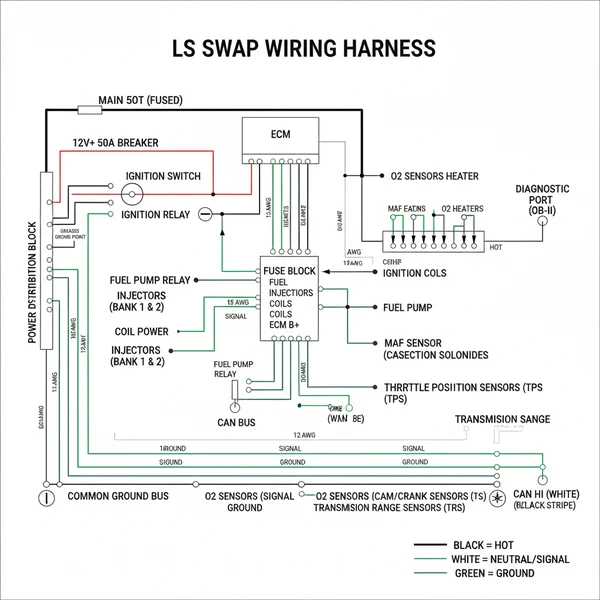

LS Swap Wiring Harness Diagram: Connection Guide

An LS swap wiring harness diagram illustrates how to integrate the engine’s sensors and fuel injection system with your vehicle’s power source. By identifying the primary hot wire and ground wire connections, you can ensure proper ECU communication. This visual guide simplifies complex circuits, making it easier to route power and signals correctly.

📌 Key Takeaways

- The diagram bridges the gap between the PCM and the vehicle chassis

- Identifying the correct pinouts for the PCM is the most critical step

- Always use high-quality automotive-grade wire to prevent heat damage

- Label every wire clearly before routing through the firewall

- Use this diagram during the mock-up phase to plan wire lengths

Embarking on a modern engine conversion requires more than just mechanical skill; it demands a deep understanding of electrical integration. Whether you are dropping a Gen III or Gen IV small block into a classic muscle car or a late-model truck, the ls swap wiring harness diagram serves as your essential roadmap. This technical guide bridges the gap between the fuel-injected intelligence of the engine control module and the simplified electrical systems of your project vehicle. By the end of this article, you will understand how to identify critical circuits, manage power distribution, and successfully interface your engine’s sensors with the rest of your build.

The heart of any modern engine management system is the Powertrain Control Module (PCM), which acts as the brain. An ls swap wiring harness diagram visually represents the complex web of connections that allow this brain to communicate with the heart—the engine. The diagram typically splits into two primary sections: the engine-side connectors and the vehicle-side interface. On the engine side, you will find leads for the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, fuel injectors, and coil packs. Each of these is precision-engineered to operate at a specific voltage, often requiring a steady 5V reference from the PCM.

Most LS harnesses utilize a color-coded system to distinguish between data signals and power delivery. High-current components like the starter and alternator require a heavy gauge wire, whereas sensor signals use much thinner, shielded wiring to prevent electromagnetic interference.

The vehicle-side interface is where the builder must perform the most manual labor. This section of the diagram highlights the “stand-alone” requirements: constant 12V battery power, switched ignition power, and the fuel pump relay trigger. While automotive wiring differs from household electrical, the logic remains similar. Just as a 3-way light switch uses a traveler wire to pass current between two points, your harness uses trigger wires to signal the fuel pump or cooling fans. The common terminal in your fuse block acts as the distribution point where the main hot wire from the battery provides the necessary amperage to keep the system running.

[DIAGRAM_PLACEHOLDER: A detailed LS Swap Wiring Harness Diagram showing the PCM connectors (Red/Blue or Green/Blue), the OBD-II port, the fuse block integration, and individual sensor leads like the Crank Position Sensor and Throttle Position Sensor.]

Understanding how to read the ls swap wiring harness diagram is the first step toward a successful first start. Follow these steps to interpret the data and begin your installation:

- ✓ Identify the PCM Connectors: Most LS harnesses feature two large 80-pin connectors, often color-coded Red and Blue or Green and Blue. Locate these on your diagram first to understand the origin of every wire.

- ✓ Map the Power Distribution: Locate the hot wire inputs. You will need a constant battery source (typically a large 10 or 12 gauge wire) and a switched ignition source that stays “hot” during both the “On” and “Start” key positions.

- ✓ Establish the Grounds: Every circuit needs a path back to the source. The ground wire connections on an LS engine are non-negotiable. Look for the ground locations on the rear of the cylinder heads and the engine block on your diagram.

- ✓ Configure the Fuel System: Your diagram will show a lead for the fuel pump relay. Unlike a simple brass screw terminal on a household switch, this wire provides a voltage signal to the relay, which then completes the high-draw circuit to the pump.

- ✓ Interface the Gauges: Identify the tachometer output and coolant temperature leads. These allow your factory dashboard to communicate with the new engine.

Before you begin the physical installation, gather the necessary tools. You will need a high-quality wire crimper, a digital multimeter to check voltage and continuity, heat shrink tubing, and a soldering iron for permanent connections. Avoid using “butt connectors” or “T-taps” as they are prone to failure in high-vibration automotive environments.

Never connect the harness directly to the battery without a fuse block. An unfused hot wire can cause a catastrophic electrical fire if it shorts against the chassis. Ensure all power leads are protected by appropriately rated fuses as specified in your diagram.

