Mercruiser Raw Water Cooling System Diagram: Expert Guide

A Mercruiser raw water cooling system diagram illustrates the flow of external water through the pickup, pump, and heat exchanger. It helps identify blockages that trigger the check engine light. Using this schematic ensures proper hose routing and helps diagnose performance issues linked to the ECU monitoring system effectively.

📌 Key Takeaways

- Visualizes the external water flow path for engine cooling.

- Identify the sea pump impeller as the critical flow source.

- Ensure all hose clamps meet the required torque spec to prevent leaks.

- Use the diagram to trace blockages causing a diagnostic code.

- Refer to this when performing annual winterization or pump service.

Maintaining your boat’s engine requires a clear understanding of its internal mechanics, and for many owners, the mercruiser raw water cooling system diagram is the most essential map in their toolbox. Whether you are dealing with a classic sterndrive or a modern inboard setup, knowing how water travels from the lake or ocean through your engine block is vital for preventing catastrophic failure. This guide provides a detailed breakdown of the cooling circuit, explaining how each component interacts to manage thermal loads. By following this comprehensive overview, you will learn to identify potential points of failure, understand flow patterns, and ensure your vessel remains reliable during every excursion on the water.

Understanding the Mercruiser Raw Water Cooling System Diagram

The primary purpose of a mercruiser raw water cooling system diagram is to illustrate the path of external water as it enters the engine to absorb heat. Unlike a closed-loop system that uses antifreeze, a raw water system draws directly from the environment. The diagram typically begins at the water intake—either through the sterndrive’s lower unit or a thru-hull seacock. From there, the water is pulled by a high-capacity pump and pushed through a series of hoses, coolers, and the engine block before being expelled through the exhaust system.

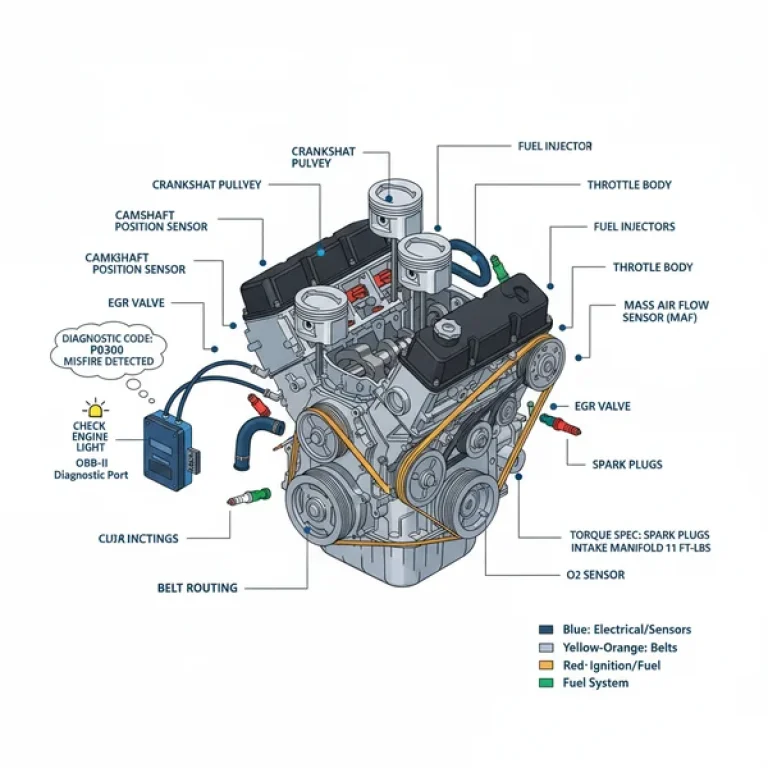

In a visual breakdown, the diagram is usually color-coded. Blue lines represent cold, incoming raw water. As the water enters the engine block and cylinder heads, it absorbs combustion heat, and the diagram transitions to orange or red to signify the heated discharge. Key elements included in these diagrams are the sea strainer, the belt-driven or crankshaft-mounted water pump, the oil cooler, the power steering cooler, the thermostat housing, and the exhaust manifolds and risers.

Variations exist depending on whether your MerCruiser is a carbureted V6 or a fuel-injected V8. Newer models integrated with an ECU often feature additional sensors shown on the diagram, which monitor temperature and pressure to protect the engine. Regardless of the specific model, the fundamental logic remains the same: the system must maintain a constant coolant flow to prevent the internal metal components from reaching temperatures that could warp heads or melt gaskets.

