The Ford Fusion serpentine belt diagram provides the essential routing path for the drive belt across pulleys like the alternator and water pump. Proper alignment ensures the engine’s peripheral systems function correctly. Use a tensioner tool to release the belt, then follow the diagram to prevent misrouting and mechanical damage.

📌 Key Takeaways

- Visualizes the specific path for the drive belt across all engine pulleys

- The automatic tensioner is the most critical component for belt removal

- Ensure the belt is fully seated in the pulley grooves to prevent fraying

- Use the diagram to avoid reverse-rotating the alternator or water pump

- Consult the diagram during routine maintenance or when hearing belt squeal

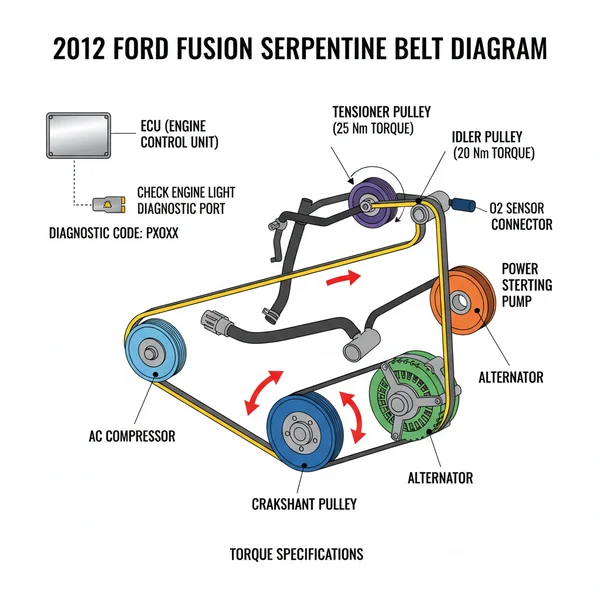

Maintaining your vehicle involves understanding the intricate dance of pulleys and belts under the hood. For owners of the 2012 Ford Fusion, the serpentine belt diagram serves as an essential roadmap for ensuring the engine’s peripheral systems function correctly. Whether you are dealing with a squealing noise upon startup or performing preventative maintenance, having a clear understanding of the 2012 ford fusion serpentine belt diagram is vital for a successful repair. This guide will walk you through the routing configurations for both the 2.5L and 3.0L engines, providing you with the technical specifications, necessary tools, and expert tips to replace your accessory belt with confidence. By the end of this article, you will be equipped to handle this common DIY task while avoiding costly mistakes.

The 2012 Ford Fusion utilizes different belt layouts depending on the engine size. The 2.5L I4 engine uses a single, long serpentine belt, while the 3.0L V6 engine utilizes a main serpentine belt for most accessories and a separate, smaller “stretch-fit” belt specifically for the water pump.

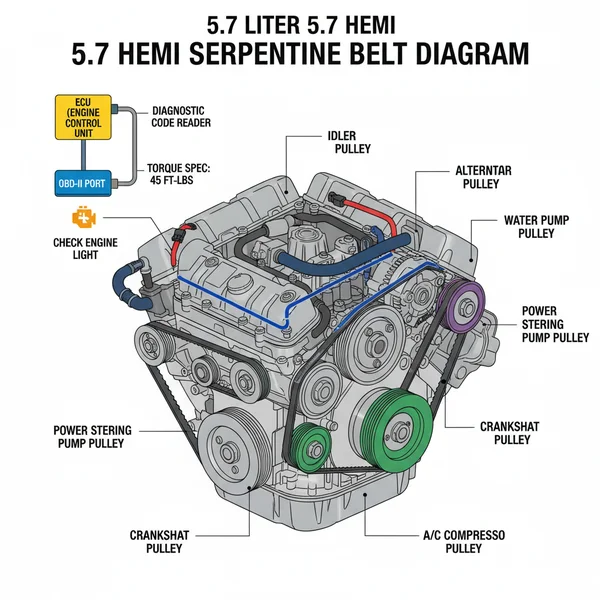

The serpentine belt diagram is a schematic that shows the exact path the belt must take to connect the crankshaft to various engine accessories. In the 2012 Ford Fusion, this belt—often called the accessory belt—is responsible for transferring rotational energy to the alternator, the air conditioning (A/C) compressor, and the power steering pump (on models without electric power steering). The diagram typically highlights the difference between “grooved” pulleys and “smooth” pulleys. This is a critical distinction: the grooved side of the belt must always face the grooved pulleys, while the flat, smooth back of the belt generally rides against smooth idler pulleys or the tensioner pulley.

