Craftsman Leaf Blower Fuel Line Diagram: Routing Guide

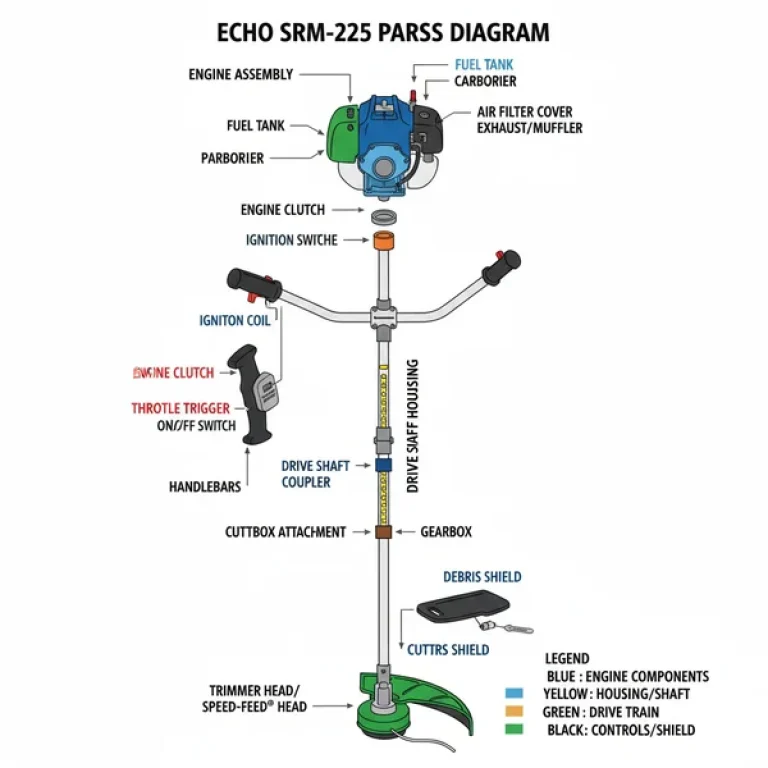

A Craftsman leaf blower fuel line diagram illustrates the specific path from the fuel tank filter to the carburetor and primer bulb. It identifies the thicker suction line that pulls fuel into the engine and the thinner return line that sends excess gas back to the tank, ensuring the engine remains primed and operational.

📌 Key Takeaways

- Identifies the correct ports for suction and return lines on the carburetor

- Locating the fuel filter is the most important step for engine startup

- Ensure airtight seals to prevent vacuum leaks and engine stalling

- Use high-quality Tygon tubing to prevent premature line degradation

- Refer to this diagram whenever the engine fails to prime or stay running

Restoring your outdoor power equipment to peak performance starts with understanding its internal plumbing. If you have ever felt overwhelmed by a tangle of translucent tubes after a carburetor cleaning, you are not alone. This guide provides a definitive look at the craftsman leaf blower fuel line diagram, ensuring you can route your lines with the precision of a master technician. Whether you are dealing with a handheld model or a powerful backpack unit, the fuel delivery system follows a specific logic that must be maintained for the engine to fire. By the end of this article, you will understand the flow from the fuel tank to the carburetor and back again, allowing you to troubleshoot starting issues and maintain your tool for years to come.

