Front Suspension Dodge Ram 1500 Front End Parts Diagram: Fix

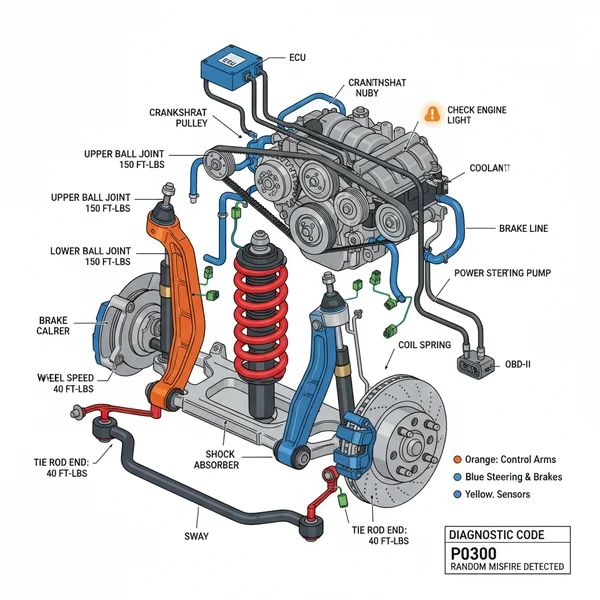

This diagram illustrates the complex assembly of control arms, struts, tie rods, and ball joints that maintain wheel alignment and ride quality. By identifying these components, owners can troubleshoot noises or vibrations, ensuring every bolt meets the required torque spec for safe driving and optimal vehicle handling on any terrain.

📌 Key Takeaways

- Visualizing the relationship between upper and lower control arms

- Identifying ball joints and tie rod ends for replacement

- Ensuring fasteners are tightened to the correct torque spec

- Checking alignment stability after suspension work

- Diagnosing front-end clunks or uneven tire wear

Maintaining the integrity of a heavy-duty truck involves more than just oil changes and tire rotations; it requires a deep understanding of the mechanical systems that keep the vehicle stable and safe. For owners and mechanics alike, finding a precise front suspension dodge ram 1500 front end parts diagram is often the first step in diagnosing vibrations, steering play, or uneven tire wear. These trucks are designed to handle significant payloads and towing stresses, which puts immense pressure on the front-end components. By utilizing a comprehensive diagram, you can identify exactly which bushings, joints, or struts require attention before a minor squeak turns into a major safety hazard. This article serves as your ultimate guide to interpreting these diagrams, understanding how each component functions within the system, and mastering the process of maintaining or replacing these critical parts.

