DC to DC Charger Wiring Diagram: Installation Instructions

A DC to DC charger wiring diagram illustrates how to connect an auxiliary battery to a vehicle alternator while maintaining electrical isolation. It shows the routing of the hot wire from the starter battery, through fuses, to the charger input, and finally to the house battery using a shared ground wire.

📌 Key Takeaways

- Illustrates the precise current flow from the vehicle alternator to the auxiliary battery.

- Crucial for identifying fuse placement to protect the system from overcurrent.

- Always ensure a robust ground wire connection for system efficiency and safety.

- Utilize an ignition trigger to prevent the auxiliary load from draining the starter battery.

- Essential for DIY camper van, boat, or overlanding vehicle power management.

Installing a dual battery system in your vehicle or camper requires precision, and having a clear dc to dc charger wiring diagram is the most critical tool in your arsenal. Whether you are upgrading an overlanding rig or setting up a van conversion, understanding how to route power from your alternator to a secondary battery ensures your equipment stays powered without draining your engine’s starting battery. This comprehensive guide will walk you through the complexities of DC-to-DC charging systems, explaining the specific electrical paths, the importance of wire thickness, and how to safely manage the flow of energy. By the end of this article, you will have the confidence to interpret a wiring schematic and execute a professional-grade installation that protects your vehicle’s sensitive electronics.

A DC-to-DC charger acts as a smart bridge between your vehicle’s alternator and an auxiliary battery, ensuring the house battery receives the correct charging profile regardless of alternator fluctuations.

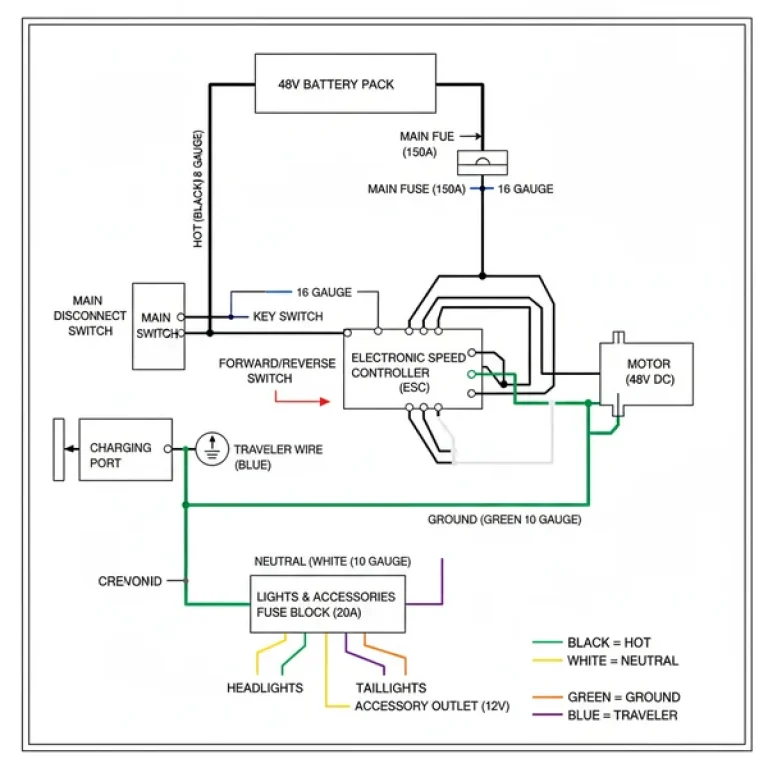

A standard dc to dc charger wiring diagram illustrates the relationship between four primary points: the starter battery, the charger unit, the auxiliary battery, and the vehicle chassis. Unlike a simple solenoid or isolator, the charger unit features sophisticated internal circuitry that boosts or regulates the incoming voltage to meet the specific needs of AGM, Lithium, or Gel batteries. The diagram typically displays a heavy-duty “hot wire” running from the positive terminal of the starter battery, through a high-amperage fuse, and into the input terminal of the charger.

