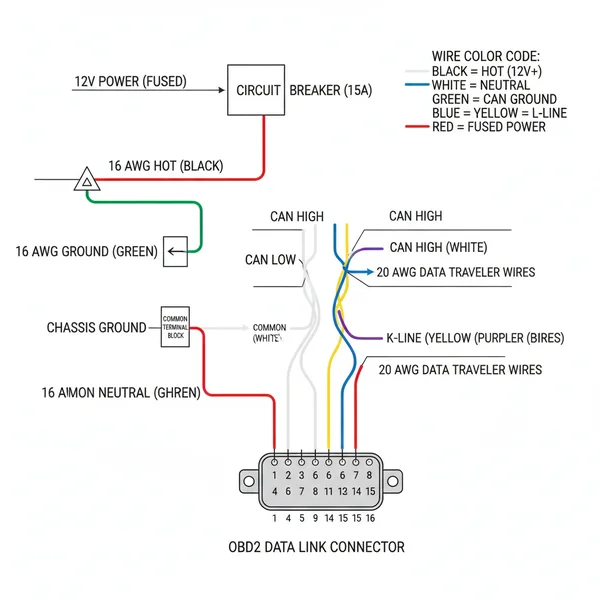

OBD2 Data Link Connector Wiring Diagram: Pinout Guide

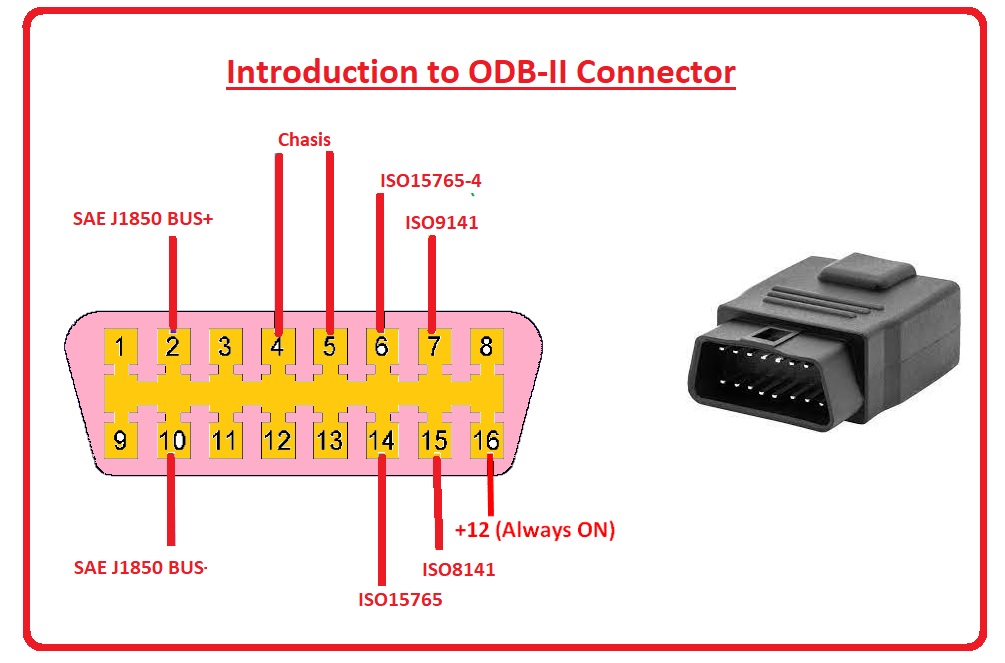

An OBD2 data link connector wiring diagram displays the 16-pin layout used for vehicle diagnostics. It identifies power pins, signal lines, and grounds necessary for scan tool communication. Standard pins include Pin 16 for battery power and Pins 4 and 5 for chassis and signal grounds, ensuring proper data transmission between the PCM and external tools.

📌 Key Takeaways

- Provides a visual map of the 16-pin diagnostic port interface.

- Identify Pin 16 to confirm the device receives constant battery power.

- Always check ground integrity to prevent communication errors or module damage.

- Use a multimeter to verify pin voltages before connecting expensive scan tools.

- Refer to this diagram when your OBD2 scanner fails to link with the vehicle.

Navigating the electrical architecture of a modern vehicle requires precision, especially when diagnosing complex engine codes or communication errors. Having access to a correct obd2 data link connector wiring diagram is the fundamental first step for any technician or DIY enthusiast looking to interface with the On-Board Diagnostics system. This specific diagram acts as a roadmap for the 16-pin interface, detailing exactly how the vehicle’s Electronic Control Units (ECUs) communicate with external scanning tools. By understanding this layout, you gain the ability to troubleshoot “no communication” issues, verify power delivery to your scan tool, and ensure that the integrity of the high-speed data bus is maintained. In this article, you will learn the standardized pinout configurations, how to test for power and ground, and the critical differences between various communication protocols.

