Eaton Fuller 10 Speed Transmission Parts Diagram: Repair Guide

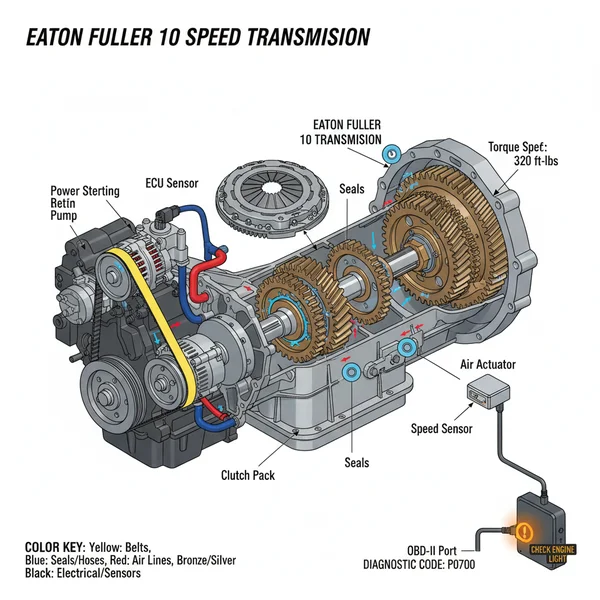

An Eaton Fuller 10 speed transmission parts diagram illustrates the internal gear sets, sliding clutches, and shift forks within the main and auxiliary sections. It helps technicians identify specific part numbers for seals, bearings, and air valves while providing the correct torque spec for reassembly and diagnosing mechanical failures effectively.

📌 Key Takeaways

- Main purpose: Visualizing the relationship between the main case and auxiliary section components.

- Most important component: The sliding clutch and shift fork assembly responsible for gear engagement.

- Safety/critical: Always ensure the air system is drained before servicing air-controlled components like the range valve.

- Practical application: Use the diagram to cross-reference OEM part numbers to ensure exact fitment during a rebuild.

- When to use: When experiencing shifting difficulties or performing a full transmission overhaul.

Navigating the complexities of heavy-duty machinery requires precision, and having a detailed Eaton Fuller 10 speed transmission parts diagram is an essential first step for any technician or fleet owner. Whether you are performing a routine inspection, a mid-life overhaul, or a complete rebuild, understanding the spatial relationship between the twin countershafts, the mainshaft, and the auxiliary section is vital. This guide provides a comprehensive breakdown of the internal architecture of the Eaton Fuller 10-speed, explaining how to interpret technical drawings and why accurate part identification is the difference between a successful repair and a costly roadside breakdown. By the end of this article, you will have the knowledge needed to identify every critical component within the gearbox housing.

The Eaton Fuller 10 speed transmission parts diagram is more than just a map; it is a schematic representation of one of the most durable pieces of drivetrain technology in the trucking industry. The diagram typically splits the transmission into three primary sections: the front (clutch) housing, the main case, and the auxiliary section. The main case contains the input shaft, the mainshaft, and the iconic twin countershafts. This twin-countershaft design is a hallmark of Eaton Fuller, as it splits the torque load between two separate shafts, allowing for a shorter, lighter transmission that can handle massive amounts of torque.

Most Eaton Fuller diagrams use a numbering system that correlates to a Master Part List. Always cross-reference your specific model number (e.g., FRO-16210C) found on the transmission tag with the diagram to ensure you are ordering the correct gear tooth counts and shaft lengths.

In a standard exploded view, you will see the input shaft at the front, which includes the drive gear and the pilot bearing surface. Moving inward, the diagram illustrates the mainshaft assembly, which holds the sliding clutches and the various speed gears (1st through 5th in the low range). The color-coding in modern digital diagrams often highlights the “High Range” versus “Low Range” components to help users understand the shift logic. You will also notice the auxiliary section at the rear, which houses the range cylinder and the synchronization hardware that allows the transmission to jump from the low 1-5 gear set to the high 6-10 gear set.

Reading an Eaton Fuller 10 speed transmission parts diagram requires a systematic approach to ensure no small washer or snap ring is overlooked. Follow these steps to master the interpretation and use of these technical documents:

- ✓ Locate the Identification Tag: Before looking at a diagram, find the metal tag on the transmission case. This tag provides the model and serial number, which determines which specific diagram variation you need.

- ✓ Identify the Section: Determine if your issue is in the main case or the auxiliary section. The auxiliary section is the most common area for air-related shifting issues, while the main case usually involves gear or bearing wear.

- ✓ Trace the Torque Path: Use the diagram to follow the flow of power from the input shaft, through the countershafts, and out to the output shaft. This helps in diagnosing which gear set is failing based on which gear “slips” or “grinds.”

- ✓ Check for Superseded Parts: Manufacturers often update part designs. A good diagram will note if a specific bearing or seal has been replaced by a newer, more durable version.

When you are ready to perform a teardown or part replacement using the diagram as your guide, you will need several specialized tools. A heavy-duty floor jack or transmission jack is non-negotiable, as these units can weigh over 600 pounds. You will also need a set of internal and external snap ring pliers, a bearing puller, and a high-quality torque wrench to meet the strict torque spec requirements for the case bolts and the output nut.

Never attempt to disassemble the auxiliary section without first exhausting the air system. Residual air pressure in the range cylinder can cause components to eject with dangerous force.

If you are working on an automated version, such as the UltraShift 10-speed, the diagram will also include an ECU (Electronic Control Unit) and various solenoids. In these advanced systems, troubleshooting often begins with an OBD-II style diagnostic tool (specifically the J1939 protocol for heavy-duty vehicles). If your check engine light or “Service Transmission” lamp is illuminated, you should pull the diagnostic code before cracking open the case. Often, a shifting issue is an electrical or air supply problem rather than a mechanical gear failure.

