Diagram Reverse Light Wire Color: Identification Guide

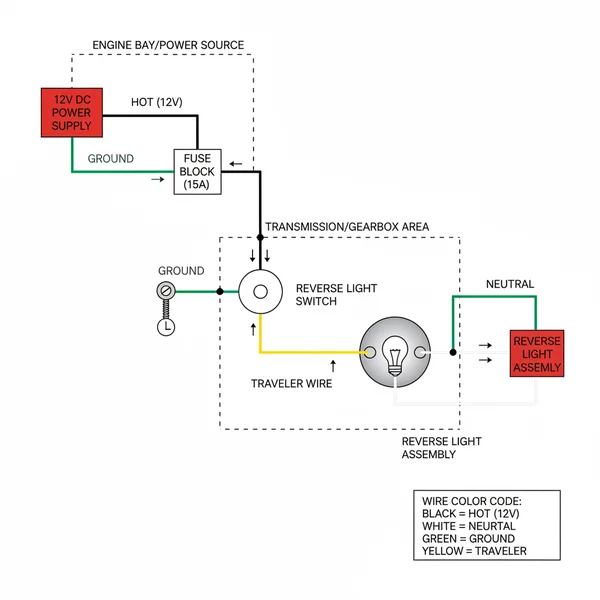

Reverse light wiring typically uses a specific color code to distinguish the hot wire from the ground wire. By following a wiring diagram, you can identify the common terminal and traveler wire configurations. This ensures current flows correctly from the switch to the lamps, maintaining a safe and functional backup lighting system.

📌 Key Takeaways

- The diagram helps identify specific wire colors for backup light circuits.

- Identification of the hot wire and neutral wire connections is vital.

- Always check the common terminal for proper power distribution.

- Use a multimeter to verify current flow before making permanent splices.

- Essential for troubleshooting dim bulbs or non-functional reverse lights.

Whether you are installing a modern backup camera, adding auxiliary LED pods for better nighttime visibility, or simply repairing a malfunctioning tail light assembly, identifying the correct diagram reverse light wire color is the most critical step of the process. For many DIY enthusiasts, diving into a vehicle’s electrical system can feel overwhelming due to the sheer volume of harnesses and connectors tucked away behind interior panels. Having a comprehensive wiring diagram eliminates the guesswork, preventing accidental short circuits that could damage sensitive electronic control modules. In this guide, we will break down the standard color schemes, the components of a backup light circuit, and the exact steps you need to take to safely tap into your vehicle’s power source. You will learn how to differentiate between a signal wire and a ground, how to measure voltage accurately, and how to ensure your new connections last for the life of the vehicle.

Understanding the Reverse Light Wiring Architecture

A standard automotive reverse light circuit is a relatively straightforward DC system, but its components can vary significantly between manufacturers. When looking at a diagram reverse light wire color schematic, the first thing to recognize is the flow of electricity. The circuit typically begins at the fuse box with a hot wire that carries 12-volt power to the transmission’s neutral safety switch or a dedicated reverse gear sensor. When you shift the vehicle into reverse, this switch closes, allowing the current to flow through a traveler wire toward the rear of the vehicle.

In many domestic vehicles, such as those from Ford or GM, you will often find a light green or dark blue wire acting as the primary power source for the backup lamps. Conversely, many European or Japanese imports utilize a red wire with a silver or white stripe. The diagram will also illustrate the ground wire, which completes the circuit by connecting the bulb socket to the vehicle’s chassis. While residential AC wiring uses a neutral wire to return current to the source, in automotive DC applications, the metal body of the car serves as this return path.

If you are working with an aftermarket relay to power high-draw accessories, your diagram might include a common terminal. This is the point where the primary power source meets the switching mechanism. Inside the relay, you will find connections for the coil and the switch contacts, often labeled with numbers like 85, 86, 87, and 30. Understanding these labels is essential because using the wrong gauge of wire or misidentifying the hot wire can lead to overheating. Most reverse circuits use 16 or 18-gauge wire, which is sufficient for standard incandescent bulbs but may need upgrading if you are installing high-output stadium-style reverse lights.

While wire colors vary by manufacturer, the physical location of the reverse wire is most commonly found in the driver-side kick panel or the main harness running along the door sills toward the trunk. Always consult a vehicle-specific pinout diagram before cutting any wires.

[DIAGRAM_PLACEHOLDER: A professional wiring schematic showing a 12V battery connected to a fuse, leading to a gear selector switch. From the switch, a “Reverse Signal Wire” (labeled with color variations) travels to the rear tail light assembly. The assembly shows a bulb connected to a black “Ground Wire” which terminates at a chassis ground point. A secondary branch shows a relay setup where the reverse wire triggers a “Common Terminal” to power an auxiliary LED light.]

Step-by-Step Guide to Identifying and Connecting the Reverse Wire

Navigating a complex wiring harness requires a methodical approach. Follow these steps to ensure you locate the correct diagram reverse light wire color and establish a secure, professional-grade connection.

- ✓ Multimeter or Test Light

- ✓ Wire Strippers and Crimping Tool

- ✓ Heat Shrink Tubing and Electrical Tape

- ✓ Vehicle-Specific Wiring Schematic

Never perform electrical work while the engine is running. When testing the reverse circuit, set the parking brake firmly and have an assistant sit in the vehicle with their foot on the brake to shift the gear selector while the engine is off (Key On, Engine Off mode).

