Dual Axle Trailer Brake Wiring Diagram: Complete Setup Guide

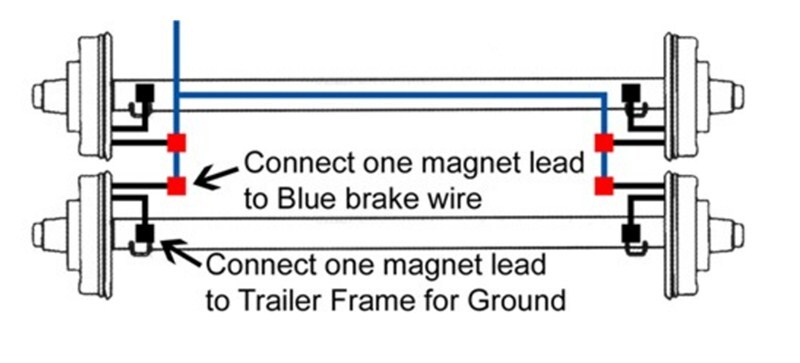

A dual axle trailer brake wiring diagram illustrates how to connect electric brakes to a towing vehicle. It shows the flow from the hot wire to each wheel assembly, ensuring synchronized braking. Proper grounding and secure connections at the common terminal are vital for reliable stopping power across all four wheels.

📌 Key Takeaways

- Visualizes the electrical path for four individual brake magnets.

- Identify the blue brake controller wire as the primary hot wire.

- Ensuring a solid ground wire connection prevents intermittent brake failure.

- Wiring brakes in parallel ensures consistent voltage across both axles.

- Use this diagram when installing new magnets or diagnosing loss of power.

When you are hauling a heavy load, your vehicle’s stopping power becomes your most critical safety feature. Understanding a dual axle trailer brake wiring diagram is the first step in ensuring your electric braking system functions reliably under pressure. Whether you are building a new utility trailer or repairing an existing car hauler, the electrical connections between your tow vehicle and the trailer’s four individual brake magnets must be precise. This comprehensive guide provides a clear visual and conceptual roadmap, covering everything from the 7-way connector to the specific wire gauges required for optimal performance. You will learn how to route power efficiently, identify common connection points, and troubleshoot issues that could otherwise lead to dangerous brake failure on the road.

Comprehensive Breakdown of the Wiring Diagram

The core of a dual axle trailer brake wiring diagram is the path of the electric signal from the brake controller inside your truck to the four brake magnets located at each wheel hub. Unlike a single axle setup, a dual axle configuration requires a parallel wiring scheme to ensure that all four brakes receive equal voltage simultaneously. If one magnet fails or a wire is pinched on one side, a parallel circuit allows the remaining brakes to continue functioning, providing a necessary safety redundancy.

The diagram typically begins at the 7-way round plug. In standard North American wiring, the blue wire is designated as the electric brake output. This is often referred to as the traveler wire in informal contexts because it carries the braking signal across the length of the trailer. This wire leads to a central junction box, where it splits to feed both the front and rear axles. Inside this junction box, you will find a common terminal where all positive brake leads meet. It is essential to distinguish this from a residential setup; while a household switch might use a brass screw to secure a hot wire, a trailer junction box uses galvanized or stainless steel studs to prevent corrosion.

In our diagram, you will notice that the ground wire (typically white) is just as important as the power wire. Each of the four brake magnets has two wires. One connects to the blue brake feed, and the other connects to the common ground. Many installers prefer to run a dedicated ground wire back to the junction box rather than grounding to the trailer frame, as modern powder-coated frames can act as insulators and cause intermittent connectivity issues.

[DIAGRAM_PLACEHOLDER: DUAL AXLE TRAILER BRAKE WIRING SCHEMATIC]

