John Deere Z325E Belt Diagram: Routing and Installation

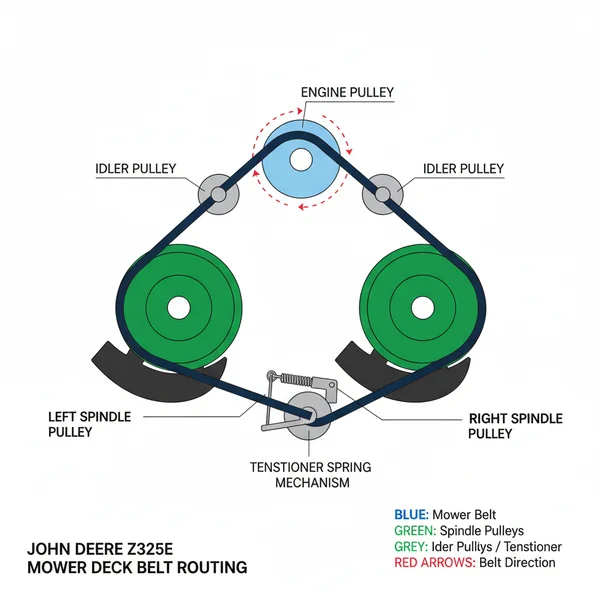

The John Deere Z325E belt diagram illustrates the precise routing of the mower deck drive belt. It shows how the belt loops around the engine drive pulley, idler pulleys, and spindle pulleys to power the blades. Understanding this layout is essential for replacing worn belts or diagnosing mower deck vibration issues.

📌 Key Takeaways

- The diagram visualizes the serpentine path required for the drive belt to function.

- The spring-loaded tensioner pulley is the most critical component for belt engagement.

- Always disconnect the spark plug wire before inspecting any belt configuration.

- Use the diagram to verify the belt is seated on the correct side of each idler.

- Consult this diagram during annual maintenance or when the belt slips during use.

Maintaining a high-performance zero-turn mower like the John Deere Z325E requires a keen eye for detail, especially when it comes to the complex drive and mower deck systems. Finding a clear and accurate john deere z325e belt diagram is the first step toward a successful repair or routine maintenance session. Whether you are dealing with a snapped belt in the middle of a job or simply performing a seasonal inspection, understanding how the belt weaves through various pulleys is essential. This guide provides a comprehensive breakdown of the belt routing, ensuring you can restore your machine’s cutting power and maneuverability with confidence. You will learn the specific layout of the system, the function of each component, and the safest way to execute a replacement.

Understanding the John Deere Z325E Belt Layout and Components

The internal structure of the John Deere Z325E relies on two primary belt systems: the traction drive belt and the mower deck belt. The john deere z325e belt diagram specifically illustrates the serpentine path these belts take to transfer power from the engine’s crankshaft to the wheels and the cutting blades. In this configuration, the mower deck belt is usually the focus of homeowner maintenance, as it endures the most stress from tall grass and debris.

The diagram identifies several critical elements within the system. First, you have the engine drive pulley, which is the primary power source located directly under the engine block. From there, the belt travels to a series of idler pulleys. These idlers are strategically placed to maintain the correct direction and tension. Some idlers are “flat” and ride on the back (flat side) of the belt, while others are “V-shaped” to cradle the interior of the belt. The spindle pulleys are located on top of the mower deck and are responsible for spinning the blades.

Each component in the layout serves a purpose. The tensioner arm, equipped with a heavy-duty spring, ensures that the belt remains tight enough to prevent slipping but flexible enough to handle the engagement of the PTO (Power Take-Off). Understanding this layout is crucial because an incorrectly routed belt can spin the blades backward, cause excessive heat buildup, or even result in the belt jumping off the pulleys entirely during operation.

[DIAGRAM_PLACEHOLDER – A detailed visual showing the Z325E mower deck with pulleys labeled: Engine Drive Pulley, Fixed Idler, Tensioner Idler, Left Spindle, and Right Spindle. Arrows indicate the direction of belt travel in a serpentine pattern.]

The Z325E typically features the Accel Deep™ mower deck. While the general configuration remains consistent, always check your specific deck size (usually 42, 48, or 54 inches) as the belt length and exact pulley spacing may vary slightly between these models.

