Manual Briggs and Stratton Parts Diagram: Repair Guide

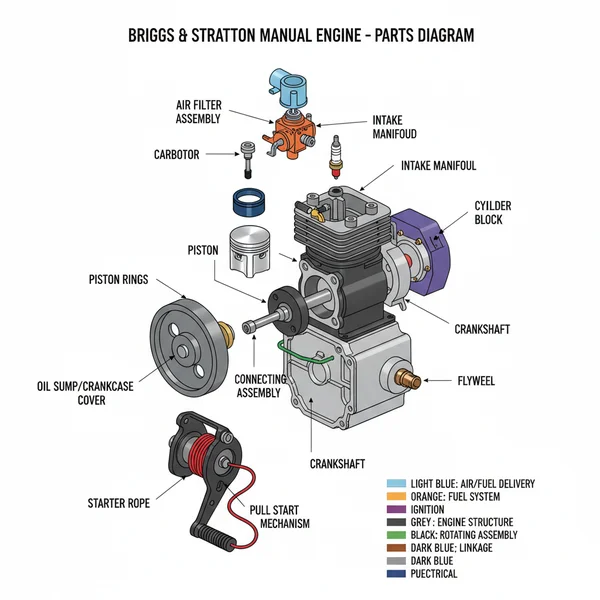

A manual Briggs and Stratton parts diagram provides a visual breakdown of the engine’s internal and external configuration. It allows users to identify specific component locations, understand the system layout, and find precise part numbers required for repairs or routine maintenance, ensuring the engine structure remains in peak operating condition throughout its lifespan.

📌 Key Takeaways

- Simplifies the identification of OEM replacement parts

- The Model-Type-Code numbering system is the most critical identifier

- Always disconnect the spark plug before inspecting engine parts

- Use the exploded view to understand the order of assembly

- Essential for DIY maintenance and complex engine rebuilds

When you are faced with a sputtering engine or a lawnmower that refuses to start, having access to a manual briggs and stratton parts diagram is the difference between a successful DIY repair and an expensive trip to the mechanic. These diagrams serve as the definitive visual map for your engine’s internal and external architecture, allowing you to identify every nut, bolt, and gasket with precision. By understanding the layout of your specific engine model, you can confidently order replacement parts and perform complex maintenance tasks. In this guide, we will explore how to navigate these technical illustrations, interpret the various engine systems, and use the structural layout to keep your equipment running at peak performance.

A parts diagram is often referred to as an “exploded view.” This means the components are shown slightly separated from one another to reveal how they fit together within the overall system.

Understanding the Main Diagram Layout and Structure

The primary structure of a manual briggs and stratton parts diagram is designed to break down a complex machine into digestible visual sections. Most diagrams are organized by major engine systems. For instance, you will typically find separate pages or sections for the cylinder head, the crankshaft and piston assembly, the carburetor and fuel delivery system, and the blower housing. This segmented approach ensures that the user is not overwhelmed by hundreds of parts at once, allowing for a focused look at the specific area requiring attention.

In these diagrams, each individual component is assigned a reference number. This number is not the actual part number you use for ordering; instead, it acts as a bridge between the visual illustration and the parts list table located elsewhere in the manual. The visual breakdown often includes lines or “callouts” that show the exact orientation of a part. For example, a washer will be shown in the precise order it sits on a bolt, ensuring you don’t install it backward or in the wrong sequence during reassembly.

Variations in these diagrams are common depending on the “Type” and “Code” of your engine. Briggs and Stratton engines are produced in various configurations to suit different manufacturers, such as those building pressure washers versus those building riding mowers. While the core engine block might look identical, the external configuration—such as the muffler style, the air cleaner layout, or the governor linkage—can vary significantly. The diagram accounts for these differences by using specific callout boxes or footnotes that indicate which part applies to which specific engine “Type.”

This placeholder represents a comprehensive system layout showing the relationship between the fuel tank, carburetor, intake manifold, and cylinder assembly.

Step-by-Step Guide to Interpreting Your Parts Diagram

Navigating a manual briggs and stratton parts diagram requires a systematic approach to ensure you are looking at the correct data for your specific machine. Follow these steps to master the interpretation of your technical manual.

Always take a high-resolution photo of the engine’s identification plate before searching for diagrams. The numbers are often stamped into the metal and can be hard to read once the engine gets dirty or hot.

- ✓ Step 1: Locate the Model, Type, and Code: Before opening a diagram, you must find the numbers stamped into your engine. These are usually found on the blower housing, the muffler guard, or just above the spark plug. Without these three sets of numbers, you cannot be certain the diagram you are viewing matches your engine’s internal configuration.

- ✓ Step 2: Identify the Functional System: Determine which part of the engine you are working on. If the engine won’t start, focus on the “Fuel System” or “Ignition System” pages. If the engine is smoking, look for the “Cylinder and Piston” section. Isolating the system prevents confusion and speeds up the identification process.

- ✓ Step 3: Trace the Reference Numbers: Once you find the visual representation of the component you need, note its reference number (e.g., Ref. No. 163). Follow the dotted lines in the diagram to see how that part interacts with its neighbors. This reveals the assembly order, which is critical for maintenance.

