Honda Civic Serpentine Belt Diagram: Route & Install Guide

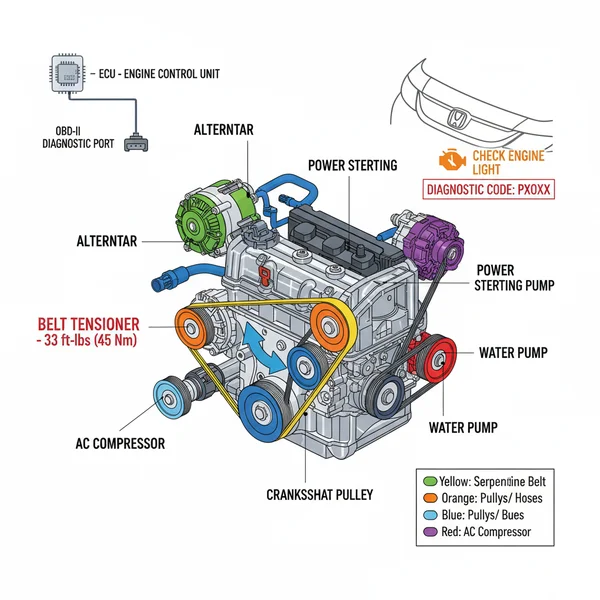

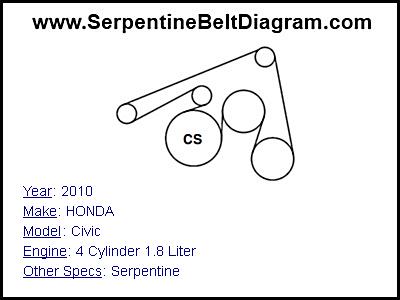

The Honda Civic serpentine belt routing diagram illustrates the precise path the drive belt takes around the alternator, water pump, AC compressor, and crank pulley. Ensuring the belt follows this layout is critical to prevent accessory failure or engine overheating. Use a tensioner tool to release pressure during removal and installation.

📌 Key Takeaways

- Main purpose of this diagram is to ensure correct rotation of all engine accessories.

- The auto-tensioner is the most important component to identify for belt release.

- Always ensure the engine is off and the battery is disconnected for safety.

- Check for belt fraying or glazing whenever the belt is removed for inspection.

- Use this diagram when performing routine maintenance or after an accessory failure.

When you are performing routine maintenance on your vehicle, having a clear 2010 honda civic serpentine belt diagram is essential for ensuring the longevity of your engine components. This comprehensive guide is designed to help DIY enthusiasts and car owners navigate the complexities of the accessory belt system. By following the instructions below, you will learn how to identify each pulley, understand the routing path, and execute a successful replacement. We will cover the necessary tools, safety precautions, and technical specifications, such as the torque spec for mounting bolts, to ensure your repair meets professional standards.

The serpentine belt in a 2010 Honda Civic, particularly the common 1.8L R18 engine variant, is a single continuous loop that drives multiple peripheral devices. Unlike older vehicles that used several individual V-belts, this modern accessory belt system utilizes one multi-ribbed belt to power the alternator, the air conditioning compressor, and the water pump. The diagram displays a complex “S” shape or serpentine path that weaves between these components. Each pulley has a specific surface; some are ribbed to grip the inner side of the belt, while others are smooth and contact the flat backside of the belt.

The primary drive source in the 2010 honda civic serpentine belt diagram is the crankshaft pulley located at the bottom of the engine block. As the engine runs, this pulley rotates, providing the mechanical energy needed for the rest of the system. The belt then travels up toward the alternator, which generates electrical power for the battery and the ECU. The water pump pulley is another critical stop, as it facilitates coolant flow throughout the engine block to prevent overheating. Furthermore, the air conditioning compressor pulley is integrated into this loop to provide cabin cooling. A central feature of this diagram is the auto-tensioner, which uses a spring-loaded mechanism to maintain constant pressure on the belt, preventing slippage. While the internal timing chain synchronizes the engine valves, the external serpentine belt ensures all external systems function in harmony.

