Chevy Truck Fuel Line Diagram: Routing and Replacement

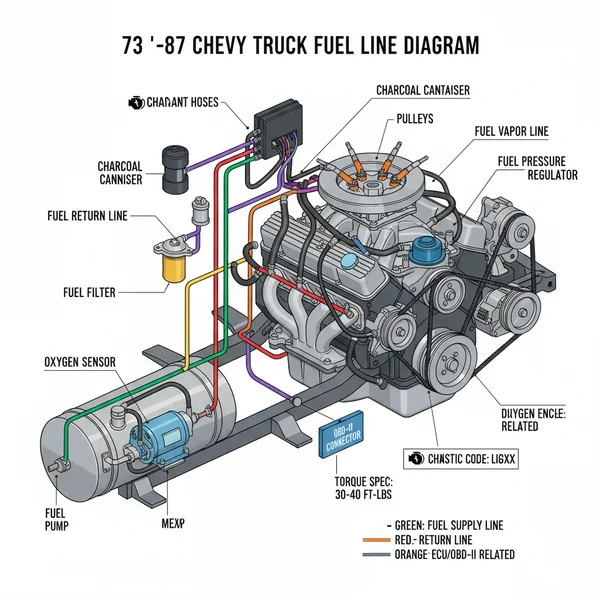

A Chevy truck fuel line diagram illustrates the path from the fuel tank to the engine, including the fuel pump, filter, and charcoal canister. It identifies high-pressure supply lines and low-pressure return lines, ensuring proper fuel delivery and preventing leaks that might trigger a check engine light on modern EFI conversions.

📌 Key Takeaways

- Visualizes the entire fuel delivery system from tank to carburetor or EFI

- Identify the main supply line versus the smaller vapor return line

- Always use fuel-rated hoses and clamps to prevent dangerous leaks

- Trace lines along the frame rail to check for rust or damage

- Essential for troubleshooting fuel starvation or pump failure

When restoring or maintaining a classic Square Body, having an accurate 73 – ’87 Chevy truck fuel line diagram is essential for ensuring both performance and safety. These iconic pickups, spanning over a decade of production, featured several different fuel delivery configurations ranging from basic mechanical carbureted setups to the more advanced Throttle Body Injection (TBI) systems introduced in the final year of the generation. Understanding the routing of supply lines, return lines, and vapor recovery systems is the first step in diagnosing fuel delivery issues or performing a complete frame-off restoration. This guide will walk you through the nuances of the fuel plumbing, the components involved, and how to successfully navigate the complex routing found in dual-tank configurations.

Understanding the Fuel System Architecture

The 73 – ’87 Chevy truck fuel line diagram typically illustrates a system that begins at the fuel tank—or tanks—located outside the frame rails. On many models, particularly the C/K 10 and 20 series, a dual-tank setup was a popular option. This configuration requires a motorized selector valve mounted to the inner frame rail, which is a common failure point. The diagram depicts the main supply line (usually 3/8 inch) and the return line (typically 5/16 inch), which help regulate pressure and prevent vapor lock by circulating cool fuel back to the tank.

In earlier models (1973-1986), the diagram focuses on a mechanical fuel pump mounted to the passenger side of the engine block, driven by a pushrod off the camshaft. However, for the 1987 model year, the system transitioned to an electric in-tank pump to support the TBI system. This 1987 version of the diagram is significantly different as it includes an ECU (Engine Control Unit) to manage fuel pulses and a high-pressure filter located along the frame rail. Regardless of the year, the lines are generally routed along the inside of the passenger-side frame rail to protect them from road debris and exhaust heat, eventually crossing over to the engine near the front crossmember.

[DIAGRAM_PLACEHOLDER – A detailed technical illustration showing the routing from the fuel tank selector valve, along the passenger frame rail, into the mechanical fuel pump or TBI unit, including vapor canister lines.]

The visual breakdown of the system also includes the charcoal canister (EVAP system), which is usually located in the driver-side front corner of the engine bay. Lines from the fuel tank vent are routed forward to this canister to manage fuel vapors. When looking at a 73 – ’87 Chevy truck fuel line diagram, you will notice three distinct lines on later models: the supply line, the return line, and the vent line. Properly identifying these is critical because reversing the supply and return lines can lead to a “no-start” condition or severe pressure issues within the tank.

