Manual Briggs and Stratton Parts Diagram: Repair Guide

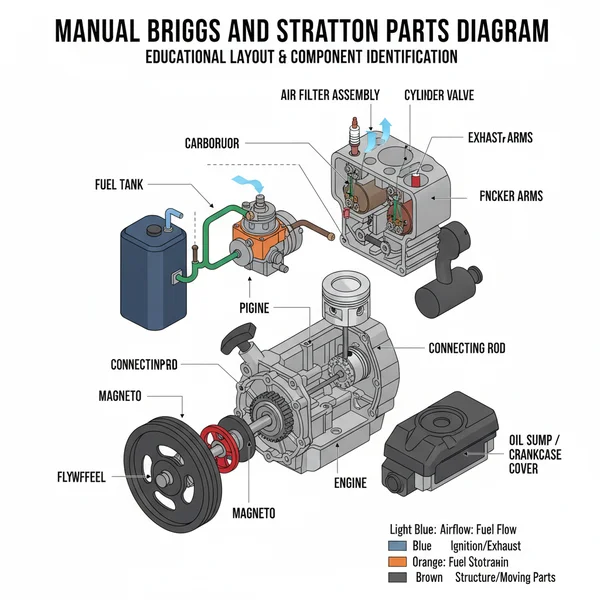

A manual Briggs and Stratton parts diagram provides a visual structure of engine components, detailing the exact configuration of your specific model. This technical layout allows owners to identify replacement parts, understand the fuel or cooling system, and ensure correct reassembly during routine maintenance or complex mechanical repairs.

📌 Key Takeaways

- Provides a visual map for accurate parts identification

- The engine block and carburetor are critical components to identify

- Always cross-reference model numbers to ensure part compatibility

- Use the exploded view to understand the assembly sequence

- Refer to this when ordering spares or troubleshooting mechanical failures

When you are faced with a sputtering lawnmower engine or a pressure washer that refuses to start, the first step toward a successful repair is consulting a manual briggs and stratton parts diagram. These technical illustrations act as a vital roadmap, providing a transparent view of the internal structure and layout of your specific engine model. By utilizing these diagrams, you can move past the guesswork and identify the exact component required for your repair. In this comprehensive guide, we will explore how to interpret these visual configurations, locate your specific model numbers, and use these schematics to ensure your equipment remains in peak operating condition.

Understanding the Engine Layout and Component Structure

The primary purpose of a manual briggs and stratton parts diagram is to provide an “exploded view” of the engine system. In this visual configuration, every part is shown slightly hovering away from where it would normally sit, allowing you to see how individual pieces fit together. Typically, these diagrams are organized by specific engine groups to prevent the illustration from becoming overly cluttered. You will generally find separate pages or sections for the cylinder assembly, the fuel system, the blower housing, and the ignition controls.

Each component in the diagram is assigned a reference number. It is a common mistake for beginners to assume the number next to the part in the drawing is the actual part number. Instead, this reference number points you to a corresponding table located below or beside the image. This table contains the actual manufacturer part number, the part name, and often the quantity used in that specific system. This distinction is critical because while a reference number like “601” might appear on dozens of different engine diagrams, the actual part number it links to will be unique to your engine’s specific build and configuration.

Briggs and Stratton engines use a Model-Type-Code system. The first sets of numbers identify the engine displacement and basic design, while the code identifies the exact date and assembly line where the engine was manufactured. Always have these numbers ready before looking at a parts diagram.

[DIAGRAM_PLACEHOLDER: Exploded View of a Standard Single-Cylinder Engine Layout] 1. Air Filter Assembly (Filter, Housing, Pre-cleaner) 2. Fuel System (Carburetor, Gaskets, Linkage) 3. Ignition System (Armature, Spark Plug, Stop Wire) 4. Cylinder Head Group (Valves, Springs, Head Gasket) 5. Crankcase Group (Crankshaft, Piston, Connecting Rod) 6. Rewind Starter (Pulley, Spring, Grip)

How to Read and Interpret Your Parts Diagram

Navigating a manual briggs and stratton parts diagram effectively requires a systematic approach. Without a clear process, it is easy to become overwhelmed by the dozens of small springs, washers, and gaskets shown in the structure. Follow these steps to ensure you are interpreting the data correctly and ordering the right parts for your repair.

