John Deere STX38 Parts Diagram: Repair & Maintenance Guide

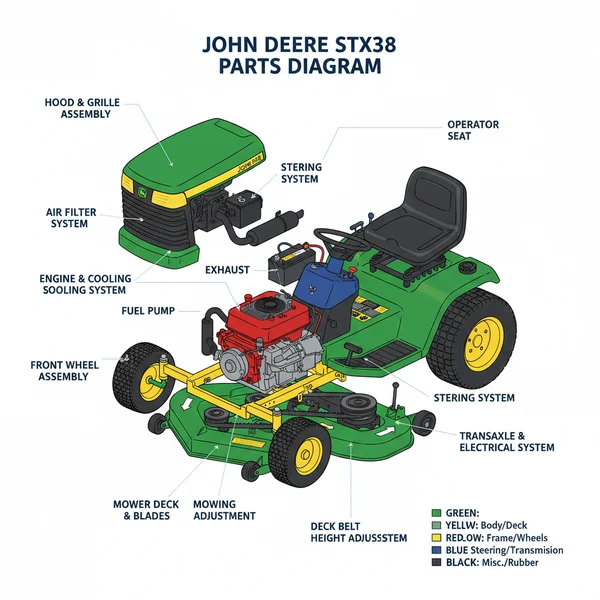

A John Deere STX38 parts diagram provides a visual representation of the mower’s internal structure. It identifies every component within the drive, engine, and deck systems, allowing owners to understand the exact configuration needed for successful repairs, ordering replacement parts, and maintaining the unit’s overall performance through accurate visual mapping.

📌 Key Takeaways

- Main purpose of this diagram is identifying exact part numbers and hardware placement for the STX38 model.

- The drive belt and mower deck assembly configuration are the most critical systems to identify for routine maintenance.

- Always disconnect the spark plug before inspecting or touching any components shown in the diagram for safety.

- Use the exploded view to see how small washers and spacers fit within the larger mechanical system.

- Consult this diagram during annual maintenance or when performing complex engine and transmission repairs.

Maintaining a classic lawn tractor requires precision, especially when sourcing replacement components for a machine as storied as the John Deere STX38. Whether you are performing a routine oil change or a complete deck overhaul, having access to a comprehensive john deere stx38 parts diagram is the primary step in ensuring your repair is accurate and safe. This guide provides a detailed breakdown of the tractor’s mechanical systems, helping you identify specific parts, understand their spatial relationship within the chassis, and execute repairs with the confidence of a professional technician. By the end of this article, you will be able to navigate complex exploded views and manage your tractor’s maintenance lifecycle effectively.

Understanding the Layout and Component Structure

The John Deere STX38 is renowned for its straightforward design, but its internal configuration contains several distinct systems that require individual attention. When you look at a general parts diagram, the machine is typically divided into major sub-assemblies: the engine and hood, the steering and front axle, the electrical system, the drive train (transmission), and the mower deck. Understanding the layout of these sections is vital because the STX38 underwent a significant mid-production change, resulting in two distinct versions: the “Yellow Deck” and the “Black Deck” models.

In a standard parts diagram, each component is assigned a reference number that corresponds to a master parts list. The visual breakdown uses an “exploded view” technique, where parts are shown slightly separated from one another but aligned along their axis of assembly. For example, in the steering system diagram, you will see the steering wheel at the top, followed by the bushing, the steering shaft, and finally the pinion gear that interacts with the sector gear. This structure allows you to see not just the part itself, but the washers, nuts, and spacers that are essential for a tight fit.

Color-coding is rarely used in official technical diagrams, but modern digital versions often highlight the specific system you are viewing—such as the fuel system or the braking configuration—to prevent confusion. It is important to note that the STX38 used a Kohler Command engine (typically 12.5 or 13 horsepower), and the engine diagram will be distinct from the chassis diagram. Always verify your tractor’s serial number before ordering, as small revisions in the wiring harness or belt lengths occurred throughout the production run.

(Hood/Engine)

|

[Front Axle] ---- [Steering Column]

| |

[Mower Deck] <--- [Chassis/Frame] ---> [Fuel Tank]

| |

(Drive Belts) [Transmission/Rear Axle]

Step-by-Step Guide to Interpreting the Diagram

Reading a technical parts diagram can feel overwhelming at first, but following a systematic approach will make the process seamless. Use these steps to navigate the john deere stx38 parts diagram and translate the visual information into a successful repair.

Before starting, locate your Product Identification Number (PIN) or serial number, usually found on the frame above the front left wheel or under the seat. This number is the only way to ensure 100% accuracy when matching parts.

- Identify the Sub-System: Start by narrowing down which part of the tractor needs work. If the blades won’t engage, focus on the “Mower Deck” or “PTO Clutch” diagram. If the tractor won’t move, look for the “Drive Train” or “Transmission” layout.

- Locate the Primary Component: Find the largest, most recognizable part in that section (e.g., the mower deck shell or the transmission housing). This serves as your visual anchor.

- Trace the Hardware Chain: Look at the lines connecting the parts. A diagram will show you exactly where a bushing sits in relation to a bracket. If you have taken a machine apart and forgotten which way a spacer faces, the exploded view is your blueprint for reassembly.