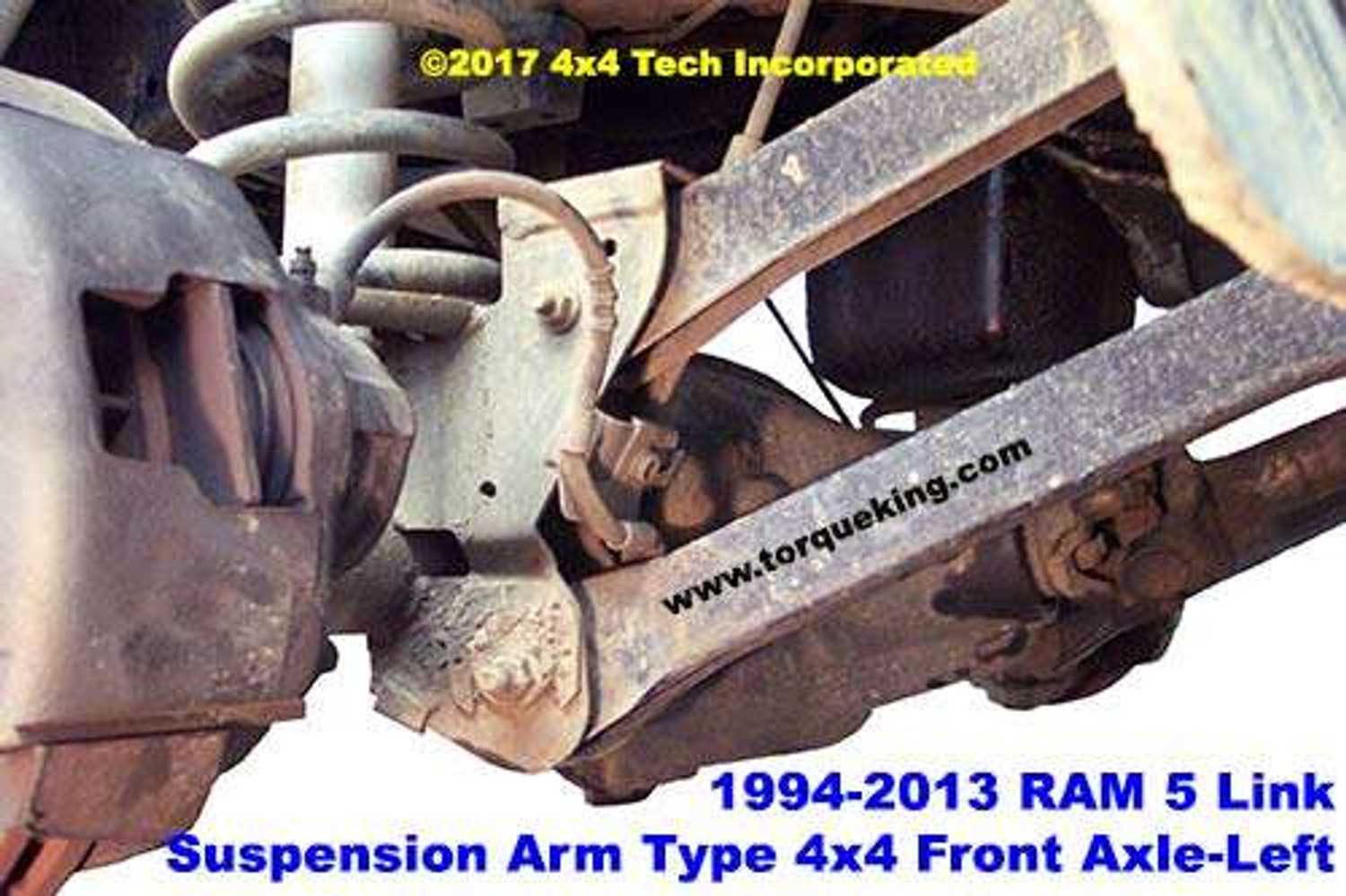

Most Dodge Ram 1500 models utilize an Independent Front Suspension (IFS) system. Unlike a solid axle, this design allows each wheel to move independently, improving ride quality and handling on varied terrain.

Decoding the Front Suspension Dodge Ram 1500 Front End Parts Diagram

When looking at a professional-grade front suspension dodge ram 1500 front end parts diagram, you will notice a complex assembly of interlocking metal arms, rubber cushions, and hydraulic dampeners. The primary purpose of this diagram is to provide a “blown-out” view, showing how every bolt and washer fits into the larger assembly.

The diagram is typically categorized into three main sub-sections: the control arms, the dampening system, and the steering linkage. At the top of the assembly, you will find the Upper Control Arm (UCA). This A-shaped component works in tandem with the Lower Control Arm (LCA) to maintain the vertical alignment of the wheel. The diagram will clearly label the ball joints located at the outer tips of these arms; these are the pivot points that allow the wheels to turn and move up and down simultaneously.

Another critical element featured in the diagram is the coilover or strut assembly. This part is responsible for supporting the vehicle’s weight and absorbing road shocks. Below this, the stabilizer bar (or sway bar) is depicted connecting the left and right sides of the suspension. This bar is essential for preventing “body roll” during cornering. In the diagram, you will see the sway bar links, which are the small rods that connect the bar to the control arms. Understanding these labels is vital because a failure in a small link can cause the same level of noise as a failure in a much larger, more expensive component.

How to Read and Interpret the Suspension Diagram

Interpreting a technical diagram requires a methodical approach. It is not just about identifying a part; it is about understanding the relationship between moving components. Follow these steps to effectively use your parts diagram for maintenance or repair:

- ✓ 1. Identify Your Specific Drivetrain: Ensure the diagram matches your vehicle. 4WD models feature front CV axles and a differential, which are not present on 2WD models.