The output side of the diagram shows a similar high-current cable extending to the auxiliary battery. A crucial element often highlighted is the common ground or negative return path. In many diagrams, you will see a ground wire connecting the charger and both batteries to a central point on the vehicle’s frame. For modern vehicles equipped with “smart” alternators, the diagram will also include a smaller-gauge ignition trigger wire. This signal wire tells the charger to begin pulling power only when the engine is running, preventing the system from accidentally depleting the starter battery when the vehicle is stationary. Labels on these diagrams are color-coded, usually with red representing the positive “hot” lines and black or blue representing the ground or common return lines. Understanding these labels is vital because, unlike household AC systems that might utilize a neutral wire or a traveler wire on a brass screw terminal, DC systems are strictly polarized and rely on massive current flow through specific gauges of copper.

[DIAGRAM_PLACEHOLDER: A detailed technical wiring schematic showing a 40A DC-to-DC charger connected to a starter battery (Input) and a Lithium auxiliary battery (Output), including fuse placements, ignition trigger wire for smart alternators, and a shared chassis ground.]

Always disconnect the negative terminals of all batteries before beginning installation to prevent short circuits and potential fire hazards.

Interpreting a dc to dc charger wiring diagram and translating it into a physical installation is a step-by-step process that demands attention to detail. Follow these steps to ensure a successful setup:

- Select the Correct Wire Gauge: Before touching any tools, determine the distance between your batteries. Because DC systems are sensitive to voltage drop, you must use a heavy-duty gauge wire (such as 6 AWG or 4 AWG) for the main power runs. If the wire is too thin, the charger will struggle to reach the target voltage.

- Mount the Charger: Find a dry, ventilated location for the charger. Ideally, it should be close to the auxiliary battery to minimize voltage drop on the output side. Secure it to a flat surface using the manufacturer-provided brackets.

- Install the Input Fuse: Place a high-quality fuse or circuit breaker as close as possible to the starter battery. This “hot wire” fuse protects the entire length of the cable running through your vehicle. If the cable chafes and shorts against the chassis, the fuse will blow, preventing a fire.

- Run the Main Power Cables: Route the positive cable from the starter battery fuse to the “Input” terminal on the DC-to-DC charger. Then, run a cable from the “Output” terminal of the charger to the positive terminal of your auxiliary battery. Ensure you use protective looming to prevent the insulation from rubbing against sharp metal edges.

- Establish the Common Ground: Connect the negative terminal of the auxiliary battery to the charger’s ground terminal. Then, run a heavy ground wire from the charger to a solid, paint-free point on the vehicle chassis. This completes the circuit. In DC electronics, this ground serves the purpose that a neutral wire would in an AC system, providing the return path for the current.

- Connect the Ignition Trigger (Optional): If your vehicle has a smart alternator (common in most vehicles built in the last decade), locate a fuse in your engine bay that is “hot” only when the ignition is on. Connect a thin 18-gauge wire from this fuse to the ignition signal terminal on the charger. This acts like a switch, similar to how a traveler wire operates in a light switch circuit, telling the charger when to activate.

- Final Battery Connections: Double-check all connections against your dc to dc charger wiring diagram. Ensure there are no loose strands of copper. Once verified, connect the positive leads to the batteries, followed by the negative leads.

- Testing: Start the vehicle and use a multimeter to check the voltage at the auxiliary battery. You should see the voltage rise as the charger enters its “Bulk” charging stage.

Use tinned copper lugs and marine-grade heat shrink for every connection. This prevents oxidation and ensures the longevity of your electrical system in harsh environments.

Even with a perfect dc to dc charger wiring diagram, issues can arise during or after installation. One of the most common problems is the charger failing to turn on. This is often caused by a faulty ignition trigger connection or a blown fuse near the starter battery. If the charger is on but the auxiliary battery isn’t reaching full charge, the culprit is usually voltage drop caused by an insufficient wire gauge.

Another frequent issue is overheating. If the charger is mounted in a confined space without airflow, it may throttle its output to protect its internal components. Look for warning lights on the unit; most modern chargers use a series of LED flashes to indicate specific errors like over-voltage, under-voltage, or short circuits. If you notice a burning smell or see smoke, immediately disconnect the system and check for a “hot wire” that might be shorting against the frame. While DIY installation is common, if you are uncomfortable identifying which terminal is the common terminal or struggle to find a reliable ground, it is wise to consult a professional auto electrician to avoid damaging your vehicle’s ECU.

