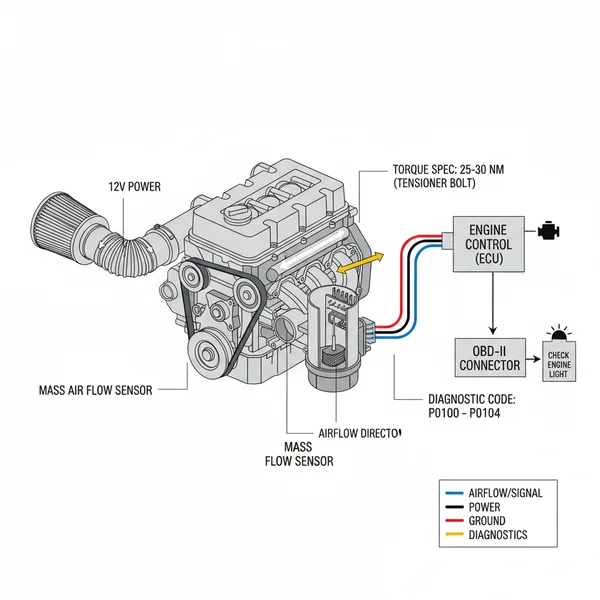

A mass air flow sensor diagram illustrates the electrical connections between the MAF sensor and the ECU. It identifies the signal, ground, and power wires, helping you diagnose a check engine light or specific diagnostic code. Understanding this layout is essential for testing sensor voltage and ensuring proper fuel-to-air ratios.

📌 Key Takeaways

- The diagram visualizes the wiring between the sensor and the engine computer

- The signal wire is the most critical component for ECU data transmission

- Always disconnect the battery to prevent electrical shorts during testing

- Use an OBD-II scanner to cross-reference diagram data with live sensor readings

- Refer to this diagram when experiencing stalling or poor fuel economy

Understanding the internal layout and electrical pinout of your vehicle’s intake system is essential for any DIY mechanic or automotive enthusiast. This comprehensive guide provides a detailed mass air flow sensor diagram and explanation to help you navigate the complexities of engine air management. By the end of this article, you will be able to identify key sensor components, interpret electrical signals sent to the engine control unit, and perform precise troubleshooting to resolve performance issues. Whether you are dealing with a rough idle or preparing for a routine cleaning, having the correct visual and technical references ensures your repairs are both safe and effective.

Understanding the Mass Air Flow Sensor Diagram Components

A mass air flow sensor diagram serves as a blueprint for the air intake system’s “brain.” The diagram typically illustrates the sensor’s position between the air filter box and the throttle body. In most modern vehicles, the MAF sensor consists of a plastic housing tube containing the sensing element—often a platinum “hot wire” or a grid-style “hot film.” The diagram highlights the airflow direction, which is critical because installing a sensor backward will lead to immediate engine failure and a rapid check engine light.

