Honda CRV Serpentine Belt Diagram: Routing & Maintenance

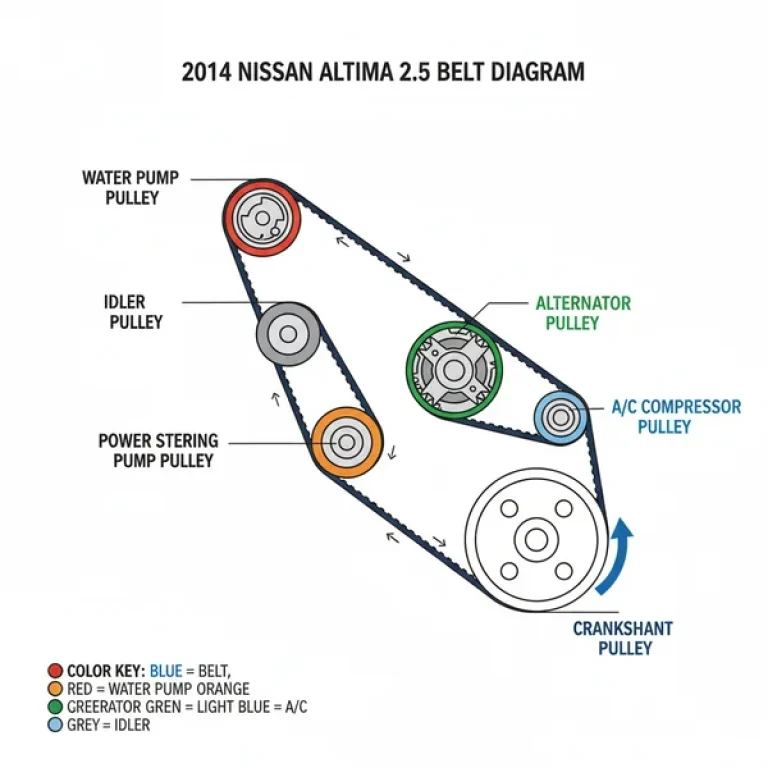

The 2004 Honda CRV serpentine belt diagram illustrates the specific path the drive belt takes around the engine pulleys, including the alternator and tensioner. Proper belt routing ensures the alternator generates sufficient auxiliary power for towing needs, such as operating your brake controller, running lights, and turn signals through an RV blade connector.

📌 Key Takeaways

- Identifies the correct routing path for the single drive belt

- Ensures the alternator provides stable auxiliary power for towing

- Critical for the operation of running lights and turn signal safety

- Helps locate the automatic tensioner for easier belt replacement

- Essential for troubleshooting electrical issues related to the brake controller

Finding an accurate 2004 honda crv serpentine belt diagram is essential for maintaining the health of your vehicle’s engine and its various peripheral systems. Whether you are experiencing a persistent squeal under the hood or you are performing preventative maintenance before a long road trip, understanding how the belt routes around the various pulleys is the first step toward a successful DIY repair. This comprehensive guide will walk you through the specifics of the K24 engine’s belt layout, the tools required for replacement, and how the health of your belt directly impacts your vehicle’s electrical performance—especially if you are using your CR-V to power accessories like a trailer’s running lights or a brake controller. By the end of this article, you will have the confidence to inspect, interpret, and replace your serpentine belt with professional precision.

The 2004 Honda CR-V utilizes a single serpentine belt to drive the alternator, power steering pump, and air conditioning compressor. This “serpentine” design means one belt does the work of three, making its integrity vital for every drive.