- ✓ 2. Locate the Reference Numbers: Diagrams use numbers rather than names. Cross-reference these numbers with the parts list provided by the manufacturer to get the exact OEM part name.

- ✓ 3. Trace the Load Path: Follow the diagram from the wheel hub inward. This helps you understand how force travels from the tire through the knuckle, ball joints, and into the frame via the control arms.

- ✓ 4. Check for Fastener Details: A good diagram will include the locations of every nut and bolt. Pay close attention to the torque spec noted in the manual, as over-tightening can crush bushings, while under-tightening can lead to catastrophic failure.

- ✓ 5. Identify Wear Points: Focus on the areas labeled with rubber bushings or “boots.” These are the most common failure points shown on any front suspension dodge ram 1500 front end parts diagram.

Before starting any work, gather the necessary tools: a heavy-duty floor jack, jack stands, a torque wrench, a ball joint press, and a basic socket set.

Never work under a vehicle supported only by a jack. Suspension components are under high tension; use jack stands and ensure the vehicle is on level ground before beginning disassembly.

Troubleshooting Common Front-End Issues

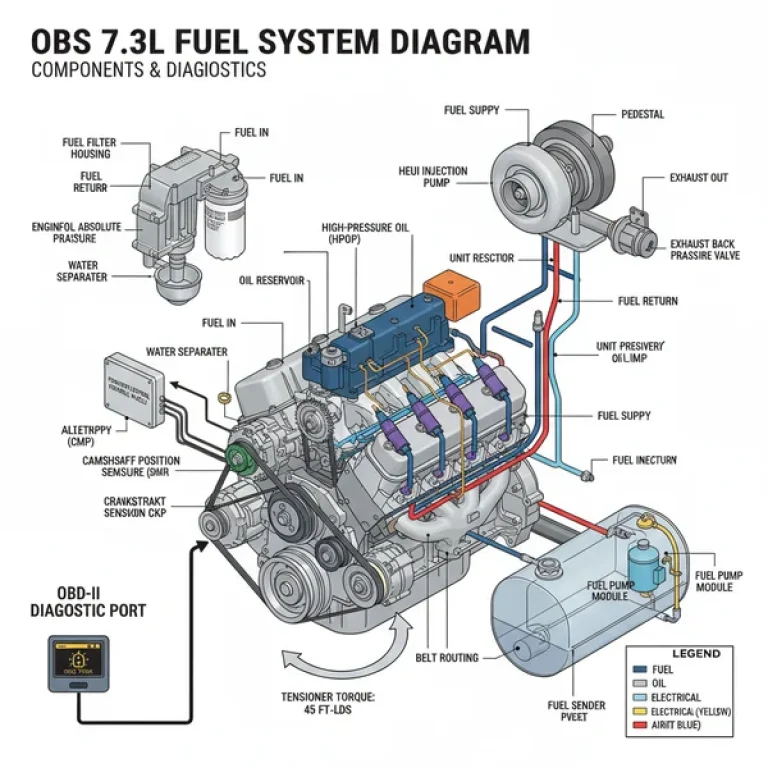

Suspension problems often manifest as physical sensations or audible cues. While engine faults might trigger the ECU to send a diagnostic code and illuminate the check engine light, the suspension system is largely mechanical and requires “human diagnostics.” You won’t find an OBD-II port that tells you a ball joint is failing; instead, you must rely on the diagram to inspect the physical hardware.

Common symptoms include a “clunking” sound when driving over speed bumps, which often points to worn sway bar bushings or links. If the truck feels like it is “wandering” across the lane, the tie rod ends or the steering rack might be at fault. A “death wobble” or severe vibration at highway speeds is often caused by a combination of worn control arm bushings and out-of-balance tires.

By comparing your physical findings to the parts diagram, you can pinpoint the specific component. For example, if you see grease leaking from a rubber boot on the steering linkage, the diagram will help you identify whether you are looking at the inner tie rod or the outer tie rod end. This precision prevents you from “parts cannoning”—the expensive mistake of replacing good parts in hopes of fixing a problem.