[DIAGRAM_PLACEHOLDER: 2010 Honda Civic Serpentine Belt Routing – 1.8L Engine]

1. Alternator (Top Center)

2. Water Pump (Right Side)

3. A/C Compressor (Bottom Front)

4. Crankshaft Pulley (Bottom Rear)

5. Auto-Tensioner (Left Center)

Step-by-Step Installation and Interpretation

Interpreting the diagram requires a keen eye for the direction of the belt’s travel. To begin any work on the belt system, you must first prepare the vehicle and gather the correct tools. For the 2010 Honda Civic, you will primarily need a 19mm long-handle wrench or a specialized serpentine belt tool. This tool is used to bypass the cramped engine bay and reach the tensioner bolt.

Always document the belt routing before removal. While diagrams are helpful, taking a high-resolution photo of your specific engine bay can provide a secondary reference for exactly how the belt sits on the pulleys.

1. Safety First: Ensure the engine is completely cool to the touch. Set the parking brake and disconnect the negative battery terminal. This prevents the engine from accidentally cranking and ensures that no electrical shorts occur while working near the alternator.

2. Access the Tensioner: Open the hood and locate the auto-tensioner. In the 2010 Civic, the tensioner is located on the passenger side of the engine. There is a specific 19mm hex cast into the tensioner arm. This is not a standard mounting bolt, but rather a “nut” designed for your wrench to grip.

3. Release Tension: Fit your 19mm wrench onto the tensioner’s hex head. Slowly pull the wrench toward the front of the car (clockwise). This motion will compress the internal spring and create slack in the belt.

4. Remove the Old Belt: While holding the tensioner in the released position with one hand, use your other hand to slide the belt off the uppermost pulley, which is usually the alternator. Once the belt is off one pulley, you can slowly release the wrench and remove the belt entirely from the engine bay.

5. Clean the Pulleys: Before installing the new belt, inspect the grooves of every pulley. Use a stiff brush to remove any rubber deposits or debris. This ensures the new belt seats properly and prevents premature wear.

6. Route the New Belt: Following the 2010 honda civic serpentine belt diagram, begin by wrapping the belt around the crankshaft pulley at the bottom. Proceed to the A/C compressor and water pump. Ensure the ribbed side of the belt matches the ribbed pulleys. Save the alternator or the tensioner pulley for the final step.

7. Final Seating: Rotate the tensioner again using your 19mm wrench to create the necessary slack. Slide the belt over the final pulley. Release the tensioner slowly, allowing it to apply pressure to the new belt.

8. Verify Alignment: This is the most critical step. Check every pulley to ensure the belt is perfectly centered. If the belt is even one rib off, it can shred or fly off the moment the engine starts.

Never place your fingers between the belt and the pulley. If the wrench slips or the tensioner snaps back, it can cause severe injury. Always handle the belt from a safe distance or use a reaching tool.

Common Issues and Troubleshooting

The accessory belt system is usually very reliable, but several issues can arise over time. The most frequent symptom is a high-pitched squealing noise, especially during cold starts or when the air conditioning is turned on. This usually indicates that the belt has stretched or the tensioner has lost its spring force.

