AMP Research Power Step Parts Diagram: Complete System Layout

An AMP Research Power Step parts diagram illustrates the full mechanical and electrical system, including the drive motor, linkage assembly, controller, and wiring harness. By studying this layout, users can identify specific hardware components for maintenance, ensuring the retractable structure operates smoothly and safely during vehicle entry and exit.

📌 Key Takeaways

- Map out all hardware for maintenance or repair needs

- The motor and linkage assembly are the most critical parts

- Ensure proper electrical grounding for system safety

- Use the diagram to find exact replacement part numbers

- Consult the layout when steps fail to deploy correctly

Whether you are a seasoned mechanic or a first-time DIY truck enthusiast, having a clear and detailed amp research power step parts diagram is essential for maintaining the performance of your electric running boards. This visual guide provides a comprehensive overview of the internal components and external hardware that make up the automated entry system. By understanding the specific layout and system configuration, you can accurately identify individual parts for replacement, perform routine maintenance, or execute a flawless installation. This article explores the intricate structure of the power step system to ensure your vehicle remains accessible and functional in all conditions.

Detailed Main Diagram Description and System Layout

The amp research power step parts diagram serves as the master blueprint for the entire retractable stepping system. It breaks down the assembly into several critical sub-systems: the mechanical linkages, the motorized drive unit, the electrical backbone, and the stepping platform itself. Understanding the relationship between these components is the first step in mastering the system’s operation.

At the core of the layout are the linkages. Every system features a Drive Linkage and an Idler Linkage. The Drive Linkage is easily identified in the diagram by its integrated mounting bracket for the electric motor. In contrast, the Idler Linkage acts as a support structure, pivoting freely to maintain the board’s alignment as it deploys or retracts. These linkages are precision-engineered to handle the weight of passengers while maintaining a low profile when tucked against the vehicle’s rocker panel.

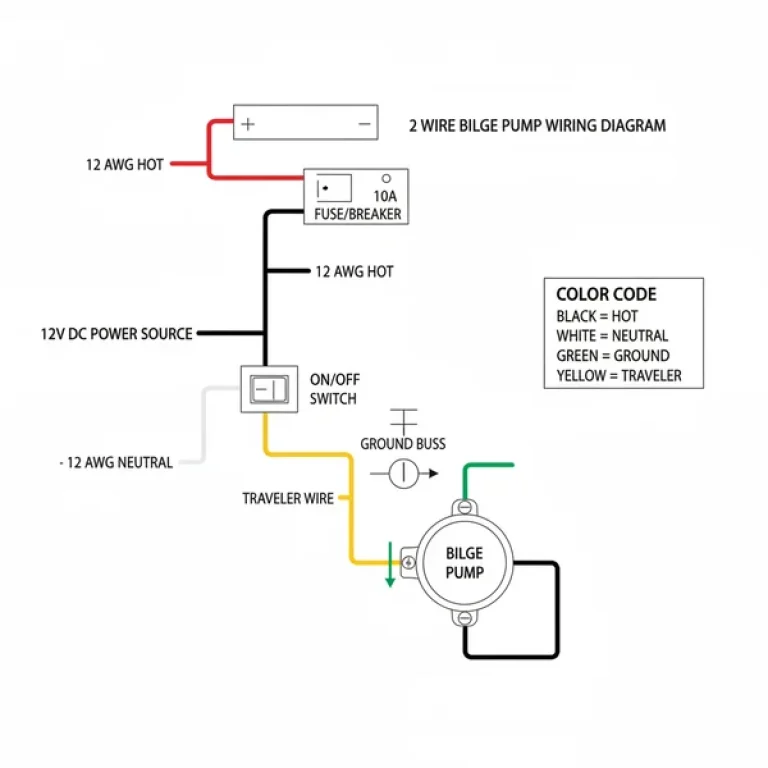

The electrical configuration is represented by the wire harness and the Smart Controller (often referred to as the STB or Step-to-Bumper controller). The diagram illustrates how the harness connects the battery to the controller, and subsequently, how the controller sends signals to the motors and the LED light kits. Color-coding in the wiring diagram typically follows a standard convention: red for power, black for ground, and specific trigger wires that tap into the vehicle’s door sensors or OBD-II port.

Most power step diagrams are vehicle-specific. While the general components remain the same, the mounting brackets and linkage shapes vary significantly between a heavy-duty truck and a compact SUV. Always verify your specific model number before ordering replacement hardware.

