Blower Motor Resistor Wiring Diagram: Speed Control Fixes

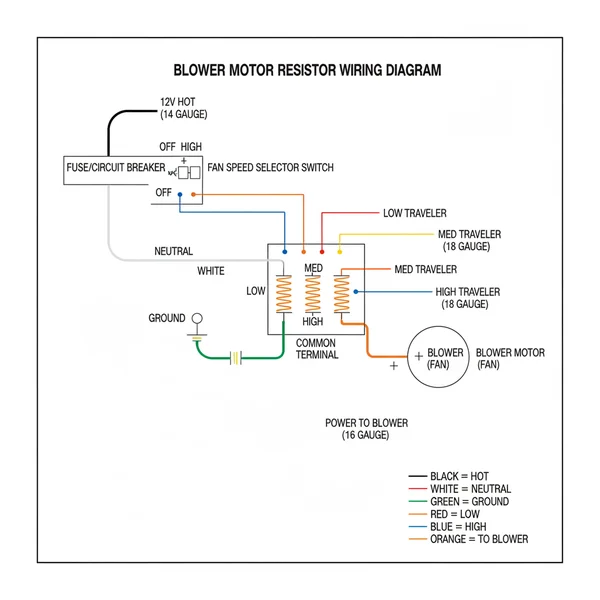

A blower motor resistor wiring diagram shows the circuit where current flows from a hot wire to a switch’s common terminal. Electricity then moves through a specific traveler wire into the resistor block to reduce voltage, finally reaching the motor and returning via a ground wire to control fan speed.

📌 Key Takeaways

- Identifies the electrical path for multiple fan speed settings

- The resistor block is the most critical component for voltage regulation

- Always disconnect power to avoid shorting the hot wire during testing

- Use color codes on the diagram to match physical wires in the harness

- Essential for diagnosing why a fan only works on the highest setting

When your vehicle’s climate control system begins to fail, specifically when the fan only operates on the highest speed setting, understanding a blower motor resistor wiring diagram becomes an essential skill. This diagram serves as a roadmap for the electrical current that regulates the intensity of your cabin’s airflow. Navigating these schematics can seem daunting at first, but having the correct diagram is critical for diagnosing whether you have a faulty switch, a blown thermal fuse, or a melted wiring harness. In this guide, you will learn how to identify the various terminals, trace voltage paths, and ultimately restore functionality to your heating and cooling system by following technical specifications and safety protocols.

A blower motor resistor works by placing different levels of resistance in the path of the electrical current. Higher resistance results in lower fan speeds, while the “High” setting typically bypasses the resistor entirely to provide full battery voltage to the motor.

Understanding the Main Components of the Wiring Diagram

The architecture of a blower motor resistor wiring diagram is designed to show how electricity flows from the battery, through the fuse box, into the HVAC control switch, and finally through the resistor block to the blower motor. The diagram is a series of interconnected lines representing the automotive-grade wires, usually ranging from 12 to 16 gauge depending on the current load requirements. Because the blower motor pulls a significant amount of amperage, the gauge of the wire is crucial; thinner wires would overheat under the load required to spin the heavy squirrel-cage fan.

In a standard diagram, you will notice the hot wire coming from the ignition-switched power source. This power usually passes through a high-amperage fuse or a relay before reaching the common terminal on the fan speed switch. From the switch, several wires—often referred to in electrical terms as traveler wires—extend to the different pins on the blower motor resistor. Each of these pins corresponds to a specific speed setting (Low, Medium 1, Medium 2). The internal structure of the resistor contains coils or ceramic-mounted filaments that dissipate energy as heat, thereby reducing the voltage that reaches the motor.

The diagram will also clearly indicate the ground wire. In most automotive DC circuits, the ground completes the circuit by connecting the blower motor back to the vehicle’s chassis. It is common to see a black wire connected to a brass screw or a dedicated grounding point on the body of the car. If your diagram shows a neutral wire, it is typically referring to the return side of the circuit in an AC-converted system or a specific naming convention used in some international service manuals to denote the common ground path.

While most manual systems use a stepped resistor, newer vehicles with automatic climate control may use a “Blower Motor Control Module.” The wiring diagram for these modules is more complex, featuring a pulse-width modulation (PWM) signal wire from the car’s computer. However, for the majority of DIY repairs, the focus remains on the multi-pin resistor block. You will see labeled terminals such as “A, B, C, D” or numbered “1, 2, 3, 4,” which correspond to the input from the dash switch and the final output to the motor.

Step-by-Step Guide to Interpreting and Installing

Reading a wiring diagram is the first step in a successful repair. Follow these steps to interpret the diagram and proceed with a replacement or diagnostic check.

- Identify Power and Ground: Start by finding the battery symbol or the “B+” mark. Trace the hot wire through the fuse to the HVAC switch. Then, locate the ground wire (usually indicated by a symbol with three horizontal lines of decreasing length) to ensure you know where the circuit completes.

- Map the Speed Circuits: Look at the switch on the diagram. You will see several output paths. Each of these is a traveler wire that leads to a specific terminal on the resistor. Note the color codes (e.g., BLU/WHT for Blue with a White stripe) to help you identify the physical wires in your vehicle.

- Check the Thermal Fuse: On the diagram, the resistor block often contains a symbol for a thermal fuse. If the fan only works on “High,” the diagram helps you see that High bypasses the resistor, while all other speeds must pass through this thermal fuse. If it’s blown, no voltage will pass on lower settings.

