Ford Fusion 2.5 Belt Diagram: Routing & Installation

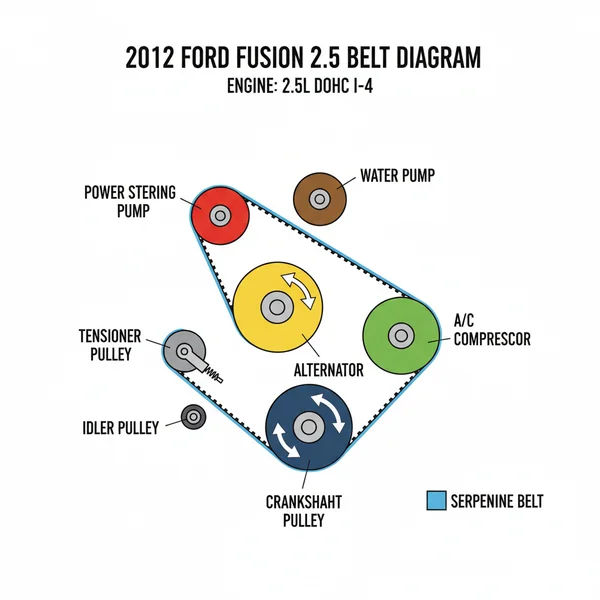

The serpentine belt diagram for the Ford Fusion 2.5L engine illustrates the specific routing configuration around the alternator, water pump, and AC compressor. This visual layout ensures the drive system operates correctly, helping you identify each pulley component and maintain the proper tension for reliable vehicle performance during belt replacement tasks.

📌 Key Takeaways

- Main purpose of this diagram

- Most important component to identify

- Safety or critical consideration

- Practical application tip

- When to use this diagram

Maintaining your vehicle’s engine efficiency starts with understanding its primary drive system. If you are performing a repair or routine maintenance, having a clear 2012 ford fusion 2.5 belt diagram is essential for ensuring every pulley is correctly engaged. This guide provides a detailed visual and descriptive breakdown of the serpentine belt layout, helping you identify each component and its role within the system. You will learn the specific routing path, the necessary tools for the job, and professional techniques to ensure a successful belt replacement without the guesswork. By following this comprehensive overview, you can avoid common installation errors that lead to premature wear or mechanical failure.

Understanding the 2.5L Serpentine Belt Configuration

The serpentine belt in the 2012 Ford Fusion 2.5L engine is a single, continuous loop that powers multiple peripheral devices. This system is designed for high efficiency, using a multi-ribbed belt that grips several pulleys simultaneously. The layout is specifically engineered to maximize surface contact with each component, ensuring that the alternator, air conditioning compressor, and water pump receive consistent rotational energy from the crankshaft.

In this specific configuration, the belt routing follows a serpentine path—hence the name—weaving around various tensioners and idlers to maintain the necessary grip. The structure of the engine bay requires the belt to navigate tight spaces, making the visual 2012 ford fusion 2.5 belt diagram a vital reference tool.

Key elements within the diagram include:

- ✓ Crankshaft Pulley: Located at the bottom of the engine, this is the primary drive source that provides power to the entire belt system.

- ✓ Alternator: Positioned near the top of the engine, it converts mechanical energy into electrical power to charge the battery and run electronics.

- ✓ A/C Compressor: Responsible for the air conditioning system, this pulley is often one of the lower components in the routing.

- ✓ Water Pump: Crucial for cooling, the water pump pulley on the 2.5L engine is driven by the outer side of the belt.

- ✓ Tensioner Pulley: This spring-loaded component maintains the correct pressure on the belt to prevent slipping.

On the 2.5L I4 Duratec engine found in the 2012 Fusion, the belt tensioner is located towards the front-middle of the engine block. Unlike older V6 models, the 2.5L layout is relatively accessible once the front passenger wheel well splash shield is removed.