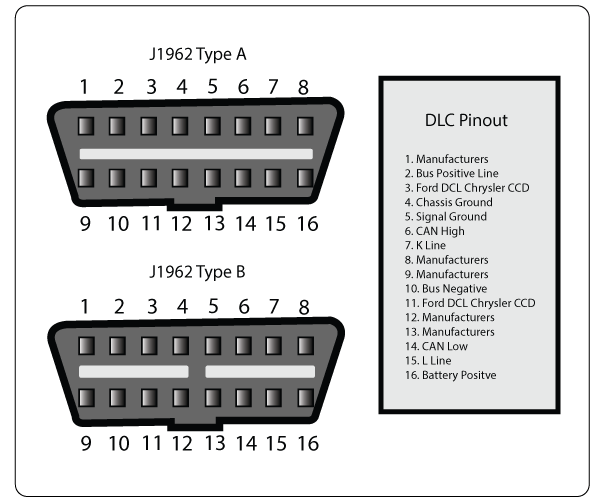

The OBD2 Data Link Connector (DLC) is standardized under SAE J1962. While the shape and certain pin assignments are universal, manufacturers often use “discretionary” pins for brand-specific features like supplemental restraint systems or body control modules.

Decoding the OBD2 Data Link Connector Wiring Diagram

The primary obd2 data link connector wiring diagram features a trapezoidal 16-pin configuration designed to prevent incorrect orientation when plugging in a diagnostic tool. Understanding the components of this diagram requires a focus on three main categories: power supply, grounding, and data transmission. In a standard setup, Pin 16 is designated as the battery positive terminal, providing constant 12V power. This is essentially the hot wire of the diagnostic port, ensuring the scan tool can operate even when the ignition is in the off position. Conversely, Pins 4 and 5 serve as the grounding backbone, with Pin 4 typically serving as the chassis ground and Pin 5 acting as the signal ground for the sensitive data circuits.

The data communication pins are where variations often occur depending on the vehicle’s protocol. The most common modern standard is the Controller Area Network (CAN) bus, which utilizes Pin 6 (CAN High) and Pin 14 (CAN Low). Other protocols, such as ISO 9141-2 or KWP2000, utilize Pin 7 (the K-Line) and occasionally Pin 15 (the L-Line). When viewing a diagram, the gauge of the wiring is also a factor; power and ground wires are usually a slightly heavier gauge than the twisted-pair data lines to handle the current load and reduce electrical interference.

While automotive systems use Direct Current (DC), those familiar with residential wiring might look for a common terminal or a neutral wire. In the context of an OBD2 port, the “common” reference is always the vehicle’s chassis. Unlike a home light switch that might use a brass screw for a hot wire connection or a traveler wire for 3-way switching, the OBD2 port relies on crimped metal sockets housed within a plastic female connector. The diagram will clearly label these sockets from 1 to 16, typically moving from top-left to bottom-right when looking at the front of the connector.

[DIAGRAM_PLACEHOLDER: A detailed 16-pin OBD2 DLC pinout showing Pin 16 as 12V Power, Pin 4 as Chassis Ground, Pin 5 as Signal Ground, Pin 6 as CAN High, and Pin 14 as CAN Low. Labels include “12V Battery,” “Chassis GND,” “Signal GND,” and “CAN Bus High/Low”.]

Step-by-Step Guide to Reading and Testing the DLC

Interpreting an obd2 data link connector wiring diagram is only the beginning; you must be able to translate that digital information into physical testing. Follow these steps to safely diagnose your vehicle’s diagnostic port:

- ✓ Identify the Orientation: Look at the DLC in your vehicle (usually under the dashboard on the driver’s side). Compare the wider top edge and narrower bottom edge to your diagram to ensure you aren’t reading the pin numbers in reverse.

- ✓ Measure the Voltage at Pin 16: Set your multimeter to DC voltage. Place the red probe in Pin 16 and the black probe on a known good metal ground on the vehicle chassis. You should see approximately 12.6V (battery voltage).

- ✓ Verify the Ground Wires: Switch your multimeter to the Continuity or Ohms setting. Test Pin 4 against the vehicle chassis; the resistance should be near zero. Repeat this for Pin 5, which is the signal ground wire.

- ✓ Check CAN Bus Resistance: With the vehicle battery disconnected, measure the resistance between Pin 6 and Pin 14. A healthy CAN bus system typically shows 60 Ohms (due to two 120-Ohm terminating resistors in parallel). If you see 120 Ohms, one resistor or circuit is open.

- ✓ Trace Discretionary Pins: If your vehicle uses Pin 1, 8, or 9, refer to the manufacturer-specific section of your diagram. These may carry proprietary signals for the ABS or infotainment systems.

Never use a test light on the data pins (Pins 6, 14, 7). The high current draw of a traditional bulb can fry the sensitive communication transceivers inside the vehicle’s main computer. Only use a high-impedance digital multimeter.

When working with these circuits, it is helpful to think of the system in terms of basic electronics. Although you won’t find a neutral wire as you would in a 120V AC circuit, the signal ground (Pin 5) acts as the return path for data signals, ensuring a clean reference point for the ECU. Maintaining the integrity of the wire gauge during repairs is vital; using a wire that is too thin can cause signal degradation, while a wire that is too thick may not fit the specialized pins of the connector.