1. Access the Rear Light Assembly: Open your trunk or tailgate and remove the access panels or screws holding the tail light housing in place. Gently pull the housing away from the body to reveal the bulb sockets and the wiring harness.

2. Identify the Bulb Socket: Look for the specific socket that houses the clear reverse light bulb. Count the wires leading into this socket. Usually, there are two: a colored power wire (the hot wire) and a black or brown ground wire.

3. Verify Voltage with a Multimeter: Turn the vehicle’s ignition to the “On” position without starting the engine. Set your multimeter to DC Voltage (20V range). Place the black probe on a clean metal part of the chassis (ground) and the red probe onto the terminal of the colored wire. With the car in Park, the reading should be 0V. Have your assistant shift into Reverse; the reading should jump to approximately 12.6V.

4. Locate the Wire in the Main Harness: If you are installing a backup camera at the front of the car, you will need to find this same wire in the driver-side kick panel. Use your diagram reverse light wire color guide to find the matching color in the large bundle of wires. Repeat the voltage test here to confirm it is the correct traveler wire.

5. Prepare the Connection: Once confirmed, use a “military splice” or a high-quality T-tap to connect your accessory wire. Avoid using cheap “scotchloks” as they can cut through the copper strands and cause resistance issues over time.

6. Secure the Ground: If your accessory requires its own ground, do not simply twist it around a brass screw. Use a ring terminal and find a factory ground bolt or drill a small hole into the chassis, sanding away the paint to ensure metal-to-metal contact.

7. Insulate and Test: Wrap all connections in heat shrink tubing or high-quality electrical tape. Reassemble the tail light housing and test the system one last time to ensure both the factory lights and your new accessories function perfectly.

Common Troubleshooting Issues

Even with a perfect diagram, electrical projects can run into snags. One of the most common issues is a “phantom voltage” reading. This occurs when a multimeter shows a small amount of voltage (1-3 volts) even when the reverse gear is not engaged. This is often caused by the vehicle’s computer sending low-voltage pulses to check if the bulbs are burnt out. In this case, you may need a relay to “clean” the signal for a backup camera.

Another frequent problem is a blown fuse immediately after installation. This usually indicates that the hot wire has come into contact with the chassis or that the total amperage of your new lights exceeds the factory fuse rating. Check the gauge of your wiring; if you are running multiple high-power lights off a single 18-gauge traveler wire, you are likely overloading the circuit. Always ensure your common terminal connections are tight, as a loose wire can create an arc, leading to heat damage or a fire.

If your reverse lights are dim after tapping into the wire, you are likely experiencing a voltage drop. Solve this by using the reverse light wire only as a “trigger” for a relay that pulls direct power from the battery via a fused 12-gauge hot wire.

Best Practices and Maintenance

When working with automotive wiring, longevity is just as important as initial functionality. Because the rear of a vehicle is constantly exposed to moisture, road salt, and vibrations, your connections must be weatherproof. Always use marine-grade heat shrink tubing that contains an internal adhesive; when heated, this adhesive melts and creates a waterproof seal around the wire splice.

For those using a terminal block or a custom switch panel, pay attention to the hardware. While a brass screw is excellent for conductivity, it can loosen over time due to road vibrations. Use a drop of thread-locker or a lock washer to keep your terminals secure. Additionally, always route your wires away from moving parts like the trunk hinges or hot components like the exhaust system. Use plastic loom or corrugated tubing to protect the harness from chafing against sharp metal edges of the bodywork.

Finally, document your work. If you used a specific diagram reverse light wire color that differed from the factory manual, or if you added a new fuse into an empty slot in the panel, write it down and keep it in the glove box. This will save you or a future mechanic hours of diagnostic time if a problem arises years down the road. High-quality components and a disciplined approach to the wiring process ensure that your vehicle’s electrical system remains safe and reliable for the long haul.

Frequently Asked Questions

What is diagram reverse light wire color?

A diagram reverse light wire color chart is a visual reference tool used to identify the specific insulation colors for electrical paths in a vehicle’s backup system. It helps technicians distinguish the hot wire providing power from the ground wire, ensuring the traveler wire delivers voltage to the bulbs only when in reverse.

How do you read diagram reverse light wire color?

To read the diagram, start by locating the power source and following the line to the switch. Look for labels indicating the common terminal and where the traveler wire connects to the bulbs. Pay attention to the legend for abbreviations denoting specific colors for the hot wire and the neutral wire.

What are the parts of diagram reverse light wire color?

The primary parts include the battery, the reverse light switch on the transmission, the wiring harness, and the bulb sockets. The diagram illustrates how the traveler wire links the switch to the bulbs, while the ground wire completes the circuit back to the chassis, often passing through a common terminal junction.

Why is common terminal important?

The common terminal is important because it acts as the central connection point for power distribution in many lighting circuits. In a reverse light setup, it ensures the hot wire is correctly routed through the switch. Without a secure connection at this terminal, the traveler wire may fail to receive necessary voltage.

What is the difference between traveler wire and hot wire?

The hot wire is the constant power source from the fuse box to the switch, while the traveler wire is the specific line that only carries current when the reverse gear is engaged. While both are part of the live circuit, the traveler wire’s state changes based on the transmission switch position.

How do I use diagram reverse light wire color?

Use the diagram by first matching the visual representations to the actual wiring harness in your vehicle. Identify the hot wire to test for voltage, then check the traveler wire for continuity to the lights. This systematic approach allows you to pinpoint breaks or shorts between the common terminal and bulbs.