- ✓ Step 1: Locate the Engine Identification Numbers – Before opening the diagram, find the Model, Type, and Code numbers stamped directly onto the engine. These are usually found on the blower housing, the muffler guard, or just above the spark plug.

- ✓ Step 2: Access the Correct Diagram Group – Navigate to the section of the manual that matches the area of the engine you are working on. If you are fixing a leak, look for the “Cylinder” or “Oil Seal” group. If the engine won’t start, focus on the “Fuel System” or “Ignition” layout.

- ✓ Step 3: Identify the Exploded Component – Visualizing the structure is key. Find the physical part on your engine and match it to the visual representation in the diagram. Pay close attention to the orientation of the part—many parts, like pistons or seals, must be installed in a specific direction.

- ✓ Step 4: Trace the Reference Number – Once you have located the part visually, follow the leader line to the reference number. Note this number down carefully.

- ✓ Step 5: Cross-Reference with the Parts List – Look for the reference number in the parts list table. This will provide the actual manufacturer part number. Check for any footnotes, as some parts may have been “Superceded” (replaced) by a newer, improved part number.

- ✓ Step 6: Verify the Manufacturing Code – Some engines had mid-year design changes. If the parts list mentions “Before Code 08051200,” ensure your engine’s code number falls within that specific range before ordering.

Never attempt to disassemble the engine while it is hot or while the spark plug wire is connected. Disconnecting the spark plug is the most important safety step to prevent accidental engine startup during inspection.

To interpret these diagrams correctly, you will need basic tools like a magnifying glass (for small print), a notepad for recording sequences, and a digital camera to take “before” photos of the engine configuration to compare against the diagram during reassembly.

Troubleshooting Common Issues Using the Diagram

One of the greatest benefits of a manual briggs and stratton parts diagram is its ability to help you troubleshoot missing or incorrectly installed components. Often, when a piece of equipment is purchased used, previous owners may have performed “jury-rigged” repairs. By comparing your physical engine layout to the official diagram, you can identify if a critical component like a governor spring or a heat shield is missing entirely.

Another frequent issue is the confusion over gasket configuration. In many engine models, several gaskets may look nearly identical but have slight variations in hole placement to accommodate different fuel system requirements. The diagram will clearly show the exact stacking order of gaskets, spacers, and diaphragms. If you are experiencing poor engine performance after a carburetor cleaning, consult the diagram to ensure you haven’t installed a gasket backward, which could block vital fuel or air passages.

If you find that the part on your engine does not match the diagram at all, you may have an “aftermarket” modification. In these cases, the diagram helps you identify what the original structure should look like, allowing you to revert the engine to its factory specifications for better reliability.

If you are struggling to find a part number, check the “Common Specifications” section of the manual. Often, high-wear items like spark plugs and air filters are listed in a quick-reference table outside of the main exploded diagrams.

Best Practices for Maintenance and Component Selection

To maximize the lifespan of your engine, use the manual briggs and stratton parts diagram as a preventative maintenance tool rather than just a repair guide. By understanding the system as a whole, you can identify “wear sets”—groups of parts that should typically be replaced at the same time. For example, when replacing a carburetor, the diagram will show the intake manifold gaskets and the air cleaner gasket. Replacing these as a set ensures a proper vacuum seal and prevents future air leaks.

When selecting parts, always prioritize Original Equipment Manufacturer (OEM) components. While aftermarket parts may be cheaper, the internal structure and material quality often differ. A manual briggs and stratton parts diagram is designed specifically for OEM tolerances. Using off-brand parts can sometimes lead to fitment issues where the part does not align with the illustrated configuration, potentially causing damage to surrounding components.

Keep a digital copy of your parts diagram on your smartphone or tablet. This allows you to zoom in on complex areas of the layout while you are standing over the engine in the garage. Furthermore, marking your diagram with the dates of previous repairs can create a valuable maintenance log. If you see that you are replacing the same component (like a starter rope) more frequently than the diagram suggests is normal, it may indicate an underlying issue with a related system, such as a rough pulley or an alignment problem.

