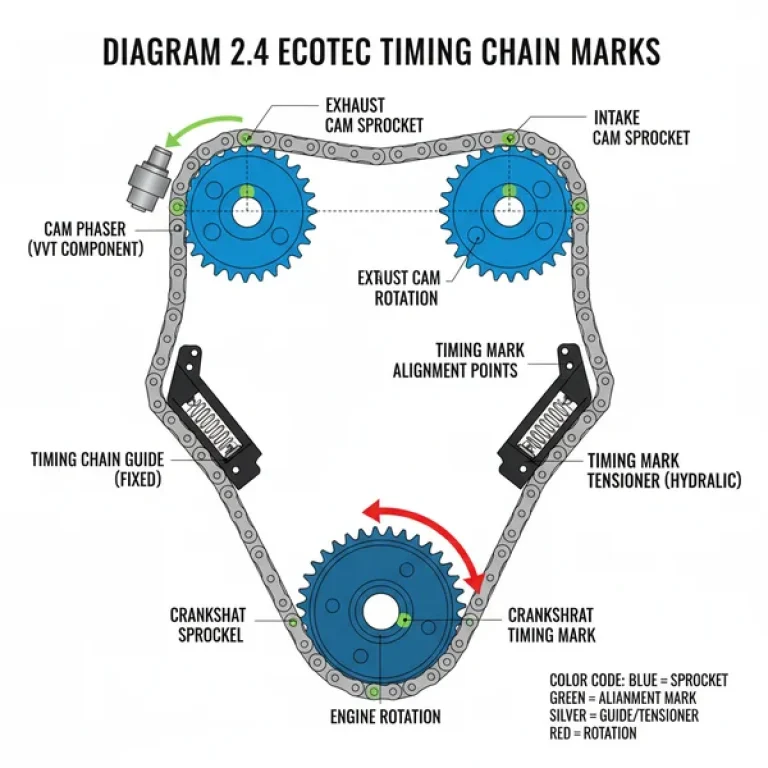

The 7.3 Powerstroke uses a gear-driven internal system for timing. While you may be used to looking for a timing chain in other engines, the 7.3 relies on heavy-duty gears located behind the front cover to manage engine synchronization, which is vital for the mechanical fuel pump’s timing and operation.

- 1. Locate the Fuel Selector Valve: Start under the truck on the driver-side frame rail. The diagram shows fuel lines from both tanks entering this motorized valve. Ensure the electrical connections are clean, as this valve is a common failure point for fuel starvation.

- 2. Inspect the Mechanical Pump: Look deep into the “valley” of the engine behind the fuel bowl. The mechanical pump is driven by a plunger riding on the camshaft. Check the weep hole on the pump; if diesel is present, the internal diaphragm has failed and requires replacement.

- 3. Examine the Fuel Bowl and FPR: The fuel bowl cleans the fuel before it hits the injectors. On the side of the bowl is the FPR. Inside the FPR is a small screen that can become clogged with debris. Cleaning this screen is a vital maintenance task often overlooked.

- 4. Verify Pressure at the Schrader Valve: On the side of the fuel bowl, there is a port that looks like a tire valve. Use a mechanical fuel pressure gauge here to verify you have between 50-65 PSI at idle. Low pressure here indicates a failing pump or a stuck-open FPR.

- 5. Check for Leaks in the Valley: Fuel lines lead from the bowl to the cylinder heads. Because these lines are subject to high vibration, the seals (vibrating sleeves) can fail. Use your diagram to identify the blue or black fluorocarbon sleeves and check them for dampness.

- 6. Analyze Return Flow: The system returns excess fuel and air from the FPR back to the tanks. If you find air in the system, check the suction side lines (between the tank and pump) for cracks, as the pump will pull air in easier than it pulls thick diesel.

Always wear eye protection when testing fuel pressure. Diesel under high pressure can penetrate the skin, causing serious injury. Ensure the engine is cool before reaching into the valley to avoid burns from the turbocharger or coolant crossover pipes.

When reassembling components, always adhere to a specific torque spec. For example, the fuel bowl mounting bolts typically require 20-30 lb-ft, while the fuel line fittings (banjo bolts) need to be snugged carefully to 35 lb-ft to prevent crushing the copper washers. Over-tightening can lead to cracked housings, while under-tightening will result in persistent leaks.

Common Troubleshooting and Diagnostic Codes

When the fuel system fails, the ECU (Engine Control Unit) may not always trigger a specific “low fuel pressure” light because the OBS 7.3 lacks a factory fuel pressure sensor. However, you might see a check engine light related to injection control pressure. Using an OBD-II adapter with specialized software (like Forscan), you can look for a diagnostic code such as P1211 or P1212. These codes often indicate that the High-Pressure Oil System (which fires the injectors) is struggling to compensate for a lack of fuel.

If your truck exhibits a “bogging” sensation under load, the obs 7.3 fuel system diagram helps you pinpoint the restriction. Common issues include:

- ✓ Clogged Tank Pickups: The “shower head” filter inside the tank often disintegrates, causing the pump to suck air when the tank is below 1/4 full.

- ✓ Blown Fuel Heater Fuse: If the fuel heater inside the bowl shorts out, it blows the fuse that also powers the PCM (Powertrain Control Module), resulting in a no-start.

- ✓ FPR Spring Fatigue: Over time, the spring in the regulator weakens, dropping fuel pressure and causing poor atomization.

Best Practices for Maintenance and Upgrades

To keep your fuel system in top shape, consistency is key. Diesel fuel acts as both a lubricant and a coolant for your injectors. A failure in the fuel supply can lead to expensive injector damage.