How to Use the 2012 Ford Fusion 2.5 Belt Diagram for Installation

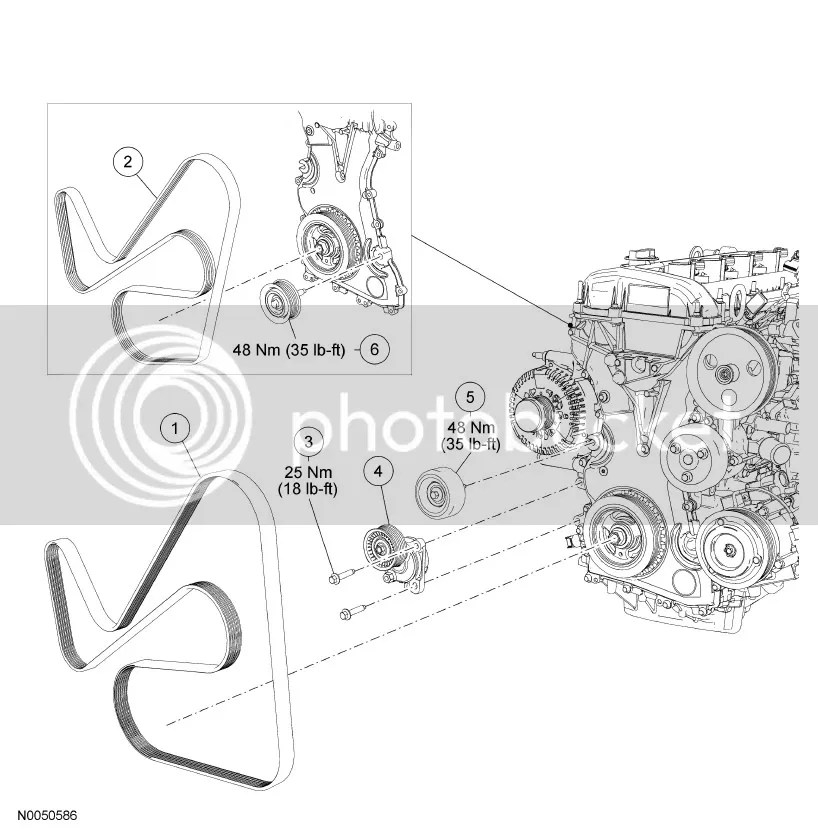

Interpreting the 2012 ford fusion 2.5 belt diagram requires a methodical approach. Before you begin the physical replacement, you must familiarize yourself with the layout and the direction in which the belt wraps around each pulley. The belt has two sides: the ribbed side and the smooth side. Generally, ribbed pulleys (like the alternator and crankshaft) contact the ribbed side of the belt, while smooth idler pulleys contact the back or smooth side of the belt.

Follow these numbered steps for a safe and accurate installation:

1. Preparation and Access: Park the vehicle on a level surface and engage the parking brake. For the best access to the 2.5L belt system, you may need to jack up the front passenger side of the vehicle and remove the tire. This allows you to remove the plastic splash shield inside the wheel well, giving you a direct line of sight to the crankshaft and tensioner.

2. Identify the Tensioner: Locate the automatic belt tensioner. It features a center bolt (usually 15mm) that you will use to rotate the tensioner arm. Refer to your configuration diagram to ensure you are applying force in the correct direction (usually clockwise) to compress the internal spring and release the belt’s grip.

3. Document the Current Path: Even with a diagram, it is helpful to take a photo of the existing belt structure. Look for how the belt weaves between the water pump and the alternator.

4. Release Tension and Remove: Using a long-handled serpentine belt tool or a breaker bar with the appropriate socket, rotate the tensioner. Once the belt slackens, slide it off the topmost pulley (the alternator is usually the easiest). Slowly release the tensioner arm back to its resting position and pull the old belt out through the wheel well.

5. Inspect the Pulleys: Before installing the new belt, spin each pulley by hand. They should spin smoothly without noise or “play.” If a pulley feels gritty or wobbles, that component must be replaced to prevent the new belt from failing prematurely.

6. Route the New Belt: Begin routing the new belt according to the 2012 ford fusion 2.5 belt diagram. It is often easiest to start from the bottom (crankshaft and A/C compressor) and work your way up. Ensure the ribs of the belt are perfectly seated in the grooves of the pulleys.

7. Apply Tension: Rotate the tensioner arm once more to open up the necessary space. Loop the final section of the belt over the last pulley (the alternator or the tensioner itself, depending on your reach).

8. Final Verification: Before starting the engine, double-check that the belt is not offset on any pulley. If the belt is even one “rib” off-center, it will shred immediately upon startup.

Never place your fingers between the belt and a pulley while the tensioner is under pressure. If the tool slips, the tensioner can snap back with enough force to cause serious injury.

Common Issues & Troubleshooting

The serpentine belt is a wear item, but it can also signal deeper issues within the engine’s accessory system. Using the 2012 ford fusion 2.5 belt diagram as a reference, you can often pinpoint where a failure started.

One of the most frequent problems is a high-pitched squealing noise. This usually indicates a loss of tension or a glazed belt surface. If the squeal occurs specifically when the air conditioning is turned on, the issue likely resides with the A/C compressor clutch or the belt’s grip on that specific pulley.