For the 2.5L inline-four engine, the routing is relatively straightforward but requires careful attention to the tensioner’s location, which is situated between the alternator and the crankshaft. On the 3.0L and 3.5L V6 models, the complexity increases slightly. You will notice that the diagram includes a tensioner pulley that must be rotated to create slack. Understanding the visual breakdown is essential because misrouting the belt by even one pulley can result in the accessories spinning in the wrong direction or the belt rubbing against the engine block, leading to immediate failure.

graph TD

CP((Crankshaft Pulley)) --> AC((A/C Compressor))

AC --> WP((Water Pump))

WP --> AL((Alternator))

AL --> IP((Idler Pulley))

IP --> TE((Tensioner))

TE --> CP

In the 2.5L configuration specifically, the belt starts at the large crankshaft pulley at the bottom. It then travels upward toward the alternator. From the alternator, it loops over an idler pulley, moves down to the A/C compressor, and finally passes over the spring-loaded tensioner before returning to the crankshaft. It is important to note that unlike older vehicles that used a timing belt to drive the water pump, the 2012 Fusion uses a robust internal timing chain for engine synchronization, meaning the external serpentine belt is strictly for accessory components and coolant flow management.

Never attempt to service the serpentine belt while the engine is running or while the ignition is in the ‘On’ position. Disconnect the negative battery cable to ensure the engine cannot be started accidentally during the process.

Performing a belt replacement using the 2012 ford fusion serpentine belt diagram requires a systematic approach. Follow these steps to ensure a professional-grade installation:

1. Preparation and Tool Gathering: You will need a 3/8-inch or 1/2-inch drive long-handled ratchet or a dedicated serpentine belt tool. You may also need a 10mm socket to remove the plastic splash shield located in the passenger-side wheel well. This shield provides the necessary side-access to the crankshaft and tensioner.

2. Map the Routing: Before removing the old belt, compare the current routing with the 2012 ford fusion serpentine belt diagram. If the diagram is missing from your under-hood sticker, draw a quick sketch of how the belt loops around each pulley. Take note of which pulleys are grooved and which are smooth.

3. Release Tension: Locate the automatic tensioner pulley. On the 2.5L engine, you will typically place your tool into the square hole or on the bolt head of the tensioner arm. Rotate the tensioner clockwise (or as specified for your engine variant) to compress the internal spring. This will create slack in the belt.

4. Remove the Belt: While holding the tensioner in the “released” position, slip the belt off the uppermost idler pulley. Once the belt is off one pulley, you can slowly release the tensioner and then fully remove the belt from the remaining pulleys.

5. Inspect the Pulleys: With the belt removed, spin each accessory pulley by hand. Listen for grinding noises and feel for any “play” or wobbling. The alternator, A/C compressor, and idler pulleys should spin smoothly. If a pulley is seized, it will cause the new belt to snap almost immediately.

6. Route the New Belt: Begin threading the new belt starting from the bottom crankshaft pulley. Follow your diagram precisely. It is often easiest to leave the tensioner or a smooth idler pulley as the final step. Ensure the belt ribs are perfectly seated within the grooves of the pulleys.

7. Apply Tension and Verify: Rotate the tensioner again to create enough slack to slip the belt over the final pulley. Once in place, release the tensioner slowly. Double-check the entire path to ensure the belt hasn’t slipped halfway off any pulley.

8. Final Test: Reinstall the splash shield and lower the vehicle. Reconnect the battery. Start the engine briefly and observe the belt’s movement. It should run straight without any chirping or vibrating.

- ✓ 3/8-inch or 1/2-inch drive breaker bar

- ✓ 10mm and 15mm sockets

- ✓ New EPDM serpentine belt

- ✓ Automotive work lights or flashlight

Common issues with the 2012 Ford Fusion belt system often manifest as audible cues. A high-pitched squeal usually indicates a loose belt, a failing tensioner, or a glazed belt surface. If the belt slips significantly, the alternator may fail to provide adequate charge to the battery. This can cause the ECU (Engine Control Unit) to detect a voltage drop, triggering the check engine light and storing a diagnostic code such as P0562 (System Voltage Low) in the OBD-II system.