- ✓ Voltage Drop: Caused by thin wires or poor connections.

- ✓ Grounding Issues: Ensure the chassis connection is bare metal, not painted.

- ✓ Blown Fuses: Check for shorts along the length of the positive cable.

To get the most out of your dual battery setup, follow these best practices. First, always match your charger’s settings to your battery chemistry. A Lithium (LiFePO4) battery requires a significantly different charging profile than a standard lead-acid battery. Using the wrong setting can shorten the battery’s lifespan or lead to safety risks. Second, keep your wiring organized. Use cable ties to secure wires away from moving parts or hot engine components.

In terms of cost-saving, while it may be tempting to use cheaper household wiring components, avoid them at all costs. Household items like a brass screw terminal or a neutral wire are designed for AC current and will not withstand the vibration and high-amperage demands of a vehicle’s DC system. Invest in high-quality, multi-strand automotive cable. Finally, conduct a bi-annual maintenance check. Over time, vibrations can loosen the common terminal connections or cause the ground wire to vibrate loose from the chassis. Tightening these connections and checking for corrosion ensures your dc to dc charger wiring diagram continues to reflect a healthy, working system.

A properly executed dc to dc charger wiring diagram is the foundation of a reliable mobile power system. By understanding how to manage voltage, choosing the correct wire gauge, and ensuring a solid ground, you transform your vehicle into a self-sustaining power station. Whether you are charging a small battery for a fridge or a massive lithium bank for an off-grid cabin, the principles remain the same: prioritize safety, use quality components, and always verify your connections against the schematic. With this guide, you are now ready to tackle your installation and enjoy the freedom of unlimited power on the open road.

Step-by-Step Guide to Understanding the Dc To Dc Charger Wiring Diagram: Installation Instructions

Identify the starter battery and auxiliary battery locations within your vehicle.

Locate the common terminal or chassis ground point to ensure a clean return path.

Understand how the hot wire routes through a high-amp fuse to the charger input.

Connect the charger to the ignition source via a signal or traveler wire.

Verify that the neutral wire or ground connections are secure and free of corrosion.

Complete the installation by checking battery voltage levels and testing the charger output.

Frequently Asked Questions

What is DC to DC charger wiring diagram?

A DC to DC charger wiring diagram is a visual roadmap for installing a battery-to-battery charging system. It depicts how current flows from a vehicle alternator to a secondary house battery. The diagram highlights essential connections for the hot wire and ground wire, ensuring the auxiliary system charges safely without depleting the main battery.

How do you read DC to DC charger wiring diagram?

To read this diagram, follow the lines from the input power source to the charger terminals. Identify symbols for fuses, breakers, and the common terminal. Look for the ignition trigger line, which acts like a traveler wire to signal the charger to start, and ensure the negative paths return to a central ground point.

What are the parts of DC to DC charger?

The primary parts include the charger unit, high-capacity fuses, a heavy-gauge hot wire for power transfer, and a dedicated ground wire. In complex setups involving AC-DC components, you might also see a neutral wire for the shore power side, along with a common terminal used for centralizing negative connections across the vehicle chassis.

Why is ground wire important?

The ground wire is critical because it completes the electrical circuit, allowing current to return from the auxiliary battery to the charger. Without a solid connection to a common terminal or the vehicle chassis, the charger cannot function efficiently, leading to voltage drops, heat buildup, and potential damage to expensive lithium batteries.

What is the difference between DC to DC and isolators?

A standard isolator simply connects batteries in parallel, while a DC to DC charger uses a hot wire to boost and regulate voltage for a specific battery profile. Unlike a simple traveler wire setup, the charger provides a multi-stage charge, ensuring the house battery reaches full capacity regardless of the alternator output.

How do I use DC to DC charger diagram?

Use the diagram by first mounting the charger in a ventilated area. Follow the schematic to run heavy-gauge wire from the starter battery to the charger input. Ensure the ground wire is bonded to the common terminal. Finally, connect the ignition trigger to ensure the charger only operates when the engine is running.