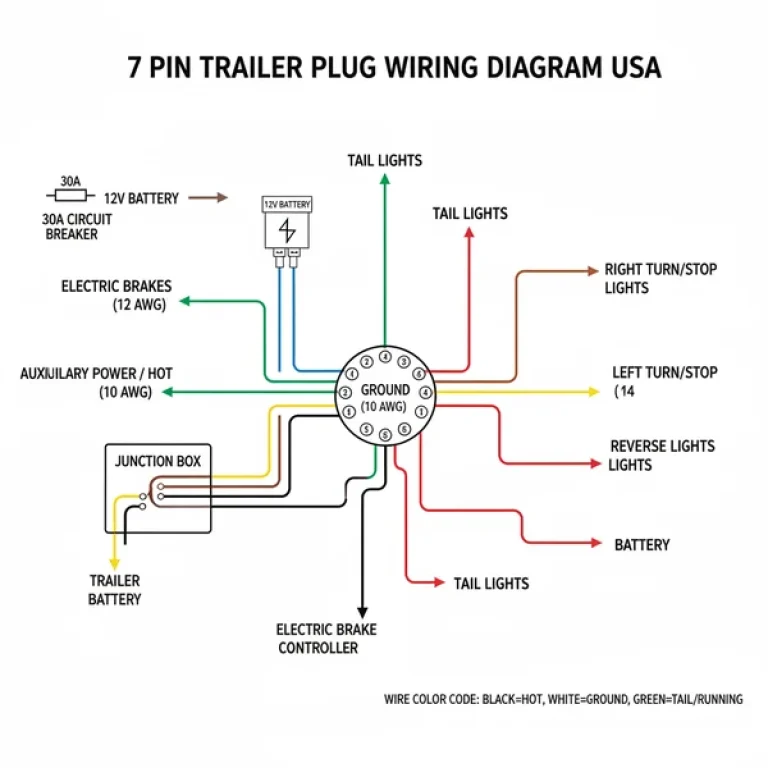

Visualizing the 7-Way Connector (Blue: Brakes, White: Ground, Black: 12V Battery, Green: Tail/Running, Red: Left Turn, Brown: Right Turn, Yellow: Reverse). The Blue wire splits at the junction box to reach all four magnets in a parallel loop.

Step-by-Step Installation and Interpretation Guide

Following a dual axle trailer brake wiring diagram requires a methodical approach to ensure that no connections are swapped. Unlike alternating current systems that use a neutral wire, DC trailer systems rely on a simple positive-and-ground circuit. Here is how to execute the installation correctly:

- ✓ Step 1: Mount the Junction Box – Install a weatherproof junction box on the interior of the trailer tongue. This serves as the “brain” for your wiring and makes future maintenance significantly easier.

- ✓ Step 2: Prepare the 7-Way Cable – Strip the outer jacket of your 7-way molded cable to reveal the inner wires. The blue (brake) and white (ground) wires are your primary focus. Ensure the blue wire is at least 12 gauge to handle the current draw of four magnets.

- ✓ Step 3: Establish the Main Feed – Connect the blue wire from the 7-way plug to the common terminal stud in the junction box. From this same stud, run two separate 12-gauge wires: one down the left side of the trailer and one down the right side.

- ✓ Step 4: Route the Axle Wires – Run the wires through the trailer frame or inside protective conduit. At each axle, the wire should drop down to the brake backing plate. Use heat-shrink butt connectors to join the feed wire to one of the two wires protruding from the brake magnet.

- ✓ Step 5: Connect the Ground Loop – Take the second wire from each magnet and connect it to a common ground wire. This ground wire must eventually lead back to the junction box and connect to the heavy-duty white ground wire from the tow vehicle.

- ✓ Step 6: Secure and Insulate – Use UV-resistant zip ties to secure the wiring every 12 to 18 inches. Ensure there is enough “slack” or a service loop at the axle move-points to account for the suspension travel.

- ✓ Step 7: Final Voltage Test – With the trailer connected to the tow vehicle, use a multimeter to check the voltage at the furthest magnet. You should see a steady increase in voltage as someone manually slides the brake controller in the cab.

To complete this project, you will need a high-quality wire stripper, a crimping tool, a multimeter, and heat-shrink tubing. Always use 10 or 12 gauge wire for brake lines to prevent voltage drop over long distances. Standard 14 or 16 gauge wire is sufficient for lighting but can overheat when used for dual axle braking systems.

Electric brake magnets are not polarity sensitive. This means either wire coming out of the magnet can be used for power or ground. However, once you choose a wire for power, consistency is key for troubleshooting. Do not confuse these DC wires with AC house wiring; there is no neutral wire in this circuit, only a return path to the battery negative.

