Dodge Ram 2500 Front End Diagram: Suspension Repair Guide

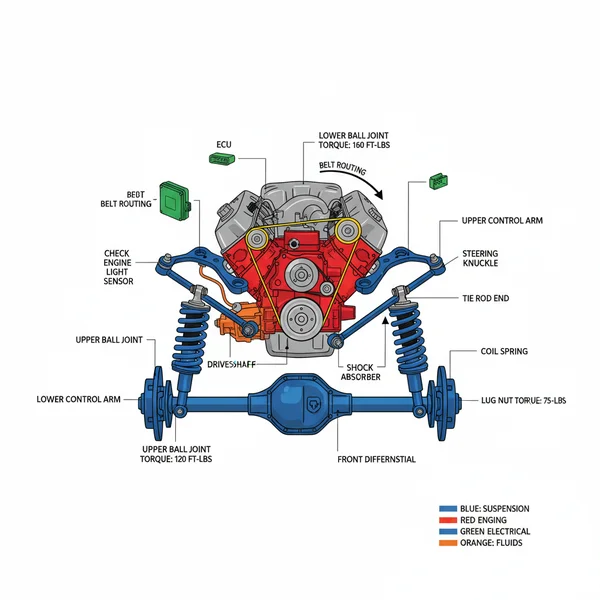

A Dodge Ram 2500 front end diagram displays the complex layout of the 4WD solid axle or 2WD independent suspension. It highlights critical parts like track bars, ball joints, and steering stabilizers. Using this guide ensures you apply the correct torque spec during repairs, preventing death wobble and ensuring long-term drivability.

📌 Key Takeaways

- Visualizes the relationship between the track bar, drag link, and tie rods

- The track bar is the most critical component for preventing death wobble

- Always use a calibrated torque wrench to meet factory specifications

- Check wheel speed sensors if your ABS light is illuminated

- Use this diagram during routine inspections for worn bushings or leaks

Maintaining the heavy-duty performance of a heavy-duty truck requires a deep understanding of its mechanical skeleton, particularly the front suspension dodge ram 2500 front end diagram. This guide is designed to provide you with a comprehensive visual and technical breakdown of the components that keep your truck stable under heavy loads and smooth on rough terrain. By studying the detailed schematics, you will learn how to identify wear in ball joints, understand the geometry of the track bar, and recognize how steering linkages interact. Whether you are performing a routine inspection or a complete front-end overhaul, having the correct diagram ensures that every bolt and bushing is accounted for, ultimately preserving the longevity and safety of your vehicle.

Understanding the Front Suspension Geometry

The front end of a heavy-duty truck like the Dodge Ram 2500 is significantly more complex than a standard passenger vehicle. Most models utilize a solid front axle supported by a multi-link coil spring suspension system. This design is preferred for its durability and load-carrying capacity. The front suspension dodge ram 2500 front end diagram illustrates how the axle is located and stabilized by several key components. The primary elements include the upper and lower control arms (often referred to as control links), which prevent the axle from moving forward or backward.

A critical component highlighted in any front-end diagram is the track bar. This bar connects the frame to the axle diagonally, preventing lateral (side-to-side) movement. Because these trucks are often used for towing and hauling, the track bar bushings are under immense pressure and are common points of failure. Additionally, the steering linkage—comprising the drag link, tie rod ends, and pitman arm—is mapped out to show how steering input from the gearbox translates to the wheels. You will also notice the location of the steering stabilizer, which acts as a shock absorber for your steering system, minimizing the vibrations felt through the steering wheel.

Most 2500 series trucks utilize a “Five-Link” suspension system. This includes two upper control arms, two lower control arms, and one track bar. Understanding how these five points triangulate the axle is essential for troubleshooting alignment issues.

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing a solid front axle for a heavy-duty truck. Labels include: A. Track Bar, B. Drag Link, C. Tie Rod, D. Upper Control Arm, E. Lower Control Arm, F. Shock Absorber, G. Coil Spring, H. Steering Stabilizer, I. Ball Joints (Upper/Lower), J. Pitman Arm.]

Step-By-Step Guide to Interpreting and Servicing the Front End

Using a diagram to service your truck requires a systematic approach. Suspension work can be dangerous if the vehicle is not properly supported, as the components are under significant tension from the coil springs. Follow these steps to safely use your diagram for inspection or component replacement.

