Bypass Heater Control Valve Diagram: Installation & Flow

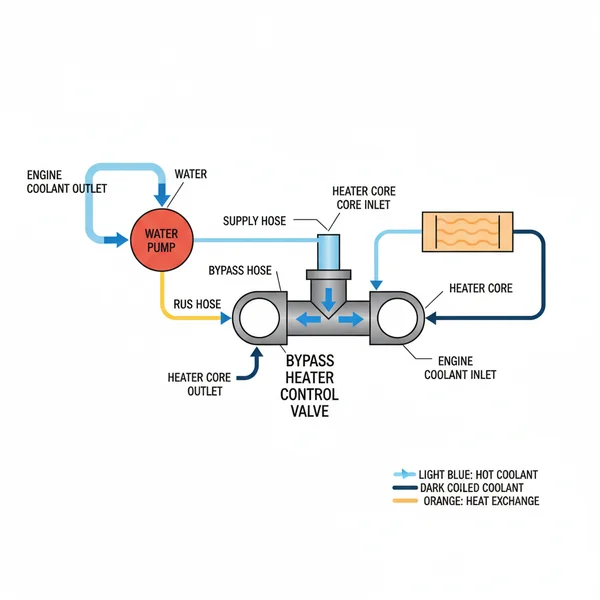

A bypass heater control valve diagram illustrates the system configuration responsible for regulating coolant flow between the engine and heater core. It maps out the layout of hoses and valves, showing how the component diverts hot liquid to maintain engine temperature while providing cabin heat on demand.

📌 Key Takeaways

- The diagram clarifies the flow path of engine coolant between the block and heater core.

- Identifying the bypass port is crucial for correct coolant routing and pressure balance.

- Ensure all hose connections match the illustrated configuration to prevent overheating.

- Use the visual layout to diagnose heating or cooling inconsistencies in the cabin.

- Reference this structure during heater valve replacement or vacuum line repair.

Navigating the complexities of your vehicle’s cooling system can be daunting, especially when you encounter issues with the interior heating or unexpected coolant leaks. When these problems arise, having a clear and accurate bypass heater control valve diagram is the first step toward a successful DIY repair. This diagram acts as a roadmap, illustrating the critical flow paths of engine coolant as it moves between the engine block and the heater core. By understanding this system, you can effectively diagnose whether a valve is stuck, leaking, or failing to divert heat into the cabin. This guide will provide you with a comprehensive look at the valve’s structure, the logic behind the bypass configuration, and how to use this visual data to maintain your vehicle’s temperature regulation effectively.

A heater control valve is designed to regulate the flow of hot coolant into the heater core. In a “bypass” configuration, the valve doesn’t just stop the flow; it reroutes the coolant back to the engine to ensure consistent pressure and cooling even when the cabin heat is turned off.

Understanding the Bypass Heater Control Valve Diagram Structure

The bypass heater control valve diagram typically represents a four-port system, which is the most common layout for modern bypass configurations. Unlike a simple shut-off valve that has only two ports (inlet and outlet), a bypass valve is integrated into the cooling system to manage two distinct circuits. To interpret the diagram correctly, you must first identify the primary components. The diagram will show the engine block as the source of heat, the heater core as the heat exchanger for the cabin, and the bypass valve as the central junction box.

The visual breakdown of the diagram usually involves four distinct hose connections. The first port is the “Inlet from Engine,” which carries hot pressurized coolant. The second is the “Outlet to Heater Core.” The third port is the “Return from Heater Core,” and the fourth is the “Bypass Return to Engine.” In the diagram, these are often color-coded to signify temperature. Red lines generally indicate high-temperature coolant flowing from the engine, while blue or purple lines might represent coolant that has passed through the heater core and is returning to the water pump or radiator.