For the 1987 model year, the fuel system is pressurized to roughly 9-13 PSI for TBI engines. Unlike earlier carbureted models that used low-pressure rubber hoses, the ’87 requires high-pressure rated fuel injection hose and O-ring style fittings to prevent leaks.

Step-by-Step Guide to Interpreting and Installing Fuel Lines

Navigating a 73 – ’87 Chevy truck fuel line diagram and physical installation requires a methodical approach. Follow these steps to ensure a leak-free and safe installation.

1. Identify Your Configuration: Before touching a wrench, determine if your truck is a single or dual-tank model and whether it is carbureted or TBI. Single-tank models have a direct run to the pump, while dual-tank models utilize a switching solenoid. Locate these components on your diagram to understand the flow direction.

2. Relieve System Pressure: For 1987 models with an ECU, you must relieve the pressure before disconnecting lines. You can do this by removing the fuel pump fuse and cranking the engine until it stalls. For older carbureted models, simply ensure the engine is cold.

3. Inspect the Frame Routing: Follow the lines from the tank forward. The lines should be secured with frame clips to prevent vibration. Vibration is the leading cause of “hard line” failure, as it can cause the metal to rub against the frame and develop pinhole leaks.

4. Disconnect and Measure: If replacing lines, use flare nut wrenches (also known as line wrenches) to avoid stripping the soft metal fittings on the fuel pump or selector valve. If you are fabricating new lines, use the old lines as a template for your tube bender to match the factory contours.

5. Install the Fuel Pump and Filter: When installing a mechanical pump, ensure the pushrod is coated in assembly lube and held in its uppermost position. Apply the correct torque spec to the mounting bolts (usually 15-20 ft-lbs) to prevent oil leaks from the mounting plate.

6. Route Near the Engine: Be extremely careful when routing lines near the front of the engine. Ensure the lines clear the accessory belt and the timing chain cover. Heat is the enemy of fuel; keep lines away from the exhaust manifold to prevent “vapor lock,” a condition where fuel boils in the line and stalls the engine.

7. Verify Connections and Test: Once all lines are tight, prime the system. On ’87 models, cycling the key will trigger the ECU to prime the pump. On older trucks, you may need to crank the engine or manually prime the carburetor. Check every fitting for moisture.

Never use generic “clear” vinyl tubing or low-pressure heater hoses for fuel lines. Gasoline will degrade these materials rapidly, leading to engine fires. Always use SAE J30R7 or J30R9 rated fuel hoses.

Common Issues and Troubleshooting

Owners of 1973-1987 Chevy trucks often face specific fuel-related hurdles. One of the most common issues is a failure of the fuel tank selector valve. If your truck runs out of gas while the gauge shows a half-tank, or if it refuses to draw from one side, the selector valve or its associated wiring is likely the culprit. The 73 – ’87 Chevy truck fuel line diagram helps you identify which port on the valve corresponds to which tank, allowing you to bypass the valve for testing purposes.

