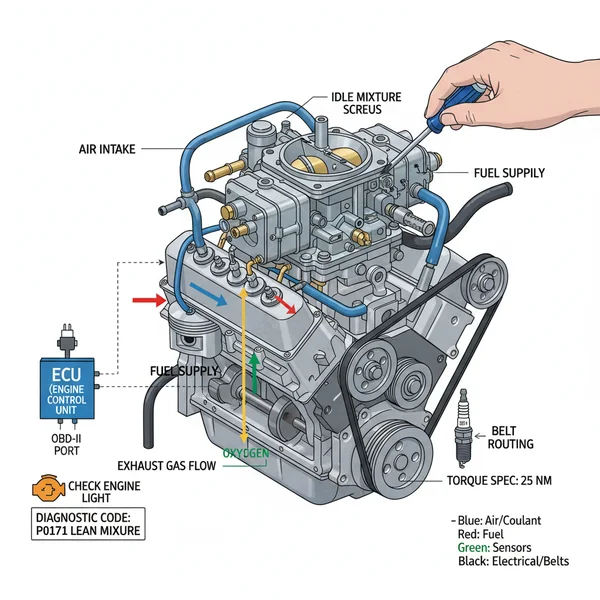

A carburetor mixture screw diagram illustrates the location of idle and high-speed needles. Adjusting these controls the air-fuel ratio. Turn screws inward to lean the mixture and outward to richen it until the engine runs smoothly without a check engine light or stalling, ensuring peak combustion efficiency.

📌 Key Takeaways

- Identifies the physical location of idle and high-speed adjustment screws

- The idle mixture screw is the most critical component for smooth low-RPM operation

- Avoid overtightening screws to prevent damaging the sensitive needle seats

- Adjust in small 1/8-turn increments and wait for the engine to stabilize

- Use this diagram when troubleshooting poor idle, stalling, or high fuel consumption

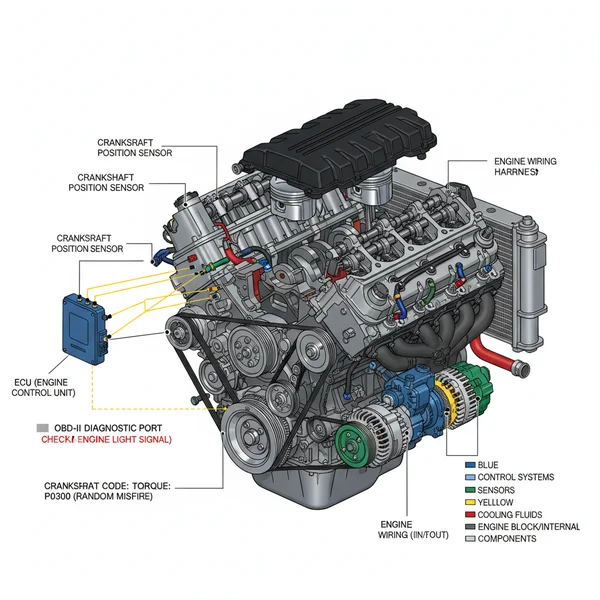

Achieving the perfect balance of air and fuel is the cornerstone of engine performance, yet it remains one of the most misunderstood tasks in classic automotive maintenance. Having a high-quality diagram how to adjust carburetor mixture screws is more than just a convenience; it is a critical roadmap that prevents costly errors. While modern vehicles rely on an ECU to manage these ratios automatically, vintage and performance engines require manual intervention. A proper diagram identifies the subtle differences between idle speed screws and idle mixture screws, ensuring you do not accidentally alter the wrong parameter. In this guide, you will learn how to interpret these diagrams, locate your adjustment points, and fine-tune your engine for maximum efficiency and throttle response.

A carburetor mixture screw typically regulates the amount of fuel entering the idle circuit. Turning the screw clockwise “leans” the mixture (less fuel), while turning it counter-clockwise “richens” it (more fuel).

