F150 3.5 Ecoboost Turbo Diagram: Troubleshooting & Repair

This F150 3.5 Ecoboost turbo diagram illustrates the complex plumbing between the twin turbochargers, wastegates, and intercooler. Use it to trace vacuum lines or boost leaks when a check engine light appears. Proper identification of hoses and actuators is essential for resolving performance issues and restoring engine power efficiently.

📌 Key Takeaways

- Visualizes the routing of air, oil, and coolant to the twin turbos

- Identifying the wastegate actuators and boost control solenoid

- Always verify vacuum line integrity before replacing expensive turbo components

- Use the diagram alongside an OBD-II scanner for precise troubleshooting

- Essential for fixing boost leaks or replacing manifold gaskets

Navigating the complex engine bay of a modern truck requires more than just a basic understanding of mechanics; it requires a precise roadmap. Understanding the f150 3.5 ecoboost turbo diagram is the first step toward mastering your vehicle’s performance and ensuring its longevity. Whether you are performing a routine inspection, upgrading components, or diagnosing a sudden loss of power, a clear visual and conceptual map of the twin-turbocharger system is indispensable. This guide provides a deep dive into the architecture of the 3.5L Ecoboost’s forced induction system, explaining how air, oil, and coolant interact to produce the massive torque these engines are known for. By the end of this article, you will be able to identify every major component, trace the flow of energy through the system, and use diagnostic tools to keep your engine running at peak efficiency.

Understanding the F150 3.5 Ecoboost Turbo Layout

The 3.5L Ecoboost engine utilizes a twin-turbocharged configuration, meaning there are two separate turbochargers—one for each cylinder bank. In a standard f150 3.5 ecoboost turbo diagram, you will notice that the system is divided into “Bank 1” (passenger side) and “Bank 2” (driver side). Each turbocharger is bolted directly to the exhaust manifold to minimize “turbo lag,” which is the delay between pressing the accelerator and feeling the boost. The diagram typically labels the high-pressure side, the low-pressure side, and the various pathways for lubrication and temperature management.

The main components featured in the diagram include the turbine housing, the compressor housing, the wastegate actuator, and the blow-off valve (BOV). The turbine housing is the “hot side,” where exhaust gases spin the internal wheel. The compressor housing is the “cold side,” which draws in ambient air, compresses it, and sends it toward the intercooler. A critical but often overlooked aspect of the diagram is the coolant flow path. These turbos are water-cooled, meaning engine coolant is pumped through the center bearing housing to prevent the oil from “coking” or baking onto the internal shafts after the engine is turned off.

The 3.5L Ecoboost uses a parallel turbo setup, not a sequential one. Both turbos are the same size and operate simultaneously to provide a smooth, broad torque curve rather than one large burst of power at high RPMs.

Visualizing the system also requires understanding the vacuum and electronic controls. Modern iterations of this engine use electronic wastegate actuators managed by the ECU (Engine Control Unit). This allows the truck’s computer to make millisecond adjustments to boost pressure based on altitude, temperature, and load. When looking at a diagram, these are usually represented by thin lines connecting the turbo housing to the electronic control solenoids located near the top of the engine intake manifold.

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing the Bank 1 and Bank 2 turbochargers, color-coded with Red for Exhaust Flow, Blue for Intake Air, Green for Coolant Flow, and Yellow for Oil Lubrication. Labels include the Intercooler, Wastegate Actuators, and MAP Sensors.]

Step-by-Step Guide: How to Read and Interpret the Turbo System

Interpreting an f150 3.5 ecoboost turbo diagram can be daunting for beginners, but following a logical flow makes the process much simpler. To properly use the diagram for DIY repairs or performance tuning, follow these steps to trace the system from start to finish.

- ✓ Step 1: Identify the Air Intake Path – Locate the air filter box in the diagram. Trace the two large plastic pipes leading away from the air box; these are the “low-pressure” pipes that feed fresh air into the compressor inlet of each turbo.

- ✓ Step 2: Trace the Compression Phase – Follow the air as it exits the compressor housing. The diagram will show these pipes merging into a single, larger pipe that leads to the intercooler (located behind the front bumper). This is where the air is cooled to increase density.