While the transmission is a standalone unit, it relies on the engine for cooling and power. During a transmission service, it is best practice to inspect the engine’s accessory belt and cooling system. A restricted coolant flow to the transmission oil cooler can cause the transmission fluid to overheat, leading to premature bearing failure and gear pitting. While you won’t find a timing chain inside the transmission, ensuring the engine is timed correctly prevents harmonic vibrations that can rattle and damage the input shaft splines.

Identifying problems early can save thousands of dollars in hard-part damage. If you notice a “growling” noise that disappears when the clutch is depressed, the diagram will likely point you toward the input shaft bearing or the constant-mesh gear set. If the transmission is jumping out of gear, the diagram can help you locate the shift detent springs and balls, which are often the culprit.

Another common issue is “range hang-up,” where the transmission refuses to shift from 5th to 6th gear. By consulting the Eaton Fuller 10 speed transmission parts diagram, you can locate the range piston and O-rings. Often, a simple $20 seal kit can fix a problem that feels like a total transmission failure. If you see a diagnostic code related to “Incompatible Gear Ratio,” it usually suggests that the ECU is sensing a speed mismatch, which may be due to a failing speed sensor—clearly marked on the rear of the auxiliary section diagram.

When reassembling, use a small amount of petroleum jelly to hold the needle bearings in place on the countershafts. This prevents them from falling out during the delicate process of dropping the shafts into the case.

To ensure the longevity of your Eaton Fuller 10-speed, follow these maintenance best practices:

1. Lubrication is Life: Use only synthetic transmission fluids that meet Eaton’s PS-386 specification. This fluid handles high heat better and ensures that the coolant flow through the external cooler is not hindered by sludge or varnish.

2. Air System Hygiene: Most shifting issues start in the air dryer. If moisture enters the transmission air lines, it will corrode the range and splitter cylinders. Replace your air dryer cartridge annually.

3. Torque Matters: Always follow the exact torque spec for the PTO covers and the shift tower bolts. Over-tightening can warp the aluminum covers, leading to persistent leaks.

4. Monitor the Dash: If you have an automated model, don’t ignore a flickering check engine light. Early intervention when a diagnostic code first appears can prevent a “limp mode” event on the highway.

- ✓ Quality Over Cost: When replacing gears, choose genuine Eaton Fuller parts or high-quality aftermarket equivalents. Cheap gears often have poor surface hardening and will whine or fail prematurely.

- ✓ Synchronizer Inspection: Always replace the high-low range synchronizer during any auxiliary section repair. It is a wear item and is significantly cheaper to replace while the unit is already open.

In summary, the Eaton Fuller 10 speed transmission parts diagram is an indispensable tool for maintaining the backbone of the trucking industry. By understanding the relationship between the twin countershafts and the mainshaft, and by integrating modern diagnostic techniques like checking for a diagnostic code via the OBD-II interface, you can keep your drivetrain running smoothly for hundreds of thousands of miles. Whether you are checking the torque spec on a rebuild or ensuring proper coolant flow to the transmission cooler, a methodical approach based on an accurate diagram is your best path to success. Don’t wait for a check engine light to familiarize yourself with these components—proactive study of your transmission’s internal map is the mark of a truly professional technician.

Step-by-Step Guide to Understanding the Eaton Fuller 10 Speed Transmission Parts Diagram: Repair Guide

Identify – Start by identifying the specific model number on the transmission ID tag to ensure you have the correct diagram.

Locate – Locate the main section and auxiliary section components on the schematic to understand the power flow.

Understand – Understand how the air lines connect to the slave valve and range cylinder for proper shifting functionality.

Apply – Apply the specified torque spec to the case bolts and PTO covers as indicated in the diagram’s notes.

Verify – Verify that all spacers and snap rings are positioned exactly as shown in the exploded view during reassembly.

Complete – Complete the process by checking for any active diagnostic code using an OBD-II scanner if the vehicle has electronic controls.

Frequently Asked Questions

What is Eaton Fuller 10 speed transmission parts diagram?

This diagram is a technical schematic that visualizes every internal and external component of the gearbox. It details the arrangement of gears, shafts, and the air system. By using this map, mechanics can accurately identify part locations, ensure proper assembly order, and locate specific repair kits for maintenance.

How do you read Eaton Fuller 10 speed transmission parts diagram?

Begin by identifying the main sections, typically the front case and the rear auxiliary section. Use the numbered callouts to match components with the provided parts list. Pay close attention to orientation symbols and exploded views that show how bearings and spacers stack together on the main shaft.

What are the parts of Eaton Fuller 10 speed transmission?

The primary parts include the input shaft, main shaft gears, countershafts, and the range cylinder. Additionally, the assembly contains shift forks, sliding clutches, and a complex air system. On newer automated models, the ECU communicates with sensors to manage shift points and monitor the overall health of the system.

Why is the air system important?

The air system controls the range and splitter functions, allowing the transmission to toggle between high and low gear sets. If an air leak occurs, it might trigger a diagnostic code or a check engine light on the dashboard. Maintaining correct air pressure is vital for smooth, synchronized gear transitions.

What is the difference between manual and UltraShift versions?

While both share similar mechanical gear layouts, the UltraShift version uses an ECU and electronic actuators instead of a manual floor shifter. Manual versions rely on driver input, whereas automated versions use an OBD-II interface for troubleshooting and scanning for a specific diagnostic code during a malfunction or failure.

How do I use Eaton Fuller 10 speed transmission parts diagram?

Use the diagram as a reference during teardown and reassembly to ensure every washer and gear is correctly placed. Refer to the diagram’s notes to find the exact torque spec for housing bolts. This prevents leaks and mechanical failure, ensuring the transmission operates reliably under heavy loads.