Holley Sniper Fuel Line Diagram: Installation and Routing

A Holley Sniper fuel line diagram illustrates the flow from the fuel tank to the throttle body, including the high-pressure pump, filters, and return line. Correct routing ensures the ECU receives consistent pressure, preventing a check engine light or lean conditions. Always follow specific torque spec guidelines for leak-free fuel connections.

📌 Key Takeaways

- Main purpose of this diagram is to ensure correct flow direction and pressure regulation.

- The high-pressure fuel pump and regulator are the most important components to identify.

- Fittings must meet the manufacturer’s torque spec to prevent dangerous high-pressure leaks.

- Always use EFI-rated hoses and clamps capable of handling 58+ PSI requirements.

- Use this diagram during initial plumbing or when troubleshooting fuel delivery errors.

Transitioning from a traditional carburetor to a modern Electronic Fuel Injection (EFI) system is one of the most rewarding upgrades you can perform on a classic engine. However, the success of this conversion hinges almost entirely on the integrity of your fuel delivery system. This comprehensive guide provides a detailed Holley Sniper fuel line diagram and technical walkthrough to ensure your installation is leak-free, high-performing, and safe. By understanding the flow of fuel from the tank to the throttle body and back, you can avoid common pitfalls that lead to poor engine performance or mechanical failure. You will learn about component placement, fitting types, and how the fuel system interacts with the central ECU to manage your engine’s needs.

Understanding the Holley Sniper Fuel Line Diagram

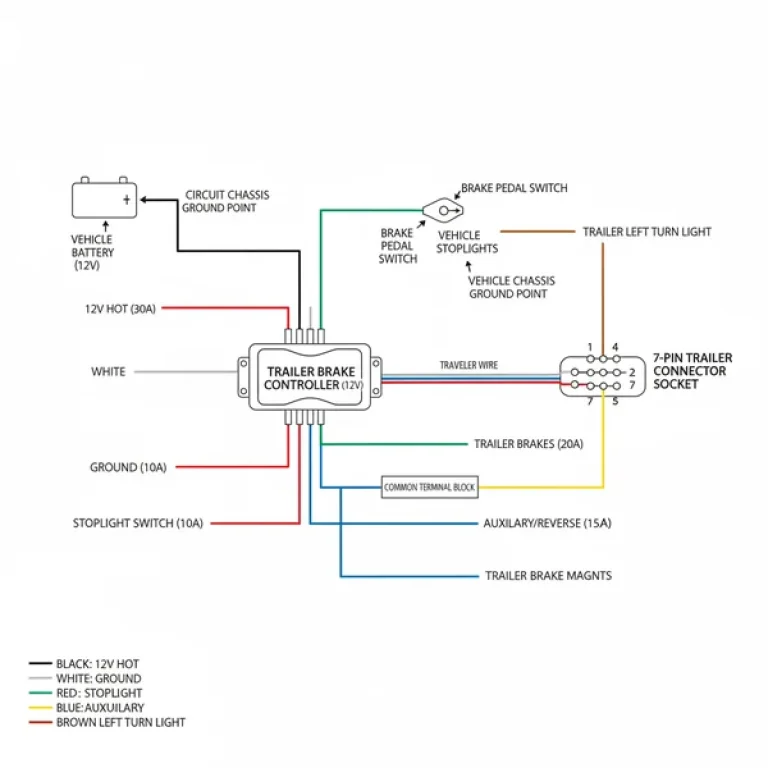

The Holley Sniper fuel line diagram is a visual representation of a “return-style” fuel system, which is the gold standard for EFI reliability. Unlike older carbureted systems that operate at 5 to 7 PSI, the Sniper EFI requires a constant, regulated 58 PSI to function correctly. The diagram illustrates a continuous loop: fuel is drawn from the tank, pressurized, filtered, sent to the throttle body, and any excess fuel is returned to the tank.