- ✓ Step 3: Locate the Throttle Body and Sensors – After the intercooler, the diagram shows the air moving upward into the throttle body and intake manifold. Look for the Manifold Absolute Pressure (MAP) sensors here, which report boost data to the ECU.

- ✓ Step 4: Map the Exhaust Drive – Now, look at the exhaust manifolds on the sides of the engine. Trace the exhaust flow into the turbine side of the turbos. This is the energy source that spins the compressor.

- ✓ Step 5: Verify Lubrication and Cooling Lines – Identify the small metal lines bolted to the top and bottom of the turbo center section. The top lines are usually the oil feed, while the side-mounted lines handle the coolant flow.

Necessary Tools for Turbo Inspection

To use the diagram effectively during a physical inspection, you will need a few specialized tools. An OBD-II scanner is essential for reading boost pressures and checking for a check engine light. For physical work, a set of 1/4-inch and 3/8-inch drive sockets is required, along with a precision torque spec manual to ensure all bolts are tightened to factory standards. Because the turbos are tucked tightly against the engine block, long-reach pliers and a mirror on a telescoping wand are also highly recommended.

Never attempt to work on the turbochargers immediately after driving. The turbine housings can reach temperatures exceeding 1,000 degrees Fahrenheit. Allow the engine to cool for at least two to three hours before touching any components identified in the diagram.

Common Issues and Troubleshooting with the Turbo Diagram

When something goes wrong with the 3.5L Ecoboost, the check engine light is often the first indicator. Using your diagram, you can narrow down the source of the problem by identifying which component correlates to a specific diagnostic code. For instance, a P0299 code indicates an “Underboost” condition. By looking at the diagram, you can systematically check the “hot side” for exhaust leaks, the “cold side” for loose plastic charge pipes, or the wastegate actuator for mechanical failure.

Another frequent issue is the “wastegate rattle,” a metallic clucking sound heard during deceleration. The f150 3.5 ecoboost turbo diagram helps you locate the actuator arm and the linkage. If this linkage becomes loose, the ECU cannot accurately control boost, leading to poor fuel economy and reduced towing capacity. Additionally, checking for oil in the intercooler pipes (visible in the diagram at the lowest point of the system) can help you diagnose failing turbo seals before they lead to a catastrophic engine failure.

If you encounter a P0299 code, use a smoke machine to test the intake tract. Often, the leak isn’t the turbo itself, but a hairline crack in the plastic “hot side” pipe that only opens up under high pressure.

Maintenance Tips and Best Practices

To keep the components in your f150 3.5 ecoboost turbo diagram functioning correctly, proactive maintenance is vital. Turbochargers spin at speeds exceeding 150,000 RPM, meaning even the slightest lubrication issue can cause total failure. Always use high-quality full synthetic oil and change it more frequently than the manufacturer’s maximum interval, especially if you tow heavy loads. Clean oil ensures the coolant flow and oil passages remain clear of sludge.