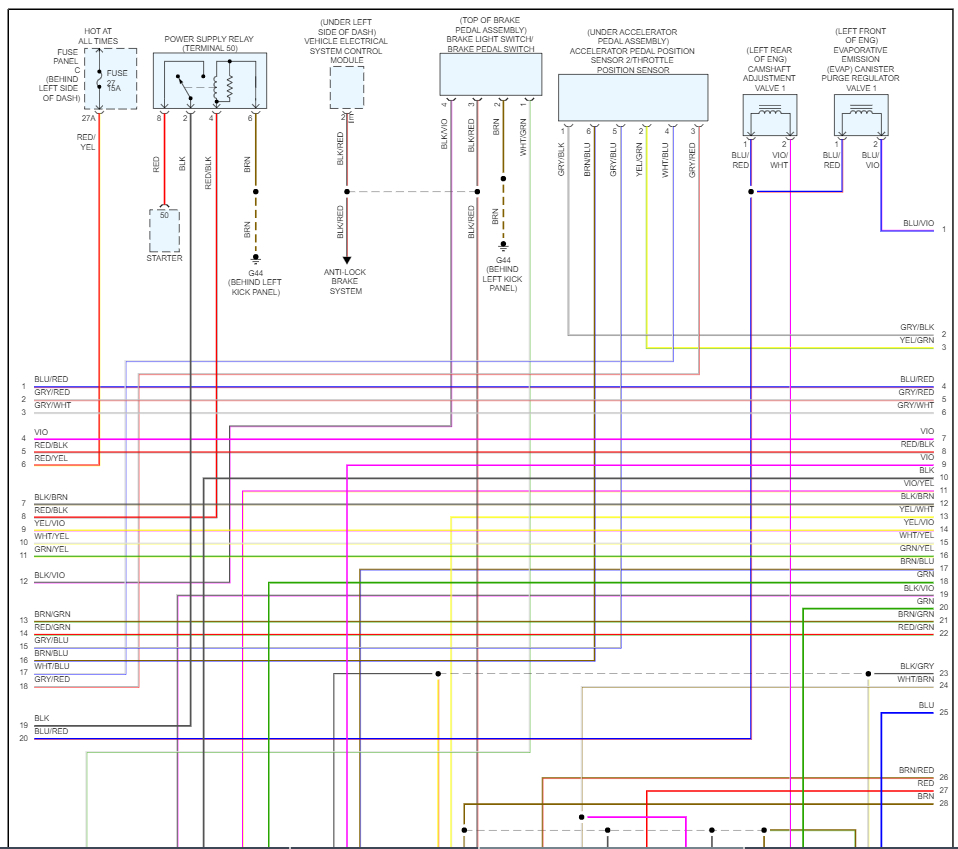

The electrical portion of the diagram is particularly vital. It shows the multi-pin connector, usually consisting of four to six wires. These wires represent the power supply (12V or 5V from the ECU), the ground wire, the signal wire (which sends frequency or voltage data back to the computer), and often an integrated Intake Air Temperature (IAT) sensor. By studying the color-coding in your specific vehicle’s mass air flow sensor diagram, you can use a multimeter to probe the back of the connector and verify if the sensor is receiving the correct voltage.

The mass air flow sensor (MAF) measures the density and volume of air entering the engine. This data allows the ECU to calculate the exact amount of fuel needed for efficient combustion, directly impacting your fuel economy and power output.

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing a cross-section of a hot-wire MAF sensor inside an air intake duct. Labels include: 1. Air Flow Direction Arrow, 2. Protective Mesh/Screen, 3. Platinum Sensing Wire, 4. Thermistor (IAT), 5. Electrical Connector Pins, 6. Outer Housing, 7. Mounting Flange.]

Variations in these diagrams occur based on the sensor technology used. For instance, older “vane meter” sensors utilize a physical flap, whereas modern digital sensors use frequency-based signals. The diagram also helps you differentiate the MAF sensor from surrounding components like the accessory belt or the cooling system hoses, ensuring you don’t accidentally disconnect the wrong harness during a busy repair session.

How to Read and Use the MAF Sensor Diagram: A Step-by-Step Guide

Interpreting a mass air flow sensor diagram is the first step in successful automotive diagnostics. Follow these steps to use the diagram for inspection, cleaning, or replacement.

- ✓ Step 1: Identify the Air Intake Path – Open the hood and locate the air filter box. Use your diagram to trace the ducting toward the engine. The MAF sensor is typically the first electrical component located immediately after the air filter.

- ✓ Step 2: Compare Connector Pinouts – Look at the electrical connector on your vehicle and compare it to the diagram. Note the wire colors. The diagram will specify which pin is the “Signal” and which is “Ground.” This is essential for testing with a voltmeter.

- ✓ Step 3: Check for Physical Obstructions – Referring to the diagram’s internal view, check the protective screen. If debris has bypassed the filter, it can snag on the screen, causing turbulence that confuses the sensor.

- ✓ Step 4: Disconnect with Care – Press the locking tab on the harness. Diagrams often show the clip location, which can be hidden on the underside of the sensor. Avoid pulling on the wires themselves to prevent internal breakage.

- ✓ Step 5: Clean the Sensing Element – If the diagram indicates a hot-wire style sensor, use a specialized MAF cleaner. Do not touch the wire with your fingers or a brush, as it is extremely fragile and can snap under the slightest pressure.

- ✓ Step 6: Verify the Sealing Ring – The diagram will show an O-ring or gasket where the sensor meets the housing. An air leak here (often called a “false air” leak) will cause the ECU to receive incorrect data, leading to a lean engine condition.

- ✓ Step 7: Reinstall and Observe Torque Specs – When tightening the mounting screws, refer to the factory torque spec. Over-tightening can crack the plastic housing, while under-tightening can lead to vibrations that interfere with the diagnostic code readings.

- ✓ Step 8: Reset the OBD-II System – After the mechanical work is complete, use an OBD-II scanner to clear any stored codes and monitor the “Grams per Second” (g/s) PID to ensure the new or cleaned sensor is reading within the manufacturer’s range.

