Club Car Precedent Wiring Diagram: Repair & Troubleshooting

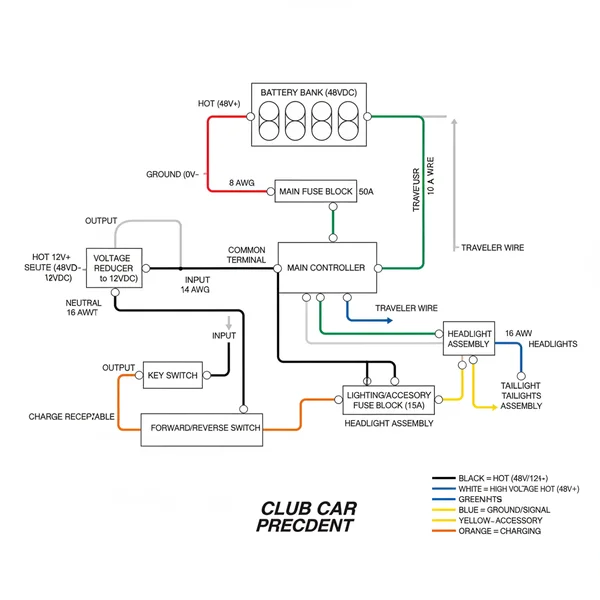

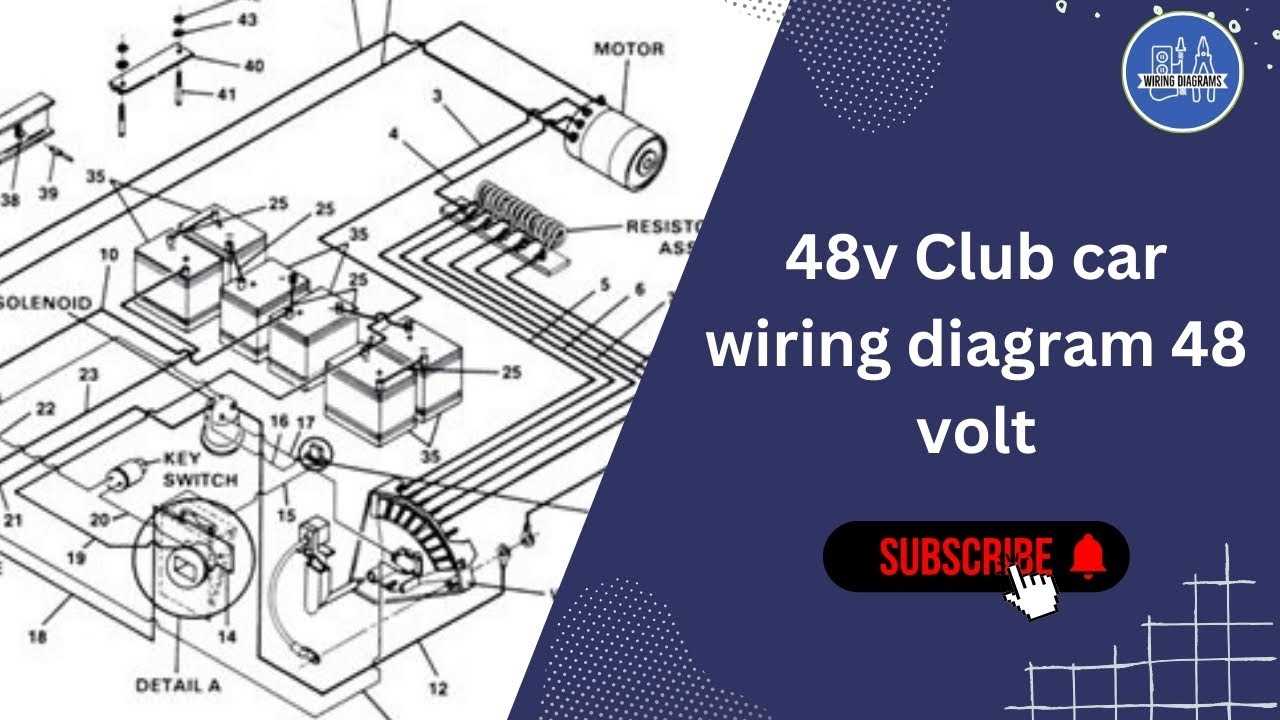

A Club Car Precedent wiring diagram provides a visual map of the 48V electrical system, including the battery bank, motor controller, and solenoid. By tracing the hot wire from the batteries through the common terminal on the solenoid, users can diagnose power delivery issues, identify faulty switches, and ensure proper grounding for safe operation.

