Honda Accord V6 Serpentine Belt Diagram: Routing Guide

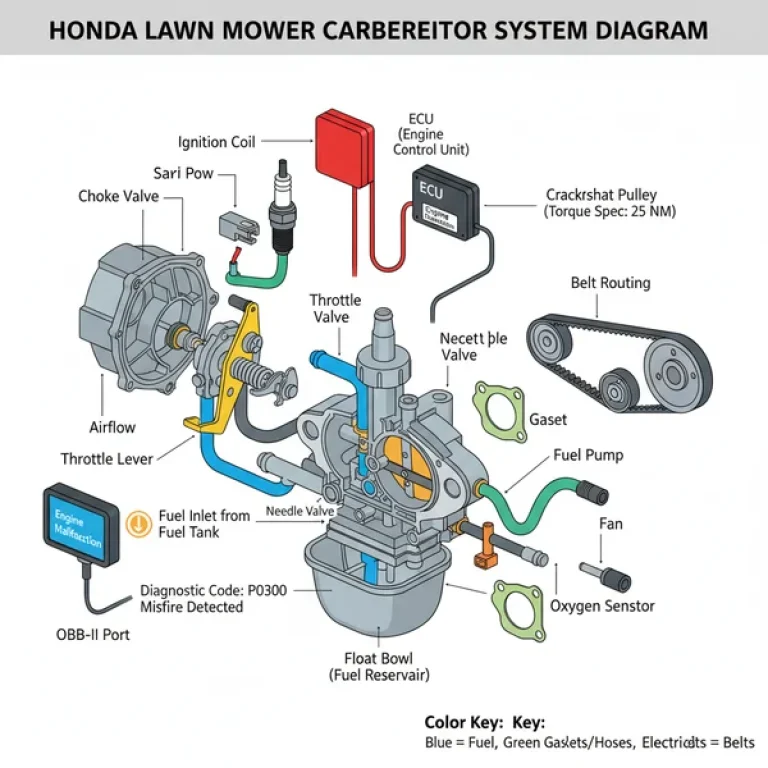

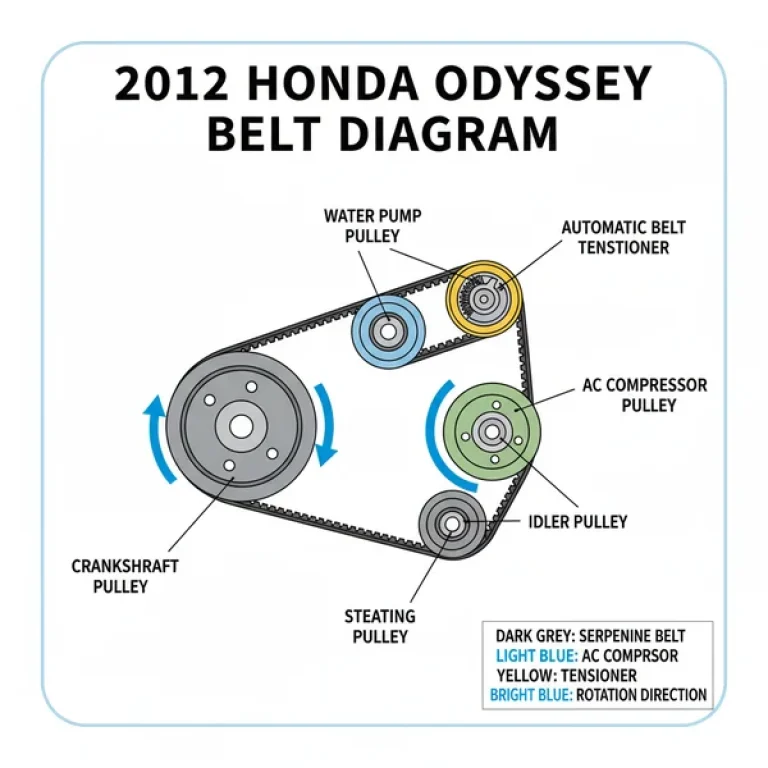

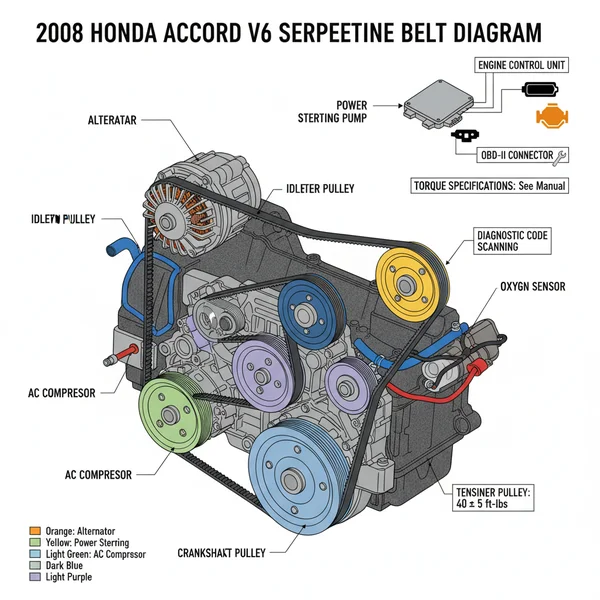

The Honda Accord V6 serpentine belt diagram illustrates the specific path the drive belt takes around the alternator, power steering pump, AC compressor, and crank pulley. Using the auto-tensioner is vital for proper installation. Correct routing ensures no check engine light triggers due to accessory failure or electrical issues monitored by the ECU.

📌 Key Takeaways

- Visual map of the 3.5L engine’s accessory drive system

- Identification of the hydraulic or spring-loaded auto-tensioner

- Critical importance of seating the belt in pulley grooves

- Preventing electrical system failure and engine overheating

- Reference for DIY belt replacement or tensioner service

Navigating the complex engine bay of a 3.5L V6 engine requires a clear roadmap, especially when it comes to routine maintenance like belt replacement. This guide provides a definitive 2008 honda accord v6 serpentine belt diagram and a comprehensive walkthrough to help you master this DIY task. Understanding how the accessory belt interacts with your vehicle’s vital systems is crucial for maintaining performance and preventing unexpected breakdowns. Whether you are a seasoned home mechanic or a beginner looking to save on labor costs, you will learn the exact routing path, the tools required for the job, and the technical specifications necessary to ensure a professional-grade installation. By the end of this article, you will have the confidence to inspect, remove, and install a new belt while ensuring all pulleys are properly aligned and tensioned.

