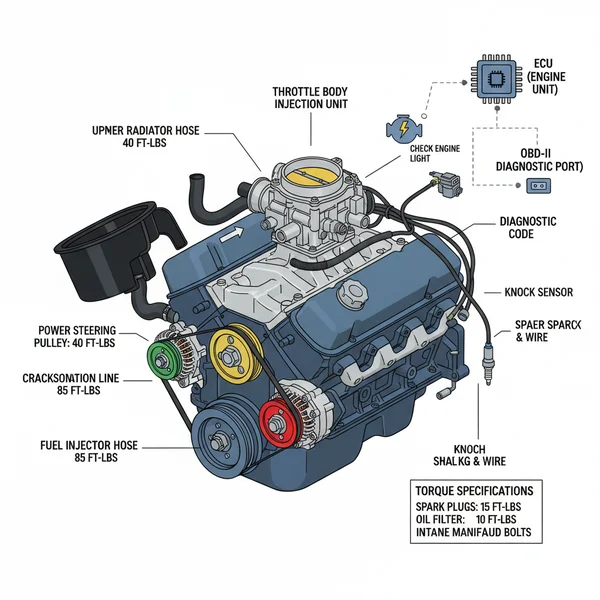

Chevy 350 TBI Engine Diagram: Troubleshooting & Assembly

A Chevy 350 TBI engine diagram illustrates the fuel injection layout, vacuum lines, and electrical sensors. It helps mechanics identify components like the injectors, throttle body, and distributors. Use it to troubleshoot a check engine light by locating the specific sensors sending data to the ECU for proper engine performance.

📌 Key Takeaways

- Provides a visual map for fuel delivery and vacuum routing.

- Crucial for identifying the throttle body and fuel injector placement.

- Always verify sensor ground connections for electrical stability.

- Use it to reference specific component locations for routine maintenance.

- Essential for diagnosing sensor failures or complex vacuum leaks.

The Chevrolet 350 Throttle Body Injection (TBI) engine represents a pivotal era in automotive engineering, bridging the gap between classic carbureted muscle and modern electronic fuel injection. For DIY mechanics and restoration enthusiasts, having a reliable chevy 350 tbi engine diagram is essential for navigating the complex web of vacuum lines, sensors, and electrical connections that define this powerplant. This comprehensive guide provides a detailed breakdown of the 5.7L TBI architecture, explaining how each component interacts to maintain idle quality, fuel efficiency, and reliability. By the end of this article, you will be able to identify every major sensor, understand the internal cooling and timing mechanisms, and troubleshoot common performance issues with precision.

Understanding the Chevy 350 TBI Architecture

The chevy 350 tbi engine diagram typically highlights the transition from mechanical fuel delivery to an electronically controlled system. Unlike multi-port injection systems where each cylinder has its own injector, the TBI system utilizes a dual-injector unit mounted atop the intake manifold, resembling a traditional carburetor in appearance but functioning through an Engine Control Unit (ECU). The diagram serves as a map for the three primary subsystems: fuel delivery, air intake, and the electronic sensor array.

At the heart of the diagram is the throttle body assembly itself. This unit houses two fuel injectors that spray a finely atomized mist into the bores of the intake manifold. Flanking the throttle body are the Idle Air Control (IAC) valve and the Throttle Position Sensor (TPS). The IAC valve is a stepper motor that manages the engine’s idle speed by bypassing air around the throttle plates, while the TPS tells the ECU exactly how far the driver has pressed the accelerator.

Visualizing the vacuum routing is perhaps the most critical aspect of the diagram. The 350 TBI relies heavily on vacuum signals to operate the Exhaust Gas Recirculation (EGR) valve and the Charcoal Canister for emissions control. A leak in any of these lines, often represented by thin black or color-coded lines in a technical schematic, can lead to a rough idle or a “check engine light” event. Furthermore, the diagram illustrates the location of the Manifold Absolute Pressure (MAP) sensor, which is usually mounted on a bracket near the rear of the intake manifold or on the firewall. This sensor is the “brain” that measures engine load, allowing the ECU to adjust fuel trim and spark timing dynamically.