Step-by-Step Guide to Interpreting and Installing the Belt

Navigating the john deere z325e belt diagram can feel overwhelming at first glance, but following a logical sequence makes the task manageable even for beginners. Before you begin, ensure you have the necessary tools: a 3/8-inch or 1/2-inch drive ratchet (depending on the tensioner bolt), a pry bar or belt tool, work gloves, and safety glasses.

Always park the mower on a level surface, engage the parking brake, and remove the ignition key. Disconnect the spark plug wires to prevent any accidental engine start-up while your hands are near the deck pulleys.

- Lower the Mower Deck: Start by moving the deck lift lever to its lowest possible position. This provides maximum clearance between the deck and the mower frame, giving you more room to maneuver the belt around the pulleys.

- Remove Deck Shields: Use a wrench or socket to remove the plastic or metal belt guards covering the outer spindles. This exposes the system and allows you to clear out any packed grass clippings that might interfere with the layout.

- Relieve Belt Tension: Locate the tensioner pulley. Using your ratchet or a dedicated belt tool, rotate the tensioner arm away from the belt. This will create slack, allowing you to slip the old belt off the engine drive pulley or one of the spindles.

- Analyze the Old Path: Before fully removing the old belt, compare its current configuration to your john deere z325e belt diagram. Note where the “V” side of the belt sits in the grooves and where the flat side meets the flat idlers.

- Route the New Belt: Beginning at the engine drive pulley (rear of the machine), thread the new belt forward toward the deck. Follow the diagram carefully: route it around the left spindle, through the central idlers, and finally around the right spindle.

- Final Tensioning: Once the belt is seated in all pulley grooves according to the structure shown in the diagram, pull back the tensioner arm once more and slide the belt onto the final idler pulley. Release the arm slowly to apply tension.

- Manual Check: Before starting the engine, rotate the pulleys by hand (with the spark plugs still disconnected) to ensure the belt moves smoothly and stays centered on every component.

- Reinstall Guards: Replace the spindle covers and any hardware removed during the process. Reconnect the spark plugs and test the mower in a clear, safe area.

If you find it difficult to move the tensioner arm, use a long-handled breaker bar. The extra leverage makes compressing the heavy tensioner spring much easier and safer for your knuckles.

Troubleshooting Common Belt and Pulley Issues

Even with a perfect john deere z325e belt diagram, issues can arise during or after installation. One of the most common problems is the belt slipping or “smoking.” This usually indicates that the belt is incorrectly routed, causing it to rub against a stationary bracket or the edge of a pulley. If you smell burning rubber, shut down the engine immediately and re-verify the layout against the diagram.

Another frequent issue is premature belt wear or “shredding.” This is often caused by a seized idler pulley or a damaged spindle bearing. If a component in the system does not spin freely, it creates friction that will melt the belt in seconds. While you have the belt off, spin each pulley by hand. They should rotate smoothly without grinding noises or wobbling. If you detect any resistance, that pulley component must be replaced to prevent future belt failure.

Lastly, if the mower leaves an uneven cut, the belt might be stretched or the tensioner spring might be fatigued. A stretched belt won’t provide the necessary torque to the blades, causing them to slow down when they hit thick grass. Always ensure the tensioner arm moves freely and the spring has plenty of “snap” back toward the belt.

Maintenance Tips and Best Practices

To get the longest life out of your belt and maintain the integrity of the system, regular maintenance is mandatory. Grass buildup is the number one enemy of mower belts. Moisture trapped in grass clippings can cause pulleys to rust and the rubber in the belt to degrade over time.

- ✓ Clean After Every Use: Use a leaf blower or compressed air to clear grass from the top of the deck and around the pulleys after each mowing session.

- ✓ Inspect for Cracks: Once a month, visually inspect the belt for “checking” or small cracks on the interior ribs. This is a sign that the rubber is drying out and a failure is imminent.

- ✓ Use Genuine Parts: While aftermarket belts are cheaper, John Deere OEM belts are engineered with specific cord materials designed to handle the exact tension of the Z325E system.

- ✓ Check Alignment: Ensure the deck is leveled properly. An unlevel deck can cause the belt to run at an angle, putting stress on the pulley flanges.