Understanding the 2004 Honda CR-V Serpentine Belt Diagram

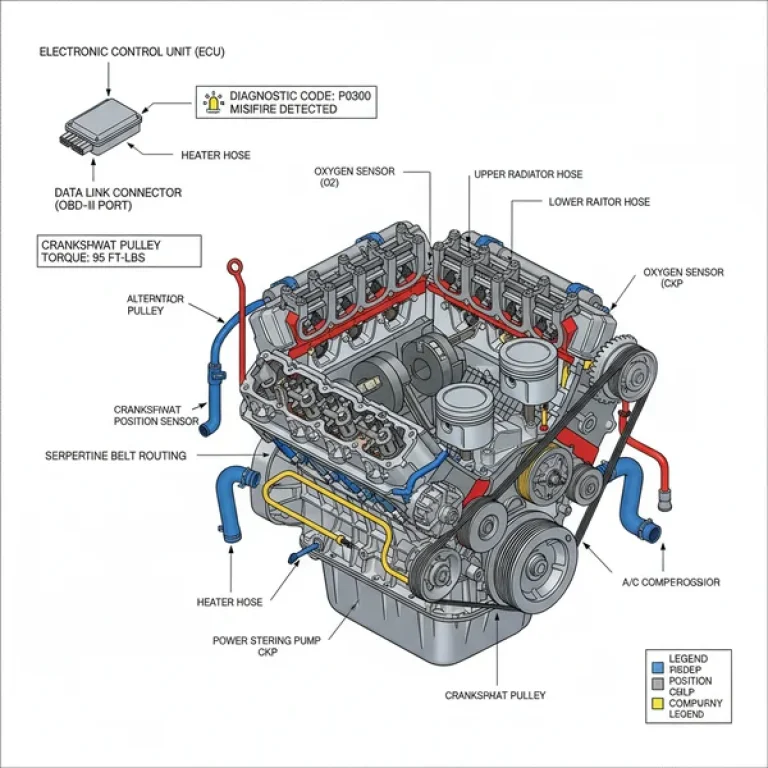

The serpentine belt on the 2004 Honda CR-V follows a specific, winding path around six distinct points of contact. Understanding these components is crucial because the belt’s tension and routing determine how efficiently your engine’s power is transferred to auxiliary systems. At the heart of this system is the crankshaft pulley, which provides the rotational force. From there, the belt travels to the alternator, which is responsible for generating electricity to charge your battery and run your electronics. If you are towing a camper, the alternator’s output is what provides the auxiliary power to your 7-way RV blade connector, ensuring your trailer battery stays charged while in transit.

The diagram reveals a layout where the belt passes over the power steering pump, providing the hydraulic pressure needed for easy maneuvering. It then dips down to the air conditioning compressor. A key element in the diagram is the auto-tensioner. Unlike older vehicles that required manual adjustment, the 2004 CR-V features a spring-loaded tensioner pulley that automatically maintains the correct pressure on the belt. The routing path is often described as a “sideways-S” configuration. The belt’s ribbed side must always face the grooved pulleys (alternator, AC, power steering, and crankshaft), while the smooth back side of the belt typically rides against the smooth idler or tensioner pulleys.

For those who have modified their CR-V for light towing, the belt’s interaction with the alternator is particularly important. A slipping belt can lead to inconsistent voltage, which might cause errors in a sensitive brake controller or result in dimming running lights on your trailer. If your trailer uses a flat connector for basic lighting, or a more complex 7-way plug for an electric brake system, the serpentine belt is the unsung hero that keeps the current flowing steadily through the ground pin and into your trailer’s harness.

Step-by-Step Installation and Interpretation Guide

Reading the 2004 honda crv serpentine belt diagram is only half the battle; applying that knowledge requires a methodical approach. Follow these steps to ensure a safe and effective replacement process.

- Preparation and Safety: Ensure the engine is completely cool to the touch. Park the vehicle on a level surface and engage the parking brake. Disconnect the negative battery terminal to prevent any accidental electrical shorts, especially if you are working near the alternator terminals.

- Locate the Routing Diagram: Most 2004 CR-Vs have a small sticker under the hood showing the belt path. If yours is missing, refer to the diagram provided in this guide. Take a digital photo of your current belt setup before removal as an extra point of reference.

- Access the Tensioner: The auto-tensioner is located on the front of the engine block. You will need a 14mm long-handled wrench or a specialized serpentine belt tool. Space is tight in the CR-V engine bay, so a slim tool is highly recommended.

- Release Tension: Place your wrench on the tensioner pulley bolt. To release the tension, rotate the wrench counter-clockwise (toward the front of the vehicle). You will feel the spring resistance. Hold the tensioner in this “open” position with one hand while using your other hand to slip the belt off the uppermost pulley (usually the power steering pump).

