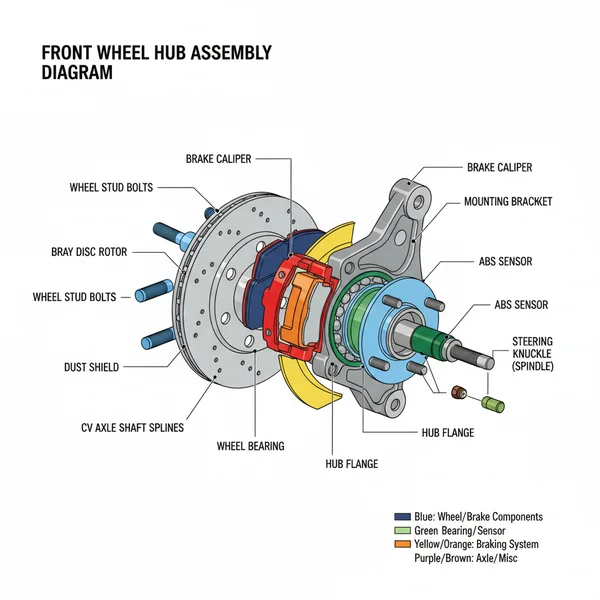

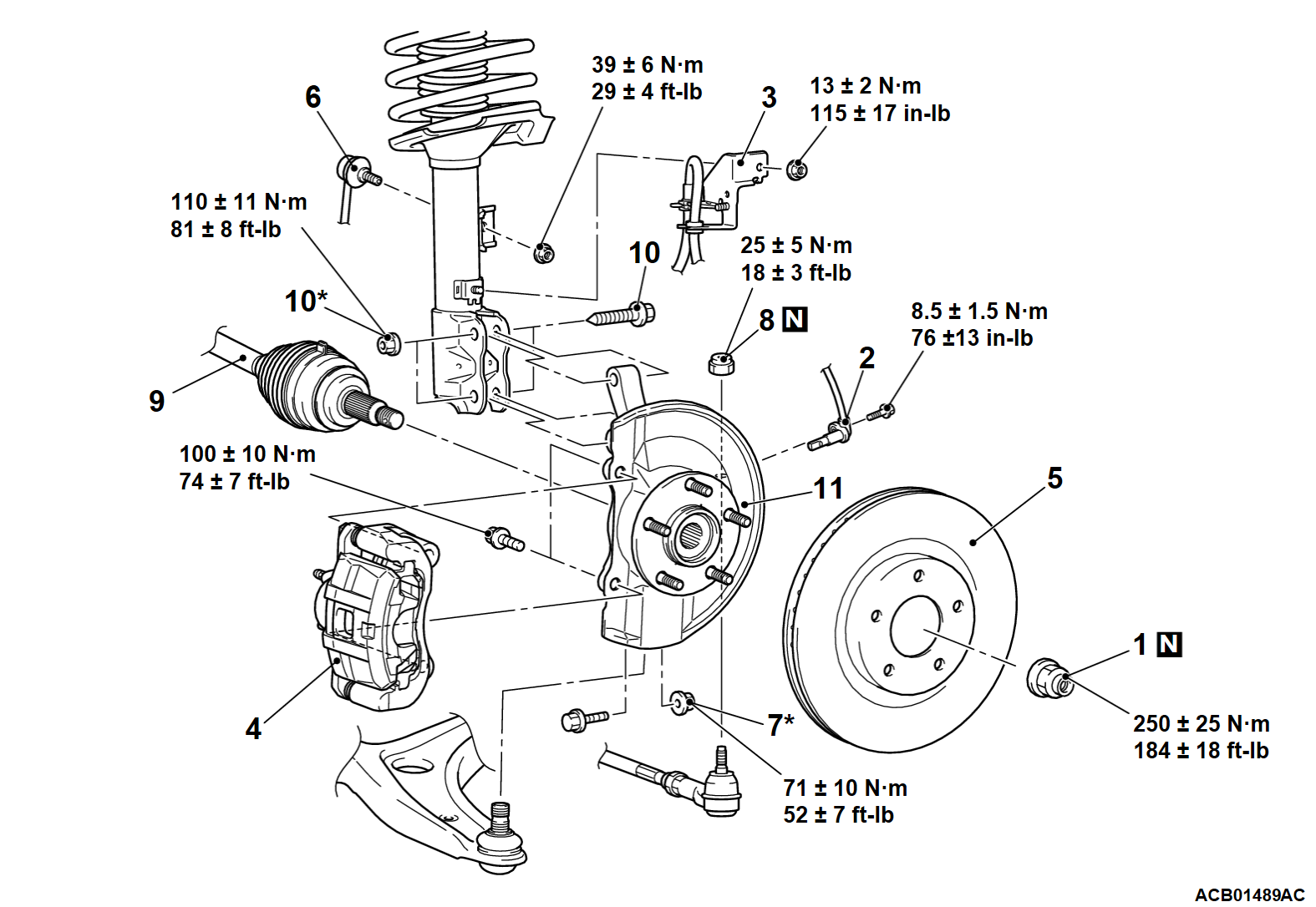

Front Wheel Hub Assembly Diagram: Identifying Key Parts

A front wheel hub assembly diagram illustrates the essential configuration of parts that connect the wheels to the vehicle. It details the system layout, showing how the wheel bearing, hub, studs, and ABS sensors interact to ensure smooth rotation and structural integrity while supporting the car’s weight during operation.