Most Chevy 350 TBI engines produced between the mid-1980s and mid-1990s utilize an OBD-I diagnostic system. While similar to the modern OBD-II protocol found in later vehicles, retrieving a diagnostic code from an OBD-I system often requires a specific jumper wire or a specialized scanner capable of reading the ALDL (Assembly Line Diagnostic Link) port.

How to Interpret and Use the Engine Diagram

Reading a chevy 350 tbi engine diagram requires a systematic approach. Whether you are performing a simple tune-up or a complex timing chain replacement, following these steps ensures you don’t miss critical connections or specifications.

- Identify the Fuel Circuit: Start by locating the fuel inlet and return lines. On the 350 TBI, these are metal lines that enter the rear of the throttle body. The diagram will show the fuel pressure regulator integrated into the back of the TBI unit. Ensuring these lines are correctly seated is vital for fire safety and fuel pressure stability.

- Locate the Electronic Sensors: Use the diagram to find the Coolant Temperature Sensor (CTS), typically located on the front of the intake manifold near the thermostat housing. This sensor is crucial because it tells the ECU when to exit “Open Loop” mode and enter “Closed Loop” mode for better fuel economy.

- Trace the Vacuum Schematic: Follow the lines from the TBI base to the EGR valve, the PCV valve (located in the valve cover), and the MAP sensor. A high-quality diagram will distinguish between “Ported Vacuum” and “Manifold Vacuum,” which is essential for correct emissions equipment operation.

- Analyze the Accessory Belt Path: The front of the engine diagram will show the serpentine accessory belt routing. Ensure the belt passes over the alternator, power steering pump, air conditioning compressor, and water pump in the correct orientation. Incorrect routing can lead to reverse water pump rotation and immediate overheating.

- Examine the Ignition System: Locate the HEI (High Energy Ignition) distributor at the rear of the engine block. The diagram will show the firing order (1-8-4-3-6-5-7-2) and the routing for the spark plug wires. Correct wire management prevents inductive crossfire, which can cause engine hesitation.

- Verify Ground Connections: Electronic fuel injection is highly sensitive to electrical “noise.” The diagram should indicate the main engine grounds, usually located on the back of the cylinder heads or near the thermostat housing. Clean grounds are non-negotiable for a healthy ECU signal.

When working with the fuel system on a 350 TBI, always depressurize the lines first. Even after the engine is off, the TBI injectors and lines can hold residual pressure. Failure to do so can result in fuel spraying onto hot engine components or into your eyes.

Troubleshooting Common TBI Issues

Even with a perfect chevy 350 tbi engine diagram in hand, problems can arise. One of the most frequent complaints is a stumbling idle or a sudden check engine light. Using the diagram to locate the diagnostic port is your first step. By flashing the “diagnostic code” through the dashboard light, you can identify if a sensor like the Oxygen (O2) sensor or the MAP sensor has failed.

Vacuum leaks are the “silent killers” of TBI performance. Over time, the rubber lines shown in your diagram can become brittle and crack. If your engine is searching for a steady idle, use a small amount of carburetor cleaner to spray around the base of the throttle body and the vacuum ports indicated on the diagram. If the engine RPM changes, you’ve found your leak.

Another common issue involves the coolant flow and its effect on the ECU. If the thermostat sticks open, the engine never reaches the proper operating temperature. The CTS will continue to send a “cold” signal to the ECU, causing the injectors to dump excess fuel, mimicking a rich-running carburetor. Referencing your diagram to find and test the CTS with a multimeter can save you hundreds of dollars in unnecessary part replacements.

Best Practices and Maintenance Tips

To keep your Chevy 350 TBI running for another few hundred thousand miles, adherence to specific maintenance standards is required. One of the most overlooked areas is the timing chain. While the TBI system handles fuel and spark electronically, the mechanical link between the crankshaft and camshaft can stretch over time.

- ✓ Check the Timing Chain: Every 100,000 miles, check for excessive play in the timing chain to ensure the valve timing aligns with the ECU’s spark commands.