Most MerCruiser engines utilize a sacrificial anode system within the cooling circuit to prevent galvanic corrosion. When studying your diagram, ensure you locate the drain plugs, as these are critical for winterization and clearing debris.

Step-by-Step Guide to Interpreting and Maintaining the System

Reading a mercruiser raw water cooling system diagram might seem daunting at first, but following the flow logically makes the process manageable. Use the following steps to trace the system and perform basic inspections or installations.

- Identify the Intake Point: Locate where water enters the system. On Alpha One or Bravo drives, water is typically drawn through the side vents of the lower gearcase. For large inboard engines, look for the thru-hull pick-up and the emergency shut-off seacock. Ensure this area is free of barnacles or weeds.

- Inspect the Raw Water Pump: Following the diagram, the next stop is the pump. On many MerCruiser engines, this is an impeller-based pump driven by the accessory belt. Check the belt tension; a slipping belt will cause an immediate drop in coolant flow and an eventual overheat.

- Trace the Oil and Power Steering Coolers: Before reaching the engine block, the cold water usually passes through small heat exchangers for the engine oil and power steering fluid. These are common spots for “coke bottle” clogs—debris like small stones or plastic bits often get stuck here.

- Analyze the Thermostat Housing: The thermostat acts as the traffic cop of the system. When the engine is cold, the thermostat remains closed, circulating water through a bypass. Once the engine reaches operating temperature, it opens to allow full flow through the block. If you are replacing this, always use a marine-grade gasket and tighten the bolts to the specific torque spec found in your service manual.

- Examine the Exhaust Manifolds and Risers: This is the final stage of the diagram. Raw water mixes with exhaust gases in the risers and is pushed out of the boat. Because these components are exposed to both high heat and raw water, they are prone to internal rusting.

- Locate the Drain Points: For maintenance or winterization, find the blue plastic thumb-screws or brass plugs indicated on your diagram. These allow you to drain the system to prevent freeze-cracking.

Never run your MerCruiser engine without a water source (flushing muffs or being in the water). The rubber impeller in the raw water pump can be destroyed by friction heat in less than 30 seconds if run dry.

To perform these checks, you will need a basic set of socket wrenches, a flat-head screwdriver for hose clamps, and a torque wrench. If your engine is a newer MPI (Multi-Port Injection) model, having a basic scan tool to interface with the OBD-II style port can help you monitor live temperature data as you work through the system.

Common Issues and Troubleshooting with the Cooling Path

Even with a perfect mercruiser raw water cooling system diagram in hand, parts will eventually wear out. The most frequent issue is a gradual increase in operating temperature, often caused by a worn impeller. If the rubber vanes on the impeller become brittle or break, they can travel downstream and clog the thermostat housing or the heat exchangers.

Another common problem involves the ECU (Engine Control Unit). On modern MerCruiser engines, the ECU monitors the cooling system via temperature sensors. If the system detects an overheat, it may trigger a check engine light or even put the engine into “Guardian Mode,” which limits RPM to prevent damage. In these cases, you may see a specific diagnostic code indicating a cooling fault.

- ✓ Symptom: Steam coming from the exhaust. Cause: Insufficient water flow or a leaking riser gasket.

- ✓ Symptom: Check engine light on dash. Cause: Sensor detecting temperature above the safe threshold.

- ✓ Symptom: Water in the engine oil. Cause: Internal failure of the manifold or a blown head gasket due to overheating.

If troubleshooting via the diagram does not reveal a visible leak or clog, it is time to seek professional help. A marine technician can perform a pressure test on the block or use an infrared thermometer to find “hot spots” that indicate internal blockages.