When inspecting the front end, perform a “dry park test.” Have an assistant turn the steering wheel back and forth while you observe the components. This makes it easier to spot “play” in the joints that might be hidden when the vehicle is stationary.

Maintenance and Best Practices for Long-Term Reliability

To keep your Dodge Ram 1500 driving smoothly, proactive maintenance is essential. Every time you perform an oil change, take five minutes to inspect the front end. Look for torn boots, leaking struts, or dry-rotted rubber. If your truck is equipped with greasable aftermarket parts, ensure they are topped off with high-quality chassis grease.

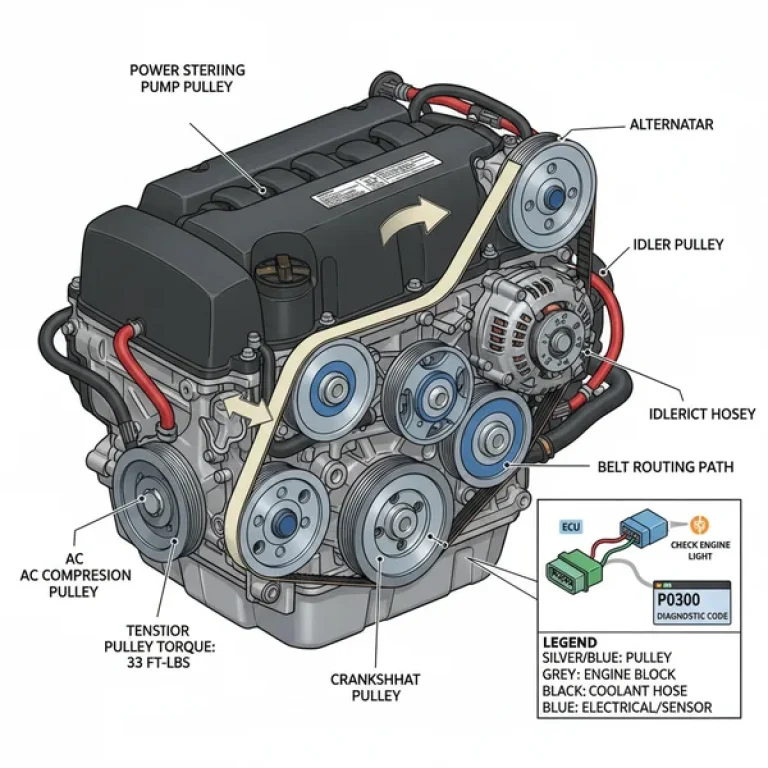

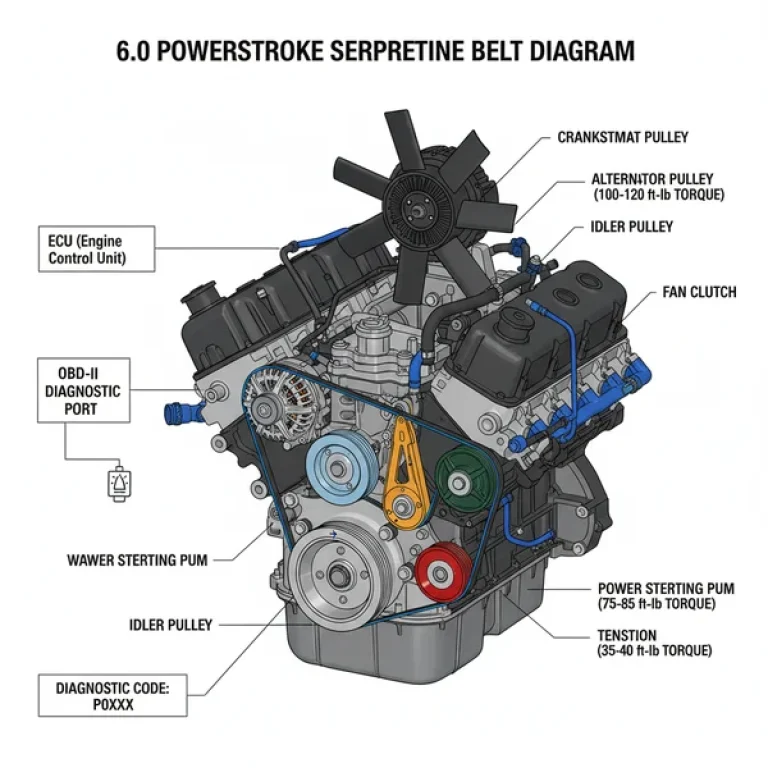

While you are under the truck, it is also a good habit to check related systems. Even though they aren’t part of the suspension, inspecting the accessory belt for fraying and looking for signs of leaks that could disrupt coolant flow can save you from a breakdown later. While the timing chain is tucked safely inside the engine, the vibrations from a failing suspension can actually cause premature wear on engine mounts and other exterior accessories over thousands of miles.

When it comes to replacing parts identified in your front suspension dodge ram 1500 front end parts diagram, always opt for high-quality or heavy-duty components. The Ram 1500 is a heavy truck, and “economy” grade parts often fail within a year of installation. Look for parts with a lifetime warranty and, where possible, choose components with grease fittings.

Finally, never skip the alignment. Any time you loosen a control arm bolt or replace a tie rod, the geometry of your front end changes. Even a fraction of an inch of misalignment can ruin a set of expensive tires in less than 500 miles. A professional alignment ensures that the hard work you put into your suspension repair pays off with a truck that tracks straight and handles like new.

In conclusion, the front suspension dodge ram 1500 front end parts diagram is more than just a piece of paper; it is a roadmap to vehicle longevity. By understanding the components, following proper torque spec guidelines, and remaining vigilant about wear and tear, you can ensure your truck remains a reliable workhorse for years to come. Whether you are a weekend warrior or a professional mechanic, mastering the front end is the key to a safe and comfortable driving experience.

Step-by-Step Guide to Understanding the Front Suspension Dodge Ram 1500 Front End Parts Diagram: Fix

Identify – Start with identifying the main structural components like upper and lower control arms and the steering knuckle.

Locate – Locate the steering linkages, including the inner and outer tie rod ends and the rack and pinion unit.