- Prepare Your Tools: You will need a digital multimeter, a socket set (usually 5.5mm, 7mm, or 8mm for resistor screws), a flashlight, and perhaps a wire stripping tool if the connector is melted.

- Perform a Voltage Test: With the ignition on and the fan switch set to “Low,” use your multimeter to check for voltage at the corresponding pin on the resistor connector. Refer back to the diagram to ensure you are probing the correct terminal. You should see a voltage reading lower than the full battery voltage.

- Verify the Common Terminal: Ensure the common terminal on the switch is receiving full battery voltage. If the switch has power but the traveler wires do not, the issue lies in the switch, not the resistor.

- Replace the Resistor: Once confirmed faulty, unplug the wiring harness. Remove the mounting screws (often secured to a brass screw or plastic housing) and pull the resistor out of the ductwork. Insert the new unit, ensuring the gasket is seated properly to prevent air leaks.

- Final Continuity Check: Before reassembling the dashboard or kick panel, reconnect the harness and test all fan speeds. Use the diagram one last time to confirm that the wire colors in the plug match the positions indicated in the schematic.

Blower motors draw high current. Always disconnect the negative battery terminal before cutting or splicing any wires to prevent short circuits or accidental airbag deployment if working near the passenger side dashboard.

Common Issues and Troubleshooting

The most frequent problem resolved by a blower motor resistor wiring diagram is the “one-speed fan” syndrome. When the internal coils of the resistor fail or the thermal fuse pops, the circuit is broken for all paths except the direct 12V bypass. Using the diagram, you can pinpoint exactly where the continuity breaks.

Another common issue is a melted connector. Because of the heat generated by electrical resistance, the plastic housing of the wiring harness can fail. If you look at your diagram and then at your vehicle’s harness, and you see charred plastic around the hot wire or the common terminal, the resistance has increased beyond safe levels. This is often caused by a blower motor that is beginning to seize; it draws too much amperage, which creates excess heat at the resistor—the weakest link in the chain.

- ✓ Symptom: Fan only works on High. Cause: Blown resistor or thermal fuse.

- ✓ Symptom: No fan speeds work. Cause: Blown fuse, faulty relay, or bad ground wire.

- ✓ Symptom: Burning smell from vents. Cause: Melting wiring harness or debris on the resistor coils.

Tips and Best Practices for Long-Term Repair

When replacing components based on your blower motor resistor wiring diagram, quality matters. Always opt for Original Equipment Manufacturer (OEM) parts or high-quality aftermarket equivalents. Cheap resistors often use inferior thermal fuses that may blow prematurely or fail to provide the correct voltage drops, leading to inconsistent fan speeds.

Whenever you replace a blown resistor, always check your cabin air filter. A clogged filter restricts airflow, which is necessary to cool the resistor. Without that airflow, the new resistor will overheat and fail within weeks.

Maintenance is also a factor in electrical longevity. Ensure that the grounding point—where the ground wire meets the chassis—is free of corrosion. A rusty brass screw or oxidized terminal increases resistance, which generates heat and reduces the efficiency of the blower motor. If you find the wiring harness is damaged, don’t just tape it; purchase a pigtail replacement kit and solder the connections. Using heat-shrink tubing over soldered joints is the best way to ensure the 12-gauge or 14-gauge wires remain protected from moisture and vibration.

Finally, consider the age of your blower motor. If you have replaced the resistor multiple times, the motor itself is likely drawing too much current. Use your diagram to find the power lead to the motor and test the amperage draw with a clamp meter. If it exceeds the manufacturer’s specification (often 15-20 amps on high), replacing the motor along with the resistor is the most cost-effective long-term solution. By following the blower motor resistor wiring diagram accurately and maintaining the surrounding components, you can ensure a reliable HVAC system for years to come.

Frequently Asked Questions

What is a blower motor resistor wiring diagram?

This diagram is a visual map of the electrical circuit responsible for controlling HVAC fan speeds. It illustrates how power moves from the fuse box through the selector switch and resistor pack. By following the lines, you can see how different resistance levels are applied to vary the motor’s output.

How do you read a blower motor resistor wiring diagram?

Start by locating the power source or hot wire. Trace the path to the common terminal on the fan switch. From there, identify each traveler wire leading to the resistor assembly. Finally, follow the output from the resistor to the blower motor and ensure it concludes at the ground wire.

What are the parts of a blower motor resistor?

The system consists of the resistor block containing several coils, a thermal fuse for safety, and a multi-pin connector. It interfaces with the blower motor and the dash-mounted switch. The diagram also highlights the common terminal and various traveler wires that dictate which resistance path the current will take.

Why is the traveler wire important?

The traveler wire is essential because it bridges the connection between the speed selector switch and the resistor stages. Each fan speed (Low, Medium-Low, Medium-High) usually has its own dedicated traveler wire. If one wire breaks, that specific speed will stop working while the high speed usually remains functional.

What is the difference between a hot wire and neutral wire?

The hot wire carries live voltage from the battery or fuse block into the control circuit. In automotive DC systems, the neutral wire is functionally the ground wire, providing the return path to the battery negative. Proper identification ensures that you are measuring voltage on the correct side of the motor.

How do I use a blower motor resistor wiring diagram?

Use the diagram to perform diagnostic tests with a voltmeter or test light. By knowing which pin on the common terminal corresponds to which fan speed, you can verify if power is leaving the switch. It also helps you locate ground wire points that may be corroded or loose.