Diagram Reverse Light Wire Color: Identify & Understand Wiring

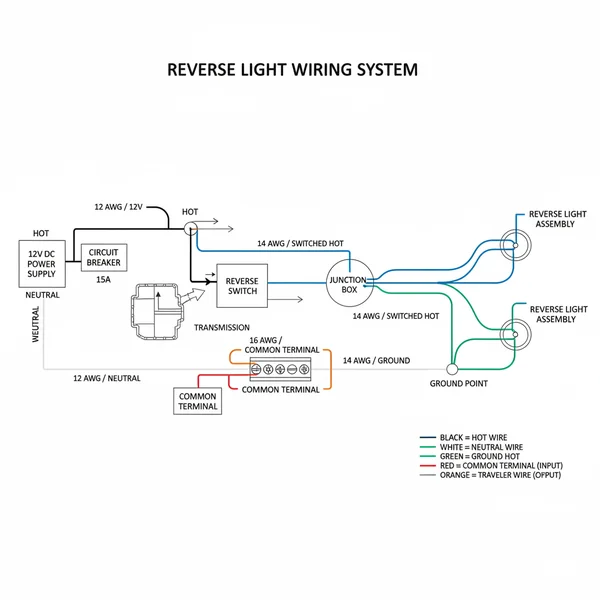

A reverse light wiring diagram illustrates the specific color codes for the hot wire, ground wire, and power connections to your vehicle’s reverse lights. This visual guide helps identify the correct common terminal and ensure proper installation or troubleshooting of your reverse light system, preventing incorrect connections.

📌 Key Takeaways

- Main purpose of this diagram is to identify the correct wire colors for reverse lights.

- The most important component to identify is the reverse light switch, which activates the circuit.

- Always disconnect the vehicle’s battery (ground wire) before working on electrical components for safety.

- Use a multimeter to verify voltage and continuity, especially for the hot wire and common terminal.

- Use this diagram for installing aftermarket accessories, troubleshooting non-functional lights, or replacing damaged wiring.

Understanding the intricate wiring of your vehicle’s reverse lights is crucial for both safety and functionality. This comprehensive guide will illuminate the exact purpose of each wire, helping you decipher any “diagram reverse light wire color” you encounter. By the end, you’ll possess the knowledge to accurately identify, connect, and troubleshoot your reverse light system, ensuring your vehicle remains safe and compliant on the road. We’ll explore the diagram’s components, offer a step-by-step interpretation, and provide essential tips for successful implementation.

Deciphering the Reverse Light Wiring Diagram

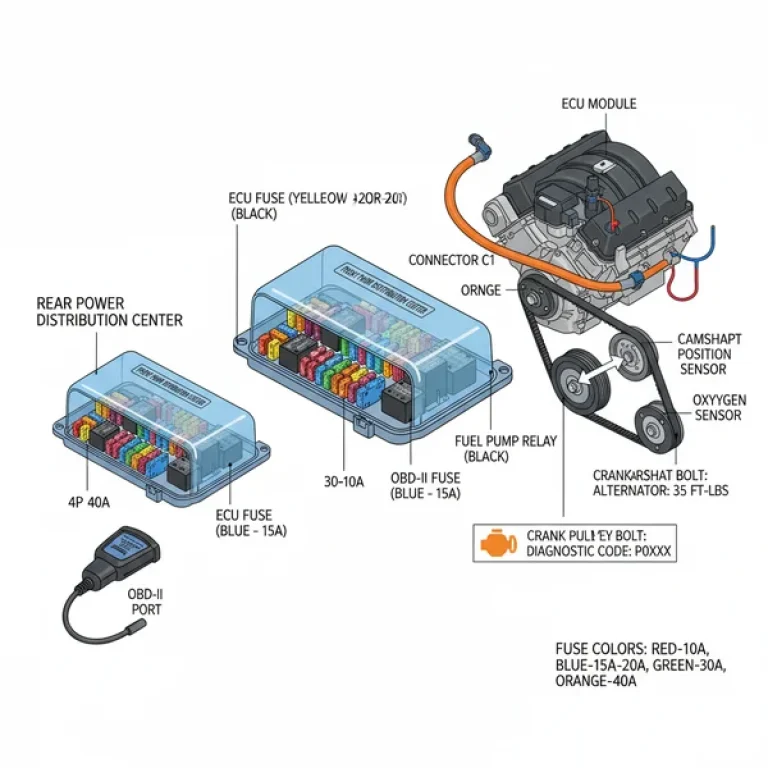

A typical reverse light wiring diagram illustrates the electrical path from the power source through a switch to the reverse lights and finally to ground. At its core, you’ll usually find the battery as the power origin, a fuse for circuit protection, the reverse light switch (often integrated into the transmission or gear selector), and the reverse light bulbs themselves, which are typically housed within the tail light assembly.