📌 Key Takeaways

- Provides a roadmap for the 48V DC electrical system and control circuits

- Helps identify critical connections between the MCOR and speed controller

- Ensures safe battery series connections to prevent short circuits

- Simplifies the installation of aftermarket accessories like light kits

- Essential for diagnosing ‘no-go’ situations or intermittent power loss

Navigating the complex electrical architecture of a modern golf cart can feel like a daunting task, but having a reliable club car precedent wiring diagram is the single most important tool in your maintenance arsenal. Whether you are troubleshooting a sudden loss of power, installing a high-speed controller, or adding street-legal light kits, understanding how the current flows from your battery bank to the motor is essential for a successful project. This guide provides a comprehensive breakdown of the Precedent’s electrical system, covering everything from high-voltage propulsion circuits to low-voltage accessory lines, ensuring you have the knowledge to perform repairs safely and efficiently.

The Club Car Precedent typically utilizes a 48-volt DC system. While the chassis and body remained largely consistent over the years, the internal electronics transitioned through different drive systems, most notably the IQ, Excel, and Eric systems. Always verify your serial number to ensure your wiring matches the specific controller and motor configuration of your vehicle.

Understanding the Main Wiring Diagram Components

The primary club car precedent wiring diagram is a roadmap of the vehicle’s central nervous system. At its core, the diagram illustrates the relationship between the battery pack, the motor controller, the solenoid, and the motor itself. For the Precedent model, the battery configuration usually consists of six 8-volt batteries connected in series to achieve a total output of 48 volts. In the diagram, the hot wire (the main positive lead) typically originates from the positive terminal of the first battery in the sequence, while the ground wire (the main negative lead) connects to the last battery, often passing through an On-Board Computer (OBC) or a shunt depending on the model year.

The diagram also highlights the “control circuit,” which is a lower-amperage path that signals the cart to move. This includes the key switch, the Forward/Reverse switch, and the Multi-Step Potentiometer (MSP) or MCOR (Motor Controller Output Regulator). You will notice color-coded lines representing different signals: blue often handles the ignition signal, while orange and brown wires manage the directional signals sent to the controller. The controller acts as the brain, receiving these low-voltage inputs and then releasing high-amperage power to the motor’s common terminal and field windings. Visualizing these as two separate but intersecting systems—the high-power “muscle” and the low-power “nerves”—is the best way to interpret the schematics.