In conclusion, mastering the use of a manual briggs and stratton parts diagram is the hallmark of a savvy equipment owner. It transforms the daunting task of engine repair into a logical, step-by-step process. By understanding the layout, respecting the structure of the various engine systems, and carefully cross-referencing every component, you can ensure your machinery runs efficiently for years to come. Whether you are performing a routine tune-up or a major overhaul, the parts diagram remains your most valuable tool in the workshop.

Step-by-Step Guide to Understanding the Manual Briggs And Stratton Parts Diagram: Repair Guide

Identify your engine’s model, type, and code numbers stamped on the metal housing.

Locate the specific diagram page that matches your engine’s series and configuration.

Understand how the exploded view connects individual components to the main engine structure.

Apply the part numbers found in the legend to your specific maintenance or repair needs.

Verify that the orientation of the layout matches your physical engine before disassembly.

Complete the repair by following the assembly sequence illustrated in the detailed system diagram.

Frequently Asked Questions

What is manual briggs and stratton parts diagram?

This diagram is a detailed visual representation showing the internal and external components of an engine. It illustrates the mechanical structure, allowing users to see how individual parts fit together within the system. It is essential for identifying the specific configuration needed for ordering accurate replacement parts for your model.

How do you read manual briggs and stratton parts diagram?

To read the diagram, start by locating the model number on your engine. Match this to the document to ensure the layout is correct. Look for exploded views where components are drawn slightly apart, showing their assembly order and how they relate to the overall engine system and structure.

What are the parts of manual briggs and stratton?

The parts include major components like the cylinder head, crankshaft, and piston, alongside peripheral systems such as the carburetor and air filter. The diagram details every nut, bolt, and gasket, providing a comprehensive view of the engine’s configuration and how each part contributes to the overall mechanical system.

Why is the carburetor component important?

The carburetor is a vital component because it manages the air and fuel mixture required for combustion. Within the engine system, it dictates performance and efficiency. Understanding its position in the diagram helps you troubleshoot starting issues or poor idling by identifying related gaskets and linkages within the layout.