At the heart of the system is the fuel pump, which must be high-pressure rated. The diagram typically begins at the fuel tank, showing a 100-micron pre-filter installed before the pump to protect it from large debris. From the pump, the fuel travels through a 10-micron post-filter. This second filter is critical because the fuel injectors in the throttle body have very tight tolerances; even microscopic particles can cause a “check engine light” or a specific “diagnostic code” related to fuel trim issues.

The lines then reach the throttle body, which houses the internal ECU. On a standard Sniper unit, there are multiple ports. The “Inlet” port receives the pressurized fuel. The internal regulator maintains the pressure, and the “Outlet” port connects to the return line. In the diagram, these are usually color-coded: red for the high-pressure feed line and blue or green for the low-pressure return line. It is also important to note how the lines are routed through the engine bay, staying clear of moving parts like the accessory belt and the timing chain cover to prevent abrasion or heat soak.

[DIAGRAM_PLACEHOLDER: HOLLEY SNIPER EFI FUEL PLUMBING SCHEMATIC]

Visual elements include: Fuel Tank -> Pre-Filter (100 micron) -> External/Internal Pump -> Post-Filter (10 micron) -> 3/8″ Feed Line -> Sniper Throttle Body Inlet -> Internal Regulator -> 3/8″ Return Line -> Fuel Tank.

Step-by-Step Installation Guide

Reading a Holley Sniper fuel line diagram is only half the battle; the actual physical installation requires precision and a strict adherence to safety protocols. Follow these steps to ensure a professional-grade setup.

Most Sniper kits utilize -6AN fittings and 3/8-inch fuel lines. Ensure your hoses are rated for EFI pressures (at least 100 PSI) and are compatible with modern ethanol-blended gasoline.

- Mount the Fuel Pump: If you are using an external pump, mount it as low as possible and as close to the fuel tank as the layout allows. Fuel pumps are much better at “pushing” fuel than “pulling” it. Ensure the pump is mounted to a sturdy section of the frame away from the exhaust.

- Install the Filters: Place the 100-micron pre-filter between the tank and the pump. Place the 10-micron post-filter after the pump but before the fuel reaches the engine bay. Ensure the flow arrows on the filter housings point toward the engine.

- Route the Feed Line: Run the 3/8-inch high-pressure line along the vehicle’s frame rail. Use rubber-lined P-clamps to secure the line every 12 to 18 inches. When entering the engine bay, ensure the line does not interfere with the accessory belt or the cooling fans.

- Connect to the Throttle Body: Apply a small amount of thread sealant (never use Teflon tape on AN fittings) to the NPT-to-AN adapters. Thread them into the throttle body ports. Tighten them to the proper torque spec—usually 15-20 lb-ft for -6AN fittings, but always verify with your specific manufacturer’s guide. Connect the feed line to the port labeled “Inlet.”

- Install the Return Line: Connect a second 3/8-inch line to the “Outlet” port of the throttle body. This line carries unused fuel back to the tank. It is vital that the return line has no kinks, as backpressure in the return line will cause the fuel pressure to spike, confusing the ECU and causing a rich-run condition.

- Integrate Electrical and Sensors: While not a fuel line, the coolant flow sensor is vital. Install the coolant temperature sensor into a high-flow area of the intake manifold to ensure the ECU knows when to transition from “warm-up” mode to “closed-loop” fueling.

- Final Safety Check: Before starting the engine, turn the ignition to the “On” position to prime the pump. Inspect every fitting for leaks. Do not attempt to start the engine if you smell raw gasoline.

Never route fuel lines near the timing chain cover or hot exhaust manifolds. Heat can cause “vapor lock” or, worse, a fire if a line were to fail. Always maintain at least 6 inches of clearance from heat sources.

Common Issues & Troubleshooting

Even with a perfect Holley Sniper fuel line diagram, issues can arise during the initial startup or after several miles of driving. The Sniper system is highly sensitive to fuel pressure fluctuations. If your engine is stumbling or the handheld display shows a “diagnostic code,” the fuel system is the first place to look.

One common problem is the “check engine light” flashing due to lean spikes. This is often caused by an inadequate fuel pump or a clogged 10-micron filter. If the pump cannot maintain 58 PSI under load, the ECU cannot compensate. You can verify this by checking the “Fuel Flow” or “Target AFR” on your Sniper handheld.