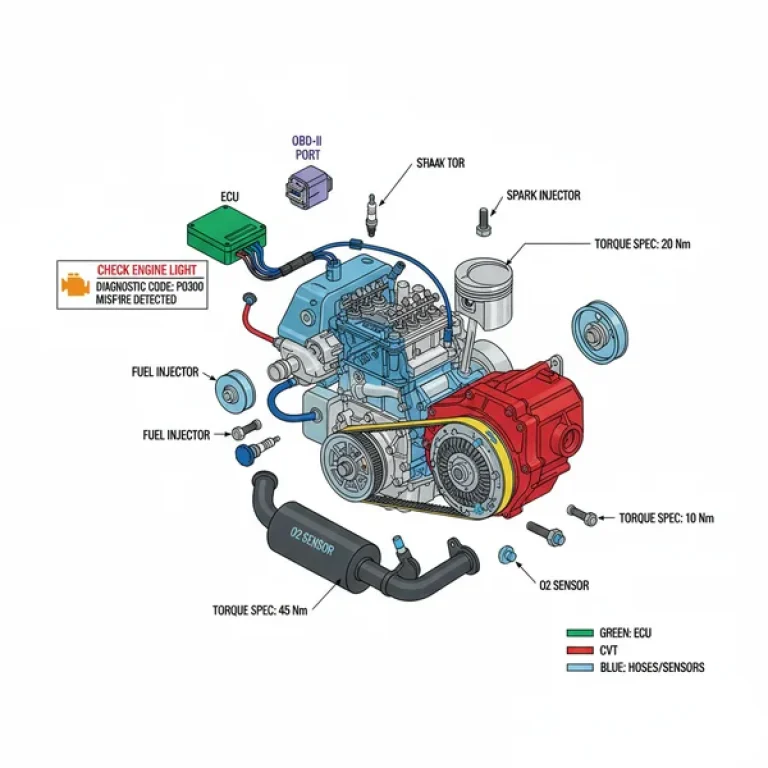

[DIAGRAM_PLACEHOLDER: CLUB CAR PRECEDENT WIRING LAYOUT]

(A visual map showing the 48V battery series, the 16-pin controller plug, the solenoid connections, and the motor terminal layout A1, A2, F1, F2)

Step-by-Step Guide to Reading and Implementing the Diagram

Before you begin any electrical work, it is imperative to follow a structured approach to prevent short circuits or damage to expensive electronic components. Follow these steps to interpret your club car precedent wiring diagram and apply it to your cart.

Always switch the cart to “TOW” mode and disconnect the main negative battery cable before touching any wiring. A 48V system carries enough energy to cause severe burns, weld tools to the frame, or destroy the motor controller instantly if shorted.

Step 1: Identify Your Drive System

Before looking at a specific diagram, determine if you have an IQ or Excel system. Look at the serial number; if it starts with “PQ” or “AQ,” you likely have an IQ system. This is crucial because the pin-out on the controller harness differs between these versions. The IQ system uses a different throttle signal than the Excel system, and following the wrong diagram will result in a cart that won’t move.

Step 2: Trace the High-Current Battery Loop

Locate the main hot wire on your diagram. This should be a heavy gauge cable, usually 4 or 6 AWG, running from the main positive battery terminal to one side of the large solenoid posts. From the other side of the solenoid, a cable runs to the “B+” terminal on the controller. Ensuring these high-current paths are clean and tight is the first step in any wiring project.

Step 3: Connect the Solenoid Control Wires

The solenoid has two large posts and two small posts. On the diagram, the small posts receive the activation signal. One small post is usually connected to a neutral wire or ground side of the circuit, while the other receives 48V when the key is on and the pedal is pressed. If your diagram shows a diode across these small terminals, ensure the striped end faces the positive side.

Step 4: Map the Motor Terminals

The motor will have four main terminals labeled A1, A2, F1, and F2. Use the diagram to connect these to the corresponding ports on the controller. F1 and F2 are the field wires (usually thinner gauge), while A1 and A2 are the armature wires. Swapping these can cause the motor to run backward or cause the controller to enter a fault state.

Step 5: Wiring Accessories and Switches

If you are installing a light kit, you may encounter a brass screw on the back of the switch. This is often the terminal for the hot wire coming from your 12V reducer. In complex setups where lights are controlled from two different locations, you might even see a traveler wire configuration similar to home wiring, though this is rare in stock cart setups and usually limited to high-end custom builds. Ensure your 12V accessories are grounded back to a common bus bar rather than the 48V negative to prevent voltage imbalances.

Step 6: Verify the On-Board Computer (OBC) Connection

Most Precedents utilize an OBC to regulate charging. The wiring diagram will show a black wire passing through a hole in the OBC. This is the 10-gauge ground wire that allows the computer to sense how much energy has left the batteries. If this wire is bypassed or incorrectly mapped, your charger may fail to turn on or could overcharge your batteries.

Common Issues & Troubleshooting

When the reality of your cart’s wiring doesn’t seem to match the club car precedent wiring diagram, it usually points to a few common culprits. One of the most frequent issues is terminal corrosion. Because lead-acid batteries outgas, a thin layer of oxidation can build up on the brass screw connectors or battery posts, creating high resistance. This resistance drops the voltage delivered to the controller, leading to “shuddering” or a complete failure to launch.