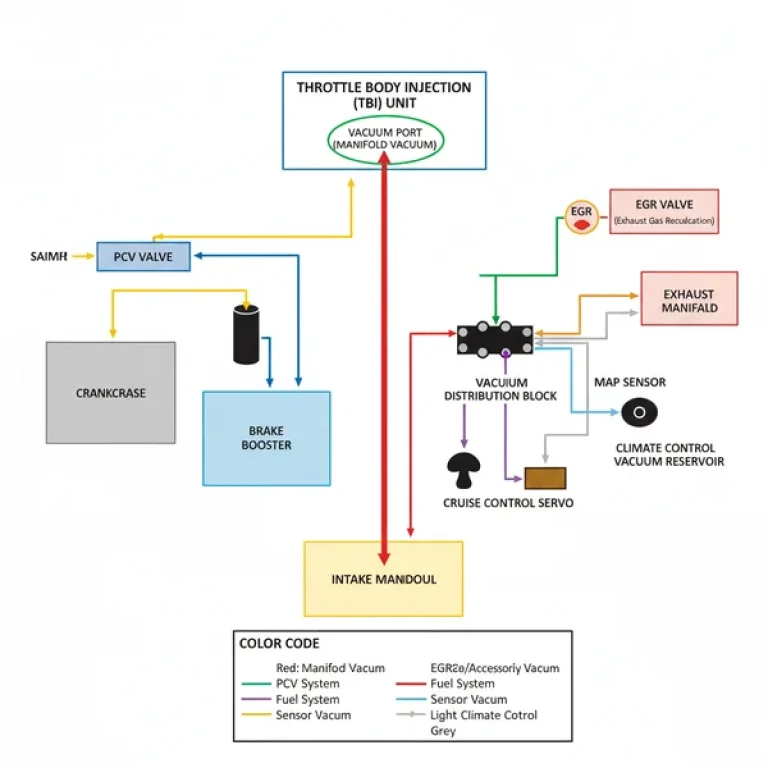

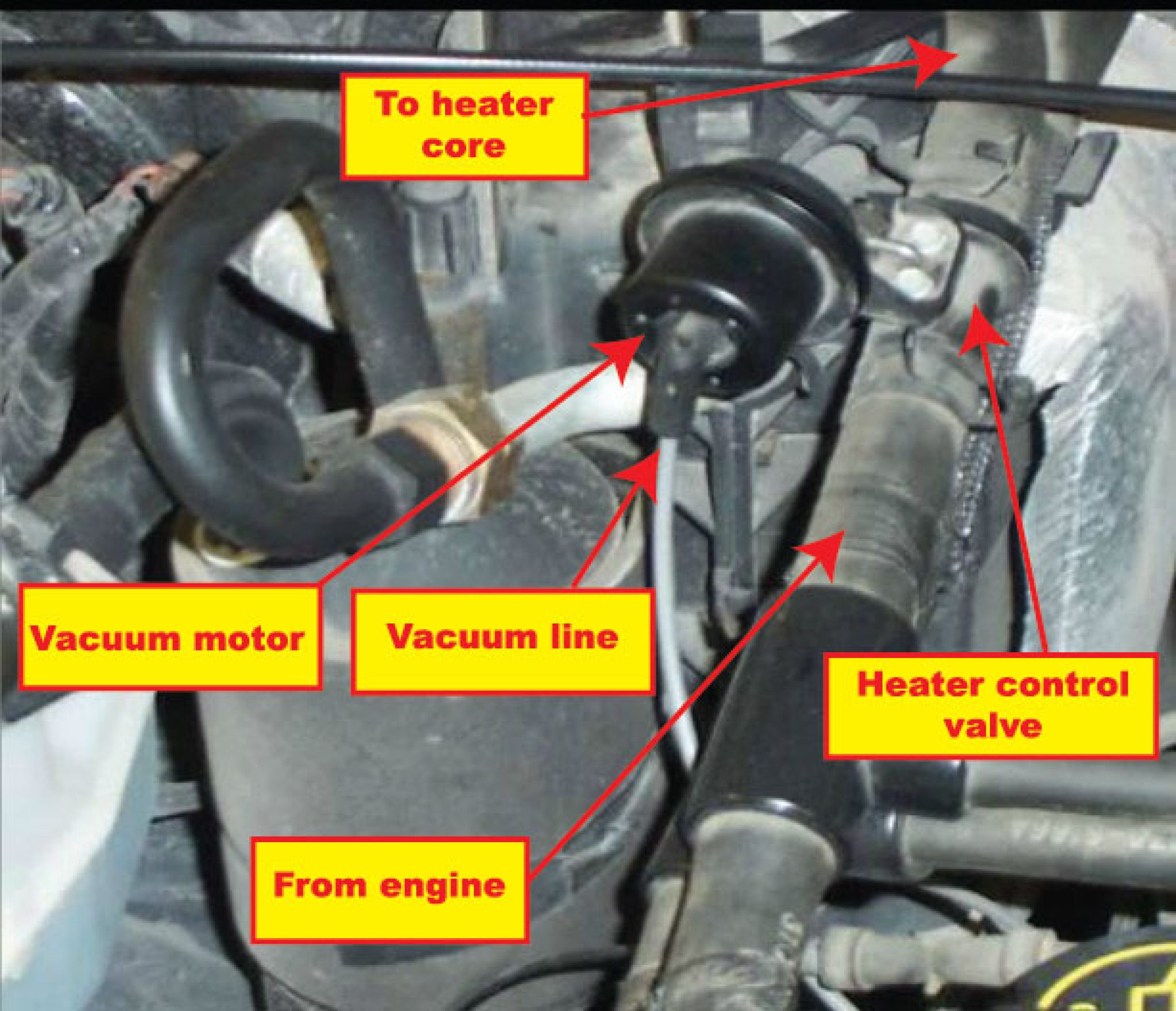

Variations in these diagrams often depend on the method of actuation. You may see a vacuum-operated layout where a small diaphragm and vacuum line are illustrated on top of the valve. Alternatively, electronic configurations will show a wiring harness connection, and manual cable-driven systems will show a mechanical linkage. The layout remains functionally similar: when the valve is “closed” for the heater core, the internal mechanism shifts to connect the engine inlet directly to the engine return port, allowing the coolant to bypass the cabin entirely without stopping the overall circulation of the system.

Figure 1: Generalized 4-Port Bypass Heater Control Valve Configuration

Step-by-Step Guide: How to Read and Implement the Diagram

Interpreting a bypass heater control valve diagram requires a systematic approach to ensure you don’t cross the coolant lines, which could lead to air pockets or localized overheating. Follow these steps to translate the diagram into a physical repair or installation.

- Identify Hose Directions: Start by looking at the arrows on the diagram. Coolant flow is directional. The hose coming from the thermostat housing or cylinder head is always your supply line. On the diagram, this connects to the “Inlet” port of the valve.

- Locate the Actuator: Find the control mechanism on the diagram. If it shows a vacuum line, locate the corresponding thin plastic or rubber tube in your engine bay. If the diagram shows a cable, look for the metal wire coming from the firewall.