Reading the diagram also requires an understanding of electrical polarity. While household systems use a neutral wire to return current to the panel, automotive systems use the entire metal chassis of the car as the return path. This means your engine, frame, and body must all be tied together with heavy-duty ground straps to ensure the PCM receives a clean signal.

Even with a perfect ls swap wiring harness diagram, challenges can arise during the first test fire. One of the most common issues is “crank but no start.” This is often caused by a missing ignition signal during the cranking phase. If your switched hot wire loses voltage when the starter is engaged, the PCM will shut down, preventing the injectors from firing.

Another frequent problem involves the Vehicle Anti-Theft System (VATS). If your diagram includes an OBD-II port, you can use a scan tool to see if the PCM is “locked.” Unless the VATS has been programmed out of the computer, the engine will typically start for two seconds and then die. Troubleshooting this requires verifying that the serial data wires are correctly pinned into the diagnostic port.

If you encounter erratic sensor readings or “ghost” codes, check your ground wire locations. A loose ground at the common terminal of the engine block is the leading cause of sensor failure and PCM communication errors.

If you notice wires getting hot to the touch, you likely have an issue with wire gauge. Using a wire that is too thin for the required amperage will create resistance, dropping the voltage and potentially melting the insulation. Always refer back to your diagram to ensure you are using the correct thickness for high-draw components like electric cooling fans or high-pressure fuel pumps.

To ensure your project remains reliable for years to come, follow these best practices for wiring. First, always label every wire. While the ls swap wiring harness diagram tells you what the colors mean, physically labeling the leads with heat-shrink labels will save you hours of frustration during future maintenance.

Second, pay close attention to wire routing. Keep your harness away from heat sources like headers and exhaust manifolds. Heat increases resistance and can eventually bake the wire insulation until it becomes brittle and cracks. Use high-temperature loom or braided sleeving to protect the harness from both heat and abrasion.

When connecting to a terminal block, treat the connection with the same care you would a brass screw on a high-end electrical fixture. Ensure the connection is tight and free of corrosion to maintain maximum conductivity.

Lastly, consider the “neatness” of your installation. A cluttered engine bay isn’t just an eyesore; it’s a diagnostic nightmare. Bundle your wires logically—grouping sensor wires together and power wires together—and secure them with nylon zip ties or p-clamps. If you are building a custom harness from scratch, remember that the traveler wire logic of complex switching can often be simplified by using high-quality relays to handle the heavy lifting.

Investing time into studying your ls swap wiring harness diagram is the best way to guarantee a successful engine swap. By understanding the relationship between the hot wire, the ground wire, and the PCM signals, you take control of your vehicle’s performance. Whether you are troubleshooting a voltage drop or pinning a new common terminal into your fuse box, the clarity provided by a comprehensive diagram is your greatest asset in the garage. With patience and the right technical resources, your LS-powered project will be ready to hit the road with factory-level reliability.

Step-by-Step Guide to Understanding the Ls Swap Wiring Harness Diagram: Connection Guide

Identify the PCM pinouts – Start with identifying the specific connectors (Blue/Green or Red/Blue) for your LS generation.

Locate the main ground wire points – Find the block, head, and chassis grounding locations to ensure electrical stability.

Understand the power distribution – Map how each hot wire feeds from the battery to the fuse block and PCM.

Connect the relay system – Link the common terminal of your fuel pump and fan relays to their respective power sources.

Verify the signal paths – Trace the traveler wire used for communication between the PCM and external dash gauges.

Complete the safety circuits – Connect the neutral wire within the neutral safety switch to prevent the engine from starting in gear.

Frequently Asked Questions

What is LS swap wiring harness diagram?

An LS swap wiring harness diagram is a visual schematic used to bridge a General Motors LS-series engine with a different vehicle chassis. It provides a roadmap for connecting injectors, sensors, and the PCM. This tool is essential for enthusiasts to ensure that the electronic fuel injection system receives consistent power.

How do you read LS swap wiring harness diagram?

Reading the diagram involves identifying color-coded paths and symbols representing components like relays and sensors. You follow each line to see where a hot wire originates and where the corresponding ground wire attaches to the frame. Understanding these paths prevents short circuits and ensures that the engine computer functions correctly.

What are the parts of LS swap wiring harness?

Key parts include the powertrain control module (PCM) connectors, fuel injector leads, and sensor pigtails for oxygen and knock sensors. Additionally, the harness contains a fuse block with integrated relays, where each common terminal manages power distribution. It also features specific circuits for the alternator, starter, and ignition systems.

Why is ground wire important?

A ground wire is critical because it completes the electrical circuit, allowing current to return to the battery. In an LS swap, poor grounding is the leading cause of sensor interference and PCM failure. Ensuring a clean, metal-to-metal connection for every ground circuit prevents erratic engine behavior and protects sensitive electronics.

What is the difference between standalone and OEM harnesses?

A standalone harness is simplified for use in any vehicle, requiring only a basic hot wire and ground connection to run. An OEM harness is complex, designed to integrate with a specific vehicle’s body control module. Standalone versions often eliminate unnecessary circuits like emissions or complex neutral wire safety loops.

How do I use LS swap wiring harness diagram?

Use the diagram by cross-referencing PCM pin numbers with the wire colors on your harness. Begin by identifying the traveler wire routes for accessories and then map out the ignition-on power sources. This methodical approach allows you to troubleshoot connectivity issues and confirm that every sensor provides accurate engine data.