The provided diagram serves as a comprehensive visual breakdown of the carburetor’s external and internal adjustment points. At first glance, the diagram highlights the “Idle Mixture Screw,” usually depicted with a tapered needle tip that fits into a precision-machined orifice. This screw is often located at the base of the carburetor body, near the mounting flange where the unit meets the intake manifold. The diagram utilizes color-coded pathways to show the flow of atmospheric air (blue) and raw fuel (green). Where these two colors merge into a yellowish gradient represents the “pre-mix” that enters the engine cylinders during idle.

Another key component featured in the diagram is the “Idle Speed Screw,” which is frequently confused with the mixture screw. The diagram distinguishes these by showing the speed screw making physical contact with the throttle linkage arm, whereas the mixture screw is recessed into the carburetor casting. You will also notice the “Transfer Slots” and “Idle Ports” illustrated in a cross-section view. These are vital for understanding how the fuel reaches the venturi. In multi-barrel configurations, such as a dual-jet or four-barrel carburetor, the diagram will show two or more mixture screws. These must be adjusted in synchronization to ensure each side of the engine receives an equal volume of the air-fuel charge. Variations exist between brands like Holley, Edelbrock, and Rochester; however, the fundamental physics of the needle-and-seat illustrated here remain consistent across most mechanical fuel systems.

[DIAGRAM_PLACEHOLDER: A detailed cross-section of a carburetor showing the idle mixture screw, throttle plate, and internal fuel passages. Labels indicate the Idle Mixture Screw, Idle Speed Screw, and the Fuel Bowl.]

Never force the mixture screw into its seat. The needle is made of soft brass and can be easily deformed, which will permanently ruin the carburetor’s ability to idle smoothly.

To effectively use the diagram how to adjust carburetor mixture screws, follow these sequential steps to ensure your engine runs at peak performance without the need for a modern diagnostic code reader.

- ✓ Step 1: Preliminary Inspection and Warm-up – Before touching the screws, ensure your engine is at full operating temperature. Monitor your temperature gauge to verify steady coolant flow through the radiator. Check the tension of your accessory belt; a slipping belt can cause erratic alternator output, which may mimic a poor idle.

- ✓ Step 2: Check Mechanical Timing – Verify that your timing chain is not stretched and that your ignition timing is set to factory specifications. A carburetor cannot be properly tuned if the mechanical timing is retarded or advanced beyond limits.

- ✓ Step 3: Locate the Mixture Screws – Using the diagram as a guide, find the idle mixture screws on the base of the carburetor. If your vehicle is a transition model between carburation and early fuel injection, ensure there is no check engine light triggered by other sensors that could interfere with your tuning.

- ✓ Step 4: Establish a Baseline – With the engine off, gently turn the mixture screws clockwise until they lightly seat. Do not apply pressure. Then, back them out exactly 1.5 to 2 full turns. This provides a “safe” starting point that will allow the engine to run while you fine-tune.

- ✓ Step 5: Adjust for Highest RPM – Start the engine. Using a tachometer, turn one mixture screw inward (clockwise) by 1/8th of a turn at a time. Listen for the engine RPM to drop or stumble. Once it stumbles, turn it back out (counter-clockwise) until you find the point where the RPM stays at its highest, steadiest level.

- ✓ Step 6: Balance the Barrels – If your carburetor has two mixture screws, repeat the process for the second screw. You may need to go back and forth between the two screws several times to ensure they are balanced and the engine is pulling the maximum vacuum possible.

- ✓ Step 7: Final Idle Speed Adjustment – Now that the mixture is optimized, your idle RPM might be higher than desired. Use the idle speed screw (identified in the diagram) to bring the RPM back down to the manufacturer’s recommended setting.

Even with a perfect diagram, troubleshooting a carburetor can be tricky because mechanical failures often mask themselves as adjustment issues. One of the most frequent problems is a vacuum leak. If you turn the mixture screw all the way in and the engine does not stall, you likely have air entering the system from a source other than the carburetor throat. This often happens if the mounting bolts are not tightened to the correct torque spec, causing the base gasket to fail.

Another common issue is “off-idle stumble.” If the engine idles well but dies when you press the gas pedal, the diagram can help you identify if the accelerator pump or the transition slots are clogged. Unlike modern cars where an OBD-II scanner would provide a diagnostic code for a lean condition, a carburetor requires you to read the spark plugs. White, blistered plugs indicate a lean mixture, while black, sooty plugs indicate a rich mixture. If adjustments to the screws do not change the engine’s behavior, the internal needle valves may be stuck, or the fuel filter could be restricted. If the engine continues to run poorly despite following the diagram, it may be time to seek professional help to check for internal manifold leaks or a worn timing chain that has jumped a tooth.

