Honda Civic Belt Diagram: Routing & Installation

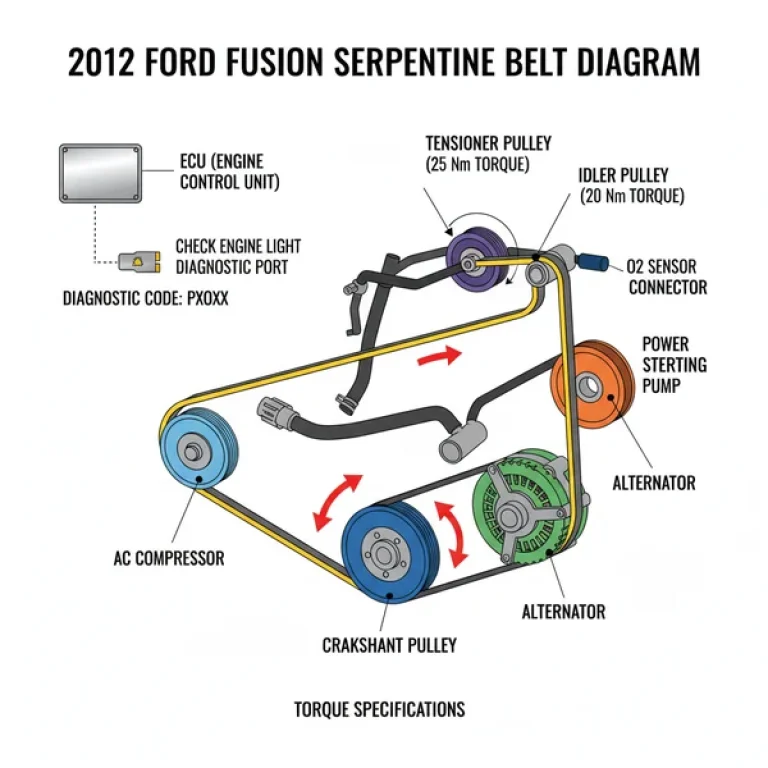

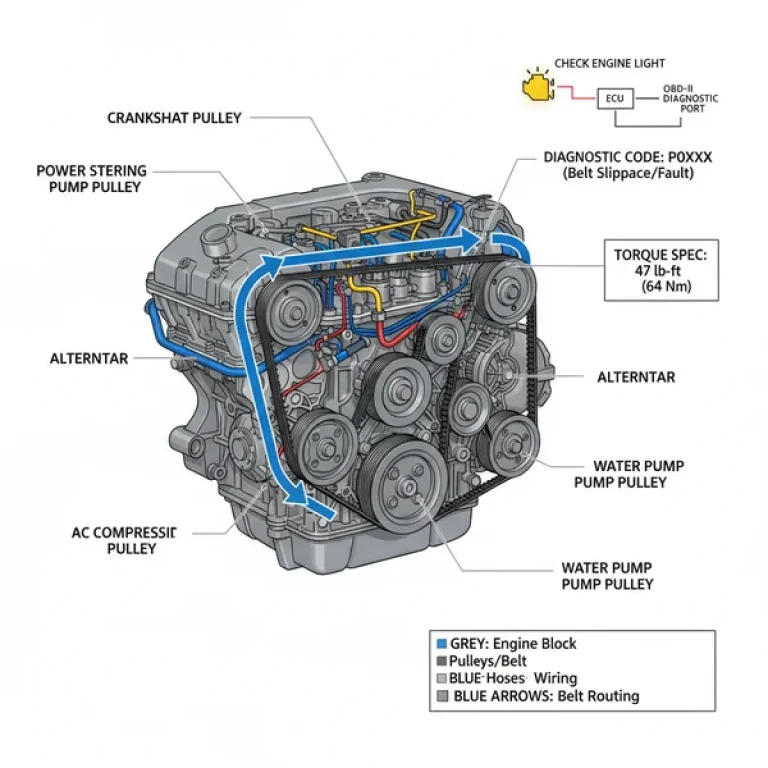

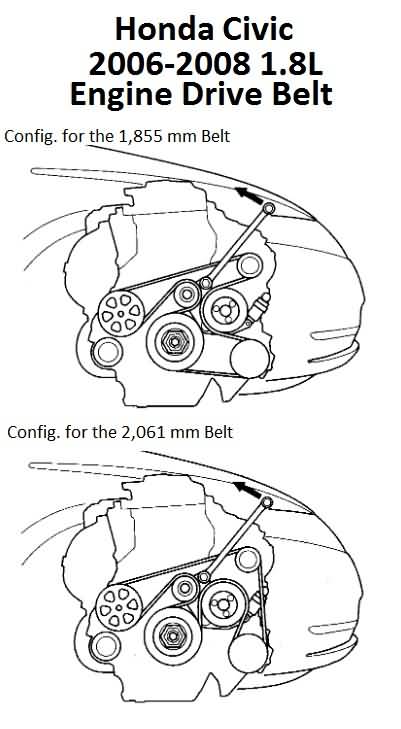

The serpentine belt routing for this vehicle follows a specific configuration connecting the alternator, water pump, and air conditioning compressor. By following the visual layout, you can ensure each component is properly engaged. This diagram is essential for correctly tensioning the system and preventing engine overheating or mechanical failure.

📌 Key Takeaways

- Main purpose is to visualize the precise routing of the serpentine belt

- The auto-tensioner is the most important component to identify

- Correct routing is a critical consideration for preventing engine damage

- Always compare the new belt path to the visual layout before tightening

- Use this diagram during belt replacement or when diagnosing pulley noise

