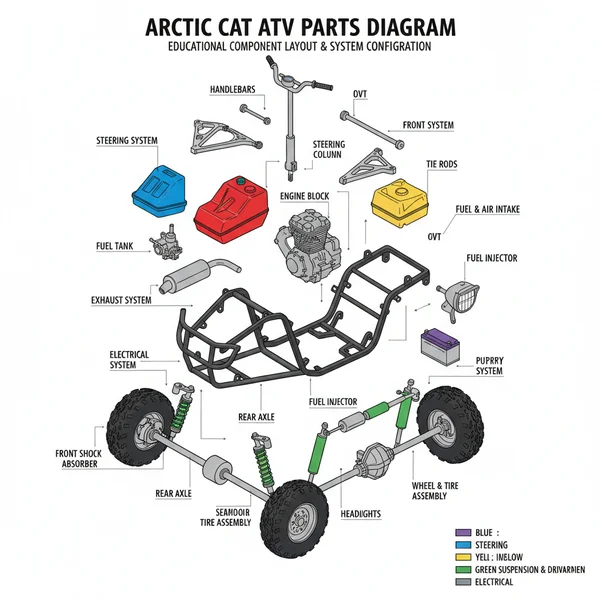

Arctic Cat ATV Parts Diagram: Repair and Identification

An Arctic Cat ATV parts diagram provides a detailed visual layout of every component within the vehicle’s assembly. By studying the system structure and configuration, owners can accurately identify replacement parts, understand how different sections connect, and perform precise maintenance or complex repairs on their specific all-terrain vehicle model.

📌 Key Takeaways

- Visually mapping every component for accurate identification

- Locating the correct OEM part numbers for ordering

- Ensuring safety by understanding the mechanical layout

- Use the diagram as a reassembly guide during repairs

- Refer to it when troubleshooting unusual engine or suspension issues

Navigating the complex internal workings of an all-terrain vehicle can be a daunting task for even the most seasoned mechanic. When you are faced with a mechanical failure or simply performing routine maintenance, a high-quality arctic cat atv parts diagram serves as your primary roadmap for success. These visual schematics bridge the gap between a pile of loose bolts and a fully functional machine. By understanding how to interpret these layouts, you gain the confidence to disassemble, repair, and reassemble your vehicle with precision. This guide will walk you through the various components of these diagrams, explaining how they are structured and providing you with the technical knowledge needed to master your ATV’s configuration.