The 2008 Honda Accord V6 utilizes a single serpentine belt (also known as an accessory belt) to drive the alternator, power steering pump, and air conditioning compressor. Unlike the timing chain found in the K-series 4-cylinder engines, this V6 J-series engine relies on a timing belt for internal synchronization, but the external serpentine belt is what keeps your electronics and climate control running.

Understanding the 2008 Honda Accord V6 Serpentine Belt Diagram

The serpentine belt system on the 2008 Accord V6 is a marvel of compact engineering. The diagram reveals a serpentine path that weaves through six distinct points of contact. To read the diagram correctly, you must first identify the largest pulley at the bottom, which is the crankshaft pulley. This is the “drive” pulley that provides the rotational force for the entire system. From the crankshaft, the belt travels upward toward the tensioner pulley and the alternator. The alternator is responsible for charging the battery and powering the ECU (Engine Control Unit) while the vehicle is running.

The routing continues toward the top of the engine, wrapping around the power steering pump. This component is essential for maintaining ease of maneuverability. If the belt slips or snaps, your steering will immediately become heavy. Following the power steering pump, the belt moves toward the A/C compressor, located lower down on the front of the engine block. Finally, the belt passes over an idler pulley, which serves to maintain the correct wrap angle and tension across the long stretches of the belt. The auto-tensioner is a spring-loaded component that automatically adjusts for belt stretch over time, though it has a limited range of motion.