Step 1: Vehicle Preparation and Safety

Before diving into the mechanical work, park the truck on a level concrete surface. Use a heavy-duty floor jack to lift the front end by the frame, not the axle, so the suspension can hang freely. Secure the truck with jack stands rated for at least 3 tons per stand. Wear safety goggles and gloves, as road debris and grease are constant factors in suspension work.

Step 2: Component Identification

Consult your front suspension dodge ram 2500 front end diagram to locate the specific part you intend to service. Start from the center of the truck and work your way out. Locate the pitman arm attached to the steering box, then follow the drag link to the passenger-side knuckle. From there, identify the tie rod that connects the passenger knuckle to the driver-side knuckle. Mapping these out physically against the diagram helps prevent errors during disassembly.

Step 3: Preliminary Inspection and Cleaning

Use a wire brush to clean the mounting points and bolts of the components you are working on. Spray all nuts and bolts with a high-quality penetrating oil. While the oil soaks, perform a visual inspection. Look for torn grease boots on the ball joints and tie rod ends. If you see fluid leaking from the steering stabilizer or shocks, they likely need replacement.

Step 4: Checking for Play

With the vehicle in the air, use a pry bar to check for movement in the control arm bushings and the track bar ends. If the axle moves independently of the frame when prying against the track bar, the bushings are shot. For ball joints, place a long pry bar under the tire and lift upward. If there is vertical movement in the knuckle, the ball joints have exceeded their service life.

Step 5: Disassembly and Specialized Tools

When removing tie rods or ball joints, you will likely need specialized tools such as a pickle fork, a Pitman arm puller, or a ball joint press. Refer to the diagram to ensure you are removing the correct cotter pins and castle nuts. Never strike the threaded portion of a joint with a hammer, as this will mushroom the metal and make removal impossible.

Step 6: Installation and Torque Spec Application

When installing new components, it is vital to follow the specific torque spec provided by the manufacturer for every bolt. Suspension components are subject to extreme vibration; under-torquing can lead to parts falling off, while over-torquing can snap bolts or crush bushings. Always tighten suspension bolts while the truck is at “ride height” (wheels on the ground) to prevent “bushing clocking,” which causes premature failure.