Navigating the engine bay of a high-mileage vehicle requires precision, and having a clear 2006 honda civic belt diagram is the first step toward a successful DIY repair or maintenance check. The serpentine belt is a single, continuous loop that powers multiple vital systems, including the alternator, air conditioning compressor, and water pump. Without a proper understanding of the belt’s configuration, even a simple replacement can become a frustrating puzzle. This guide provides a comprehensive breakdown of the belt’s layout, the tools required for service, and expert tips to ensure your Civic remains reliable on the road.

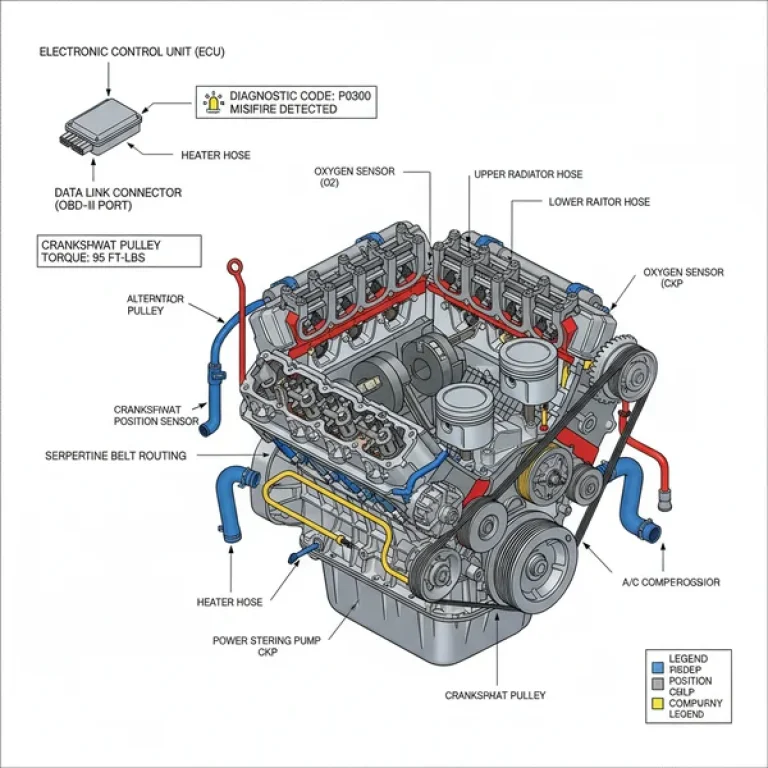

The 2006 Honda Civic primarily uses the 1.8L R18 engine. This specific configuration uses a serpentine belt system that relies on a hydraulic-style auto-tensioner. Unlike older models with multiple V-belts, this single belt system must be routed perfectly to ensure all components spin in the correct direction.