Another frequent problem is the failure of the tensioner internal spring. If the tensioner does not apply the correct torque spec to the belt, the belt will vibrate excessively, leading to premature wear on the alternator bearings and the water pump. Use the diagram to identify if the belt is tracking off-center, which is a classic sign of a misaligned pulley or a worn tensioner pivot arm. If you notice “chunking”—where sections of the belt ribs have broken off—replace the belt immediately to avoid a total loss of coolant flow and power steering.

When replacing the belt, always replace the tensioner and idler pulleys at the same time if the vehicle has over 100,000 miles. These components have bearings that wear out at similar rates to the belt itself, and a new, stiff belt can put extra stress on old bearings, causing them to fail shortly after the repair.

To maximize the lifespan of your new belt, always opt for high-quality EPDM (Ethylene Propylene Diene Monomer) belts rather than older neoprene versions. EPDM belts do not crack as visibly as older belts; instead, they lose rib depth, much like a tire loses tread. You can purchase a low-cost belt wear gauge to check if the grooves have become too deep, indicating it is time for a replacement.

Cost-saving advice for 2012 Ford Fusion owners involves routine inspection. Every time you change your oil, take a moment to look at the belt routing and condition. If you see any fluid contamination—such as oil from a leaky front crank seal or coolant from a water pump weep hole—address the leak immediately. Fluids will chemically degrade the rubber, leading to sudden belt failure.

Finally, ensure you are following the specific requirements for your engine. If you have the 3.0L V6, remember that the water pump belt is a “stretch-to-fit” style and does not have a traditional tensioner. This requires a special installation tool to “walk” the belt onto the pulleys without damaging the cords. By following the 2012 ford fusion serpentine belt diagram and these best practices, you ensure your vehicle remains reliable, efficient, and free of unexpected electrical or cooling system failures. Proper maintenance today prevents the headache of a broken belt on the side of the road tomorrow.

Step-by-Step Guide to Understanding the Ford Fusion Serpentine Belt Diagram: Routing And Replacement

Identify the belt routing by locating the diagram usually found on the radiator shroud or under the vehicle’s hood.

Locate the automatic tensioner and use a long-handled tool to rotate it, releasing tension from the drive belt.

Understand how the belt sits in the grooves of the alternator and AC compressor pulleys before starting the removal.

Connect the new belt by looping it around the crankshaft first, following the specific path illustrated in the diagram.

Verify that the belt is centered on all pulleys and that the ECU hasn’t logged a diagnostic code from slippage.

Complete the installation by tightening the tensioner bolt to the manufacturer’s torque spec to ensure long-term belt stability.

Frequently Asked Questions

What is Ford Fusion serpentine belt diagram?

The Ford Fusion serpentine belt diagram is a visual map showing how the drive belt weaves through various pulleys, including the crank, alternator, and AC. It ensures the belt rotates every component in the correct direction. Without this guide, misrouting can lead to mechanical failure, overheating, or poor engine performance.

How do you read Ford Fusion serpentine belt diagram?

To read the diagram, identify the crankshaft pulley as the starting point. Follow the line to each subsequent pulley, noting whether the belt goes over or under. Circles represent pulleys, and the line represents the belt’s ribbed or smooth side, indicating which side contacts each specific pulley surface correctly.

What are the parts of Ford Fusion serpentine?

The system includes the belt itself, the crankshaft pulley, the alternator, the water pump, and the air conditioning compressor. It also features an idler pulley for guidance and an automatic tensioner. These components work together to power essential vehicle systems while the tensioner maintains the necessary pressure for operation.

Why is the ECU important for belt issues?

While the belt is mechanical, the ECU monitors engine sensors. If a slipping belt causes the alternator to undercharge or the engine to overheat, the ECU will trigger a check engine light. Using an OBD-II scanner can reveal a specific diagnostic code related to these charging or cooling system issues.

What is the difference between ribbed and smooth pulleys?

In the diagram, the belt’s ribbed side must contact ribbed pulleys, while the smooth back side contacts smooth pulleys like the idler. Misaligning these surfaces causes rapid belt wear, excessive noise, and eventual failure. Always ensure the belt’s profile matches the pulley type indicated in the visual routing guide.

How do I use Ford Fusion serpentine belt diagram?

Use the diagram as a reference during replacement. First, locate the tensioner to release belt pressure. Remove the old belt, then thread the new one following the diagram’s path. Ensure every rib is seated correctly before releasing the tensioner and verifying the final alignment against the provided visual guide.