Pro Tips and Best Practices for System Longevity

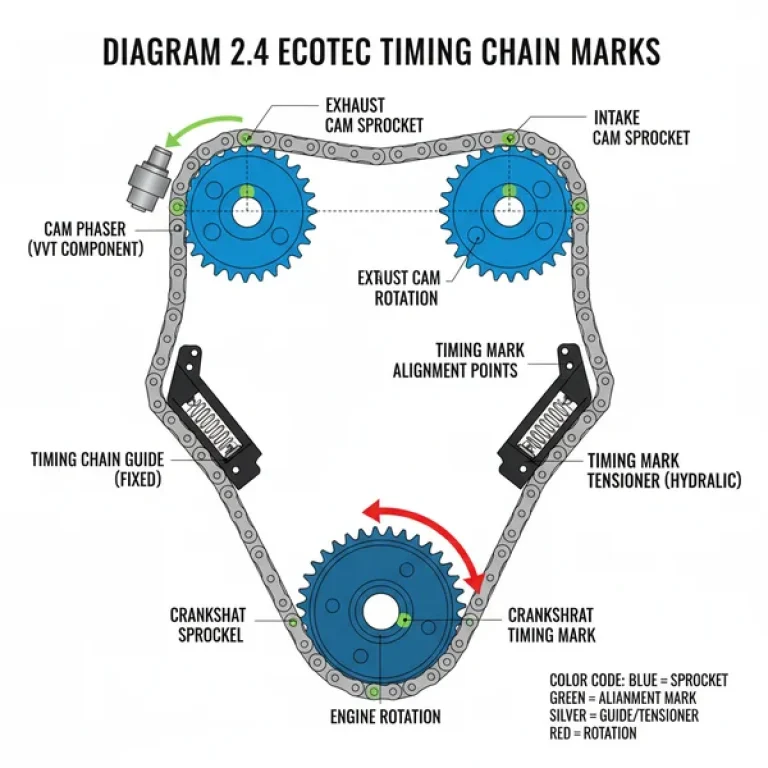

To keep your cooling system running efficiently, proactive maintenance is better than reactive repairs. One of the best habits you can develop is flushing the system with fresh water after every use, especially if you boat in saltwater. Salt crystallization can quickly narrow the passages in your engine, reducing the effective coolant flow and leading to premature corrosion of the timing chain cover or internal gaskets.

Replace your raw water impeller every two seasons regardless of how the engine performs. It is a low-cost insurance policy against a ruined vacation and expensive engine repairs.

When replacing components, always adhere to the manufacturer’s torque spec for bolts. Over-tightening a thermostat housing can crack the cast iron or aluminum, leading to a persistent leak. Furthermore, keep a close eye on your accessory belt. If the belt is frayed or glazed, it won’t spin the water pump at the necessary speed, causing intermittent overheating issues that are difficult to diagnose.

Finally, invest in high-quality OEM (Original Equipment Manufacturer) parts when possible. While aftermarket impellers and gaskets might be cheaper, they often lack the precise fitment required for the high-pressure environment of a marine engine. By utilizing your mercruiser raw water cooling system diagram for regular inspections and following these best practices, you ensure that your engine stays cool and performs at its peak for years to come. Understanding the intricacies of your diagnostic code readouts and the mechanical flow of water will turn you from a casual boater into a confident captain capable of maintaining a shipshape vessel.

Frequently Asked Questions

What is Mercruiser raw water cooling system diagram?

This diagram is a visual schematic showing how lake or sea water enters the engine to dissipate heat. It maps the path from the intake through the oil coolers and heat exchangers. Understanding this layout is essential for locating sensors that communicate with the ECU to prevent overheating during operation.

How do you read Mercruiser raw water cooling system diagram?

Start at the water intake point, usually the lower unit or thru-hull fitting. Follow the lines representing hoses through the sea pump and thermostat housing. The diagram uses arrows to show flow direction, helping you pinpoint where a diagnostic code might originate due to a specific flow restriction or blockage.

What are the parts of Mercruiser raw water cooling?

Core parts include the raw water pickup, sea pump, heat exchanger, and exhaust manifolds. Modern systems also include sensors that monitor temperature and pressure. These sensors send data to the OBD-II compatible system, which can trigger a check engine light if the water flow or temperature deviates from standard parameters.

Why is the sea pump important?

The sea pump is the heart of the raw water system, responsible for pulling external water into the engine. If the impeller fails, the engine will rapidly overheat. Monitoring this component helps avoid a check engine light and ensures the ECU doesn’t put the engine into a protective limp mode.

What is the difference between raw water and closed cooling?

Raw water systems use external water directly through the engine block, while closed cooling uses a heat exchanger and antifreeze. Closed systems are better for salt water environments. Regardless of the type, both rely on the ECU to monitor thermal efficiency and report any system failures via the diagnostic interface.

How do I use Mercruiser raw water cooling system diagram?

Use the diagram to verify that all hoses are connected to the correct ports and that flow is unobstructed. It is particularly useful when replacing parts to ensure every bolt meets the proper torque spec. It also helps trace wiring for sensors that provide data to the OBD-II interface.