Front End Dodge Ram 2500 Steering Diagram: Repair & Parts

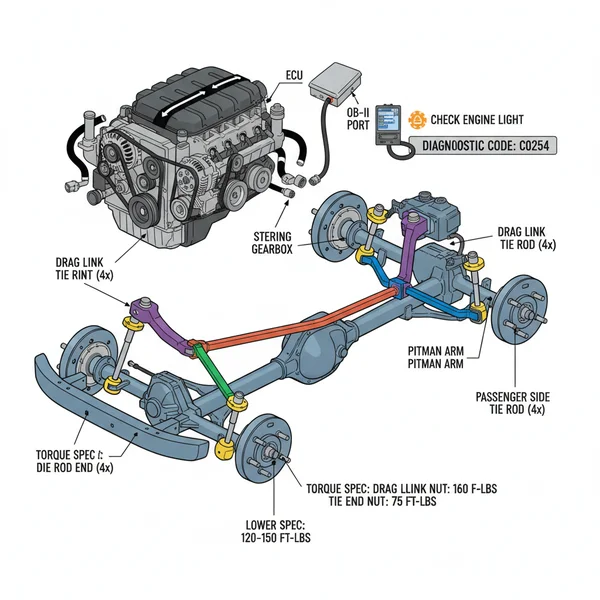

A front end Dodge Ram 2500 steering diagram maps out the heavy-duty linkage including the pitman arm, drag link, and tie rods. It is essential for identifying worn components and ensuring every bolt meets the factory torque spec, which prevents dangerous death wobble and maintains precise alignment during heavy towing operations.

📌 Key Takeaways

- Visualizes the relationship between the steering box and wheel knuckles

- Identification of the track bar as a primary stabilization point

- Strict adherence to torque settings prevents component failure

- Assists in converting between Y-style and T-style steering linkages

- Essential for diagnosing steering play or wandering issues

Maintaining a heavy-duty truck like the Dodge Ram 2500 requires a precise understanding of its mechanical architecture, particularly the steering assembly which bears the brunt of both payload and road vibration. When you are diagnosing “death wobble,” replacing worn tie rods, or performing a routine alignment, having a clear and accurate front end dodge ram 2500 steering diagram is the foundation of a successful repair. This guide provides a comprehensive breakdown of the steering components, explaining how they interact to provide directional control. By the end of this article, you will understand how to interpret these diagrams, the specific torque requirements for various fasteners, and how to troubleshoot common front-end failures that plague high-torque diesel and heavy-gas pickups.

The Dodge Ram 2500 typically utilizes a recirculating ball steering gear system combined with a “T-style” or “Y-style” steering linkage, depending on the specific model generation and whether any aftermarket upgrades have been installed.

Detailed Breakdown of Steering Diagram Components

The front end steering diagram for a Ram 2500 is a visual map of the force transfer from the steering wheel to the tires. At the top of the system sits the steering gear box, which converts the rotational motion of the steering shaft into lateral motion via the pitman arm. The pitman arm connects to the drag link, which is the primary link responsible for moving the rest of the steering assembly.

In a standard diagram, you will notice the distinction between the drag link and the tie rod. The tie rod connects the two steering knuckles together, ensuring that both front wheels turn in unison. Many Ram 2500 owners opt for a T-style steering upgrade, where the drag link connects directly to the passenger-side knuckle and the tie rod spans from knuckle to knuckle. This is often preferred over the older Y-style (Haltenberger) linkage, where the drag link attaches to the tie rod itself, which can sometimes cause “toe-change” during suspension travel.

Color-coding in a professional front end dodge ram 2500 steering diagram often highlights “wear items” in red or yellow. These include the tie rod ends and drag link ends, which contain ball joints that eventually develop play. The steering stabilizer, a hydraulic dampener mounted horizontally, is also a key feature. Its role is to absorb lateral shocks before they reach the steering wheel, protecting the driver from fatigue and preventing harmonic oscillations.

(The diagram would illustrate the Gear Box at the top-center, the Pitman Arm dropping down to the Drag Link, the Tie Rod spanning the lower section between the Steering Knuckles, and the Steering Stabilizer mounted parallel to the Tie Rod.)

Step-by-Step Guide to Using the Diagram for Inspection and Repair

Using a steering diagram is about more than just identifying parts; it is about following the flow of energy through the system to find the point of failure. Follow these steps to perform a professional-level inspection or component replacement.

- ✓ Step 1: Secure the Vehicle – Park on a level surface and engage the parking brake. If you are lifting the truck, use heavy-duty jack stands rated for at least 3 tons per stand to support the frame.

- ✓ Step 2: The Dry Park Test – With the engine off and the wheels on the ground, have an assistant rock the steering wheel back and forth. Crawl underneath and consult your diagram to identify each joint. Look for any “pop” or lateral movement in the tie rod ends and pitman arm connection.