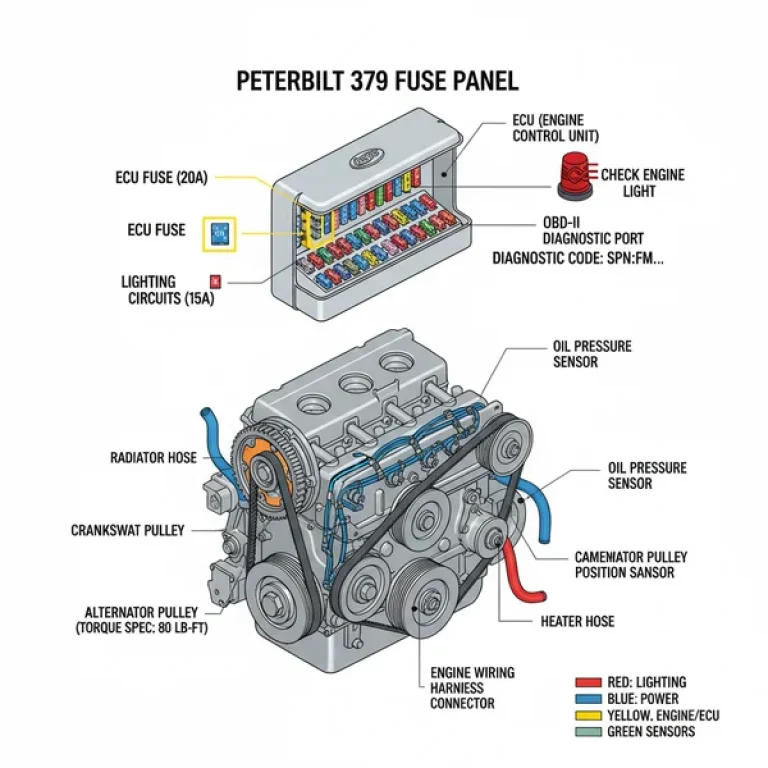

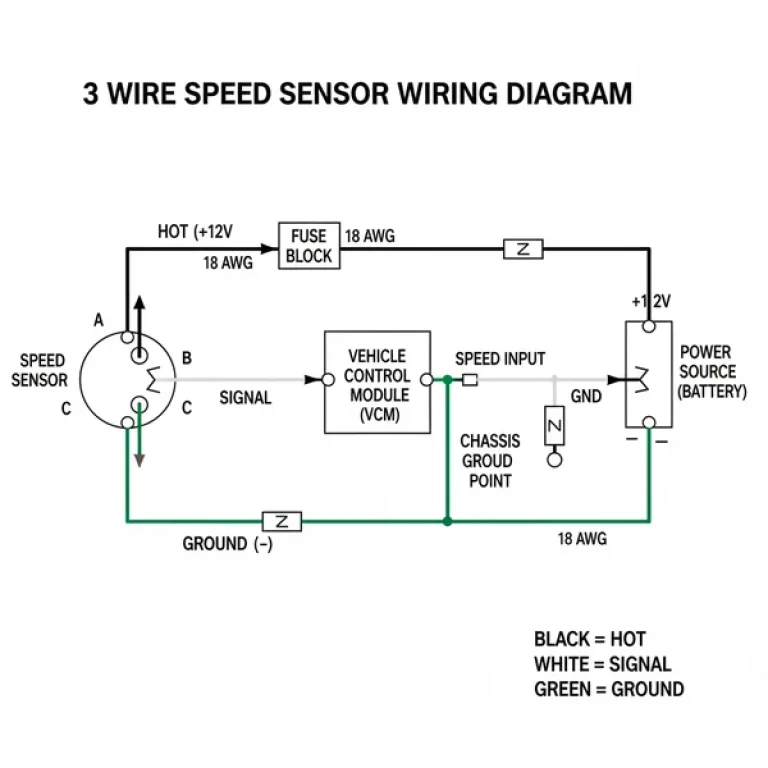

Understanding the components within a craftsman leaf blower fuel line diagram is essential because, unlike a modern vehicle equipped with an ECU and an OBD-II port, these small two-cycle engines do not provide digital feedback. The diagram typically illustrates a three-part closed-loop system: the suction (or supply) line, the return line, and the primer bulb assembly. The supply line is usually the thicker of the two lines and is equipped with a weighted fuel filter that sits at the bottom of the tank to ensure a steady stream of gasoline regardless of the blower’s angle.

The diagram highlights how the supply line connects directly to the intake nipple on the carburetor. From there, the fuel is pulled through the carburetor’s internal diaphragms. A second line then exits the carburetor and travels to the “suction” side of the primer bulb. When you press the bulb, it creates a vacuum that pulls fuel through the carburetor and then pushes the excess fuel back into the tank through the return line. This return line is typically shorter and does not require a filter. In the visual breakdown, you will notice that the primer bulb has two ports of different lengths; the longer port usually acts as the return to the tank, while the shorter port pulls from the carburetor. While this might seem simple compared to the coolant flow systems or the complex timing chain synchronization found in automotive engines, any air leak in this sequence will prevent the engine from starting.

Visualizing the path: Fuel Tank (Filter) -> Carburetor (Inlet) -> Carburetor (Outlet) -> Primer Bulb -> Fuel Tank (Return)

Most Craftsman blowers use two different sizes of Tygon tubing. The larger line is typically 3/32″ ID x 3/16″ OD for the main fuel supply, while the return line may be slightly smaller or the same, depending on the specific carburetor model.

Interpreting the craftsman leaf blower fuel line diagram and performing a replacement requires a methodical approach. Follow these steps to ensure a leak-free installation:

- ✓ Step 1: Preparation and Safety. Drain all remaining fuel from the tank into an approved container. Since you will be working near the spark plug, disconnect the lead to prevent accidental ignition. Clean the exterior of the fuel tank and carburetor to prevent dirt from entering the engine.

- ✓ Step 2: Access the Lines. Remove the air filter cover and the air filter. You may need to remove the carburetor mounting bolts. When doing so, keep track of the gaskets. Note that while small engines don’t have a specific torque spec as high as automotive head bolts, over-tightening can warp the plastic carburetor housing.

- ✓ Step 3: Identify Ports. Look at your primer bulb. Press it and feel for which port blows air out; this is the discharge port that returns fuel to the tank. The other port is the suction port that pulls fuel from the carburetor.

- ✓ Step 4: Install the Supply Line. Cut a new piece of fuel line at an angle to create a sharp point. Thread this through the fuel tank hole from the outside. Use a pair of long-reach needle-nose pliers or a wire hook to pull the line through the fuel fill neck. Once pulled out, cut the tip square and attach the fuel filter. Pull the line back until the filter sits at the bottom of the tank.

- ✓ Step 5: Connect to Carburetor. Connect the other end of the supply line to the main intake nipple on the carburetor. Ensure the fit is snug. If the line is too loose, air will enter the system, causing the engine to stall.