- ✓ Solenoid Click but No Movement: This often indicates the high-current circuit is broken even though the control circuit is working. Check the large cables for internal breaks.

- ✓ Intermittent Power: Check the 16-pin connector on the controller. Pins can become loose or corroded, losing the signal from the Forward/Reverse switch.

- ✓ Reverse Works, Forward Doesn’t: This is a classic indicator of a failed microswitch or a loose wire at the Forward/Reverse housing. Use your diagram to identify the specific wire color for the “Forward” signal.

If you find that your batteries are fully charged but the cart won’t even click, look at the fuse located on the red wire coming off the charger receptacle. If this fuse is blown, the controller will never receive the “lockout” signal, which tells the cart it is safe to move because the charger is unplugged.

Tips & Best Practices for Wiring Success

Working on a club car precedent wiring diagram implementation requires precision and the right materials. To ensure your cart remains reliable for years to come, consider these professional tips:

When upgrading to a high-performance controller, always upgrade your battery cables to 4 AWG or 2 AWG. Stock 6 AWG cables act like a bottleneck, heating up and wasting energy when the motor calls for high amperage during hill climbs.

Always use marine-grade heat shrink tubing on any new connections. The environment under a golf cart seat is acidic and damp; standard electrical tape will eventually peel off, leading to shorts. When connecting wires to switches, ensure the brass screw terminals are tightened firmly but not over-torqued, as the plastic housings on many golf cart switches can crack under pressure.

If you are adding accessories like a radio or LED bars, do not tap into just two batteries to get 16 volts or one battery to get 8 volts. This creates an imbalance in the battery pack, causing some batteries to work harder than others, which significantly shortens the lifespan of the entire set. Instead, spend the extra money on a 48V-to-12V voltage reducer. This device draws evenly from the entire pack and provides a stable 12V hot wire and neutral wire for all your add-ons.

Finally, keep a laminated copy of your club car precedent wiring diagram under the seat or in the glove box. In the event of a breakdown on the trail or the course, having the schematic handy can be the difference between a quick five-minute fix and an expensive tow back to the garage. Regular inspection of the wire loom for rub points—especially where the harness passes near the suspension—will prevent most electrical “gremlins” before they start.

Frequently Asked Questions

What is Club Car Precedent wiring diagram?

A Club Car Precedent wiring diagram is a technical illustration showing how electrical components are interconnected. It details the paths for high-current battery cables and low-voltage signal wires. Technicians use it to locate specific connection points, understand circuit logic, and identify wire colors used throughout the vehicle’s electrical harness.

How do you read Club Car Precedent wiring diagram?

To read the diagram, start at the battery pack and follow the lines to the solenoid and controller. Identify symbols for switches, motors, and fuses. Use the color-coded key to match the lines on the page to the physical wires in the cart, paying attention to terminal labels and junctions.

What are the parts of Club Car Precedent?

Key electrical parts include the battery bank, motor controller, solenoid, and MCOR throttle sensor. The system also includes a key switch, a Forward/Reverse switch, and a charging receptacle. These components are linked by a main wiring harness that carries both power and control signals to operate the golf cart.

Why is traveler wire important?

In the context of multi-way switching or signal routing, a traveler wire ensures that the control signal reaches the intended terminal regardless of switch position. In golf cart applications, similar signal wires connect the direction selector to the controller, allowing the vehicle to toggle between forward and reverse modes smoothly.

What is the difference between hot wire and ground wire?

The hot wire carries positive 48V current from the battery to power the motor and accessories. The ground wire, or negative return, completes the circuit back to the battery pack. A neutral wire concept is rarely used in DC carts, but a solid ground is vital to prevent electrical arcing.

How do I use Club Car Precedent wiring diagram?

Use the diagram by matching the terminal numbers on the controller or solenoid to the schematic. If a component lacks power, trace the path back to the common terminal to find where the break occurs. This allows for precise troubleshooting with a multimeter without guessing which wire to test.