Holley Terminator X Wiring Diagram: Installation Setup

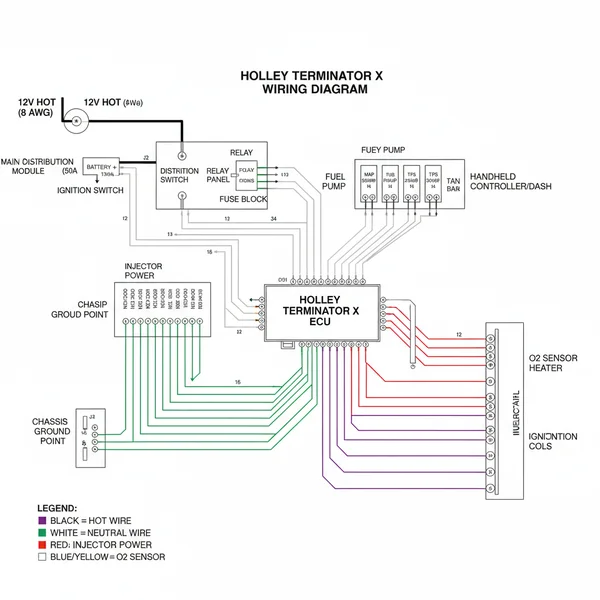

A Holley Terminator X wiring diagram serves as the master blueprint for connecting the ECU to engine sensors, injectors, and ignition. It details pinouts for the main harness, power connections, and auxiliary inputs, ensuring proper signal flow and electrical grounding to prevent interference during engine management and tuning.

📌 Key Takeaways

- Main purpose of this diagram is to map the ECU to specific engine sensors and power sources.

- The most important component to identify is the main battery power and ground leads.

- A critical safety consideration is ensuring clean, noise-free grounding directly to the battery.

- A practical application tip is to label every connector before routing the harness through the firewall.

- Use this diagram during initial installation or when adding auxiliary fans and fuel pumps.

Navigating the complexities of a modern engine management system swap requires precision, and having a clear holley terminator x wiring diagram is the single most important tool in your arsenal. Whether you are performing an LS swap or upgrading a classic small-block, the wiring harness acts as the nervous system of your vehicle, translating sensor data into performance. Understanding this diagram is not just about connecting plugs; it is about ensuring signal integrity, proper power distribution, and long-term reliability. In the following sections, you will learn how to decode the harness, identify critical pinouts, and implement a professional-grade installation that avoids the common pitfalls of amateur wiring.

Understanding the Holley Terminator X Wiring Diagram Components

The holley terminator x wiring diagram is structured to be modular, but it can appear overwhelming at first glance. The system is primarily divided into three main segments: the main power harness, the engine sensors harness, and the Input/Output (I/O) connectors. Each segment uses specific color-coding and connector shapes to prevent incorrect mating. The main ECU features two large headers, typically labeled J1A and J1B. These serve as the central hub where all data from the engine is processed.

The Terminator X system is designed to be “plug-and-play” for specific engines, but the diagram remains essential for troubleshooting custom configurations or integrating secondary accessories like electric fans and fuel pumps.

When analyzing the diagram, you will notice that power management is the foundation of the system. Unlike residential wiring where you might deal with a traveler wire or a common terminal in a three-way switch, automotive EFI systems rely on a direct “clean” power source. The diagram highlights a thick red wire and a black wire that must be connected directly to the battery terminals. This ensures that the voltage remains stable and free from the electrical “noise” generated by the alternator or starter motor.

The diagram also specifies the gauge of the wires used. High-current components like the fuel pump and the main ECU power require heavier wire to prevent voltage drops. In contrast, sensor wires use a smaller gauge because they only carry low-voltage signals. It is vital to recognize that while a household neutral wire provides a return path for alternating current, the automotive ground wire in this system must be chassis-grounded or battery-grounded to provide a solid reference for the sensors.

(The diagram illustrates the J1A and J1B ECU connectors. J1A focuses on primary engine functions including the Crank Sensor, Cam Sensor, Injectors, and Ignition Coils. J1B handles the auxiliary inputs, outputs, and the CAN bus communication for the handheld 3.5-inch touchscreen or laptop tuning interface. Color codes follow standard automotive conventions: Red for 12V+ Switched, Black for Ground, and various stripes for specific sensors like the Coolant Temperature Sensor or Map Sensor.)

Step-by-Step Guide to Reading and Installing the Harness

Implementing the holley terminator x wiring diagram into your vehicle requires a systematic approach. Before you begin, gather the necessary tools: a high-quality wire stripper, a crimping tool specifically for automotive terminals, a digital multimeter, and heat-shrink tubing.

Never use “T-taps” or “Scotchlok” connectors on an EFI system. These are prone to failure and can cause intermittent sensor signals that are nearly impossible to diagnose.

- ✓ 1. Lay out the harness on a clean floor or workbench. Compare the physical connectors to the labels on your diagram to ensure everything matches your engine’s sensor locations.

- ✓ 2. Identify the “Clean Power” leads. These are the heavy-gauge red and black wires. They must go directly to the battery. Do not use the frame or a brass screw on a junction block for these specific wires.

- ✓ 3. Locate the switched 12V+ wire (usually pink). This is your hot wire that tells the ECU to wake up. It must receive 12V when the key is in both the “On” and “Start” positions.