- ✓ Step 6: Route the Primer Lines. Connect a line from the carburetor’s “out” port to the “in” (suction) port of the primer bulb. Finally, connect a line from the “out” (discharge) port of the primer bulb back into the second hole in the fuel tank.

- ✓ Step 7: Testing. Add a small amount of fuel. Press the primer bulb 5-10 times. You should see fuel travel from the tank, through the carburetor, and into the bulb, eventually flowing back into the tank. If the bulb remains empty or feels “flat,” your lines are likely reversed.

In an automotive environment, a malfunction might trigger a check engine light or a diagnostic code like P0171 (lean mixture). In a leaf blower, you must rely on physical signs. Common issues include the primer bulb not filling with gas, fuel leaking from the tank grommet, or the engine dying when you apply throttle. These are almost always caused by brittle or cracked lines. Because gasoline with ethanol degrades rubber over time, these lines can “melt” or become hard as a rock.

Never use standard vacuum automotive hoses for a leaf blower. Only use fuel-resistant Tygon or viton tubing. Standard rubber hoses will dissolve when in contact with 2-cycle fuel mix, leading to a clogged carburetor and potential engine failure.

If you find that the engine starts but bogs down under load, check the weighted filter in the tank. If the supply line is too short, the filter may get stuck above the fuel level when you tilt the blower. Always ensure there is enough slack for the filter to move freely. If troubleshooting the fuel lines doesn’t solve the issue, you may need to check the spark arrestor screen in the muffler, which can carbon up and mimic the symptoms of a fuel delivery problem.

To get the most out of your equipment, consider these pro tips for maintenance. First, always use a fuel stabilizer if you plan to leave gas in the tank for more than 30 days. Much like how a car’s accessory belt requires periodic inspection to prevent snapped components, your fuel lines should be checked every season for flexibility.

When threading new lines through the tight holes in the fuel tank, lubricate the tip of the line with a tiny drop of 2-cycle oil. This allows the line to slide through the plastic seal without tearing or stretching, ensuring a vapor-tight fit.

Investing in high-quality, name-brand fuel lines will save you money in the long run. Cheap, unbranded clear tubing often turns yellow and cracks within a single season. If you find yourself frequently replacing lines, consider switching to ethanol-free canned fuel. While it is more expensive than pump gas, it contains no alcohol, which is the primary culprit behind the degradation of small engine fuel systems.

Mastering the craftsman leaf blower fuel line diagram is a vital skill for any DIY enthusiast. By understanding the flow of fuel and maintaining the integrity of the lines, you ensure that your blower is ready to work whenever you are. Whether you are performing a simple line swap or a full carburetor rebuild, keeping the suction and return paths clear is the secret to a reliable, hard-working machine. Proper maintenance today prevents the need for professional repairs tomorrow, keeping your yard clean and your tools in top shape.

Step-by-Step Guide to Understanding the Craftsman Leaf Blower Fuel Line Diagram: Routing Guide

Identify the two ports on the carburetor and the two holes in the fuel tank.

Locate the fuel filter and attach it to the longer suction line inside the tank.

Understand how the primer bulb pulls fuel through the carburetor rather than pushing it.

Connect the suction line to the intake port and the return line to the primer outlet.

Verify that the lines are not kinked and that the primer bulb fills with fuel when pressed.

Complete the assembly by tightening fasteners to the recommended torque spec for a leak-free seal.

Frequently Asked Questions

What is Craftsman leaf blower fuel line diagram?

A Craftsman leaf blower fuel line diagram is a visual map showing how fuel travels from the tank to the combustion chamber. Unlike automotive systems with an ECU, these small engines rely on physical routing. The diagram ensures you connect the suction and return lines to the correct carburetor ports for starting.

How do you read Craftsman leaf blower fuel line diagram?

To read the diagram, follow the lines starting at the fuel filter inside the tank. One line connects to the carburetor intake, while the other links the primer bulb to the return port. Understanding this flow is as critical as reading a diagnostic code on a modern vehicle’s dashboard.

What are the parts of Craftsman leaf blower fuel line?

The main parts include the fuel filter, the suction line, the return line, the primer bulb, and the carburetor. While you won’t find an OBD-II port here, these components work together to deliver the precise air-fuel mixture needed for the engine to ignite and maintain consistent operation.

Why is the fuel line important?

Correct fuel line installation is vital because an air leak or backwards connection prevents the engine from drawing fuel. Unlike a car’s check engine light, a leaf blower provides no electronic warning. Proper routing ensures the primer bulb functions and the engine receives constant fuel during high-RPM use.

What is the difference between suction and return lines?

The primary difference between the suction and return lines is their function and placement. The suction line features a fuel filter at the end inside the tank, while the return line is simply an open hose. Getting these swapped will prevent the engine from starting or cause immediate stalling.

How do I use Craftsman leaf blower fuel line diagram?

Use the diagram by matching the physical ports on your carburetor to the illustrated paths. Ensure you follow any specific torque spec for the carburetor mounting bolts to prevent vacuum leaks. This manual approach replaces the electronic diagnostics used in automotive repair to ensure your tool runs perfectly.