Common Issues & Troubleshooting

Even with a perfect dual axle trailer brake wiring diagram, environmental factors like road salt, moisture, and vibration can cause system failures. The most common issue encountered is a “weak” braking sensation. This is often caused by a poor ground connection. If the white ground wire is not properly seated at the common terminal or the 7-way plug, the magnets will not receive the full amperage needed to create a strong magnetic field.

Another frequent problem is an “open circuit” warning on the in-cab brake controller. This usually indicates a broken wire or a disconnected magnet. Because dual axles are wired in parallel, a break at the rear axle might only disable two of the four brakes, whereas a break near the tongue will disable all of them. Use your multimeter to check for continuity between the blue hot wire and the white ground.

If you are unsure if a magnet is working but don’t want to pull the drum, hold a pocket compass near the wheel hub while someone activates the manual override on the brake controller. If the wiring is correct and the magnet is energized, the compass needle will spin or deflect sharply toward the hub.

Intermittent “short circuits” are often found where the wire passes through the trailer frame. Over time, the vibration of the road can chafe the insulation, allowing the hot wire to touch the metal frame. If your controller shows a “Short” error, inspect every point where a wire enters or exits the trailer tubing.

Best Practices for Longevity and Performance

To ensure your wiring stands the test of time, always prioritize the quality of your connections. While a brass screw might be sufficient for a dry, stationary environment, trailers exist in a world of constant motion and moisture. Use tinned copper wire whenever possible, as it resists the “green rot” corrosion that can travel up inside the insulation of standard copper wire.

- ✓ Use Proper Gauges: Always use 10-gauge wire for the main run from the plug to the junction box, and 12-gauge for the individual drops to the magnets.

- ✓ Seal Every Connection: Never use “suitcase” connectors or electrical tape alone. Use adhesive-lined heat shrink butt connectors to create a waterproof seal.

- ✓ Maintain the 7-Way Plug: Apply dielectric grease to the terminals of your 7-way plug regularly. This prevents oxidation and ensures the hot wire and ground wire maintain a low-resistance connection.

- ✓ Protect the Harness: Run your wiring through split-loom tubing or PVC conduit. This protects the insulation from road debris and UV damage from the sun.

Investing time in a clean, organized installation based on a proper dual axle trailer brake wiring diagram will save you significant money in the long run. Professional repair shops often charge high hourly rates for electrical “ghost hunting.” By using a junction box and color-coded wires, you make the system “field-serviceable,” allowing you to identify and fix a broken traveler wire or a loose common terminal in minutes rather than hours. Keeping your braking system in top shape is not just about maintenance; it is about the peace of mind that comes with knowing your trailer will stop exactly when you need it to.

Frequently Asked Questions

What is dual axle trailer brake wiring diagram?

A dual axle trailer brake wiring diagram is a visual schematic showing how electricity travels from the vehicle controller to the four brake magnets. It identifies the path of the hot wire and the ground wire, ensuring that all four wheels receive equal power for balanced braking performance while towing.

How do you read dual axle trailer brake wiring diagram?

To read the diagram, follow the colored lines representing specific circuits. The blue line usually represents the hot wire from the brake controller. Trace it to each wheel’s common terminal, and ensure the ground wire connects back to the trailer frame or the vehicle’s negative terminal for circuit completion.

What are the parts of dual axle trailer brake wiring?

Key parts include the 7-way plug, the blue hot wire for signal transmission, and the white ground wire for completion. It also features a traveler wire to jump power between axles and a common terminal where multiple connections meet for distribution to the brake magnets inside each hub assembly.

Why is the ground wire important?

The ground wire is critical because it completes the electrical circuit. Without a clean, secure connection to the trailer frame or the negative battery terminal, the brakes will fail to engage or will operate inconsistently, creating a dangerous situation where the trailer cannot stop effectively behind the towing vehicle.

What is the difference between parallel and series wiring?

Parallel wiring delivers the same voltage to every brake magnet simultaneously, which is the standard for dual axle setups. Series wiring would divide the voltage, causing weak braking. Using a traveler wire to connect axles in parallel ensures that one magnet failure won’t disable the entire trailer braking system.

How do I use dual axle trailer brake wiring diagram?

Use the diagram as a blueprint during installation or repair. Start by identifying the main power source, then trace the traveler wire as it splits to each wheel. Verify every connection point against the schematic to ensure proper polarity and to prevent short circuits in the trailer wiring harness.