- Remove the Old Belt: Slowly let the tensioner return to its original position. Carefully thread the old belt out from around the various pulleys and remove it from the engine bay. Inspect the pulleys for any signs of bearing wear or debris.

- Route the New Belt: Begin threading the new belt starting from the bottom. Wrap it around the crankshaft pulley first, then the AC compressor. Work your way up, following the diagram precisely. Save the power steering pump or the tensioner pulley for the final step, as these are usually the easiest to access.

- Final Seating: Once the belt is routed around all but the final pulley, rotate the tensioner counter-clockwise again. Slip the belt into place. Release the tensioner slowly, ensuring the belt’s ribs are perfectly seated within the grooves of every pulley.

- Verification: Double-check the routing against the diagram. Ensure the belt isn’t hanging off the edge of any pulley. Reconnect the battery and start the engine. Listen for any unusual noises and visually inspect the belt to ensure it is tracking straight.

If you are working alone, use a small piece of cardboard or a zip tie to loosely hold the belt in place on the lower pulleys while you maneuver the top section. This prevents the belt from slipping off the crankshaft while you are reaching for the tensioner.

Common Issues and Troubleshooting

Even with a perfect 2004 honda crv serpentine belt diagram, issues can arise. The most common symptom of a failing belt is a high-pitched squealing noise, particularly during cold starts or when making sharp turns. This is often caused by a stretched belt or a failing auto-tensioner that can no longer provide adequate pressure.

Another frequent problem is belt “glazing.” This happens when the belt slips and the resulting friction heat-treats the rubber, making it smooth and shiny. A glazed belt loses its grip, which can lead to a drop in alternator output. If you notice your turn signal blinking faster than usual or your electric brake system acting intermittently, don’t just check the fuses. A slipping belt might not be spinning the alternator fast enough to maintain the voltage required for your trailer’s electrical system.

Check the tensioner for “chatter” or excessive vibration while the engine is idling. If the tensioner arm is bouncing significantly, the internal spring has likely weakened, and the tensioner itself should be replaced along with the belt. Furthermore, inspect the belt for “chunking,” where small pieces of the ribs have broken off. If you see more than three cracks in a one-inch span, the belt is at risk of snapping.

Never attempt to adjust or touch the serpentine belt while the engine is running. The belt moves at high speeds and can cause severe injury. Always ensure the ignition key is out of the vehicle before placing your hands near the pulleys.

Tips and Best Practices for Longevity

To get the most out of your 2004 Honda CR-V, maintenance should go beyond just replacing the belt when it breaks. Standard EPDM (Ethylene Propylene Diene Monomer) belts are designed to last between 60,000 and 100,000 miles, but environmental factors like heat and road salt can shorten this lifespan.

- ✓ Inspect Pulley Alignment: Ensure that no pulleys are wobbling. A misaligned pulley will cause the belt to wear unevenly and could lead to it “jumping” off the track.

- ✓ Clean the Grooves: Use a wire brush to clean any debris or old rubber out of the pulley grooves before installing a new belt. This ensures maximum surface contact.

- ✓ Check Your Electrical Load: If you frequently use a 7-way RV blade and power heavy accessories like a brake controller and auxiliary power ports, your belt works harder to keep the alternator turning under load. Consider a high-quality “heavy duty” belt variant.

- ✓ Verify the Ground: While the belt provides the power, a bad ground pin in your trailer wiring can cause electrical feedback that mimics alternator failure. Always check your wiring harness alongside your belt inspections.

When purchasing a replacement, avoid the cheapest options. Look for reputable brands that offer belts with high heat resistance. Since the 2004 CR-V engine bay can get quite hot, a quality belt will resist stretching and cracking much longer than a generic alternative. Additionally, keep an extra belt in your trunk. It is a small investment that can save you from an expensive tow bill if your primary belt fails in a remote area.