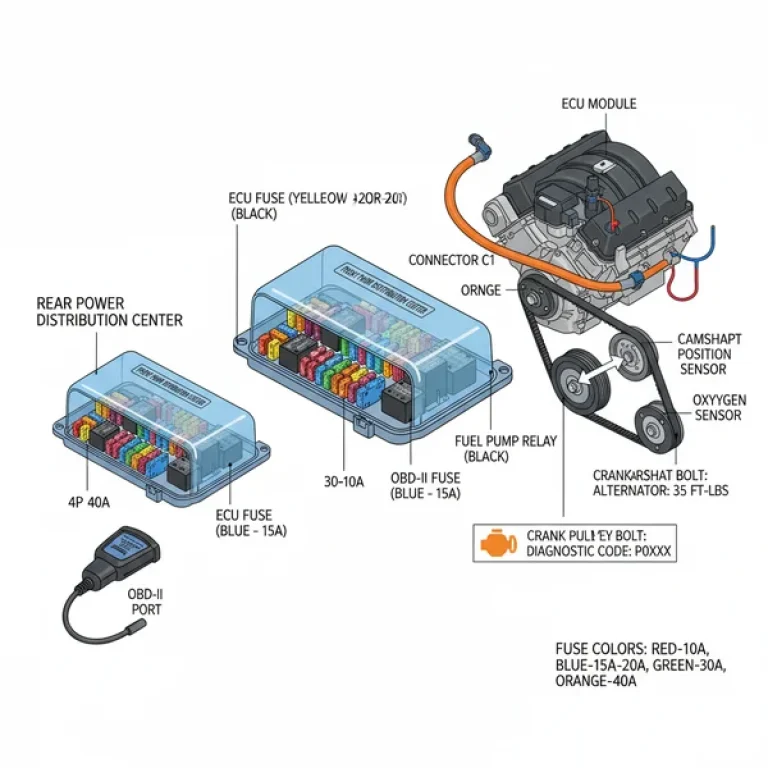

Another frequent problem involves the 1987 TBI models. While these trucks do not have a modern OBD-II port, they do have an ALDL (Assembly Line Data Link) connector. If your check engine light is on, you can jump pins A and B to flash a diagnostic code on the dashboard. Code 42 or 43 may indicate timing or electronic spark issues, but a “Lean” code often points directly back to a clogged fuel filter or a failing in-tank pump. For carbureted trucks, “vapor lock” is the primary concern, often caused by fuel lines being routed too close to the radiator or the coolant flow from the thermostat housing.

- ✓ Symptom: Engine stumbles under load. Fix: Check the frame-mounted fuel filter.

- ✓ Symptom: Gas smell near the cab. Fix: Inspect the rubber “S” hoses connecting the hard lines to the tank sending unit.

- ✓ Symptom: Hard starting when hot. Fix: Check for fuel line proximity to exhaust or verify the return line is not pinched.

Maintenance Tips and Best Practices

To keep your Chevy truck’s fuel system reliable for another fifty years, consider upgrading to stainless steel fuel lines. While more difficult to bend than original steel lines, they are virtually immune to the corrosion caused by modern ethanol-blended fuels. Ethanol is hygroscopic, meaning it attracts water, which can rust original lines from the inside out.

When replacing fuel lines, always replace the rubber grommets where the lines pass through the frame. This prevents the metal-on-metal contact that leads to leaks over time.

Maintenance should also extend to the rest of the engine bay. While you are working on the fuel lines, take a moment to inspect your accessory belt and the area around the timing chain cover for oil leaks. Oil can degrade rubber fuel hoses over time, making them soft and prone to bursting. Additionally, ensure that your coolant flow is efficient; a cooler engine bay reduces the chances of fuel vaporization issues.

If you are working on an ’87 TBI truck, remember that the fuel pump is cooled by the fuel in the tank. Habitually running the truck on “empty” can cause the pump to overheat and fail prematurely. Aim to keep at least a quarter-tank of fuel at all times. By following the 73 – ’87 Chevy truck fuel line diagram closely and using high-quality components, you can ensure your classic Chevy remains a dependable workhorse or a pristine showpiece for years to come. Whether you are chasing a diagnostic code or simply performing a weekend tune-up, a clear understanding of your fuel routing is your best tool in the garage.

Frequently Asked Questions

What is a Chevy truck fuel line diagram?

This diagram provides a visual map of the fuel routing, showing how gasoline travels from the fuel tank to the engine. It details the location of the supply line, return line, and vent lines, which is essential for maintaining proper fuel pressure and preventing leaks in classic truck restorations.

How do you read a Chevy truck fuel line diagram?

Start at the fuel tank and follow the thickest line, which is the supply line, toward the fuel pump and engine. Thinner lines represent return or vapor lines going to the charcoal canister. Identifying these pathways ensures you do not cross lines during a fuel pump or filter replacement.

What are the parts of a Chevy truck fuel system?

The system consists of the fuel tank, sending unit, supply and return lines, fuel filter, and the fuel pump. On modern engine conversions, these components interface with an ECU. Understanding these parts helps you diagnose delivery issues and ensure every connection meets the required torque spec for safety.

Why is the charcoal canister important?

The charcoal canister is a vital part of the evaporative emission system, capturing fuel vapors before they escape into the atmosphere. While classic trucks lack an OBD-II port, maintaining this component prevents heavy fuel smells and ensures the vent lines identified in the diagram function correctly for tank venting.

What is the difference between supply and return lines?

The supply line is larger and carries pressurized fuel from the tank to the engine for combustion. The return line is smaller and sends excess fuel back to the tank to regulate pressure. Correct identification is crucial for performance and prevents triggering a diagnostic code on EFI-swapped vehicle setups.

How do I use a Chevy truck fuel line diagram?

Use the diagram to trace the physical path of lines along the frame rail during a safety inspection. It helps you locate where to install inline filters and identify which lines to disconnect when removing the tank. This visual guide is indispensable for ensuring the fuel system functions without leaks.