Understanding the Main Diagram Layout

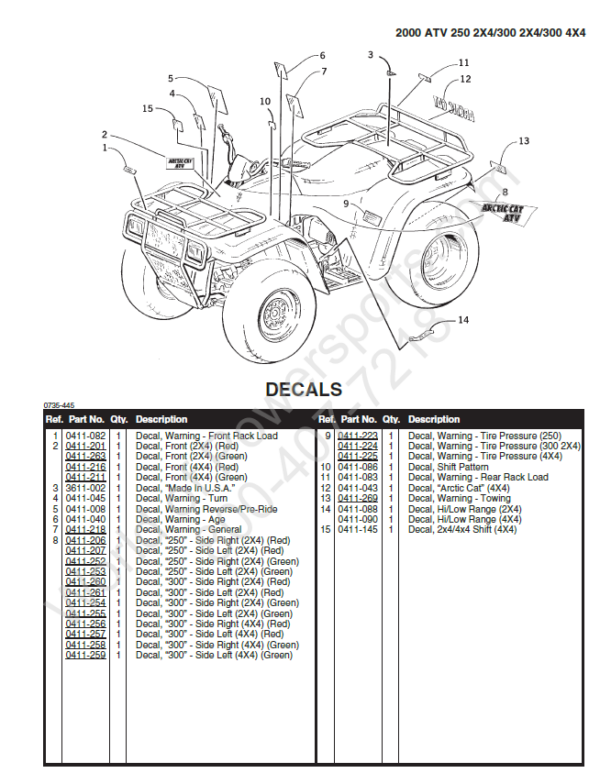

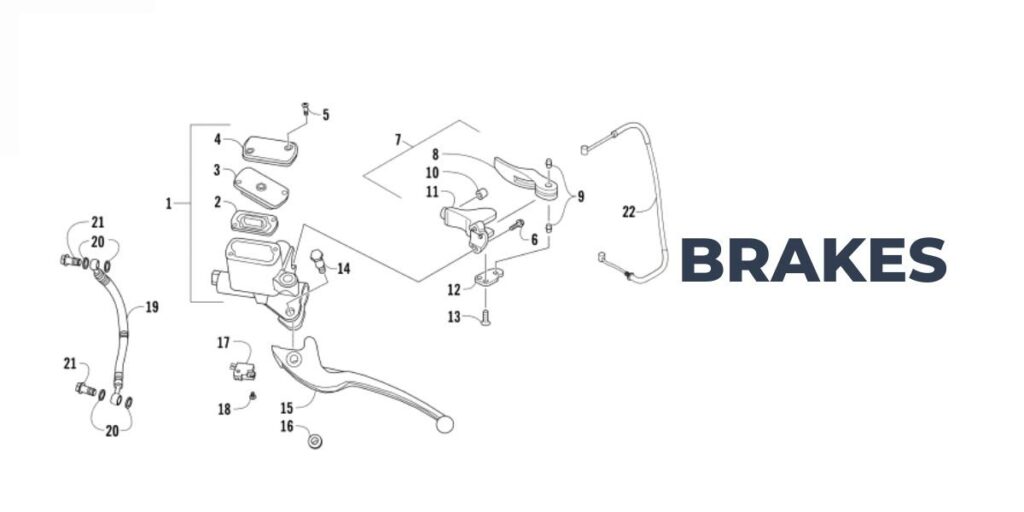

An Arctic Cat ATV parts diagram is typically presented as an “exploded view.” This means that every individual component is visually separated from its neighbors while remaining in its relative physical position. This specific layout is designed to show the assembly order and how each small washer, bolt, and gasket fits into the larger system. The diagram is usually divided into major sub-assemblies to prevent visual clutter and make navigation easier for the user.

The primary structure of these diagrams involves a numerical callout system. Each part in the visual field is assigned a number, which then corresponds to a master parts list located below or beside the image. This list provides the official part name, the unique manufacturer part number, and the quantity required for that specific assembly. For example, if you are looking at the front suspension system, the diagram will show the A-arms, bushings, and shock absorbers as distinct but related units.

Most diagrams are color-coded or use varying line weights to distinguish between primary components and hardware. Dashed lines often indicate where a bolt passes through multiple layers, or they may signify a “kit” that includes several items sold under one part number. It is important to note that variations exist based on engine displacement and trim levels. A 400cc model may share a similar frame structure with a 700cc model, but the engine and transmission diagrams will differ significantly in their internal layout and gear ratios.

Always verify your Vehicle Identification Number (VIN) before selecting a diagram. Arctic Cat often makes mid-production changes to parts like drive belts or electrical sensors that can vary even within the same model year.

Step-By-Step Guide to Using the Diagram

Interpreting an arctic cat atv parts diagram requires a methodical approach. Follow these steps to ensure you identify the correct parts and understand the installation process for your specific machine.

Step 1: Identify Your Exact Specification

Before opening a schematic, locate the manufacturer’s label on the frame (usually near the front wheels or under the seat). Write down the model name, engine size, and VIN. Arctic Cat machines are highly specialized, and parts for a “LTD” trim may not fit a standard “XT” trim. Having these details ensures you are looking at the correct version of the diagram.

Step 2: Locate the Functional System

Most digital and print manuals categorize parts by system. Identify which area you are working on: Engine, Drivetrain, Suspension, Steering, Electrical, or Body. If you are fixing a leak, you might need to look under the “Water Pump” or “Oil Pump” sub-sections rather than a general engine overview.

Step 3: Analyze the Exploded View

Study the diagram to understand the stacking order. In systems like the Continuously Variable Transmission (CVT), the order of washers and spacers is critical. The diagram shows exactly which side of a gear a shim should sit on. Take note of the orientation of components—some parts may look symmetrical but have a specific “up” or “out” side indicated by small arrows in the drawing.

Step 4: Cross-Reference Callouts

Find the number pointing to the part you need. Move to the accompanying list and find that number. This list will give you the current part number. It is helpful to search for this number online as part numbers are occasionally “superseded,” meaning the manufacturer has released an updated, improved version of that specific part with a new number.

Step 5: Prepare Your Tools and Workspace

Based on the hardware shown in the diagram (e.g., Torx bolts, hex nuts, or circlips), gather the necessary tools. Standard tools for Arctic Cat repairs usually include a metric socket set, snap-ring pliers, and a torque wrench. Ensure you have a clean surface to lay out parts in the exact order they appear in the schematic.

Step 6: Document the Disassembly

As you remove parts, compare them to the diagram. If a part on your machine doesn’t match the drawing, you may have an aftermarket modification or be looking at the wrong model year. Using the diagram as a checklist, place removed hardware into labeled containers or on a magnetic tray.

Step 7: Reassembly and Torque Specs

When putting the system back together, the diagram acts as your quality control. Ensure no “leftover” parts remain. While parts diagrams show the layout, they often do not list torque specifications; you must refer to the service manual’s text section for those specific measurements to ensure safety and longevity.

