Hustler Raptor Drive Belt Diagram: Installation & Routing

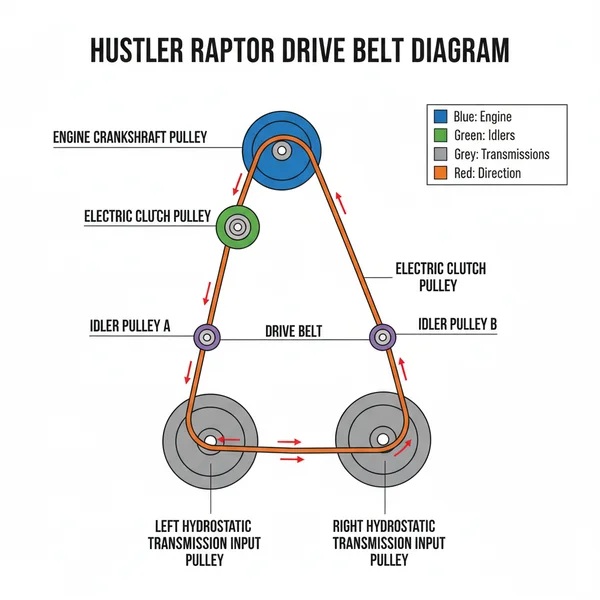

A Hustler Raptor drive belt diagram illustrates the specific path the belt follows around the pulleys, idlers, and clutch. It details the system configuration necessary to transfer power from the engine to the transmission, ensuring the mower operates smoothly without belt slippage or premature wear during heavy use.

📌 Key Takeaways

- Visualizes the complex routing path to ensure correct belt installation.

- Identifies the engine pulley as the primary power source for the system.

- Always release tension using the idler arm before attempting to remove belts.

- Check pulley alignment and debris buildup to prevent frequent belt snaps.

- Use this diagram during routine maintenance or when replacing a damaged belt.

Maintaining a zero-turn mower requires precision and a clear understanding of its mechanical assembly, and having a reliable hustler raptor drive belt diagram is the most critical tool in your maintenance arsenal. When a drive belt snaps, stretches, or slips, the mower loses its ability to move, effectively stalling your lawn care routine and potentially causing damage to the transmission system. This comprehensive guide provides a detailed visual and descriptive breakdown of the drive belt routing, ensuring you understand how each component interacts within the hydrostatic system. You will learn how to identify pulley locations, the specific configuration required for proper tension, and the necessary steps to replace a worn belt safely and efficiently. By the end of this article, you will be equipped to handle drive belt issues like a professional technician.

The drive belt system on a Hustler Raptor mower is a sophisticated closed-loop configuration designed to transfer power from the engine’s vertical crankshaft to the dual hydrostatic transmissions that control the rear wheels. The primary structure of this system consists of three main power points: the electric clutch (engine drive pulley) located at the rear of the machine and the two transmission pulleys situated atop the left and right hydro pumps. To bridge these points, the layout incorporates a series of stationary and pivoting idler pulleys that maintain tension and guide the belt around the mower’s frame.

[DIAGRAM_PLACEHOLDER: A top-down schematic illustrating the ‘T’ shaped routing path. The Engine Pulley is at the bottom center. Two Hydro Pulleys are at the top left and top right. A Spring-Loaded Idler Pulley is positioned on the left-hand side of the belt run, and a Fixed Idler is on the right.]

The system is designed with a spring-loaded tensioner pulley, which is the most dynamic part of the configuration. This specific pulley is mounted on a heavy-duty pivoting arm that compensates for belt stretch and absorbs the mechanical shock experienced during sudden speed changes or directional shifts. In the diagram, the belt’s “V” side (the narrow, wedge-shaped part) is engineered to seat deeply into the grooves of the engine drive pulley and both transmission pulleys to maximize friction and power transfer. Conversely, the flat backside of the belt typically makes contact with the flat surfaces of the idler pulleys. Understanding this distinction is vital for a successful installation, as reversing the belt or misaligning the sides will cause immediate belt failure. Note that while the Hustler Raptor series shares a consistent fundamental layout, small variations in pulley size or bracket placement may exist between the standard Raptor, Raptor SD, and Raptor X models, though the routing path remains the same across the platform.

Interpreting the hustler raptor drive belt diagram is the first step toward a successful repair. To ensure your safety and the longevity of your machine, follow these structured steps for belt replacement and routing.

Before beginning any work, park the mower on a level surface, engage the parking brake, remove the ignition key, and disconnect the spark plug wires. This prevents any possibility of the engine accidentally firing while your hands are near the drive system.