Understanding the Serpentine Belt Layout and Components

The 2006 Honda Civic serpentine belt system is a marvel of compact engineering, designed to transfer mechanical energy from the engine’s crankshaft to various peripheral accessories. To read the diagram effectively, you must first identify the key components involved in the loop. The crankshaft pulley, located at the bottom of the engine block, serves as the primary driver. As the engine runs, this pulley rotates the belt, which in turn engages the other pulleys.

In the standard 1.8L engine configuration, the belt follows a specific “S” or serpentine path. Starting from the crankshaft at the bottom, the belt typically travels upward toward the alternator, located at the top rear of the engine bay. From there, it moves across to the water pump and down toward the air conditioning compressor. A critical part of this layout is the auto-tensioner pulley. This component is spring-loaded and maintains constant pressure on the belt to prevent slipping.

The visual layout of the belt system is often categorized by the side of the belt contacting the pulley. Some pulleys are “grooved,” meaning they grip the inside ribbed surface of the belt. These include the crankshaft, alternator, and A/C compressor. Other pulleys are “flat” or “smooth,” which contact the back (smooth) side of the belt, such as the water pump or certain idler pulleys. Understanding this distinction is vital when interpreting the 2006 honda civic belt diagram, as an incorrectly routed belt can lead to component failure or engine overheating.

(Top of Engine)

[Alternator] [Water Pump]

O O

/ \ / \

(Tensioner) O / \

\ \ / \

\ \_/ \

\ O [A/C Compressor]

\ /

\ O /

[Crankshaft]

(Bottom of Engine)

Figure 1: Typical serpentine belt routing for the 1.8L R18 engine.

Step-by-Step Guide to Belt Inspection and Replacement

Replacing or adjusting the serpentine belt on a 2006 Honda Civic requires a methodical approach. Because the engine bay is relatively tight, following these steps will help you interpret the diagram and perform the task safely.

- ✓ Step 1: Preparation and Safety – Park the vehicle on a level surface and engage the parking brake. Ensure the engine is completely cool to the touch. Disconnect the negative battery terminal as a safety precaution to prevent the engine from accidentally cranking while your hands are near the pulleys.

- ✓ Step 2: Locate the Tensioner – On the 1.8L engine, the tensioner is located on the passenger side of the engine block, roughly in the middle of the belt’s path. It features a 19mm hex bolt head (or sometimes a 14mm depending on aftermarket replacements) cast into the tensioner arm.

- ✓ Step 3: Relieve Belt Tension – Use a long-handled 19mm wrench or a dedicated serpentine belt tool. Place the wrench on the tensioner bolt and rotate it slowly toward the rear of the car (clockwise). This will compress the hydraulic tensioner, creating slack in the belt.

- ✓ Step 4: Remove the Old Belt – While holding the tensioner in the compressed position, carefully slide the belt off the uppermost pulley (usually the alternator or water pump). Once the belt is free from one pulley, slowly release the tensioner arm and remove the belt entirely from the engine bay.

- ✓ Step 5: Inspect the Pulleys – With the belt removed, spin each pulley by hand. They should spin smoothly without noise, wobbling, or resistance. If you hear a grinding or “dry” sound, the bearing inside that component is likely failing and should be replaced.

- ✓ Step 6: Route the New Belt – Using the 2006 honda civic belt diagram as your reference, begin threading the new belt starting from the bottom. Wrap it around the crankshaft pulley first, then move to the A/C compressor. Work your way up, ensuring the ribs of the belt seat perfectly into the grooves of the pulleys.

- ✓ Step 7: Final Seating – Compress the tensioner again and slide the final loop of the belt over the remaining pulley. Before releasing the tensioner, double-check that the belt is centered on all pulleys. If the belt is even slightly off-center, it may shred or jump off upon startup.

- ✓ Step 8: Verify the Installation – Release the tensioner slowly. Start the engine and observe the belt for a few moments. It should run quietly and smoothly.

The hydraulic tensioner on the 2006 Civic is under significant pressure. Always use a long-handled tool to maintain leverage and keep your fingers away from the “pinch points” between the belt and the pulleys. If the wrench slips while the belt is halfway off, it can cause injury.