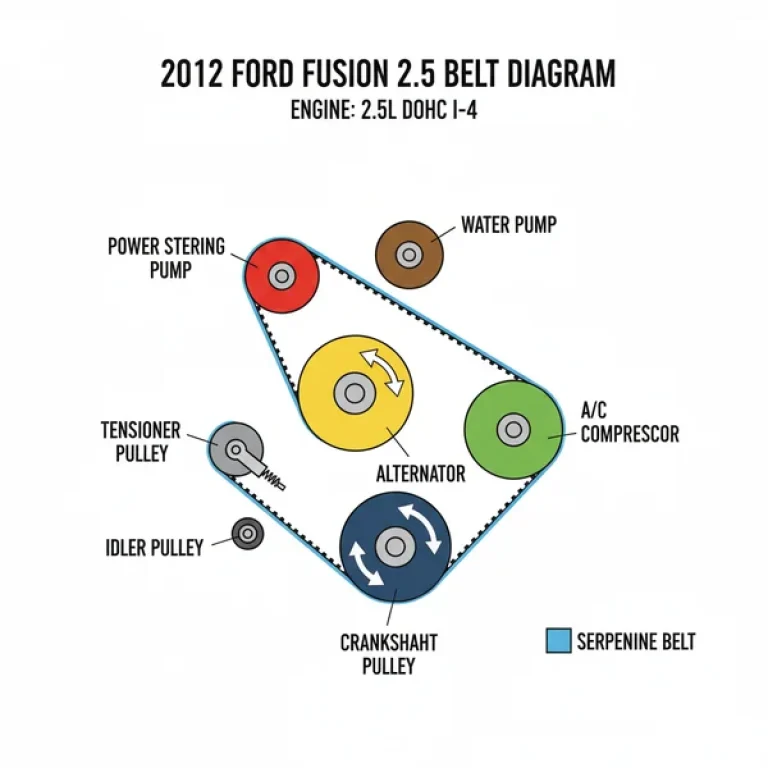

Beyond the turbos themselves, pay attention to the supporting cast of components. The accessory belt should be inspected for cracks, as it drives the water pump responsible for the coolant flow that keeps the turbos from overheating. Furthermore, while the timing chain is internal to the engine, its health is critical; a stretched timing chain can throw off the valve timing, causing the turbos to work harder to compensate for lost engine efficiency, eventually leading to premature wear.

- ✓ Check Spark Gaps: Boosted engines are sensitive to spark. Ensure your plugs are gapped correctly to prevent “blow out” under high boost.

- ✓ Monitor the Intercooler: Ensure the intercooler fins are clear of mud and debris to maintain maximum cooling efficiency.

- ✓ Respect Torque Specs: When replacing any turbo component, use a calibrated torque wrench. Over-tightening exhaust manifold bolts often leads to snapped studs due to heat expansion.

In conclusion, mastering the f150 3.5 ecoboost turbo diagram allows you to take control of your truck’s health. By understanding the flow of air, the importance of thermal management, and the role of the ECU, you can troubleshoot issues like a professional and save thousands of dollars in repair costs. Keep your OBD-II scanner handy, follow the recommended maintenance schedules, and always refer back to the technical layout when you notice a change in your engine’s performance or a new diagnostic code on your dashboard. With the right knowledge and tools, your 3.5L Ecoboost will continue to provide the power and reliability you expect for many miles to come.

Frequently Asked Questions

What is an F150 3.5 Ecoboost turbo diagram?

An F150 3.5 Ecoboost turbo diagram is a visual map showing the layout of the twin-turbocharged system. It details how the turbos connect to the exhaust manifold, intercooler, and intake. This schematic is vital for identifying vacuum lines and electronic sensors managed by the engine control unit or ECU.

How do you read an F150 3.5 Ecoboost turbo diagram?

To read the diagram, start at the air intake and follow the path through the turbo compressors to the intercooler. Use the legend to distinguish between high-pressure oil lines, coolant hoses, and vacuum tubes. Understanding these connections helps you locate specific parts when diagnosing engine performance drops.

What are the parts of the F150 3.5 Ecoboost turbo?

Key parts include the twin turbochargers, wastegate actuators, blow-off valve, and the boost control solenoid. The system also features oil supply and return lines, coolant jackets, and various charge pipes. Each component works together to force pressurized air into the engine, significantly increasing overall horsepower and torque.

Why is the boost control solenoid important?

The boost control solenoid is critical because it regulates the pressure sent to the wastegate actuators. Controlled by the ECU, it ensures the turbos provide the correct amount of boost. If this part fails, you may experience overboost or underboost conditions, often triggering a specific diagnostic code like P0299.

What is the difference between the turbo and the intercooler?

The turbocharger uses exhaust gases to compress incoming air, which generates heat. The intercooler is a heat exchanger that sits between the turbo and the engine. Its job is to cool that compressed air, making it denser and more oxygen-rich to improve combustion efficiency and overall engine power.

How do I use an F150 3.5 Ecoboost turbo diagram?

Use the diagram to trace physical components when your check engine light illuminates. By matching the schematic to your engine bay, you can perform visual inspections of hoses for cracks or leaks. It also provides the context needed to understand where to apply specific torque spec values during reassembly.