- ✓ Monitor Torque Specs: When replacing an intake manifold or throttle body gasket, always follow the specific torque spec sequence. Over-tightening can warp the aluminum TBI housing, leading to permanent vacuum leaks.

- ✓ Clean the IAC Passages: Carbon buildup in the IAC passage is a leading cause of stalling. Use a dedicated throttle body cleaner to keep this area clear.

- ✓ Inspect the Accessory Belt: A squealing accessory belt is often a sign of a failing tensioner or a misaligned pulley. Refer to your diagram to ensure the belt is seated perfectly in the grooves.

If you are experiencing intermittent power loss, check the ignition module inside the distributor. These modules are known to fail due to heat soak. Applying a fresh layer of thermal grease between the module and the distributor base (as shown in detailed ignition diagrams) can significantly extend the life of the component.

The Chevy 350 TBI remains one of the most user-friendly engines for those looking to learn the ropes of electronic fuel injection. By utilizing a comprehensive chevy 350 tbi engine diagram, you transform a confusing mess of wires and hoses into a logical, high-functioning machine. Remember that while the technology may seem dated compared to modern direct-injection systems, the principles of air, fuel, and spark remain the same. Keep your sensors clean, your vacuum lines tight, and your timing accurate, and this legendary small-block will continue to provide reliable power for years to come. Whether you are deciphering a diagnostic code or replacing a worn accessory belt, let the diagram be your ultimate guide to automotive success.

Step-by-Step Guide to Understanding the Chevy 350 Tbi Engine Diagram: Troubleshooting & Assembly

Identify the throttle body assembly at the center of the intake manifold to establish a reference point.

Locate the dual fuel injectors and the electrical harness that connects them to the main engine ECU.

Understand how the vacuum lines route from the TBI base to the EGR valve and charcoal canister.

Connect any disconnected sensors or vacuum lines according to the specific path outlined in the technical diagram.

Verify that every bolt is tightened to the manufacturer’s recommended torque spec to ensure an airtight seal.

Complete the process by scanning for any active diagnostic code if the check engine light remains illuminated.

Frequently Asked Questions

What is a Chevy 350 TBI engine diagram?

A Chevy 350 TBI engine diagram is a visual map showing the throttle body injection system, wiring, and vacuum hose routing. It identifies how the ECU manages fuel delivery through dual injectors. This diagram is essential for owners of late-80s and early-90s GM trucks needing to visualize complex engine layouts.

How do you read a Chevy 350 TBI engine diagram?

To read the diagram, start by locating the central throttle body unit and follow the lines to various sensors. Pay attention to labels for vacuum ports, electrical connectors, and fluid paths. Understanding these symbols helps you trace faults when a check engine light appears or when checking a diagnostic code.

What are the parts of a Chevy 350 TBI engine?

The primary parts include the throttle body housing, dual fuel injectors, fuel pressure regulator, and Idle Air Control valve. External components shown include the MAP sensor, oxygen sensor, and coolant temperature sensor. These sensors feed data to the ECU to ensure the engine meets the factory torque spec requirements.

Why is the ECU important in a 350 TBI system?

The ECU is the brain of the TBI system, controlling fuel timing and air-to-fuel ratios based on sensor input. It monitors for malfunctions and triggers a diagnostic code if parameters fall outside normal ranges. Without a functioning ECU, the 350 TBI engine cannot maintain idle or achieve efficient combustion.

What is the difference between TBI and OBD-II?

The main difference lies in the diagnostic architecture; most 350 TBI engines use the older OBD-I system rather than the modern OBD-II standard. While OBD-II offers standardized ports and detailed data, TBI systems often require jumping pins on an ALDL connector to flash codes via the check engine light.

How do I use the Chevy 350 TBI engine diagram?

Use the diagram to verify component placement during a rebuild or when troubleshooting performance issues. It helps you identify which vacuum line belongs to which port and ensures electrical connectors are properly seated. Always consult the diagram to find the correct torque spec for bolts to prevent vacuum leaks.