- Map the Heater Core Connections: Trace the two lines on the diagram that lead through the firewall. One is the feed (inlet) and one is the return (outlet). It is vital to match these exactly as shown to prevent reverse-flow through the heater core, which can be noisy and less efficient.

- Establish the Bypass Loop: In the diagram, notice how the return line from the heater core and the supply line from the engine “meet” inside the valve body. This internal junction is the bypass. Ensure your replacement valve is oriented so the bypass path matches the return direction to the water pump.

- Prepare Tools and Area: You will need hose clamp pliers, a coolant drain pan, and potentially new hose clamps. Ensure the engine is completely cool before attempting to work on the system.

- Execute the Installation: Remove the old valve and place the new one in the same physical orientation as the diagram. Connect the hoses one by one, securing them with clamps immediately to avoid confusion.

- Bleed the System: After the valve is installed according to the layout, refill the coolant. You must “bleed” or “burp” the system to remove air trapped in the bypass loop. Run the engine with the heater on high until it reaches operating temperature.

Never open the radiator cap or disconnect heater hoses while the engine is hot. The cooling system is under high pressure, and escaping steam or coolant can cause severe burns.

Common Issues & Troubleshooting

When your system doesn’t match the expected performance of the bypass heater control valve diagram, several common issues may be at play. The most frequent problem is a valve that is physically “stuck.” If the diagram shows the valve should be open to the heater core, but you are only getting cold air, the internal gate may be seized due to corrosion or scale buildup from old coolant.