Use a vacuum gauge connected to a manifold vacuum port while adjusting. The goal is to achieve the highest, steadiest vacuum reading on the gauge. This is far more accurate than adjusting by ear alone.

To maintain your carburetor’s performance over time, follow these best practices. First, always ensure your fuel is fresh and treated with a stabilizer if the vehicle sits for long periods. Modern ethanol fuels can degrade rubber components inside older carburetors, leading to “gumming” of the precision orifices shown in your diagram. Secondly, check your air filter regularly. A clogged filter restricts air and creates a “choke” effect, making your carefully adjusted mixture far too rich.

When performing maintenance, always verify the torque spec of the carburetor mounting nuts. Vibration from the engine can loosen these over time, leading to the vacuum leaks mentioned earlier. Additionally, keep an eye on your accessory belt and cooling system; an engine that runs too hot due to poor coolant flow will cause the fuel in the carburetor bowl to boil (vapor lock), rendering your mixture adjustments useless. Finally, consider high-quality components when rebuilding. Using genuine needle and seat kits ensures that the taper of the mixture screw matches the diagram’s specifications exactly, allowing for the most precise tuning possible. By combining the visual guidance of a diagram how to adjust carburetor mixture screws with disciplined maintenance, you can ensure your classic engine runs with the same reliability as a modern, computer-controlled vehicle.

Step-by-Step Guide to Understanding the Diagram How To Adjust Carburetor Mixture Screws: Diy Tuning

Identify the adjustment screws using the diagram to distinguish between the idle and high-speed needles.

Locate the screws on the side of the carburetor body, ensuring the engine is warm and off.

Understand how rotation affects the mixture; typically, clockwise turns lean the fuel while counter-clockwise turns richen it.

Connect a tachometer to monitor RPM changes as you slowly turn the screws in small increments.

Verify that the engine idles smoothly without hesitation, checking for any signs of flooding or lean surging.

Complete the process by ensuring no torque spec is exceeded on the delicate needle seats to prevent damage.

Frequently Asked Questions

What is diagram how to adjust carburetor mixture screws?

A carburetor mixture screw diagram is a visual map showing the placement of the idle-mixture and air-bleed screws. It helps mechanics identify which screw regulates fuel flow at specific RPM ranges. Unlike modern systems managed by an ECU, this manual adjustment is critical for maintaining the proper air-to-fuel ratio in vintage engines.

How do you read diagram how to adjust carburetor mixture screws?

To read the diagram, first identify the throttle body and intake manifold connections. Look for labeled points indicating the ‘L’ (Low speed) and ‘H’ (High speed) screws. The diagram often shows the direction of rotation, indicating that tightening usually leans the mixture while loosening it adds more fuel to the mix.

What are the parts of carburetor mixture screws?

The primary parts include the idle mixture screw, the high-speed jet, the throttle plate, and the needle valve. Some diagrams also include the choke assembly and float bowl. Understanding these components is essential because older vehicles lack an OBD-II port to provide real-time digital feedback on your fuel trims.

Why is the mixture screw important?

The mixture screw is vital because it determines engine idle quality and throttle response. If set incorrectly, the engine may misfire or stall. While a modern check engine light won’t illuminate on a classic car, poor adjustment results in carbon buildup, fouled spark plugs, and significantly reduced fuel economy over time.

What is the difference between idle and high-speed screws?

The difference between idle and high-speed screws lies in the RPM range they govern. The idle screw controls the air-fuel ratio when the throttle is closed, whereas the high-speed screw manages fuel during open-throttle operation. This manual tuning replaces the automated fuel mapping performed by a modern vehicle’s electronic ECU.

How do I use diagram how to adjust carburetor mixture screws?

Use the diagram to locate the adjustment points while the engine is at operating temperature. Follow the visual path to ensure you are turning the correct screw. Since there is no diagnostic code to guide you, rely on the diagram and engine sound to achieve a smooth and steady idle.