Step 7: Post-Installation Systems Check

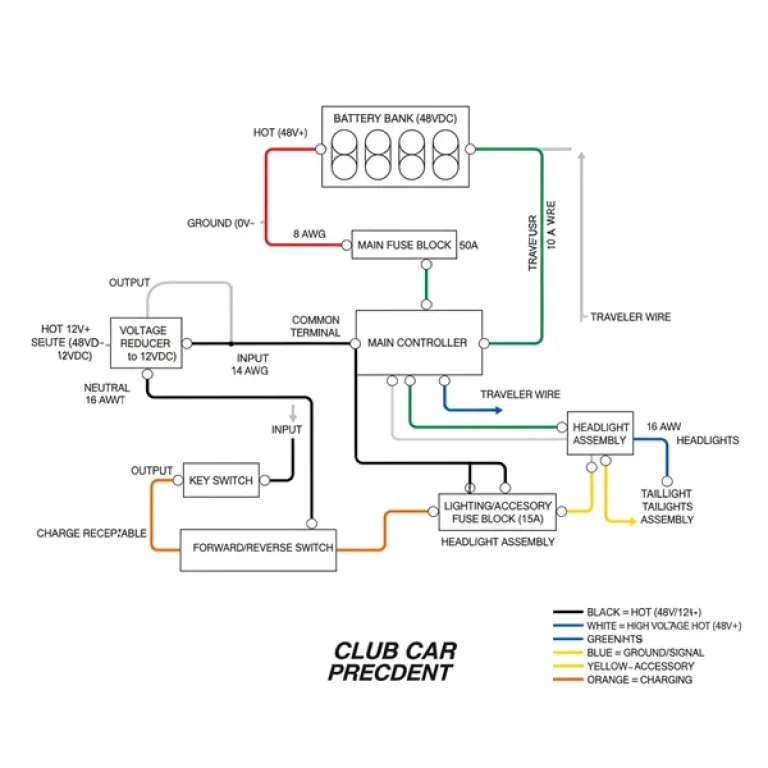

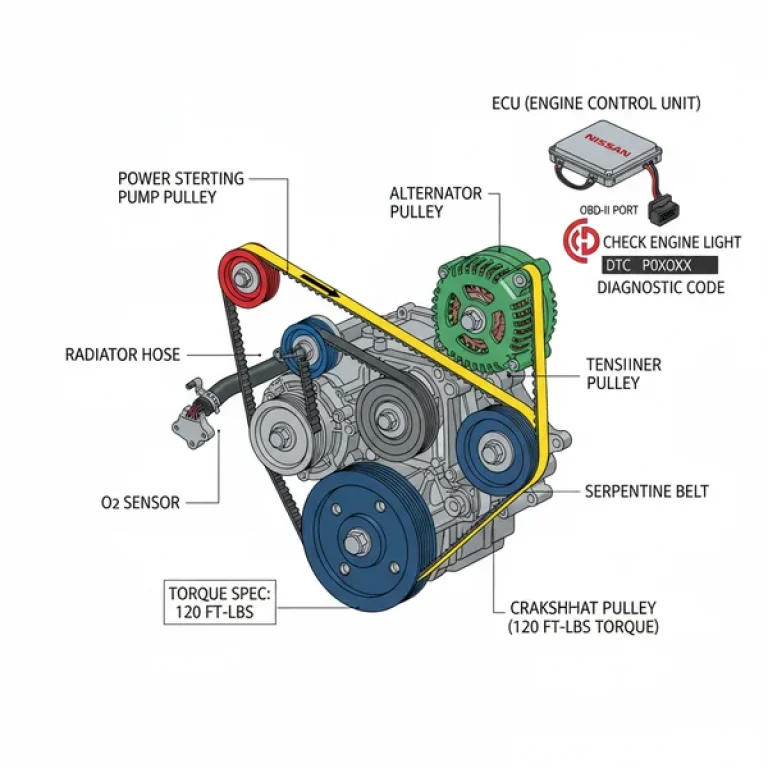

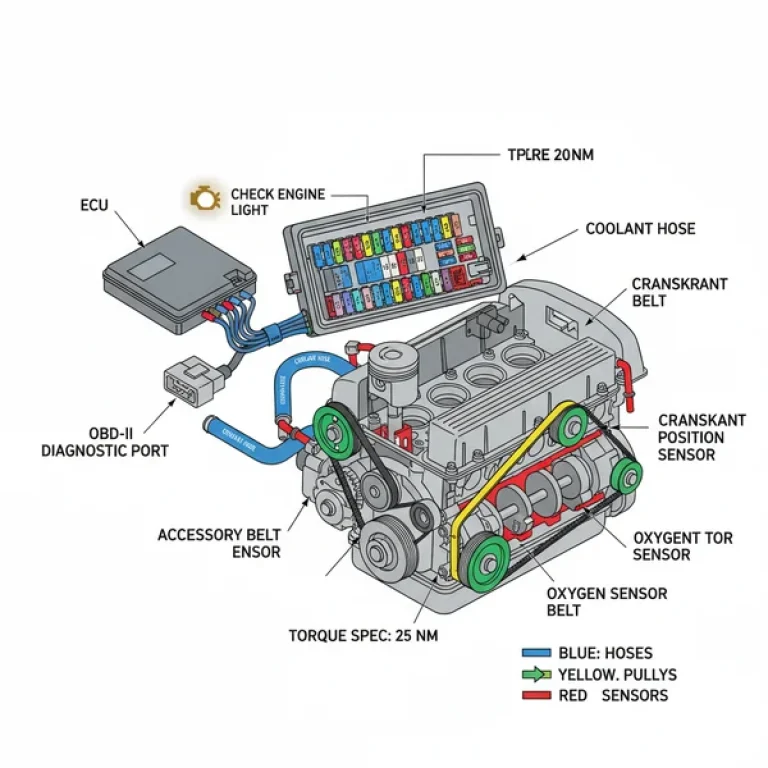

After replacing mechanical parts, it is a good practice to check the vehicle’s electronic health. While the suspension is mechanical, steering angle sensors can trigger a check engine light or a stability control warning if they are disconnected or if the alignment is severely off. Connect an OBD-II scanner to the port under the dashboard to ensure no diagnostic code has been tripped. If a code appears, it may indicate the ECU needs to recalibrate the steering center point.

The coil springs on a 2500 series truck hold an immense amount of potential energy. Never attempt to remove a shock or control arm that is supporting the weight of the spring without proper internal spring compressors or following the manufacturer’s specific unloading procedure.

Common Issues and Troubleshooting

The Dodge Ram 2500 is famous for a phenomenon known as “Death Wobble,” which is a violent shaking of the front end usually triggered by hitting a bump at highway speeds. This is almost always caused by wear in the components found on your front end diagram. The primary culprit is usually the track bar bushing or the steering stabilizer.