While specific wire colors can vary between vehicle manufacturers and models, common color conventions exist. For instance, a black wire is frequently used as the ground wire, connecting the circuit back to the vehicle’s chassis or battery negative terminal. Wires carrying switched positive voltage might be green, red, or even yellow, depending on the car’s origin. Always consult your specific vehicle’s service manual or an OEM diagram for absolute certainty, as aftermarket installations or previous repairs might introduce non-standard colors.

The diagram will visually represent the connections, using symbols for components like the battery, fuse, switch, and bulbs. Lines represent wires, and junctions show where wires connect. The reverse light switch acts as the circuit’s gatekeeper, completing the electrical path only when the transmission is placed in reverse. This sends power to the reverse light bulbs, causing them to illuminate. Each bulb will have at least two terminals: one for the incoming hot wire (carrying power from the switch) and one for the ground wire, often connecting to a brass screw or a common terminal on the light housing. Understanding these connections is key to interpreting any “diagram reverse light wire color”.

Step-by-Step Guide to Reading and Implementing the Diagram

Interpreting a reverse light wiring diagram and applying it to your vehicle requires methodical steps and attention to detail. This guide will walk you through the process, focusing on safety and accuracy.

Tools and Materials You’ll Need:

- ✓ Multimeter (for testing voltage and continuity)

- ✓ Wire strippers and crimpers

- ✓ Electrical tape or heat shrink tubing

- ✓ Assorted electrical connectors (e.g., spade, ring, butt connectors)

- ✓ Small flathead and Phillips screwdrivers

- ✓ Flashlight or work light

Always disconnect your vehicle’s negative battery terminal before performing any electrical work to prevent accidental shorts or electric shock. Wear appropriate safety gear, including eye protection.

Steps to Follow:

1. Locate Your Specific Diagram: Start by obtaining the exact wiring diagram for your vehicle’s make, model, and year. This is paramount because wire colors and routing can vary significantly. Service manuals, online resources, or dedicated automotive wiring diagram databases are excellent sources. Pay close attention to the legend that defines symbols and wire color codes.

2. Identify Key Components on the Diagram: Locate the power source (battery), the fuse protecting the reverse light circuit, the reverse light switch (often near the transmission or shifter), and the reverse light bulbs. Trace the current path from the battery, through the fuse, to the switch, then to the bulbs, and finally to the vehicle’s ground. Identify the “hot wire” supplying power and the “ground wire” completing the circuit.

3. Understand Wire Colors and Their Function: The diagram will use abbreviations or full names for wire colors (e.g., BK for black, R for red, G for green). Match these to your vehicle’s actual wiring. Typically, a black wire or a designated chassis connection serves as the ground wire. The wire carrying power to the reverse light switch will be constantly live (when the ignition is on, depending on the circuit design), while the wire from the switch to the reverse lights will only become live when reverse gear is engaged. Note the gauge (thickness) of the wires indicated; using the correct gauge is important for safety and proper function, especially if replacing sections.

4. Pinpoint Physical Locations in Your Vehicle: Using the diagram as a map, locate the actual components in your vehicle. The reverse light switch is often on the transmission housing, accessible from underneath the vehicle or sometimes from the engine bay. The reverse lights themselves are typically integrated into the rear taillight assemblies. Tracing wires can be complex, so having good lighting is essential.

5. Test for Voltage and Continuity: With the battery disconnected, use your multimeter to check continuity where necessary. Once components are installed or being tested, reconnect the battery. Carefully use the multimeter to check for the correct voltage at different points. For example, test the hot wire leading to the reverse light switch. Then, with the ignition on and the vehicle in reverse (ensure wheels are chocked and parking brake is engaged if testing from inside the vehicle), test the wire coming from the switch to confirm power is being sent to the lights. Ensure your readings align with the expected system voltage, typically 12V DC. This also helps confirm the integrity of any common terminal connections.

6. Make Secure Connections: When installing new components or repairing existing ones, ensure all electrical connections are clean, tight, and well-insulated. Use appropriate crimp connectors or solder connections for maximum reliability. For bulb connections, ensure the brass screw terminals are clean and free of corrosion for optimal electrical contact.

7. Test the System: After all connections are made and insulated, reconnect the battery, turn on the ignition, and engage reverse gear. Verify that your reverse lights illuminate correctly. Check both sides if applicable.

When testing with a multimeter, always test both voltage and continuity. Voltage checks confirm power is present, while continuity checks confirm an unbroken path for the current, helping you identify open circuits or faulty ground connections without needing power applied.

Common Issues & Troubleshooting with Reverse Lights

Even with a clear “diagram reverse light wire color”, issues can arise. Understanding common problems can help you quickly diagnose and resolve them, leveraging the diagram as your primary reference.