- ✓ Step 3: Component Removal – If a part is identified as faulty, use a pickle fork or a specialized tie rod puller to separate the tapered joints. Avoid using a hammer directly on the threads, as this will mushroom the metal.

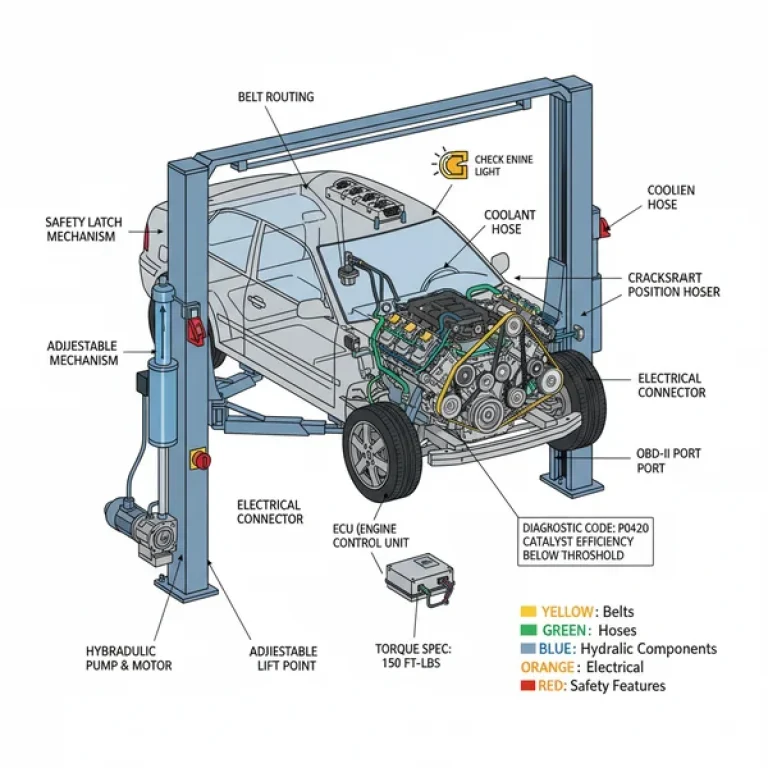

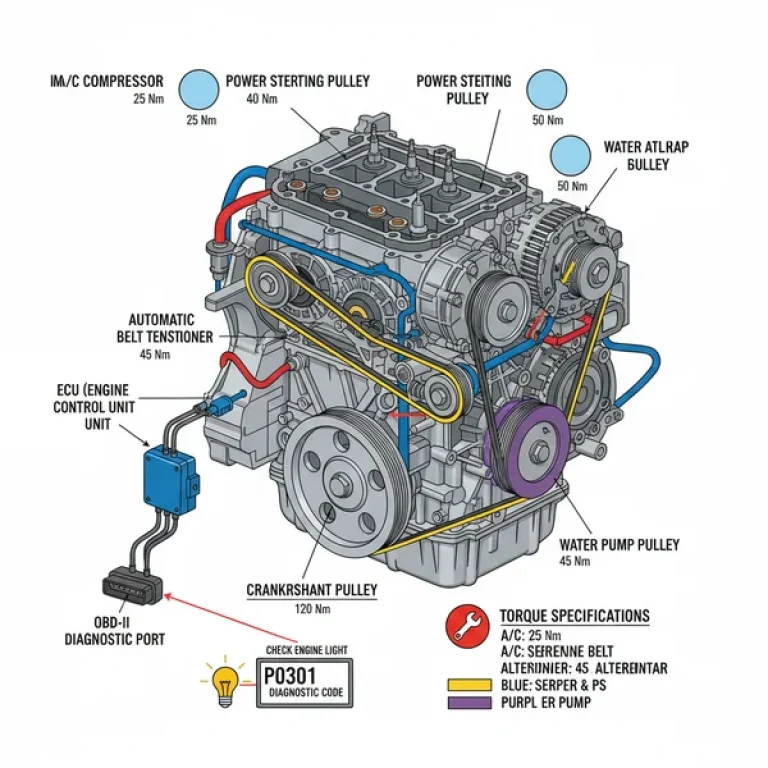

- ✓ Step 4: Check Secondary Systems – While the steering components are disconnected, check the accessory belt that drives the power steering pump. A slipping belt can mimic steering gear failure. Also, ensure there is no obstruction to the coolant flow near the power steering cooler.

- ✓ Step 5: Apply Torque Specs – When installing new parts, never guess the tightness. A loose pitman arm nut can lead to catastrophic loss of control. Use a calibrated torque wrench. Typical values for a Ram 2500 involve 185 lb-ft for the pitman arm nut and approximately 65-85 lb-ft for tie rod end nuts, but always verify with your specific service manual.