Another frequent problem is uneven tire wear. If the inside of your tires is wearing faster than the outside, it usually points to failing ball joints or incorrect camber/toe settings. Use the diagram to locate the adjustment sleeves on the tie rods and drag link. If you hear a clunking sound when driving over small bumps, check the sway bar end links and the shock absorber bushings. If you notice a diagnostic code related to the ABS or traction control, inspect the wheel speed sensor wires that run along the control arms; these are often pinched or broken during suspension work.

Tips and Best Practices for Maintenance

To keep your front end in top shape, consistency is key. Heavy-duty trucks require more frequent inspections than standard vehicles, especially if used for work.

- ✓ Grease Regularly: Many aftermarket front-end parts feature grease zerks. Apply high-quality chassis grease every 3,000 to 5,000 miles.

- ✓ Alignment After Repair: Any time you replace a tie rod, drag link, or control arm, a professional alignment is mandatory.

- ✓ Holistic Inspection: While you are under the front end, take a moment to look upward. Check your accessory belt for cracks and ensure the coolant flow from the lower radiator hose isn’t leaking onto your suspension components, as ethylene glycol can degrade rubber bushings.

- ✓ Monitor Engine Health: On high-mileage diesel or gas engines, listen for a rattling sound near the front cover which could indicate timing chain or gear wear. Mechanical health is a total-vehicle concept.

When replacing front end parts, consider upgrading to an adjustable track bar. This allows you to perfectly center the axle, especially if you have installed a leveling kit or lift, which the stock front suspension dodge ram 2500 front end diagram might not account for.

Investing in high-quality, heavy-duty replacement parts (like those with “Problem Solver” designations) can save you money in the long run. While budget parts are tempting, the labor involved in replacing them twice outweighs the initial savings. Always keep a digital copy of the front suspension dodge ram 2500 front end diagram on your phone or printed in your glovebox for quick reference during roadside emergencies or garage sessions. By following these guidelines and understanding the mechanical relationships between your truck’s components, you can ensure a safe, stable, and long-lasting driving experience.

Step-by-Step Guide to Understanding the Dodge Ram 2500 Front End Diagram: Suspension Repair Guide

Identify the main suspension type, distinguishing between the solid axle 4WD or independent 2WD setup on your Ram 2500.

Locate the primary steering components, including the drag link, tie rods, and steering box, using the visual markers.

Understand how the track bar and control arms stabilize the front end to prevent unwanted lateral movement or vibration.

Connect the mechanical findings with electronic data by using an OBD-II scanner to check for any stored diagnostic code.

Verify that every bolt is tightened to the manufacturer’s recommended torque spec to prevent component failure or loosening under load.

Complete the inspection by clearing any check engine light related to the steering angle sensor or ABS via the vehicle’s ECU.

Frequently Asked Questions

What is a Dodge Ram 2500 front end diagram?

A Dodge Ram 2500 front end diagram is a visual schematic showing the assembly of the steering and suspension systems. It identifies parts like control arms, drag links, and shocks. This tool is essential for mechanics to understand how components interact and for identifying specific replacement part numbers accurately.

How do you read a Dodge Ram 2500 front end diagram?

Reading the diagram involves matching numbered callouts to a parts list. Start from the main axle housing and trace outward to the wheels. Look for symbols indicating hardware like bushings and seals. It is crucial for locating the specific torque spec for each bolt to ensure a safe installation.

What are the parts of the Dodge Ram 2500 front end?

Key parts include upper and lower ball joints, tie rod ends, the track bar, steering stabilizer, and control arms. On newer models, wheel speed sensors are integrated, which communicate with the ECU. Understanding these parts helps when a diagnostic code indicates a failure in the traction control or ABS.

Why is the track bar important?

The track bar is vital because it centers the axle under the truck. If it fails, you may experience death wobble or erratic steering. Proper maintenance of these mechanical parts prevents the check engine light or ABS light from triggering due to sensor misalignment or excessive vibration during travel.

What is the difference between 4WD and 2WD front ends?

The primary difference lies in the load-bearing capacity and the solid axle design of the 4×4 versus the independent front suspension of some 4×2 models. Solid axles use a track bar and radius arms, requiring heavy-duty components and specific torque spec settings to handle the increased weight.

How do I use a Dodge Ram 2500 front end diagram?

Use the diagram to identify worn components by comparing your physical setup to the schematic. After finding the fault, use an OBD-II scanner if an ABS or stability light is on to read any diagnostic code. Finally, follow the diagram’s assembly order to replace the parts correctly.