In conclusion, maintaining your vehicle according to the 2004 honda crv serpentine belt diagram is a fundamental aspect of car ownership. It ensures that your power steering remains light, your cabin stays cool, and your electrical system remains robust enough to handle everything from daily commuting to towing a trailer equipped with a flat connector or full electric brake system. By following the routing guide and installation steps outlined above, you can ensure your CR-V remains reliable for many miles to come.

Frequently Asked Questions

What is Honda CRV serpentine belt diagram?

The 2004 Honda CRV serpentine belt diagram is a visual schematic showing how the single drive belt winds around various engine pulleys. It identifies the path between the crankshaft, alternator, and power steering pump. This routing is vital for maintaining steady auxiliary power to external systems like trailer running lights.

How do you read Honda CRV serpentine belt diagram?

Reading the diagram involves following the arrows that indicate the direction of belt rotation around the engine components. You should start at the largest pulley, the crankshaft, and trace the path over the alternator and tensioner. Understanding this flow is crucial when wiring a brake controller for towing.

What are the parts of Honda CRV serpentine belt?

The primary parts include the crankshaft pulley, alternator, water pump, air conditioning compressor, and the automatic tensioner. These components work together to provide energy to the vehicle’s electrical grid, which in turn powers the turn signal circuits and auxiliary power leads required for safe, long-distance trailer towing operations.

Why is the alternator pulley important?

The alternator pulley is the most critical component in this system because it converts mechanical energy into electricity. It ensures that your battery stays charged while providing the necessary current for high-draw items like a trailer brake controller. Without a properly routed belt, your running lights and turn signals will fail.

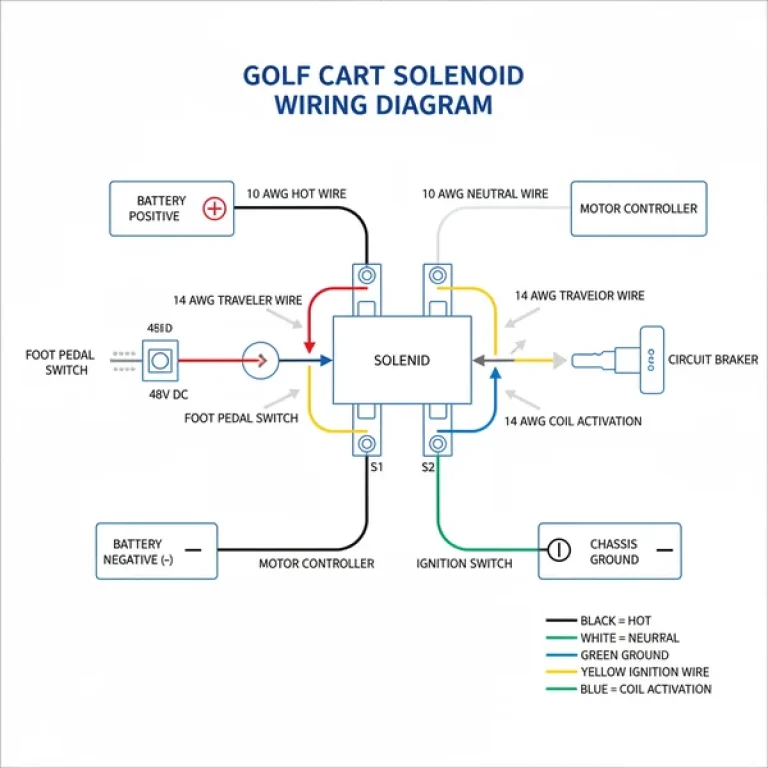

What is the difference between a belt diagram and wiring?

A belt diagram focuses on the mechanical routing of the drive belt, whereas wiring diagrams focus on electrical connections like an RV blade plug. However, they are linked; the belt must be correctly installed on the alternator to provide the auxiliary power required for complex trailer lighting and braking.

How do I use Honda CRV serpentine belt diagram?

Use this diagram when replacing a worn belt or troubleshooting charging issues. By verifying the routing, you ensure all pulleys rotate correctly. This is particularly important if you experience flickering turn signals or loss of auxiliary power to your trailer, as it indicates the alternator might not be spinning effectively.