Never use brake cleaner or carburetor cleaner on a mass air flow sensor. These chemicals leave behind a residue that can permanently damage the sensing element and trigger a permanent diagnostic code.

Common Issues and Troubleshooting with the MAF Diagram

When your vehicle experiences hesitation, poor acceleration, or a sudden drop in fuel economy, the MAF sensor is often the primary suspect. A faulty sensor typically triggers a check engine light and produces a specific diagnostic code such as P0101 (Range/Performance) or P0102 (Low Input). Using a mass air flow sensor diagram allows you to perform a “wiggle test” on the wiring harness shown in the schematic to check for intermittent opens or shorts.

One common issue that the diagram helps diagnose is contamination. Oil from “performance” air filters or dust from a poorly seated filter box can coat the hot wire. Because the wire acts as a cooling resistor, any insulation (like oil) prevents it from cooling properly, leading the ECU to believe less air is entering the engine than there actually is. This results in a “lean” condition where the engine starves for fuel.

If you observe symptoms like stalling but your OBD-II scanner shows no MAF codes, the diagram can help you rule out other mechanical failures. For instance, issues with the timing chain or a lack of proper coolant flow can sometimes mimic MAF failure symptoms. However, by checking the sensor’s voltage output against the diagram’s specifications, you can definitively prove if the sensor is the culprit or if the problem lies deeper within the engine’s mechanical timing or thermal management systems.

Tips and Best Practices for MAF Maintenance

Maintaining your mass air flow sensor is much more cost-effective than replacing it. Modern MAF sensors can be expensive, often costing hundreds of dollars. The best way to preserve the sensor is to change your air filter every 12,000 to 15,000 miles. A clean filter prevents the microscopic debris that can pit or contaminate the sensing element shown in your diagram.

When cleaning the sensor, allow it to dry completely for at least 10 minutes before reinstalling it and starting the engine. If the sensor is wet when the 12V power hits the hot wire, the thermal shock can cause the wire to snap.

When performing work near the engine, be mindful of the surrounding components. While the MAF is localized to the intake, the vibrations from a worn accessory belt or an improperly tensioned timing chain can sometimes cause electrical connector “chatter” at the MAF sensor. Ensure all mounting brackets identified in your diagram are secure and free of cracks.

If you must purchase a replacement, always opt for Original Equipment Manufacturer (OEM) parts. Aftermarket MAF sensors are notorious for having slightly different calibration curves than what the ECU expects. This can lead to a persistent check engine light even after the part is replaced. Finally, keep a digital copy of your mass air flow sensor diagram on your phone or in your toolbox; it is the most valuable tool you have for ensuring the long-term health and efficiency of your vehicle’s air induction system.

Frequently Asked Questions

What is a mass air flow sensor diagram?

A mass air flow sensor diagram is a schematic representing the electrical circuit and physical housing of the MAF sensor. It identifies the pinout locations for power, ground, and the output signal sent to the ECU. Technicians use it to verify that the sensor is accurately measuring air volume for combustion.

How do you read a mass air flow sensor diagram?

Reading this diagram involves identifying the terminal pins labeled on the sensor connector. Follow the lines from the sensor to the main wiring harness to see where they terminate at the ECU. Colors are usually indicated by abbreviations like ‘RED/WHT’ to help you trace physical wires in your vehicle.

What are the parts of a mass air flow sensor?

The primary parts include the outer housing, the internal sensing element (often a hot wire or film), and the electrical connector pins. Some sensors also integrate an intake air temperature sensor. The diagram will show how these components interface with the vehicle’s electrical system to provide real-time intake data.

Why is the ECU connection important?

The ECU connection is critical because it processes the voltage or frequency signal from the MAF sensor. If this connection is faulty, the computer cannot calculate the correct fuel injection timing. This often triggers a check engine light and results in poor engine performance or reduced fuel efficiency for the car.

What is the difference between a MAF and MAP sensor diagram?

A MAF sensor diagram focuses on measuring the actual mass of air entering the intake, while a MAP sensor diagram tracks pressure within the manifold. While both help the ECU calculate air mass, the MAF diagram will show a more complex wiring setup designed to measure direct airflow volume specifically.

How do I use a mass air flow sensor diagram?

Use the diagram to perform a voltage drop test or continuity test with a multimeter. By matching the diagram’s pinout to your physical connector, you can pinpoint where a diagnostic code like P0101 is originating. This allows you to differentiate between a failed sensor and a broken wire.