Another common issue is “belt jump,” where the belt partially or completely comes off the pulleys. This is frequently caused by a misaligned pulley or a failing tensioner. If the tensioner’s internal spring weakens, it can no longer maintain the rigid structure required for high-speed operation. Check the configuration of the tensioner; if it appears tilted or vibrates excessively while the engine is running, it requires immediate replacement.

Visual warning signs to look for on the belt include:

- ✓ Cracking: Small transverse cracks across the ribs are common as belts age, but more than three cracks in a one-inch space indicate imminent failure.

- ✓ Fraying: If the edges of the belt are unravelling, a pulley is likely misaligned.

- ✓ Oil Soaking: If you see a shiny, damp appearance, you may have an engine oil or coolant leak dripping onto the belt, which will cause it to slip and deteriorate rapidly.

Tips & Best Practices for Maintenance

To ensure the longevity of your 2012 Ford Fusion’s belt system, follow these professional maintenance recommendations. First, always choose high-quality EPDM (Ethylene Propylene Diene Monomer) belts. Unlike older neoprene belts, EPDM belts do not crack as obviously, so they require a special rib-gauge tool to check for wear.

When replacing the belt, it is highly recommended to replace the tensioner and idler pulley at the same time. These components often have the same service life as the belt, and a new belt on a worn tensioner can lead to premature failure.

Regularly clean the pulley grooves. Over time, debris and rubber dust can build up in the “valleys” of the pulley ribs. This buildup can cause the belt to sit higher than intended, altering the layout geometry and leading to noise or slippage. A small wire brush can be used to clear these grooves while the belt is removed.

Cost-saving advice for DIY enthusiasts involves performing a 15-minute inspection every time you change your oil. By checking the belt structure regularly, you can catch minor fraying before it turns into a snapped belt that leaves you stranded.

Finally, keep a copy of the 2012 ford fusion 2.5 belt diagram in your glovebox or saved on your phone. In the event of an emergency roadside repair, having the configuration readily available will significantly reduce the stress and time required to get your vehicle back on the road. Proper maintenance of this simple component ensures the health of your alternator, cooling system, and steering, preserving the overall performance of your Ford Fusion for years to come.

Step-by-Step Guide to Understanding the Ford Fusion 2.5 Belt Diagram: Routing & Installation

Identify the belt routing configuration by referencing the vehicle’s under-hood sticker or service manual.

Locate the automatic tensioner pulley within the engine layout to prepare for belt release.

Understand how the belt wraps around each individual component, noting ribbed versus smooth surfaces.

Apply the belt onto the pulleys, starting with the crankshaft and finishing at the tensioner.

Verify that the belt is perfectly seated in the grooves of every component in the system.

Complete the installation by checking tension and briefly starting the engine to ensure proper tracking.

Frequently Asked Questions

What is 2012 ford fusion 2.5 belt diagram?

It is a visual representation showing the precise path the serpentine belt takes around various pulleys. This diagram illustrates the configuration of the accessory drive system, ensuring that power is correctly distributed to the alternator, air conditioning compressor, and water pump for optimal vehicle operation and long-term maintenance needs.

How do you read 2012 ford fusion 2.5 belt diagram?

Start by identifying the crankshaft pulley as the primary source of power. Follow the lines indicating the belt’s path, noting whether it goes over or under specific components. Pay close attention to the smooth versus ribbed sides of the belt to match the pulley structure correctly during installation.

What are the parts of 2012 ford fusion 2.5 belt system?

The system consists of the crankshaft pulley, alternator, water pump, air conditioning compressor, and the automatic tensioner. Each component is strategically placed within the engine layout to maximize efficiency. The belt serves as the vital link that transfers mechanical energy from the engine to these essential vehicle accessories.

Why is the tensioner component important?

The tensioner is a critical component that maintains a constant load on the serpentine belt. Without proper tension, the belt would slip, causing a loss of power to the alternator or steering system. Its structural role prevents premature wear and ensures the entire drive configuration remains stable and quiet.

What is the difference between ribbed and smooth pulleys?

Ribbed pulleys are designed to grip the underside of the belt for maximum traction, typically found on power-generating components. Smooth pulleys, often used for idlers or tensioners, contact the flat back of the belt. Understanding this layout is vital for correct belt orientation and overall system reliability.

How do I use 2012 ford fusion 2.5 belt diagram?

Use the diagram as a reference guide before removing the old belt. Compare the drawing to your engine’s physical structure to confirm the routing path. This ensures that the new belt is seated correctly on every component, preventing mechanical failure or belt throwing during high-speed engine operation.