1. Access the Drive System: Lower the mower deck to its lowest height setting. For the best visibility and range of motion, many technicians prefer to remove the deck entirely by pulling the hitch pins and disconnecting the deck belt. This exposes the underside of the frame where the drive belt resides, tucked between the engine and the rear transaxles.

2. Identify the Belt Keepers: Look closely at the engine pulley and the hydro pulleys. You will notice small metal rods or tabs known as belt keepers. These are designed to keep the belt from jumping off during operation. In some cases, you may need to slightly loosen the bolts holding these keepers to allow enough clearance for the belt to slip through.

3. Release Belt Tension: Locate the idler arm, which is held under significant tension by a heavy-duty extension spring. Using a breaker bar or a long-handled wrench (typically a 1/2-inch or 5/8-inch square drive, depending on your specific model), insert the tool into the designated slot on the idler arm. Rotate the arm toward the engine to compress the spring. This creates the necessary slack to slip the old belt off the pulleys.

4. Remove the Old Belt: Carefully pull the belt off the engine drive pulley (the clutch) first. Once the belt is free from the engine, unthread it from the left and right transmission pulleys. Take note of any debris or “belt dust” accumulated around the pulleys, as this can indicate alignment issues or pulley wear.

5. Clean and Inspect Components: Use a stiff brush or compressed air to remove grass clippings and dirt from all pulley grooves. A clean component surface ensures better grip. Spin each idler pulley by hand; they should spin smoothly without any grinding noise or lateral “wobble.” If a pulley feels rough, replace it now to avoid a future breakdown.

6. Route the New Belt: Consult your hustler raptor drive belt diagram and begin by looping the belt around the engine pulley at the rear. Feed the belt forward toward the front of the machine. Ensure the “V” side of the belt is facing inward toward the pulley grooves.

7. Align with Hydro Pulleys: Wrap the belt around the left and right hydrostatic transmission pulleys. It is usually easier to do this while the tensioner is still in the relaxed position. Ensure the belt is properly seated inside the belt keepers you identified in step two.

8. Engage the Tensioner: Once the belt is correctly routed around the engine and transmission pulleys, use your breaker bar to pull back the idler arm once more. Slide the belt over the flat idler pulley. Slowly and carefully release the idler arm so the spring applies full tension to the belt. Verify that the belt is not twisted and is seated perfectly in every groove before reconnecting the spark plugs.

Even with a clear hustler raptor drive belt diagram, operational issues can arise over time. One frequent problem is excessive vibration or a “slapping” sound under the seat, which often indicates that the belt has stretched beyond the tensioner’s ability to compensate. If the mower fails to move when the steering levers are pushed forward, or if it feels sluggish, the belt may have slipped off due to a weak tensioner spring or a buildup of debris within the structure of the drive system.

Never attempt to adjust, touch, or inspect the drive belt while the engine is running. The high-speed rotation and high-torque nature of the hydrostatic drive system can cause severe injury or limb loss instantly.

If you notice a distinct burning rubber smell, it is a sign of friction where the belt is rubbing against a stationary component, such as a bent belt keeper or a seized idler pulley bearing. Use the diagram to verify that the belt is not routed on the wrong side of a guide pin. Furthermore, if the belt frequently snaps, check the pulley flanges for nicks or sharp edges that may be slicing the belt material during high-speed operation.

To maximize the lifespan of your hydrostatic system and ensure smooth operation, follow these professional maintenance recommendations:

- ✓ Use OEM Replacement Belts: While aftermarket belts are often cheaper, Hustler Raptor mowers require specific tension, length, and heat resistance. Genuine Hustler belts are often reinforced with aramid fibers (Kevlar) to handle the specific stresses of a zero-turn drive system.

- ✓ Monitor Spring Tension: The tensioner spring is a wear item. If the belt feels loose or “whips” during startup despite being new, the spring has likely lost its temper and should be replaced to maintain the correct layout geometry.

- ✓ Clear Debris Regularly: Grass and twigs can wedge themselves between the belt and the pulleys, causing the belt to jump or snap. Use compressed air to blow out the transmission area after every third or fourth mow.

- ✓ Check Pulley Alignment: Ensure all pulleys are on the same horizontal plane. A slightly tilted pulley will cause the belt to wear unevenly on one side, leading to premature failure.

Before you remove your old belt, take a high-resolution photo of the existing routing with your smartphone. This provides a real-world reference that complements the hustler raptor drive belt diagram and helps you identify the exact positioning of belt keepers and spacers unique to your specific mower build.