Common Issues and Troubleshooting the OBD2 Port

The most frequent problem reported by users is a “No Communication” error when plugging in a scan tool. Often, the obd2 data link connector wiring diagram reveals that the power for Pin 16 is shared with the cigar lighter or auxiliary power outlet circuit. If a penny falls into your cigarette lighter and blows the fuse, your OBD2 port will lose its hot wire connection, and the scan tool will not power up. This is a classic example of how a simple visual check of the fuse box, guided by the wiring diagram, can save hours of complex diagnostic work.

Another common issue is pin “fretting” or spreading. Over time, the female terminals inside the DLC can become loose, leading to intermittent connections. If your scan tool works on one car but not another, use a terminal tension tool to check if the sockets are gripping the pins correctly. If you find a bent pin, do not attempt to straighten it with a heavy-duty screwdriver. Use a needle-nose plier or a specialized pick to gently realign it, ensuring you don’t compromise the common terminal connection.

If you are performing frequent diagnostics, invest in an “OBD2 Breakout Box.” This device plugs into the DLC and provides banana plug ports for every pin, allowing you to test voltage and signals safely without back-probing or damaging the connector.

Tips and Best Practices for Wiring Maintenance

To ensure long-term reliability of your vehicle’s diagnostic interface, follow these best practices. First, always keep the DLC area clean. Because it is usually located in the footwell, it is prone to collecting dust and moisture, which can lead to corrosion on the brass screw-style contacts found in older adapters or the modern tin-plated pins of the DLC. A quick blast of electronic contact cleaner every few years can prevent high-resistance connections.

When performing repairs, never tap into the OBD2 hot wire (Pin 16) to power aftermarket accessories like dash cams or GPS trackers unless you are using a fused tap. Drawing too much current through the DLC circuit can cause voltage drops that interfere with diagnostic accuracy. Additionally, pay close attention to the twisted-pair nature of the CAN High and CAN Low wires. If these wires are untwisted during a repair for more than an inch or two, they become susceptible to Electromagnetic Interference (EMI), which can crash the entire vehicle communication network.

Finally, always consult a vehicle-specific obd2 data link connector wiring diagram if you are dealing with a non-standard port. While the 1996-and-newer mandate standardized the plug, the internal routing can still vary. Quality components are key; if you need to replace a damaged DLC, source an OEM-grade pigtail with the correct wire gauge and heat-shrink butt connectors to ensure a moisture-proof seal. By respecting the delicate balance of the vehicle’s data highway and following these structured guidelines, you can ensure your diagnostic sessions are always productive and safe for your vehicle’s sensitive electronics.

In conclusion, the obd2 data link connector wiring diagram is an indispensable tool for the modern garage. By mastering the pinout, understanding the relationship between the battery voltage and the ground wire, and knowing how to troubleshoot common power failures, you place yourself in a position of confidence. Whether you are a weekend warrior or a professional technician, treating the OBD2 port with the care it deserves ensures that the gateway to your vehicle’s brain remains clear and functional for years to come.

Frequently Asked Questions

What is OBD2 data link connector wiring diagram?

An OBD2 data link connector wiring diagram is a technical schematic illustrating the electrical connections for a vehicle’s 16-pin diagnostic port. It identifies where power, ground, and communication protocol wires connect. This visual guide is essential for mechanics to troubleshoot why a scan tool cannot communicate with the vehicle’s onboard computer system.

How do you read OBD2 data link connector wiring diagram?

To read this diagram, locate the trapezoidal 16-pin connector layout. Identify the pin numbers, typically ordered from left to right, top to bottom. Match the color-coded lines on the diagram to the physical wires behind the port, paying close attention to specific communication pins like CAN High and CAN Low for data.

What are the parts of OBD2 data link connector?

The main parts include the plastic 16-pin housing, the metal terminal pins, and the associated wiring harness. Internally, it consists of power circuits, chassis grounds, and data lines. Some diagrams may reference a common terminal for shared grounds or specific signal wires that facilitate communication between the scanner and the ECU.

Why is Pin 16 important?

Pin 16 is critical because it serves as the hot wire, providing constant 12V battery power to the scan tool. Without voltage at this pin, the diagnostic tool will not power up or maintain a connection. This wire is usually protected by a dedicated fuse that should be checked during troubleshooting.

What is the difference between Pin 4 and Pin 5?

While both are grounds, Pin 4 is the chassis ground wire, connected directly to the vehicle’s metal frame. Pin 5 is the signal ground, acting like a neutral wire for the electronic data circuits. Keeping these separate ensures that electrical noise from the chassis doesn’t interfere with sensitive digital communication signals.

How do I use OBD2 data link connector wiring diagram?

Use the diagram to perform ‘back-probing’ or testing at the connector. If a scanner won’t connect, use the diagram to identify which pins should have power or ground. By comparing your multimeter readings to the diagram specifications, you can pinpoint broken wires, blown fuses, or faulty communication modules efficiently.