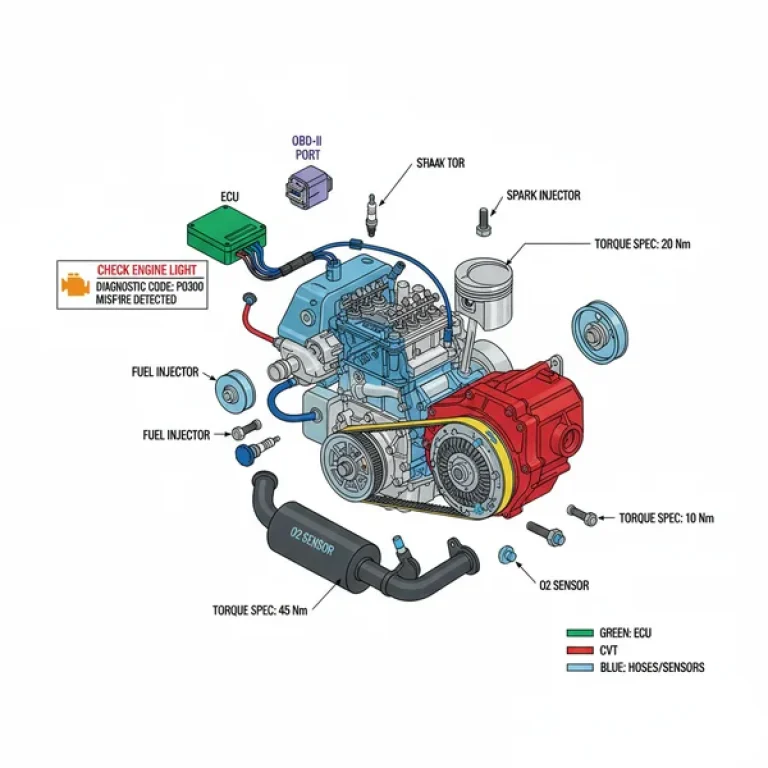

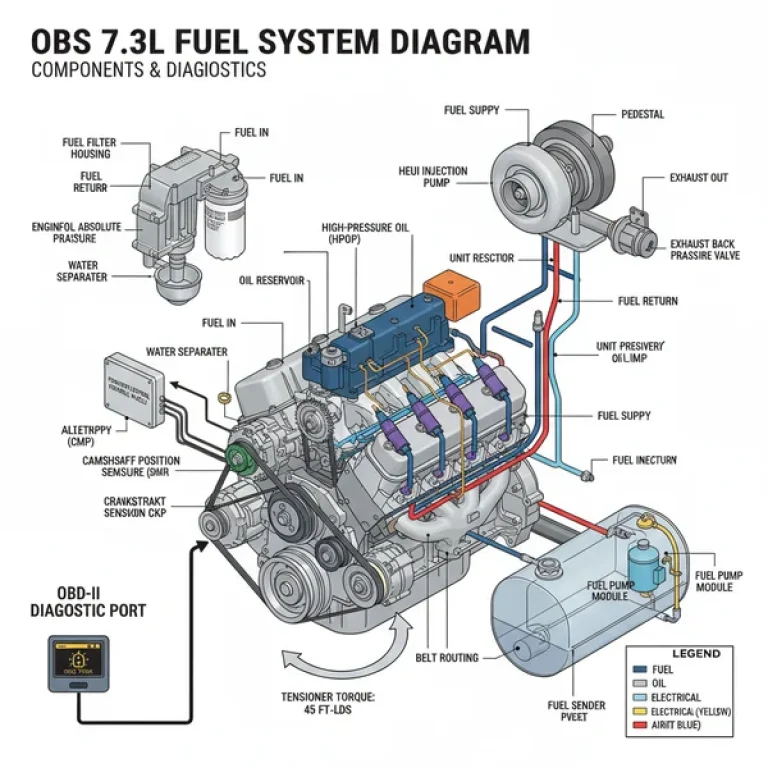

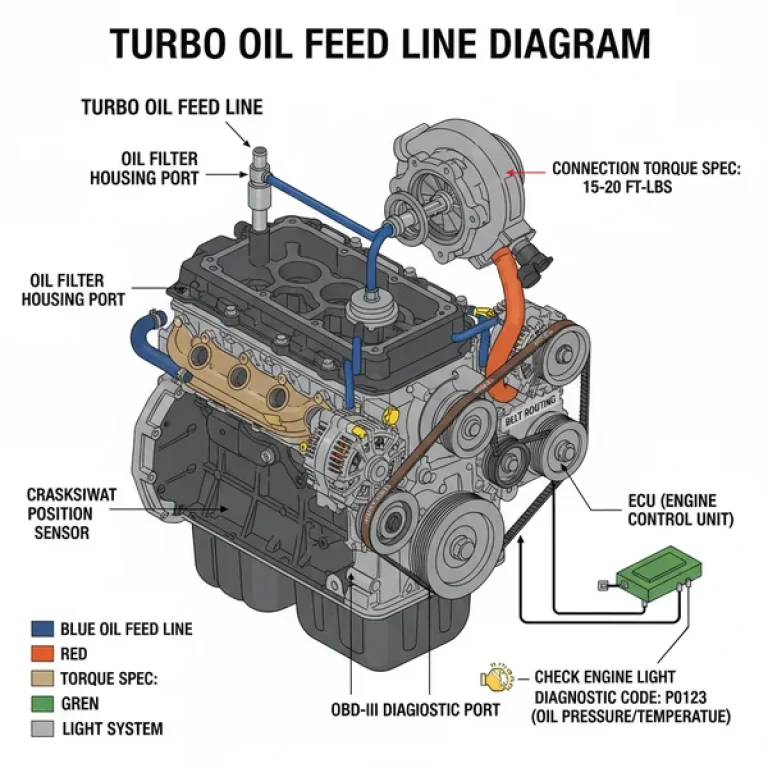

If the belt snaps or slips significantly, the alternator will stop charging the battery. This often triggers a check engine light or a battery warning light on the dashboard. In many cases, the ECU will detect an improper voltage range and store a diagnostic code such as P0562 (System Voltage Low). By using an OBD-II scanner, you can confirm if the charging system is failing due to a mechanical belt issue. Additionally, because the belt drives the water pump, a failure will immediately halt coolant flow, leading to rapid engine overheating. If you see the temperature gauge rising, pull over immediately to prevent permanent engine damage.

- ✓ Inspect for glazing (a shiny appearance on the belt surface)

- ✓ Check for cracks appearing every inch (standard wear)

- ✓ Listen for chirping, which often indicates pulley misalignment

- ✓ Ensure the tensioner indicator mark is within the specified range

Tips and Best Practices for Maintenance

Maintaining the 2010 honda civic serpentine belt diagram and its associated hardware is a cost-effective way to avoid expensive roadside repairs. Most mechanics recommend inspecting the belt every 30,000 miles and replacing it every 60,000 to 100,000 miles. However, environmental factors like extreme heat or road salt can accelerate degradation.

When replacing the belt, it is highly recommended to replace the auto-tensioner assembly as well. The internal spring and the bearing in the tensioner pulley have the same lifespan as the belt itself. Replacing them together ensures the system remains quiet and reliable.

When purchasing a replacement, opt for a high-quality EPDM (Ethylene Propylene Diene Monomer) belt. Unlike older neoprene belts, EPDM does not crack as easily; instead, it loses material in the grooves, much like a tire loses tread. You can use a specific “belt wear gauge” to check if the grooves are deep enough.

If you find yourself needing to replace the tensioner itself, pay close attention to the torque spec for the mounting bolts. For a 2010 Honda Civic, the tensioner mounting bolt typically requires approximately 33 lb-ft of torque. Using a calibrated torque wrench ensures the tensioner is securely fastened without stripping the aluminum engine block threads.