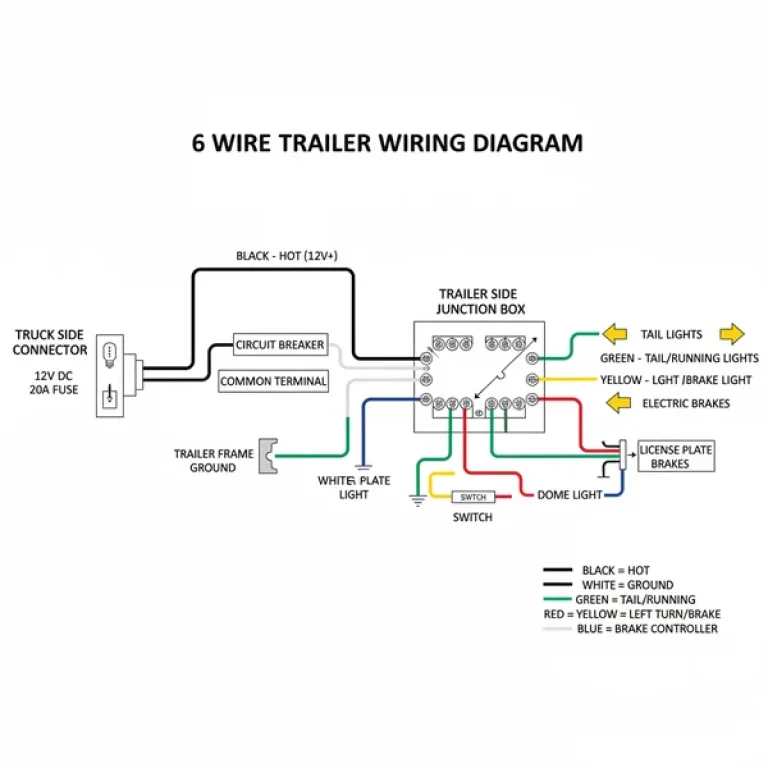

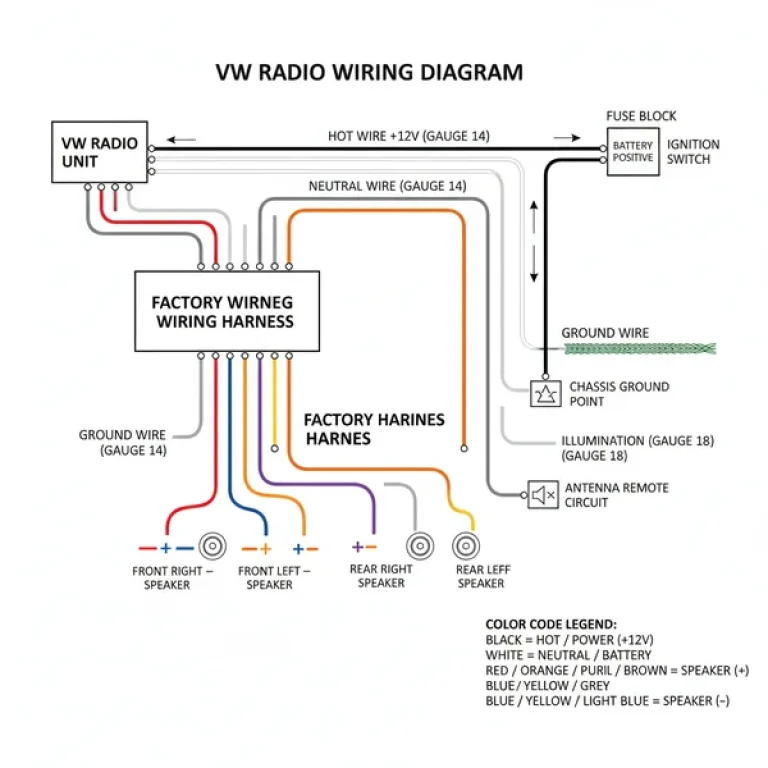

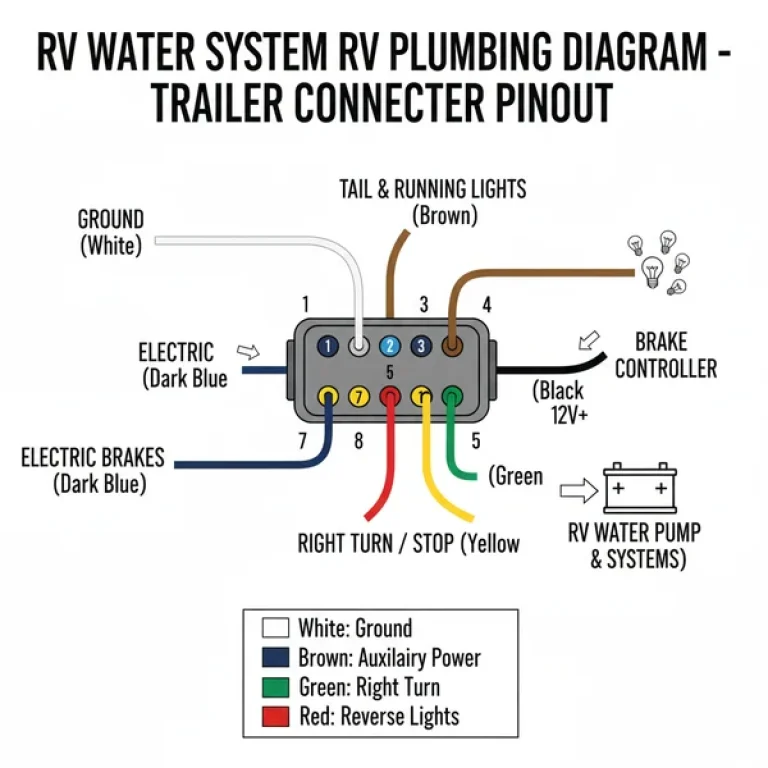

What is the difference between an exploded view and a wiring diagram?

An exploded view shows the physical structure and assembly of mechanical parts, while a wiring diagram focuses on the electrical configuration. The parts diagram is used for mechanical repairs, whereas the wiring diagram identifies how electrical components like the ignition coil connect within the engine’s internal electrical system.

How do I use manual briggs and stratton parts diagram?

Use the diagram by identifying the part you need to replace on your physical engine. Find that component in the exploded view to see its part number and position. This ensures you buy the correct replacement and understand the layout for proper reinstallation during the engine repair process.