When replacing your fuel filter, always inspect the “standpipe” in the center of the bowl. If the plastic is cracked, fuel may bypass the filter entirely, sending contaminants directly to your precision injectors.

Consider the following recommendations to maximize the lifespan of your 7.3 Powerstroke:

- Filter Changes: Change your fuel filter every 10,000 to 15,000 miles. Use high-quality OEM filters (Motorcraft) to ensure the integrated seal on the lid fits perfectly.

- Component Quality: If you must replace the mechanical pump, avoid “no-name” budget options. The labor to reach the pump is intensive; using a high-quality replacement prevents having to do the job twice.

- Bio-Diesel Caution: Older rubber lines on the OBS 7.3 may not be compatible with high concentrations of bio-diesel. If you plan to run alternative fuels, replace your soft lines with Viton or modern SAE 30R9 rated hoses.

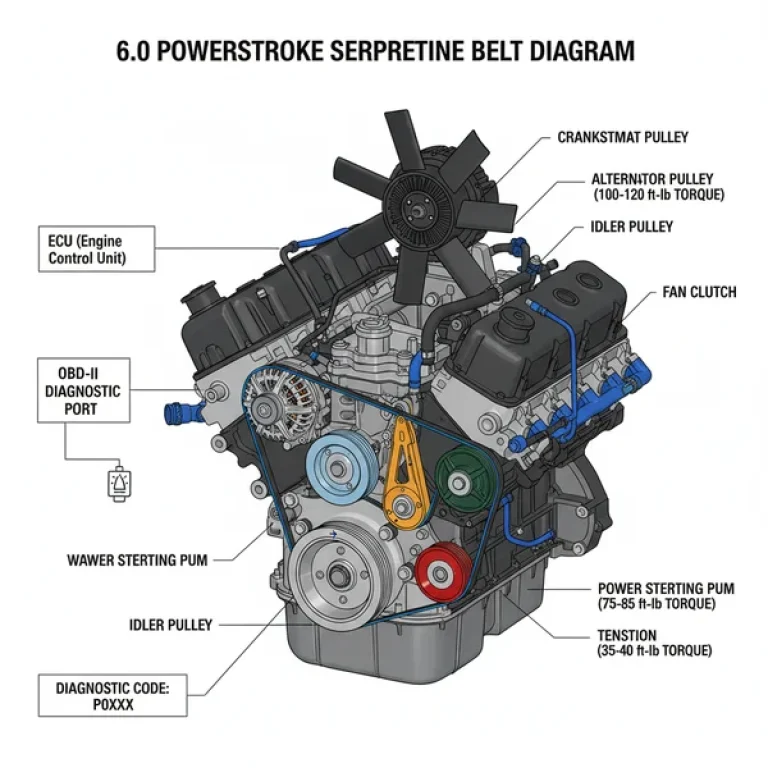

- Accessory Belt Inspection: While the fuel pump is mechanical and driven internally, always check your accessory belt and coolant flow. A cooling system failure can lead to engine overheating, which can warp the fuel bowl or cause fuel line seals to fail prematurely.

In summary, the obs 7.3 fuel system diagram is more than just a piece of paper; it is a vital tool for maintaining one of the most reliable diesel engines ever built. By understanding the path from the tank to the head, respecting the torque specs of your fittings, and keeping an eye on diagnostic codes, you can ensure your 7.3 Powerstroke continues to roar for hundreds of thousands of miles. Whether you stay with the stock mechanical setup or eventually transition to an electric fuel system, the foundational knowledge of how this engine breathes and drinks remains the same. Proper maintenance today prevents a breakdown tomorrow.

Frequently Asked Questions

What is OBS 7.3 fuel system diagram?

An OBS 7.3 fuel system diagram is a visual map showing the path diesel takes from the tanks to the engine. It details the mechanical pump, fuel bowl, and return lines. This diagram helps owners trace leaks or identify why the ECU isn’t receiving proper fuel pressure signals during operation.

How do you read OBS 7.3 fuel system diagram?

To read the diagram, start at the fuel tanks and follow the lines to the selector valve and mechanical lift pump. Note how the lines split at the fuel bowl to feed each cylinder head. Reference it when a diagnostic code indicates fuel delivery issues or significant pressure drops.

What are the parts of OBS 7.3 fuel system?

Major parts include the dual fuel tanks, selector valve, mechanical fuel pump, fuel filter bowl, and the high-pressure oil pump system that fires injectors. Each connection requires a specific torque spec to maintain a sealed environment, especially when communicating with the vehicle’s ECU for proper engine timing and performance.

Why is the fuel bowl important?

The fuel bowl is critical because it houses the filter and water separator, protecting the injectors from debris. If the bowl leaks or clogs, it can trigger a check engine light. Monitoring this area ensures the OBD-II system doesn’t register low-pressure faults during heavy engine loads or towing.

What is the difference between mechanical and e-fuel?

The stock OBS 7.3 system uses a cam-driven mechanical pump, while an e-fuel conversion uses an electric pump for consistent pressure. E-fuel systems simplify the diagram by removing the valley-mounted pump, often resolving common leaks and making it much easier for the ECU to manage precise fuel delivery.

How do I use OBS 7.3 fuel system diagram?

Use the diagram to troubleshoot hard-start conditions or power loss by verifying each connection point and component location. It is an essential reference when using an OBD-II scanner to find a diagnostic code related to fuel pressure sensors or when performing a full fuel system rebuild or maintenance.