Frequent problems include reverse lights not working at all, only one light illuminating, or intermittent operation. The diagram helps immensely by allowing you to systematically trace the circuit. If neither light works, the problem likely lies upstream, affecting both lights – perhaps a blown fuse, a faulty reverse light switch, or a break in the main hot wire supplying the switch. A multimeter set to test voltage can quickly pinpoint where the power stops flowing.

If only one light is out, the issue is usually localized to that specific light’s branch of the circuit: a burnt-out bulb, a corroded socket (affecting the brass screw terminal or common terminal), or a damaged wire specific to that light. Using your multimeter to check for voltage at the bulb’s hot terminal and continuity to ground can help isolate the problem.

Warning signs to look for include flickering lights (often indicating a loose connection or dying bulb), a burning smell (pointing to an overloaded circuit or short), or repeated blown fuses (suggesting a short circuit or incorrect wire gauge). If you encounter persistent problems or are unsure about the diagnosis, it’s always best to seek professional help from a qualified automotive electrician. They have specialized tools and expertise to handle complex electrical diagnostics safely.

Tips & Best Practices for Reverse Light Wiring

Implementing a “diagram reverse light wire color” project correctly involves more than just understanding the connections; it also benefits from adherence to best practices for longevity and safety.

Use High-Quality Components: Opt for automotive-grade wire, connectors, and switches. Cheap components are a false economy, often leading to premature failure and more extensive repairs down the line. Ensure the wire gauge matches or exceeds the original specifications to handle the required current without overheating.

Secure and Insulate All Connections: Vibrations are constant in a vehicle, so ensure all crimps are strong and all soldered joints are solid. Use heat-shrink tubing over electrical tape for superior insulation and protection against moisture and abrasion. This prevents shorts and corrosion.

Proper Wire Routing and Management: Route wires away from hot engine components, sharp edges, and moving parts. Use zip ties or automotive wire loom to secure harnesses, preventing chafing and damage. Labeling wires, especially for custom installations, can save significant troubleshooting time later.

Regular Inspections: Periodically check your reverse lights for proper function. While doing so, visually inspect visible wiring for signs of wear, damage, or corrosion. Addressing small issues early can prevent larger, more complex problems.

* Understand Load and Fusing: If you are adding aftermarket reverse lights, ensure your existing circuit can handle the additional load. If not, you may need to install a separate fused circuit directly from the battery, controlled by a relay triggered by the existing reverse light wire. This prevents overloading the factory wiring and potentially blowing fuses or causing damage. Always ensure any new circuit is properly fused according to the wire gauge and component current draw.

When replacing a reverse light switch, test the new switch for continuity before installation. This simple step can save you hours of troubleshooting if you accidentally receive a faulty part. Also, apply dielectric grease to bulb sockets and electrical connectors to prevent corrosion, especially for outdoor components.

Frequently Asked Questions

What is reverse light wiring diagram?

A reverse light wiring diagram is a visual guide that illustrates the electrical connections and components of your vehicle’s reverse lighting system. It shows the path of electricity from the power source, through the switch, to the lights, indicating specific wire colors, including the hot wire and ground wire, for proper identification and maintenance.

How do you read reverse light wiring diagram?

To read a reverse light wiring diagram, start by identifying the power source and tracing the circuit path through fuses, switches, and the common terminal to the lights. Look for symbols representing components and note the wire color codes for the hot wire and ground wire. Understand current flow from positive to negative, typically represented by arrows.

What are the parts of reverse light wiring?

The main parts of reverse light wiring typically include the battery (power source), a fuse for protection, the reverse light switch, the actual reverse light bulbs, and the connecting wires. These wires comprise the hot wire carrying power and the ground wire completing the circuit. Some systems might also feature a common terminal or relay for control.

Why is the reverse light switch important?

The reverse light switch is important because it acts as the primary activator for the reverse lights, completing the circuit only when the vehicle is shifted into reverse gear. It ensures that the hot wire provides power to the lights precisely when needed, preventing constant illumination and informing others of the vehicle’s intended movement.

What is the difference between a hot wire and a ground wire?

The hot wire carries positive voltage from the power source to a component, supplying the electrical energy needed for operation. Conversely, the ground wire provides a path for the current to return to the battery’s negative terminal, completing the circuit. The ground wire is critical for circuit completion and safety, preventing electrical hazards.

How do I use reverse light wiring diagram?

Use a reverse light wiring diagram to pinpoint specific wire colors, trace the electrical flow from the common terminal, and locate components like the switch or fuse. It helps diagnose issues such as non-functional lights or incorrect installations, ensuring you connect the hot wire and ground wire correctly for safe and effective repairs or modifications to your reverse light system.