- ✓ 4. Route the injector and coil packs. The diagram will specify “Bank 1” and “Bank 2.” Ensure these are not swapped, or the engine will experience severe misfires.

- ✓ 5. Install the Wideband O2 sensor. The harness for this sensor is sensitive to heat. Route it away from the exhaust headers and ensure the connector is seated firmly.

- ✓ 6. Connect the ground wires. Multiple black wires in the harness must be grounded to the cylinder heads. This is as critical as the neutral wire in a home circuit; without a proper return path, the sensors will provide “floating” data.

- ✓ 7. Verify the voltage at the ECU. Using your multimeter, ensure you have a solid 12.6V (or battery resting voltage) at the main pins when the ignition is turned on.

While household wiring uses a common terminal to link different paths of a circuit, the Holley system uses the ECU as the logic center. Every hot wire going to a sensor is regulated by the ECU to exactly 5 volts (the 5V reference). If you accidentally touch this to a 12V source, you risk frying the internal processors of the Terminator X.

Common Issues and Troubleshooting with the Diagram

Even with a detailed holley terminator x wiring diagram, issues can arise during the first start-up. Most problems stem from improper grounding or poor connections. If the handheld controller does not power up, your first check should be the pink switched hot wire. If this wire loses power while the engine is cranking, the ECU will reboot, and the car will never fire.

Use a dedicated test light to check for 12V during cranking. Some ignition switches cut power to accessory circuits when the starter is engaged—you must avoid these circuits for your EFI power.

Another frequent issue is electromagnetic interference (EMI). If the sensor wires are routed too close to the spark plug wires or the alternator, the voltage signals can become distorted. This often manifests as a “jittery” RPM signal in the data log. Consult the diagram to identify the shielded wires (like the crank and cam sensors) and ensure the shielding is properly grounded as instructed. Unlike a simple traveler wire in a light switch that just carries current, these data wires carry high-frequency pulses that are easily disrupted.

If you encounter a “Sensor Error” on your screen, use the diagram to trace the specific pinout for that sensor. Check for continuity between the sensor plug and the J1A/J1B connector. If you see a “low voltage” error, it usually points back to a weak ground wire or a loose battery connection.

Tips and Best Practices for a Clean Installation

A professional-looking engine bay is not just about aesthetics; it is about reliability. When following your holley terminator x wiring diagram, take the time to loom the wires properly. Use split-braid tech flex or high-temperature plastic conduit to protect the harness from sharp edges and heat.

- ✓ Label every lead: Even though the connectors are unique, labeling the wires at both ends will save hours of time during future troubleshooting.

- ✓ Maintain consistent gauge: If you need to extend any wires, always use the same or a larger wire size. Never downsize a wire, especially for fuel pump or fan triggers.

- ✓ Heat Management: The ECU is robust, but it should be mounted away from direct heat sources. Inside the cabin, under the dashboard, is the preferred location.

When working with the auxiliary inputs and outputs, you might be tempted to use hardware store components. However, for the best results, use automotive-grade relays and terminals. While a brass screw might work fine for a household lamp, automotive environments involve vibration and moisture that require sealed connectors. The common terminal on an automotive relay should be wired with a dedicated fuse to protect the ECU from high-current spikes.

Finally, always keep a physical copy of the holley terminator x wiring diagram in your vehicle’s glovebox. If you are ever on a road trip and experience a mechanical hiccup, having the map to your engine’s brain will be the difference between a quick fix and an expensive tow. By respecting the principles of voltage, proper gauge selection, and meticulous grounding, you ensure that your Terminator X system performs at its peak for years to come. Success in EFI tuning starts with the wiring; get the foundation right, and the performance will follow.

Frequently Asked Questions

What is Holley Terminator X diagram?

It is a technical illustration detailing the electrical connections between the Terminator X ECU and the vehicle’s hardware. This schematic identifies where every wire in the harness connects, including power distribution, sensor inputs, and injector outputs, providing a visual map for successful fuel injection system installation and maintenance.

How do you read Holley Terminator X diagram?

Start by identifying the central ECU connector and follow the labeled pathways to individual sensors or power sources. Look for specific pin numbers and wire color codes. Match these symbols to the physical harness connectors, ensuring each signal path aligns with the manufacturer’s specific voltage or ground requirements.

What are the parts of Holley Terminator X?

The system consists of the Electronic Control Unit (ECU), the main power harness, the injector harness, and various sensors like MAP, CTS, and TPS. It also includes the wideband oxygen sensor and the handheld controller, all of which must be correctly wired to ensure precise engine performance.

Why is ground wire important?

A dedicated ground wire is critical because it provides a stable return path for electrical current. Without a clean, direct connection to the battery, the ECU can experience significant electrical noise or RFI, leading to erratic sensor readings, poor engine performance, or even permanent damage to the internal processor.

What is the difference between hot wire and neutral wire?

In DC automotive systems, the hot wire carries positive current from the battery to the component, while the ground serves as the return. Unlike AC circuits where a neutral wire carries current back to the source, DC systems rely on the chassis or battery terminal to complete the loop.

How do I use Holley Terminator X diagram?

Use the diagram to verify every connection before applying power to the system. Reference it while routing the harness to ensure sensors are plugged into their correct ports and that auxiliary inputs are pinned to the right slots. It is your primary tool for diagnosing wiring faults and shorts.