- ✓ Step 4: Cross-Reference with the Parts List: Take your reference number to the table typically found on the following page. Match the reference number to find the actual Service Part Number. This table will also list the quantity required for each engine, which is helpful if you are replacing multiple items like head bolts or valves.

- ✓ Step 5: Check for Superseded Parts: Occasionally, the part number in an older manual has been replaced by a newer version. Modern digital diagrams will often note this. If a part looks slightly different in the diagram than it does on your machine, check the “Notes” column in the parts list for updates or design changes.

- ✓ Step 6: Prepare Tools and Workspace: Before beginning the physical teardown, use the diagram to identify the types of fasteners used. For example, if the diagram shows a Torx-head screw for the carburetor bowl, ensure you have the correct bit on hand. This prevents stripped heads and frustration.

Never attempt to disassemble the engine while it is hot. Additionally, always disconnect the spark plug wire before using a diagram to identify parts on the actual machine to prevent accidental starting.

Common Issues and Troubleshooting with Diagrams

One of the most frequent problems users face when using a manual briggs and stratton parts diagram is “part mismatch.” This usually happens when the user relies on the visual appearance of a part rather than the specific Model-Type-Code identification. Small differences in a carburetor’s throttle linkage or a gasket’s port shape might not be obvious in a general illustration but will prevent the engine from functioning if the wrong part is installed.

Another common issue is missing information regarding “non-serviceable” items. Some older diagrams may show a component as a single unit, whereas newer versions might break that unit down into smaller repairable pieces. If your diagram shows a whole assembly but you only need a single spring, you may need to look for a “Repair Kit” reference number, which the diagram usually highlights with a bracket surrounding several components.

If you find that the diagram does not match your engine at all, even after verifying the model number, it is possible that a previous owner replaced the engine or modified the blower housing with one from a different model. In such cases, professional help is recommended to identify the true “frankenstein” nature of the equipment and ensure safety.

Tips and Best Practices for Maintenance

To get the most out of your manual briggs and stratton parts diagram, treat it as a living document. Many professionals recommend printing out the specific pages related to their engine and keeping them in a plastic sleeve in the garage. This allows you to make notes directly on the page, such as torque specifications for head bolts or the date you last replaced the air filter.

Maintenance is significantly easier when you use the diagram to create a “pre-season kit.” By looking at the layout, you can identify all the consumable components—such as the spark plug, air filter, oil filter, and fuel filter—and purchase them all at once. This ensures you aren’t running back to the store halfway through a tune-up.

When ordering parts, always opt for genuine OEM (Original Equipment Manufacturer) components. While aftermarket parts may look identical in the diagram, the tolerances and material quality of genuine parts are designed specifically for the thermal demands of your engine.

Finally, use the diagram to understand the cleanliness requirements of your engine. The layout shows the cooling fins on the cylinder block. If these become clogged with grass or debris, the engine will overheat. By studying the diagram, you can see how the blower housing directs air over these fins, highlighting the importance of keeping that specific area of the engine clear. Consistent reference to your manual briggs and stratton parts diagram not only helps with repairs but also educates you on the vital preventative measures that extend the life of your equipment. With a clear understanding of the system and its components, you can maintain a high level of performance for years to come.

Frequently Asked Questions

What is a manual Briggs and Stratton parts diagram?

This diagram is a detailed technical illustration showing the specific layout and structure of an engine. It labels every individual component, from the carburetor to the spark plug, helping owners identify necessary replacement parts and understand how the mechanical system integrates to generate power and functionality for the equipment.

How do you read a manual Briggs and Stratton parts diagram?

Start by identifying the reference numbers located next to each part in the visual illustration. Cross-reference these numbers with the provided parts list to find the official manufacturer part numbers. Pay close attention to the spatial configuration to see how various components connect within the overall mechanical system.

What are the parts of a manual Briggs and Stratton engine?

Key components include the cylinder block, crankshaft, pistons, and valves which form the core engine structure. Additionally, the system includes the carburetor for fuel delivery, the flywheel for momentum, and the recoil starter, all shown in a detailed parts diagram to aid in repair and identification of parts.

Why is the engine configuration important?

Understanding the engine configuration is vital because it determines how parts fit together and function. A proper layout ensures efficient fuel combustion and mechanical movement. Without knowing the specific configuration, you risk installing parts incorrectly, which could cause significant damage to the delicate internal engine structure and components.

What is the difference between a parts diagram and a repair manual?

A parts diagram focuses specifically on the visual structure and identification of every individual component and its part number. In contrast, a repair manual provides detailed, step-by-step instructions on how to perform specific maintenance tasks, though both use diagrams to illustrate the internal system layout for the user.

How do I use a manual Briggs and Stratton parts diagram?

Use the diagram by first locating your engine’s model and type numbers. Once matched, identify the specific component you need to replace within the exploded view. This visual guide ensures you understand the correct assembly order and can source the exact parts required for your specific engine configuration.