- Verify Part Numbers: Cross-reference the reference number from the image with the numerical part list. Pay attention to “Serial Number Breaks”—some lists will say “Use Part X for serial numbers up to 123456, and Part Y for serial numbers thereafter.”

- Check for Superceded Parts: Often, John Deere will update a part design. The diagram might show an old number, but your local dealer or online database may indicate that the part has been “replaced by” a newer version.

- Analyze the Fastener Layout: Diagrams often list the specific dimensions of bolts and nuts. If you lose a bolt, the diagram can tell you it was a “3/8 x 1-1/4 inch grade 5 bolt,” allowing you to find a temporary replacement at a hardware store if necessary.

- Confirm Orientation: Note the “Front of Machine” arrow usually found in the corner of the diagram. This ensures you aren’t installing a component backward or on the wrong side of the frame.

Always disconnect the spark plug wire and the battery before performing any work based on the parts diagram. Unexpected engine starts can lead to severe injury, especially when working near the mower deck or drive belts.

Required Tools for Implementation

To properly use the information from your diagram, you should have the following tools ready:

- ✓ Complete Socket Set (Metric and SAE)

- ✓ Torque Wrench (for blade bolts and pulley nuts)

- ✓ Needle-nose pliers (for cotter pins and springs)

- ✓ Belt tensioning tool or a large pry bar

Common Issues & Troubleshooting

Even with a perfect john deere stx38 parts diagram, certain mechanical issues are more prevalent than others. The most common frustration for STX38 owners involves the belt routing. Because the tractor uses a long, winding path for both the drive belt and the mower deck belt, it is easy to misroute them around the idler pulleys. The diagram is your best friend here, as it illustrates which side of the belt (flat or V-side) should contact each pulley.

Another frequent issue is “steering slop.” By consulting the steering system configuration, you can identify if the play is coming from the sector gear or the tie rod ends. If you see visible wear on the gear teeth in the diagram’s representation, it’s a sign that the component needs replacement. Additionally, the STX38 is known for safety switch failures. The electrical system layout will help you locate the seat switch, the brake switch, and the PTO switch, allowing you to test each one with a multimeter.

If the tractor won’t start despite a good battery, use the diagram to trace the wiring from the ignition switch to the solenoid. Often, a corroded ground wire—clearly marked in the system structure—is the culprit. If troubleshooting becomes too complex or involves internal transmission gears, it may be time to consult a professional, as those components require specialized hydraulic tools.

Tips & Best Practices for Longevity

To get the most out of your John Deere STX38, consistent maintenance is key. Using the parts diagram to identify and replace wear items before they fail will save you money and prevent downtime during the mowing season.

Always use OEM (Original Equipment Manufacturer) belts for the STX38. Aftermarket belts often vary by a fraction of an inch, which can cause them to slip or burn up prematurely due to the specific tensioner configuration of this model.

Regarding cost-saving, while belts and blades should ideally be OEM, common hardware like nuts, bolts, and certain bearings can often be sourced from high-quality third-party suppliers. Use the diagram to find the specific bearing size (usually printed on the side of the old bearing) to save on costs. Furthermore, keep your mower deck clean. Grass buildup holds moisture against the metal, leading to rust. The diagram shows the various baffles and shields where debris likes to hide; make it a habit to clear these areas after every three or four mows.

Finally, document your repairs. When you use a john deere stx38 parts diagram to replace a component, highlight that part on your copy of the diagram and note the date. This creates a service history that is invaluable for future troubleshooting or if you ever decide to sell the tractor. By understanding the intricate layout and system configuration of your machine, you ensure that your John Deere STX38 remains a reliable workhorse for years to come. Proper care, guided by accurate technical data, is the hallmark of a responsible equipment owner.

Frequently Asked Questions

What is John Deere STX38 parts diagram?

A John Deere STX38 parts diagram is an exploded view illustration showing every component of the lawn tractor. It details the specific layout of the engine, transmission, and mower deck, helping users identify exact part numbers and see how various pieces of hardware fit together for assembly and structural maintenance.

How do you read John Deere STX38 parts diagram?

To read the diagram, locate the specific system you are servicing, such as the steering or drive configuration. Each component is assigned a reference number that corresponds to a parts list. Follow the lines to see the assembly order and how the mower structure is built from individual pieces.

What are the parts of John Deere STX38?

The STX38 consists of several major systems including the Kohler engine, manual or hydrostatic transmission, steering assembly, and the 38-inch mower deck. Each system contains hundreds of individual parts like belts, pulleys, blades, and electrical components that are all detailed within the comprehensive technical layout of the parts diagram.

Why is the drive belt component important?

The drive belt component is vital because it transfers power from the engine to the transmission or mower deck. If the belt structure is misaligned or worn, the mower will fail to move or cut properly. The diagram ensures you follow the correct routing for optimal mower system performance.

What is the difference between yellow and black deck versions?

The main difference lies in the mower deck structure and belt configuration. Yellow deck models typically use a different spindle and belt layout than the later black deck versions. Checking the specific parts diagram ensures you purchase the correct components compatible with your tractor’s unique serial number and deck system.

How do I use John Deere STX38 parts diagram?

Use the diagram by cross-referencing your mower’s serial number to ensure you have the right configuration. Identify the failed component on the illustration, note the reference number, and look it up in the legend to find the official manufacturer part number for accurate ordering and successful mechanical repair.