Another issue is “RFI” or Radio Frequency Interference. If your fuel lines are routed too close to your spark plug wires or the ignition coil, the electrical noise can interfere with the ECU signals. This can manifest as erratic idling or the system randomly shutting off. Ensure your fuel lines and the ECU wiring harness are separated from high-voltage ignition components.

If your Sniper system supports it, use an OBD-II adapter or the dedicated CAN-bus to USB cable to log your data. This allows you to see fuel pressure drops in real-time, making it much easier to diagnose a failing pump or a pinched return line.

Tips & Best Practices for EFI Fuel Systems

To ensure your Holley Sniper EFI system remains reliable for years to come, follow these professional maintenance and installation best practices.

- ✓ Use PTFE Lined Hoses: Modern gasoline contains additives that can permeate standard rubber hoses over time, leading to a “gas smell” in your garage. PTFE (Teflon) lined hoses are impervious to these chemicals and last significantly longer.

- ✓ Observe Torque Specs: Over-tightening AN fittings can crack the aluminum flare, leading to high-pressure leaks. Always use a proper wrench and follow the “finger tight plus a quarter turn” rule if a torque wrench isn’t available.

- ✓ Check Coolant Flow: Ensure your coolant system is burped and flowing properly. If the ECU receives an incorrect temperature reading due to an air pocket, it may dump too much fuel into the system, mimicking a fuel line pressure issue.

- ✓ Isolate the Pump: Use rubber isolators when mounting your fuel pump to the frame. This reduces the “whining” noise associated with high-pressure EFI pumps and prevents vibrations from loosening fittings over time.

Maintaining your fuel system is just as important as the initial installation. Replace your 10-micron post-filter every 10,000 to 15,000 miles to ensure the injectors receive clean fuel. Periodically inspect the lines near the accessory belt and other moving engine parts to ensure no contact has occurred due to engine torque or vibration. By following the Holley Sniper fuel line diagram and the technical advice in this guide, you will enjoy a high-performance, reliable EFI system that transforms your driving experience. Whether you are chasing a specific diagnostic code or building a system from scratch, a methodical approach to your fuel plumbing is the key to automotive success.

Frequently Asked Questions

What is Holley Sniper fuel line diagram?

This diagram is a visual map showing how fuel travels from your tank through the pump and filters to the EFI throttle body. It details the supply and return lines, ensuring the ECU maintains the correct fuel pressure. Following it prevents installation errors that could damage your engine.

How do you read Holley Sniper fuel line diagram?

To read the diagram, trace the flow from the fuel tank’s outlet through the pre-filter and pump. Follow the line to the post-filter and throttle body inlet. The return line path back to the tank is also shown, typically highlighted with arrows indicating flow direction.

What are the parts of Holley Sniper?

The primary parts include the throttle body unit with integrated ECU, a high-pressure electric fuel pump, pre- and post-fuel filters, and the fuel pressure regulator. Additionally, it involves sensors for oxygen and coolant temperature, along with an OBD-II style handheld controller for monitoring system health and codes.

Why is torque spec important?

Adhering to the correct torque spec for fuel fittings is vital to prevent high-pressure leaks and fires. Over-tightening can crack aluminum components, while under-tightening leads to fuel seepage. Proper torque ensures the flare or O-ring seals seat perfectly, maintaining system integrity and avoiding a check engine light.

What is the difference between return and returnless?

A return system uses a dedicated line to send excess fuel back to the tank, which keeps fuel cooler and pressure more stable. A returnless system regulates pressure at the pump. While Holley Sniper supports both, a return-style setup is generally preferred for consistency and easier ECU tuning.

How do I use Holley Sniper fuel line diagram?

Use the diagram as a blueprint during the plumbing stage of your EFI conversion. Match each physical component to its position in the schematic to ensure proper flow direction. It serves as a vital reference when diagnosing a diagnostic code related to fuel pressure or lean air-fuel ratios.