📌 Key Takeaways

- Explains the mechanical relationship between the axle, bearing, and wheel.

- Identifying the wheel bearing is crucial for diagnosing noise or vibration.

- Torque specifications for hub bolts are critical for vehicle safety.

- Use the diagram to locate ABS sensors before starting any brake repairs.

- Use this visual guide when performing replacements or routine inspections.

Understanding the internal mechanics of your vehicle’s drivetrain begins with a clear and detailed front wheel hub assembly diagram. Whether you are a weekend DIY enthusiast or a student of automotive engineering, having a visual reference for this critical system is indispensable for safe maintenance and repair. This guide provides a comprehensive breakdown of the hub’s structural layout, identifying every essential component from the mounting flange to the integrated wheel bearings. By the end of this article, you will have a professional-grade understanding of how this configuration supports your vehicle’s weight and facilitates smooth rotation while housing vital safety sensors.

Understanding the Front Wheel Hub Assembly Diagram

A front wheel hub assembly diagram serves as a blueprint for the mechanical heart of your wheel’s rotation system. At its core, the diagram illustrates a non-serviceable, pre-pressed unit that houses the wheel bearings, the wheel studs, and often the Anti-lock Braking System (ABS) tone ring or sensor. The configuration is designed to be a bridge between the stationary steering knuckle and the rotating wheel. In the diagram, you will typically see the hub flange as the outermost piece, which features the threaded studs where your wheel is bolted. Moving inward, the diagram reveals the internal bearing races, which are precisely engineered to withstand both radial and axial loads.

Most modern vehicles use a “sealed” hub assembly. Unlike older configurations where bearings could be greased and replaced individually, modern units are replaced as a single integrated component to ensure maximum safety and precision alignment.

The visual breakdown usually employs color-coding or specific numbering to differentiate between the stationary outer housing and the rotating inner hub. The layout also highlights the critical mounting holes used to secure the assembly to the steering knuckle. For vehicles with front-wheel drive or four-wheel drive, the diagram will show a splined center hole. This is a vital part of the system configuration, as it allows the CV axle shaft to pass through and provide torque to the wheels. Furthermore, the inclusion of the ABS sensor cable in the diagram is standard for modern vehicles, showing how the electronic system monitors wheel speed to prevent skidding during braking maneuvers.

[DIAGRAM_PLACEHOLDER – Front Wheel Hub Assembly Components: 1. Hub Flange, 2. Wheel Studs, 3. Internal Bearings, 4. ABS Sensor, 5. Mounting Bolts, 6. Splined Drive Hole]

Variations in these diagrams occur depending on whether the vehicle is a heavy-duty truck or a lightweight sedan. Heavy-duty configurations may feature an eight-lug stud pattern and a larger diameter flange to accommodate higher load capacities. Conversely, smaller vehicles might use a four-lug or five-lug layout with a more compact housing. Regardless of the specific model, the diagram remains the primary tool for identifying how the brake rotor fits over the studs and how the brake caliper bracket bridges over the entire assembly.

Interpreting the System Configuration: A Step-by-Step Guide

Reading a front wheel hub assembly diagram requires a systematic approach to ensure no component is overlooked. To use the diagram effectively for a repair or inspection, follow these steps to navigate the complex structure and layout of the system.

- Identify the Orientation: Look at the diagram to determine the “inboard” versus “outboard” sides. The outboard side faces the wheel and contains the studs, while the inboard side faces the engine and contains the mounting surface for the steering knuckle.

- Locate the Mounting Points: Most assemblies are held in place by three or four large bolts. Use the diagram to identify the exact location of these mounting ears on the hub housing. This is crucial because these bolts are often located behind the steering knuckle and can be difficult to see without a visual guide.

- Trace the ABS Wiring: If your vehicle has ABS, the diagram will show a wire harness protruding from the hub. Note the routing of this wire to avoid pinching or stretching it during installation. The diagram will show the specific connector type and the mounting clip locations.

- Examine the Splined Bore: For driven wheels, locate the central splined hole in the diagram. Count the number of teeth or grooves if the diagram provides specifications, as this must match your CV axle exactly for the power to be transmitted to the ground.

- Verify the Stud Pattern: Use the layout to confirm the Bolt Circle Diameter (BCD). This ensures that your wheel and brake rotor will fit perfectly onto the new assembly.

- Check Torque Specifications: While not always a visual element, a comprehensive diagram often includes a table of torque values. Locate the values for the hub-to-knuckle bolts and the center axle nut, which is the most critical fastener in the entire system.

Never use an impact wrench to tighten the central axle nut. Over-torquing can crush the internal bearings, while under-torquing can lead to premature failure or the wheel detaching from the vehicle.