Print out the specific page of the diagram you are using. You can mark off components with a highlighter as you install them, and you won’t have to worry about getting grease on your tablet or computer screen.

Common Issues & Troubleshooting

Even with a detailed arctic cat atv parts diagram, users often encounter hurdles. One of the most frequent problems is “ghost parts”—items shown in a general diagram that are not present on your specific model variation. This is common in wiring harnesses where certain plugs may be left empty if your ATV isn’t equipped with factory winches or heated grips.

Another issue involves hardware seized within the assembly. The diagram shows a bolt sliding out easily, but in reality, corrosion may have bonded it to a bushing. If the physical structure of your machine doesn’t allow for the movement shown in the layout, do not force it. This often indicates a hidden fastener or a specialized removal tool is required. Troubleshooting steering or suspension play becomes much easier with a diagram, as you can identify every pivot point and bushing that might be contributing to the instability.

Never substitute standard hardware for specialized ATV fasteners. Parts diagrams often specify “Grade 8” or higher bolts for suspension and engine mounts. Using inferior hardware can lead to catastrophic failure during high-speed operation.

Tips & Best Practices for Maintenance

To maximize the utility of your parts diagrams and keep your Arctic Cat running at peak performance, consider these professional recommendations:

- ✓ Use OEM Parts for Critical Systems: While aftermarket parts are often cheaper, Original Equipment Manufacturer (OEM) components are guaranteed to match the tolerances shown in your diagram perfectly. This is especially vital for internal engine parts and drivetrain seals.

- ✓ Digital Organization: Keep a digital library of diagrams for your specific machine on your phone. This allows for quick reference when you are out on the trail or at a parts store.

- ✓ Verify Superseded Numbers: Manufacturers often update part designs to fix known flaws. If the part number on your list is unavailable, check for a “superseded” number which represents the modern, improved version of that component.

- ✓ Check for Kit Availability: Often, it is more cost-effective to buy a “rebuild kit” (which includes all parts for a sub-system like a carburetor or master cylinder) rather than purchasing individual nuts and seals identified in the diagram.

In conclusion, mastering the arctic cat atv parts diagram is an essential skill for any owner looking to perform their own repairs. These schematics provide more than just a list of parts; they offer a comprehensive look at the engineering and configuration of your vehicle. By following a structured approach to reading these layouts and combining that knowledge with proper tools and safety precautions, you ensure that your ATV remains reliable for years to come. Whether you are performing a simple oil change or a complete engine overhaul, let the diagram be your ultimate guide to mechanical success.

Step-by-Step Guide to Understanding the Arctic Cat Atv Parts Diagram: Repair And Identification

Identify the specific model and assembly section you need to repair.

Locate the relevant exploded view to see the internal component layout.

Understand how the system structure connects individual parts through numerical callouts.

Cross-reference the item numbers with the parts list for the correct configuration.

Verify that the replacement part matches the visual representation in the diagram.

Complete the installation by following the assembly sequence shown in the schematic.

Frequently Asked Questions

What is Arctic Cat ATV parts diagram?

This diagram is a technical schematic illustrating every component and its specific location within the vehicle’s layout. It serves as a visual map of the entire system configuration, allowing users to see how individual parts fit together. It is an essential tool for identifying part numbers and performing DIY maintenance effectively.

How do you read Arctic Cat ATV parts diagram?

Reading the diagram requires following the numerical callouts that link specific parts to a legend or parts list. Observe the assembly structure to see how components are layered. Look for exploded views that show the internal configuration of complex units like the engine, transmission, or front-end suspension systems.

What are the parts of Arctic Cat ATV?

Key sections include the engine assembly, fuel system, drive train, and suspension components. The structural layout also covers the frame, electrical harnesses, and braking system. Each section contains various small parts like gaskets, bolts, and bearings that are critical for the overall mechanical integrity and performance of the ATV.

Why is the assembly configuration important?

Understanding the assembly configuration is vital because it ensures that every component is installed in the correct sequence and orientation. Improper layout during reassembly can lead to mechanical failure or safety hazards. Following the diagram helps maintain the manufacturer’s original specifications for optimal vehicle performance and long-term reliability.

What is the difference between OEM and aftermarket diagrams?

OEM diagrams represent the original factory configuration and specific component specifications designed by the manufacturer. Aftermarket diagrams may show generic layouts or modified structures intended for performance upgrades. Using the original Arctic Cat diagram ensures the highest compatibility and accuracy when sourcing replacement parts for standard repairs and maintenance.

How do I use Arctic Cat ATV parts diagram?

Use the diagram by first identifying the specific system you are working on, such as the carburetor or rear axle. Locate the relevant exploded view to see the internal structure. Cross-reference the item numbers with the parts list to find the exact component names and manufacturer part numbers.