- ✓ Step 6: Greasing and Finishing – If your new components have Zerk fittings, use a high-quality lithium grease until the boot just begins to swell. Over-greasing can burst the seal.

Always perform a front-end alignment after replacing any steering component. Even a 1/16th inch difference in tie rod length can lead to rapid tire wear and pull the vehicle to one side.

Common Steering Issues and Troubleshooting

The most notorious issue associated with the front end dodge ram 2500 steering diagram is the “Death Wobble.” This is a violent shaking of the front end usually triggered by hitting a bump at highway speeds. By referring to the diagram, you can methodically check the usual suspects: the track bar bushings, the steering stabilizer, and the ball joints.

Another common problem is “steering wander,” where the truck feels disconnected from the road. This often points to a worn steering gear box or a loose intermediate shaft. While the steering system is largely mechanical, modern Ram 2500s utilize sensors to communicate with the ECU (Engine Control Unit). If you notice a heavy or inconsistent steering feel, it might trigger a check engine light or a stability control warning. In these cases, connecting an OBD-II scanner is necessary to check for a diagnostic code related to the steering angle sensor or the power steering pressure switch.

If you find that the steering is stiff only when cold, check the power steering fluid level and the condition of the accessory belt. If the belt is glazed or the tensioner is weak, the pump will not provide adequate pressure, regardless of how healthy the steering linkage appears on the diagram.

Tips and Best Practices for Maintenance

To keep your Ram 2500 steering crisp and reliable, consistency in maintenance is vital. These trucks are heavy, and the Cummins turbo-diesel variants put immense weight on the front axle, accelerating the wear of every joint.

When replacing steering parts, upgrade to “greasable” versions if the OEM parts were sealed units. Being able to flush out contaminants with fresh grease during every oil change can double the lifespan of your tie rod ends.

Always prioritize high-quality replacement parts. While budget-friendly options exist, the labor involved in front-end work makes it more cost-effective to buy heavy-duty components from reputable brands like Moog, Mopar, or specialized aftermarket steering companies. These often feature larger ball studs and better sealing boots than standard replacements.

Furthermore, keep an eye on your engine’s internal health as well. While it seems unrelated, a failing timing chain or internal engine vibration can sometimes be felt through the steering column in high-mileage vehicles. Ensure your fluid levels are always topped off; a low-fluid condition in the steering reservoir can introduce air into the lines, causing cavitation and eventual pump failure. If you are doing a full rebuild, take the time to inspect the cooling lines—ensure the coolant flow is not obstructed by debris, as the power steering system on these trucks often shares cooling resources or is located in close proximity to the radiator.

In conclusion, a front end dodge ram 2500 steering diagram is more than just a picture; it is a diagnostic tool that helps you maintain the safety and drivability of your vehicle. By understanding the relationship between the ECU, the hydraulic pump, and the mechanical linkage, you can ensure your truck remains steady on the road. Regular inspections, adherence to the correct torque spec, and using quality parts will keep your steering precise for hundreds of thousands of miles. Whether you are clearing a diagnostic code or replacing a drag link, a methodical approach based on an accurate diagram is the only way to guarantee a professional result.

Frequently Asked Questions

What is a front end Dodge Ram 2500 steering diagram?

This diagram is a technical illustration showing the layout of the mechanical linkage connecting the steering wheel to the front tires. It highlights parts like the drag link, tie rods, and steering stabilizer, allowing owners to visualize how movement is transferred across the heavy-duty solid front axle system.

How do you read a Dodge Ram 2500 steering diagram?

To read the diagram, start at the steering gear box and follow the lines to the pitman arm. Observe how the drag link connects to the passenger side knuckle and how the tie rod joins both wheels. Lines and labels usually indicate where specific hardware and bushings are located.

What are the parts of the steering system?

Main parts include the steering box, pitman arm, drag link, tie rod ends, and the steering stabilizer. On modern Rams, electronic sensors may interact with the ECU. The system also includes the track bar, which secures the axle laterally, and ball joints that allow for steering pivot movement.

Why is the steering box torque spec important?

The torque spec ensures that high-stress fasteners remain tight under the immense pressure of 2500-series loads. Improperly torqued bolts can lead to ‘death wobble,’ where the front end vibrates violently. Using a calibrated torque wrench ensures that the steering linkage remains rigid and safe for highway driving speeds.

What is the difference between T-style and Y-style steering?

Y-style steering connects the drag link directly to the passenger tie rod, creating an inverted ‘Y’ shape. T-style steering, often used as an upgrade, connects the tie rod directly to both knuckles with the drag link attaching to the tie rod, offering better toe alignment stability and reduced tire wear.

How do I use a steering diagram for repairs?

Use the diagram to identify the exact location of worn bushings or bent rods. If your check engine light is on due to a steering angle sensor, the diagram helps locate the electronic components. It serves as a roadmap for disassembly and ensures all parts are reinstalled correctly.