Understand – Understand how the coil springs or struts support the vehicle weight and dampen road impact during driving.

Connect – Connect the visual diagram components to the actual hardware on your truck to assess wear or damage levels.

Verify – Verify that all replacement parts match the diagram and meet the manufacturer’s required torque spec for safety.

Complete – Complete the inspection by checking if any sensor disconnection triggered an OBD-II diagnostic code or a check engine light.

Frequently Asked Questions

What is front suspension dodge ram 1500 front end parts diagram?

A front suspension Dodge Ram 1500 front end parts diagram is a visual schematic showing the arrangement of steering and suspension components. It helps mechanics identify parts like the rack and pinion, sway bar links, and bushings, which are essential for maintaining control and ride comfort during operation.

How do you read front suspension dodge ram 1500 front end parts diagram?

To read the diagram, match the numbered callouts to the corresponding parts list provided. Focus on the connection points between the frame and the steering knuckles. Understanding how components like struts and control arms integrate is vital for accurate repairs and ensuring every bolt hits the specified torque spec.

What are the parts of front suspension dodge ram 1500?

The primary parts include upper and lower control arms, ball joints, outer tie rods, and shock absorbers. While steering parts aren’t directly linked to the ECU, modern sensors may trigger a check engine light or diagnostic code if electronic stability systems detect unexpected wheel movement or severe alignment issues.

Why is torque spec important?

Following the correct torque spec is critical for suspension components to prevent hardware failure or excessive vibration. Overtightening can snap bolts, while undertightening causes parts to shift, potentially leading to a diagnostic code in the traction control system and requiring an OBD-II scan to clear the error quickly.

What is the difference between 2WD and 4WD diagrams?

The 4WD diagram includes front drive axles and a differential, whereas the 2WD version features a simpler spindle design. Both systems require precise alignment to avoid triggering a check engine light related to the steering angle sensor, which communicates with the vehicle’s ECU for stability control monitoring.

How do I use front suspension dodge ram 1500 front end parts diagram?

Use the diagram to identify worn components before starting a repair. It assists in locating specific fasteners that require a torque spec during reassembly. If an electronic sensor is disturbed, you might need an OBD-II scanner to read a diagnostic code and reset the system through the vehicle ECU.