When it comes to cost-saving, preventative care is always cheaper than reactive repair. Replacing a $50 belt today is far better than replacing a $150 spindle or a damaged engine crank pulley later because a snapped belt wrapped around a moving part. Keeping a physical copy of the john deere z325e belt diagram taped to the inside of your garage cabinet or under the mower’s seat is a great way to ensure you’re always prepared for quick adjustments.

By understanding the configuration and structure of your mower’s drive system, you take control of your machine’s longevity. A well-maintained belt ensures a clean cut, better fuel efficiency, and a smoother ride. Use this john deere z325e belt diagram guide as your go-to resource for keeping your zero-turn in peak operating condition.

Frequently Asked Questions

What is John Deere Z325E belt diagram?

It is a visual representation of the mower’s drive system, detailing how the belt connects the engine power to the cutting blades. This diagram highlights every pulley component and shows the specific path the belt must follow through the deck structure to ensure efficient and safe mechanical operation.

How do you read John Deere Z325E belt diagram?

Start by identifying the main engine drive pulley, which is the primary power source. Follow the line representing the belt as it weaves through the fixed and adjustable pulleys. Pay close attention to which side of the belt (v-side or flat-side) contacts each specific pulley surface layout.

What are the parts of John Deere Z325E belt system?

The system consists of the drive belt, the engine crankshaft pulley, several idler pulleys for tension, and spindle pulleys that rotate the blades. This configuration relies on a tensioning arm and spring to keep the belt tight against the pulleys, preventing slippage during heavy residential mowing tasks.

Why is the tensioner component important?

The tensioner is a critical component because it maintains the necessary friction between the belt and pulleys. Without a properly functioning tensioner, the belt would slip or fall off, leading to poor cutting performance and potential damage to the mower’s internal deck system and pulley structure.

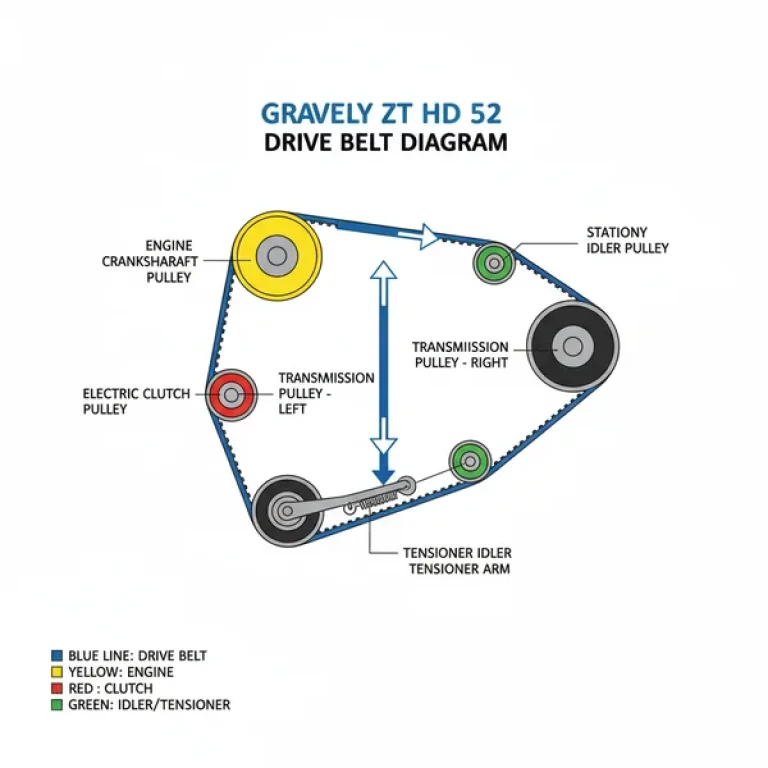

What is the difference between deck belts and drive belts?

The deck belt specifically transfers power from the engine to the mower blades for cutting grass. In contrast, the drive belt is part of the system that moves the mower forward and backward. Both require a specific layout and tension configuration to function correctly within the machine’s frame.

How do I use John Deere Z325E belt diagram?

Use the diagram as a reference guide when installing a new belt to ensure correct routing. Refer to the layout to identify damaged pulleys or to verify that the belt is seated properly within the grooves of each component, preventing premature wear and sudden operational failure.