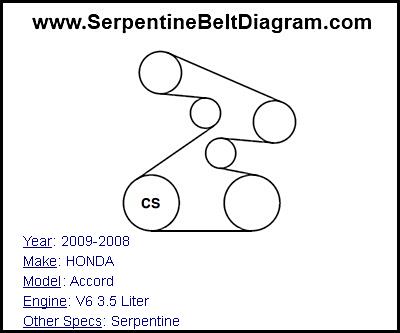

Visual Representation of 2008 Honda Accord V6 Belt Path:

(Top) Power Steering Pump

|

(Right) Alternator <—> (Left) Idler Pulley

|

(Right) Auto-Tensioner <—> (Left) A/C Compressor

|

(Bottom) Crankshaft Pulley

It is important to note that the smooth side of the belt must always ride against smooth pulleys (like the idler or tensioner), while the ribbed side of the belt must sit flush within the grooves of the drive pulleys (crankshaft, alternator, A/C, and power steering). Misaligning these surfaces will lead to immediate belt failure and potential damage to the pulley bearings. If you notice any deviation from the diagram during installation, stop immediately and re-route, as a misrouted belt may spin components in the wrong direction or cause excessive friction.

Step-by-Step Installation Guide

Replacing the serpentine belt on a V6 Accord is a manageable task if you follow a logical progression. Before starting, ensure the engine is completely cool to the touch. Working near a hot engine block or radiator can lead to severe burns. You will need a few specific tools to make this job easier: a 14mm long-handle wrench or a dedicated serpentine belt tool, a new high-quality EPDM rubber belt, and a bright flashlight to inspect the lower pulleys.

- ✓ Step 1: Preparation and Safety. Park the vehicle on a level surface and engage the parking brake. Disconnect the negative battery terminal to prevent any accidental engine starts. While not strictly necessary, removing the front passenger-side wheel and the plastic splash guard can provide significantly better access to the crankshaft and A/C compressor pulleys.

- ✓ Step 2: Locate the Auto-Tensioner. Find the tensioner pulley located between the alternator and the crankshaft. It features a 14mm bolt head cast into the tensioner arm. Note that you are not trying to loosen this bolt, but rather use it as a lever to move the spring-loaded arm.

- ✓ Step 3: Relieve Tension. Place your 14mm wrench on the tensioner bolt. Rotate the wrench slowly toward the front of the car (clockwise). This will compress the internal spring and create slack in the belt. Carefully slip the belt off the uppermost pulley (the power steering pump) first.

- ✓ Step 4: Remove the Old Belt. Once the tension is released, slowly let the tensioner arm return to its resting position. Thread the old belt out through the engine bay, taking care not to snag it on any sensors or hoses. This is the best time to spin each pulley by hand to check for grinding noises or wobbling, which could indicate a failing bearing.

- ✓ Step 5: Route the New Belt. Referencing your 2008 honda accord v6 serpentine belt diagram, begin by looping the new belt around the crankshaft pulley at the bottom. Feed it up to the A/C compressor and then across to the idler pulley. Ensure the ribs are perfectly seated in the grooves of each pulley as you go.

- ✓ Step 6: Final Seating. Save the power steering pump or the alternator for the last step. Use the wrench to once again compress the tensioner. Slip the final loop of the belt over the remaining pulley. Double-check the entire path to ensure the belt hasn’t slipped off the lower pulleys during the process.

- ✓ Step 7: Inspection and Testing. Slowly release the tensioner to apply pressure to the new belt. Inspect the alignment one last time. Reconnect the battery and start the engine. Observe the belt for a few minutes; it should run smoothly without vibrating, squealing, or jumping.

Never place your fingers between the belt and a pulley while the tensioner is compressed. If the wrench slips, the tensioner can snap back with enough force to cause serious injury. Use a long-handled tool to keep your hands clear of the “pinch zone.”

Common Issues & Troubleshooting

Problems with the serpentine belt often manifest as audible or electrical symptoms. A frequent issue encountered by Accord owners is a high-pitched squealing noise, especially during cold starts or sharp turns. This typically indicates a worn belt that has lost its grip or a tensioner that is no longer applying sufficient pressure. If the belt is glazed (appears shiny), it will slip on the pulleys, reducing the efficiency of the alternator and power steering.