Finally, always keep a record of your replacement. Note the mileage and the date in your vehicle’s maintenance log. This data is invaluable for future troubleshooting and helps maintain the resale value of your Honda Civic. By understanding the 2010 honda civic serpentine belt diagram and following these professional best practices, you can ensure your vehicle remains a dependable mode of transportation for years to come.

Frequently Asked Questions

What is a serpentine belt diagram?

A serpentine belt diagram is a visual map showing how the drive belt weaves through various engine pulleys like the alternator and AC compressor. It ensures the belt turns each component in the correct direction. Following this diagram prevents mechanical damage and ensures all belt-driven accessories function properly.

How do you read a serpentine belt diagram?

To read the diagram, identify the crankshaft pulley as the starting point. Trace the line indicating the belt’s path, noting whether it goes over or under specific pulleys. The diagram usually indicates the auto-tensioner location, which is where you apply leverage to loosen the belt during maintenance.

What are the parts of the serpentine system?

The system includes the crankshaft pulley, which provides power, and several accessory pulleys like the alternator, water pump, and air conditioning compressor. It also features an auto-tensioner and potentially an idler pulley. These components work together to power essential vehicle electronics and cooling systems while maintaining belt tension.

Why is the auto-tensioner important?

The auto-tensioner is vital because it maintains constant pressure on the belt to prevent slipping or squealing. If it fails, you might see a check engine light or experience a diagnostic code related to charging. Proper tension ensures the ECU receives consistent power and that the mechanical components operate efficiently.

What is the difference between a serpentine belt and a timing belt?

A serpentine belt drives external accessories like the alternator and AC, whereas a timing belt synchronizes the internal movement of the engine’s valves and pistons. While a broken serpentine belt causes accessory failure, a snapped timing belt can lead to severe engine damage, often requiring professional OBD-II diagnostic tools.

How do I use a serpentine belt diagram?

Use the diagram as a reference before removing the old belt. Compare the routing on the diagram to your current setup. After installing the new belt, verify the path matches the illustration perfectly. This ensures that the engine’s ECU won’t trigger errors due to improper accessory rotation or charging.