In conclusion, mastering the hustler raptor drive belt diagram is essential for any owner who wants to maintain their machine’s performance and avoid costly shop repairs. By understanding the configuration of the idlers, the role of the tensioner, and the importance of proper routing, you can ensure your mower operates at peak efficiency. Regular inspections of every component within the drive train will help you spot minor wear before it turns into a major mechanical failure, keeping your Hustler Raptor ready for any lawn care challenge.

Step-by-Step Guide to Understanding the Hustler Raptor Drive Belt Diagram: Installation & Routing

Identify the main engine pulley and the transmission pulleys to understand the start and end points of the belt path.

Locate the spring-loaded idler arm component to determine where tension is applied or released within the drive system.

Understand how the belt weaves through the layout by following the diagram’s arrows to prevent backward or incorrect routing.

Connect the new belt by looping it around the engine pulley first, then threading it through the various idlers.

Verify that the belt is seated properly in the grooves of every pulley and that the configuration matches the schematic.

Complete the installation by slowly releasing the tensioner arm and checking for any obstructions before starting the engine.

Frequently Asked Questions

What is Hustler Raptor drive belt diagram?

A Hustler Raptor drive belt diagram is a visual schematic showing the precise layout of the belt across various pulleys. It defines the system structure, illustrating how power travels from the engine to the drive wheels. This guide is essential for owners performing DIY maintenance or replacing worn components.

How do you read Hustler Raptor drive belt diagram?

To read the diagram, start by identifying the engine drive pulley, usually located at the rear. Follow the lines representing the belt as they weave through fixed pulleys and tensioning idlers. The arrows or lines indicate the specific configuration and which side of the belt contacts each component.

What are the parts of Hustler Raptor drive belt?

The system consists of several key parts: the engine drive pulley, two hydrostatic transmission pulleys, a stationary idler, and a spring-loaded tensioning idler. Together, these form a complex structure that maintains the necessary friction to propel the mower while allowing for heat dissipation and flexibility during operation.

Why is the idler pulley component important?

The idler pulley is a critical component because it maintains constant tension on the drive belt. Without proper tensioning within the system layout, the belt would slip, leading to loss of power or overheating. It also allows for easier installation by providing a way to temporarily slacken the belt.

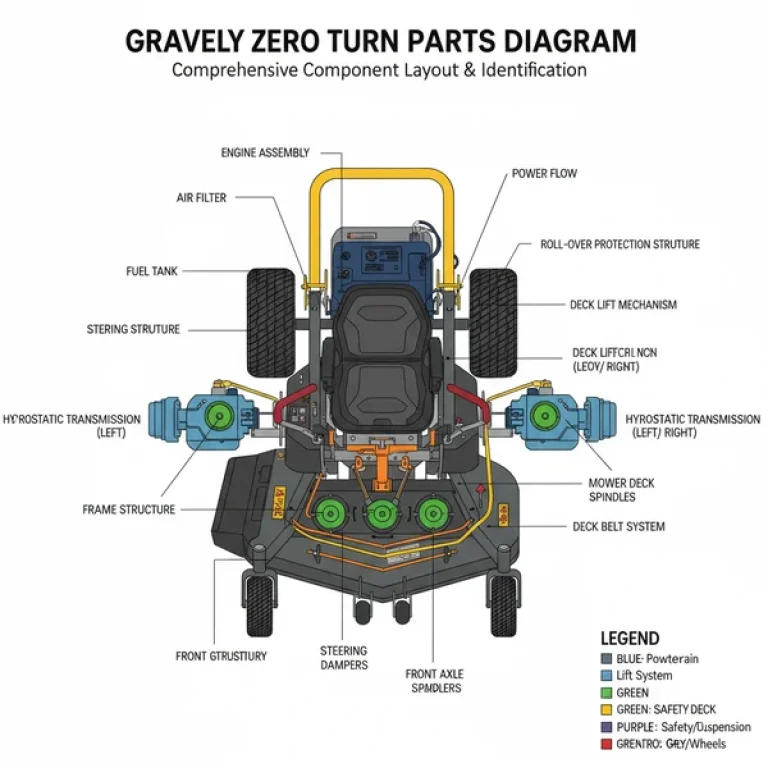

What is the difference between drive belts and deck belts?

The drive belt is responsible for moving the actual mower forward and backward via the transmission system. In contrast, the deck belt powers the cutting blades. While both involve pulleys, the drive belt layout is typically deeper within the chassis and requires different routing than the deck system.

How do I use Hustler Raptor drive belt diagram?

Use the diagram as a reference map during belt replacement. First, locate each pulley mentioned in the schematic on your mower. Then, thread the new belt through the identified layout, ensuring it sits in the grooves of every component correctly before re-engaging the tensioner for standard operation.