Another issue involves vacuum-actuated valves. If the vacuum line shown in the diagram is cracked or disconnected, the valve will default to its “fail-safe” position (usually bypass mode), leaving you without heat. You can use the diagram to trace the vacuum source back to the intake manifold or the HVAC controller to find the leak. Leakage is also a major concern; bypass valves are often made of plastic that becomes brittle over time. If you see coolant pooling near the firewall, check the four connection points illustrated in the layout. If the valve body is cracked, it cannot be repaired and must be replaced to maintain system pressure.

If you are unsure if the valve is working, feel the two hoses leading to the heater core. If one is hot and the other is cold, the valve is closed or blocked. If both are hot, the heater core itself may be clogged.

Tips & Best Practices for Maintenance

To ensure your cooling system configuration remains reliable, regular maintenance of the bypass valve is essential. One of the best practices is to perform a coolant flush at the intervals recommended by your vehicle manufacturer. This prevents the accumulation of sediment that can jam the delicate internal mechanisms of the bypass valve. When flushing, ensure you cycle the heater controls between “Hot” and “Cold” several times; this forces the valve to move, ensuring the bypass loop and the heater core loop are both cleaned.

- ✓ Use Constant-Tension Clamps: When replacing a valve, avoid over-tightening traditional worm-gear clamps, which can crush the plastic ports. Original-style spring clamps provide more uniform pressure as the plastic expands and contracts with heat.

- ✓ Lubricate Vacuum Lines: If your system uses a vacuum actuator, applying a tiny amount of silicone lubricant to the vacuum port can help prevent the rubber hose from dry-rotting or becoming impossible to remove later.

- ✓ Check for Flow Restrictions: If you are installing a new valve, verify that the interior diameter matches your hoses. A restricted valve can increase backpressure on the water pump, leading to premature pump failure.

- ✓ Quality Matters: Avoid extremely cheap unbranded plastic valves. Given the critical nature of the cooling system, an OEM (Original Equipment Manufacturer) or high-quality aftermarket valve is a small investment to prevent a catastrophic engine overheat.

In conclusion, mastering the bypass heater control valve diagram allows you to take control of your vehicle’s thermal management. By understanding how the coolant is routed, identifying the specific ports in the layout, and following proper troubleshooting steps, you can save significant money on professional repairs while ensuring your engine remains at a safe operating temperature. Always prioritize safety and use high-quality components to keep your cooling system functioning as the manufacturer intended.

Frequently Asked Questions

What is a bypass heater control valve diagram?

This diagram is a visual representation of the cooling system configuration that manages coolant flow. It shows how the bypass valve redirects fluid back to the engine when the heater is off, ensuring consistent temperature regulation and preventing pressure buildup within the vehicle’s heating structure and hoses.

How do you read a bypass heater control valve diagram?

To read the diagram, start at the engine’s coolant outlet and follow the lines representing hoses. Look for the valve component, noting the ‘in’ and ‘out’ ports. Distinguish between the primary flow to the heater core and the bypass loop that maintains engine circulation during operation.

What are the parts of a bypass heater control valve?

The main parts include the valve body, internal gate or plunger, vacuum actuator or electric motor, and the inlet and outlet ports. These elements work together within the system layout to control fluid volume and direction, ensuring heat is delivered to the cabin only when requested by the user.

Why is the bypass component important?

The bypass component is vital because it ensures the engine maintains a constant flow of coolant even when the heater core is closed. Without this specific configuration, coolant could stagnate, leading to hot spots in the engine block or potential damage to the water pump due to excessive pressure.

What is the difference between a standard and bypass valve?

A standard valve simply shuts off coolant flow to the heater core entirely. In contrast, a bypass valve redirects that flow back to the engine via a secondary port. This structure is superior for modern cooling systems that require constant circulation to maintain stable and safe operating temperatures.

How do I use a bypass heater control valve diagram?

Use the diagram as a blueprint for troubleshooting heating issues or performing a component replacement. By following the illustrated layout, you can verify that hoses are connected to the correct ports and ensure the vacuum or electrical connections are positioned according to the original system design for efficiency.