To successfully perform a replacement using the diagram, you will need a specific set of tools. These include a high-quality torque wrench, a breaker bar, a socket set (specifically large 30mm-36mm sockets for the axle nut), a hub puller (in case of rust), and brake cleaner. Always begin by securing the vehicle on jack stands and removing the wheel and brake components. Use the diagram as a checklist: once the brake rotor is off, you should see the exact layout depicted in your reference material. If the hub is seized to the knuckle due to corrosion, the diagram helps you identify safe “strike zones” where you can apply force without damaging the steering components.

Common Issues and Troubleshooting the Hub System

The front wheel hub assembly is subject to immense stress, heat, and environmental contaminants. The most frequent problem users encounter is bearing failure, which manifests as a loud growling or humming noise that changes pitch when you steer. By referring to the front wheel hub assembly diagram, you can pinpoint the internal bearings as the source of this friction. If the noise increases when turning left, it often indicates the right-side hub is failing, as the weight of the vehicle shifts to that side, putting more load on the compromised internal structure.

Another common issue is a malfunctioning ABS light on the dashboard. The diagram shows the integrated sensor and tone ring; if these become clogged with metal debris or if the wire becomes frayed, the system will trigger a fault. Additionally, physical “play” in the wheel—detected by grabbing the tire at the 12 and 6 o’clock positions and shaking it—indicates that the internal configuration of the bearing has degraded. This is a critical safety hazard. Using the diagram to understand how the hub is bolted to the knuckle allows you to see that any movement in the hub housing means the internal races are no longer holding the assembly steady.

- ✓ Growling Noise: Indicates internal bearing wear.

- ✓ ABS Warning Light: Suggests a sensor or tone ring failure.

- ✓ Steering Vibration: Often caused by a warped hub flange or loose bearings.

- ✓ Uneven Brake Wear: Can result from a hub that is no longer sitting perfectly perpendicular to the axle.

Tips and Best Practices for Hub Maintenance

To ensure the longevity of your wheel hub system, maintenance and proper installation are key. When installing a new unit found on a front wheel hub assembly diagram, always clean the mounting surface of the steering knuckle. Use a wire brush to remove rust and corrosion, and apply a very thin layer of anti-seize lubricant to the mating surfaces. This prevents the two metal components from “galvanic welding” together over time, which makes future replacements much easier.

Always replace hub assemblies in pairs. If the bearings on one side have reached the end of their service life, the other side is usually not far behind. This ensures balanced handling and braking performance.

Quality is paramount when selecting a replacement component. While budget-friendly options exist, high-quality assemblies use superior steel for the races and more durable seals to keep moisture out. Look for units that meet or exceed OEM (Original Equipment Manufacturer) specifications. Additionally, avoid driving through deep standing water whenever possible. Even though these units are sealed, rapid cooling from hot operating temperatures can create a vacuum effect that pulls moisture past the seals, leading to internal rust and premature bearing failure. Finally, always double-check your wheel lug nut torque after 50 to 100 miles of driving on a newly installed hub to ensure everything has settled correctly into its structural layout.

In summary, the front wheel hub assembly diagram is more than just a picture; it is an essential guide to the safety and functionality of your vehicle. By understanding the component layout, following precise installation steps, and recognizing the early warning signs of failure, you can maintain your vehicle’s performance and ensure a smooth, quiet ride for thousands of miles. Whether you are troubleshooting a strange noise or performing a proactive upgrade, the knowledge of this system’s configuration is a cornerstone of effective automotive care.

Frequently Asked Questions

What is front wheel hub assembly diagram?

A front wheel hub assembly diagram is a visual representation showing the internal structure and layout of the parts that allow wheels to turn. It maps out how the hub, bearings, and seals fit together within the steering knuckle system, providing a clear map for maintenance and repair.

How do you read front wheel hub assembly diagram?

Start by identifying the central hub and follow the exploded view lines to see how each component fits into the assembly. Look for labels indicating the bearing, wheel studs, and mounting bolts to understand the overall configuration and the order in which parts must be installed.

What are the parts of front wheel hub assembly?

The primary parts include the wheel hub, internal bearings, grease seals, and wheel studs. Many modern configurations also include an integrated ABS tone ring or speed sensor. This complex system component works together to provide a mounting point for the wheel while enabling frictionless rotation during driving.

Why is the wheel bearing important?

The wheel bearing is a vital component because it reduces friction during wheel rotation while supporting the entire vehicle’s weight. If this part fails, it can cause significant heat buildup, noise, and even wheel detachment, making it the most critical part of the hub assembly structure.

What is the difference between a hub and a bearing?

While often sold as one unit, the hub is the metal mounting plate for the wheel, whereas the bearing is the internal mechanism consisting of balls or rollers. In some configurations, the bearing is pressed into the hub, while others feature a pre-assembled, bolt-on system layout.

How do I use front wheel hub assembly diagram?

Use the diagram as a reference guide during disassembly and reassembly to ensure every part is placed in the correct sequence. It helps identify the location of snap rings, seals, and torque-sensitive bolts, ensuring the system structure is restored to factory specifications for safe operation.