Common Belt Issues and Troubleshooting

The serpentine belt is a wear item that eventually fails due to heat, friction, and age. Recognizing the signs of failure can save you from an expensive breakdown. The 2006 honda civic belt diagram is helpful here, as it allows you to pinpoint which component might be causing a specific noise or symptom.

The most frequent issue is a “squealing” sound, particularly during cold starts or when turning the steering wheel sharply. This usually indicates a loose or worn belt that is slipping against the pulleys. If the squeal occurs when the A/C is turned on, the issue is likely localized to the belt’s engagement with the compressor pulley.

Another common problem is “chirping,” which often points to a pulley misalignment or a failing bearing. If you notice the belt is fraying at the edges, it is a sign that one of the pulleys in the configuration is tilted or not sitting flush. Additionally, look for “glazing” on the flat side of the belt; a shiny, smooth appearance suggests the belt is getting too hot or the tensioner is no longer providing adequate pressure.

If you are struggling to see the routing path from the top of the engine, remove the front passenger-side wheel and the plastic splash shield. This provides a direct, side-view perspective of the crankshaft and A/C compressor pulleys, making it much easier to seat the belt correctly.

Maintenance Tips and Best Practices

To get the most out of your 2006 Honda Civic, proactive maintenance of the drive belt system is essential. Most experts recommend inspecting the belt every 30,000 miles and replacing it every 60,000 to 100,000 miles, depending on driving conditions. Modern belts are made of EPDM (Ethylene Propylene Diene Monomer), which does not crack as easily as older neoprene belts. Instead, they lose material from the ribs, much like a tire loses tread. You can use a belt wear gauge to check the depth of the grooves.

When purchasing a replacement, opt for high-quality OEM or reputable aftermarket brands. A cheap belt may stretch prematurely, leading to noise issues shortly after installation. It is also wise to replace the auto-tensioner at the same time as the belt if the vehicle has over 120,000 miles. Tensioners contain internal springs and hydraulic dampers that weaken over time, and a fresh tensioner ensures the new belt operates at peak efficiency.

Finally, always keep a copy of the 2006 honda civic belt diagram in your glove box or saved on your phone. If the belt snaps while you are driving, you will lose power steering and the engine will begin to overheat rapidly. Having the diagram readily available will make an emergency roadside repair significantly faster and less stressful. By understanding the system layout and following proper installation procedures, you can ensure your Civic continues to perform reliably for years to come.

Frequently Asked Questions

What is Honda Civic belt diagram?

A belt diagram is a visual map illustrating the exact path a serpentine or drive belt takes around various engine pulleys. It details the system layout, showing how power is transferred from the crankshaft to accessories like the alternator. This structure ensures all components rotate in the correct direction.

How do you read Honda Civic belt diagram?

Reading the diagram requires identifying the crankshaft pulley as the primary power source. Follow the lines representing the belt as they weave through the configuration of accessory pulleys. Note which side of the belt contacts each component, as this determines the specific routing and functional layout for the drive system.

What are the parts of Honda Civic belt system?

The primary parts include the crankshaft pulley, alternator, air conditioning compressor, water pump, and the belt tensioner. Each component plays a vital role in the vehicle’s operation. The configuration is designed to maximize space while ensuring the belt maintains consistent pressure across every pulley within the engine bay.

Why is the tensioner important?

The auto-tensioner is a critical component that maintains the correct amount of pressure on the belt. Without proper tension, the belt would slip, leading to component failure or overheating. This part of the system ensures the layout remains tight and responsive to changes in engine speed and load.

What is the difference between a timing belt and a serpentine belt?

A timing belt synchronizes the internal engine structure, specifically the crankshaft and camshaft. In contrast, a serpentine belt is an external component that powers peripheral systems like the alternator and AC. The configuration and purpose of these belts are entirely different, though both are essential for reliable vehicle performance.

How do I use Honda Civic belt diagram?

Use the diagram as a reference during belt replacement to ensure the new belt is installed in the correct configuration. Before removing the old belt, compare its current layout to the diagram. This helps identify any misrouting or worn components that might lead to system failure in the future.