When the belt fails completely, the alternator stops charging the battery. This may cause the ECU to detect low voltage, triggering a check engine light or a battery warning light on the dashboard. In such cases, scanning the vehicle via the OBD-II port may reveal a diagnostic code related to system voltage or charging circuit malfunctions. Furthermore, while the serpentine belt doesn’t directly control coolant flow (the water pump on the V6 is driven by the timing belt), a snapped belt can lead to secondary overheating if the electrical cooling fans cannot draw enough power from a dying battery. If you see signs of fraying, longitudinal cracks, or missing “ribs” on the belt, replacement is urgent to avoid being stranded.

Tips & Best Practices

To ensure the longevity of your new belt and the components it drives, follow these professional maintenance tips. First, always opt for a high-quality EPDM (Ethylene Propylene Diene Monomer) belt. Older neoprene belts are prone to cracking, whereas EPDM belts gradually lose rib depth, making them much more durable but harder to inspect visually. Use a belt wear gauge to check for depth if the belt looks okay but is squealing.

Whenever you replace the serpentine belt, take a moment to inspect the auto-tensioner’s indicator mark. Most Honda tensioners have a small “range” mark on the casting. If the pointer is outside this range with a new belt installed, the tensioner spring has likely weakened and the entire assembly should be replaced.

When performing the replacement, check for oil or coolant leaks near the pulleys. Oil contamination is the leading cause of premature belt failure, as it softens the rubber and causes it to swell and slip. If you are replacing the tensioner assembly itself, the torque spec for the mounting bolts is generally around 33 lb-ft, but always verify with your specific service manual. Keeping a spare belt in your trunk is a low-cost insurance policy for long road trips. Lastly, remember that while you are working on the accessory system, it is wise to check the health of your battery terminals; clean terminals ensure that the power generated by the alternator reaches the ECU and other critical electronics without resistance.

By following this guide and utilizing the 2008 honda accord v6 serpentine belt diagram, you have taken a major step in maintaining the reliability of your vehicle. Proper belt maintenance not only prevents the dreaded check engine light from appearing due to charging issues but also ensures that every drive is quiet and smooth. Regular inspections every 30,000 miles will help you catch wear before it leads to a roadside emergency, keeping your Accord on the road for years to come.

Frequently Asked Questions

What is a Honda Accord V6 serpentine belt diagram?

This diagram is a visual schematic that illustrates the exact path the serpentine belt must follow to connect the engine crankshaft to various accessories. For the Honda V6 engine, it maps the route through the alternator, power steering pump, water pump, and air conditioning compressor for proper mechanical operation.

How do you read a serpentine belt diagram?

To read the diagram, identify the large crankshaft pulley as your starting point. Follow the lines representing the belt as they wrap over or under auxiliary pulleys. Note the direction of the belt loops; some pulleys use the ribbed side while others use the smooth back side of the belt.

What are the parts of the Accord V6 belt system?

The system includes the crankshaft pulley, which provides power, and driven pulleys for the alternator, AC compressor, and power steering pump. It also features an automatic tensioner and an idler pulley. Each component must be aligned according to the diagram to ensure the belt remains secure during high-speed engine operation.

Why is the belt tensioner important?

The auto-tensioner maintains constant pressure on the belt to prevent slipping. If the tensioner fails, the belt may squeal or fly off, potentially causing a check engine light or an OBD-II error. Ensuring the tensioner bolt meets the correct torque spec is vital for long-term reliability and component safety.

What is the difference between a serpentine belt and a timing belt?

A serpentine belt is an external drive belt that powers accessories like the alternator and AC compressor. In contrast, a timing belt is located inside the engine and synchronizes the camshaft and crankshaft. While a broken serpentine belt stops accessories, a broken timing belt can cause catastrophic internal engine damage.

How do I use this serpentine belt diagram?

Use this diagram as a reference before removing your old belt to ensure you understand the routing. If the belt has already snapped, use the schematic to thread the replacement belt around the pulleys in the correct sequence, ensuring the belt is centered before releasing the tensioner to lock it.