The visual breakdown also highlights the hardware kit, which includes high-strength bolts, washers, and specialized shims. The shims are crucial for the configuration of the system, as they allow for micro-adjustments to ensure the step board sits perfectly level against the vehicle body. Finally, the aluminum step board itself is the most visible component, featuring a non-slip texture and end caps that protect the internal channels from road debris and moisture.

Step-by-Step Guide: How to Interpret and Use the Amp Research Power Step Parts Diagram

Reading a technical diagram can be intimidating, but following a logical progression makes the process straightforward. Whether you are troubleshooting a mechanical bind or installing a brand-new set, use these steps to navigate the system structure effectively.

- ✓ 1. Identify the Driver and Passenger Side Orientations: The diagram will specify which components are mirrored. Note that drive linkages are positioned differently based on the motor’s clearance from the frame.

- ✓ 2. Locate the Primary Mounting Points: Use the diagram to find the factory holes in your vehicle’s rocker panels or frame. The diagram shows exactly which bolts secure the linkages to these points.

- ✓ 3. Assemble the Motor to the Drive Linkage: Reference the exploded view to see how the gear on the motor meshes with the linkage gear. This often involves two or three socket head cap screws.

- ✓ 4. Route the Wiring Harness: Follow the layout path from the engine bay (battery) along the frame rails. The diagram indicates where to secure the harness using zip ties to avoid heat sources like the exhaust.

- ✓ 5. Install the Step Board: The diagram shows the T-nuts sliding into the tracks on the underside of the board. These nuts must align with the linkage arms before tightening.

- ✓ 6. Final Wiring Connections: Connect the motor plugs and the LED light wires as shown in the electrical schematic section of the diagram.

- ✓ 7. System Calibration: Ensure the doors trigger the deployment. The diagram helps you verify that the “Up” and “Down” signals are reaching the correct sides.

To complete these steps successfully, you will need a basic set of tools. Most installations require a socket set (including 10mm and 13mm), a set of hex keys (Allen wrenches), a wire stripper, and a torque wrench. Using a torque wrench is vital because over-tightening the bolts on the linkages can cause the pivot points to bind, leading to premature motor failure.

Always disconnect the negative battery terminal before beginning any work on the electrical system. The power step motors are high-torque and can cause serious injury if they activate while your hands are near the linkage pivot points.

The diagram also illustrates the safety “pinch-to-stop” technology. If you notice a component in the diagram labeled as a “pressure sensor” or “current limiter,” understand that this is the logic within the controller. If the step hits an obstruction, the controller detects a spike in electrical current and reverses the motor. Keeping this in mind helps you realize that a mechanical obstruction (like mud or ice) can mimic an electrical failure.

Common Issues and Troubleshooting with the Parts Diagram

When your power steps fail to retract or deploy, the amp research power step parts diagram becomes your primary diagnostic tool. One of the most frequent issues is a “lazy” step that moves slowly or stops halfway. By consulting the diagram, you can identify the pivot pins in the linkages. These are often the culprits, as road salt and grime can cause corrosion.

Another common problem involves the LED lighting. If the steps move but the lights do not illuminate, the diagram shows you the exact splice points in the harness. You can use a multimeter to check for 12V power at the connector shown in the layout. If the power is present at the connector but the light is dark, the LED pod itself has likely failed and needs replacement according to the part number found in the diagram’s legend.

If the steps are making a clicking noise, refer to the motor-to-linkage connection on your diagram. Ensure the gear teeth are fully engaged and the mounting bolts haven’t vibrated loose over time.

If the system is completely unresponsive, the diagram points you toward the fuse holder. Most harnesses have a 30-amp inline fuse located near the battery connection. Checking this first can save hours of unnecessary teardown. If the fuse is intact but the system is dead, the diagram helps you locate the controller mounting position so you can check for secure ground connections.

Tips and Best Practices for Long-Term Maintenance

To keep your power steps operating smoothly, you must treat the system as a moving mechanical assembly rather than a set-it-and-forget-it accessory. The amp research power step parts diagram identifies several friction points that require periodic attention.

Maintenance begins with cleaning. At least once a month, use a high-pressure hose to blast out any dirt or gravel trapped in the linkages. Once clean, apply a high-quality silicone spray lubricant to the pivot pins. Avoid using heavy greases or petroleum-based lubricants like WD-40, as these can actually attract more dust and turn into a grinding paste that wears down the bushings.

Regarding cost-saving, many users find that they don’t need to replace the entire step assembly if only one motor fails. By using the diagram to identify the specific motor part number, you can purchase the component individually. Similarly, if a step board becomes damaged by a rock, you can replace just the aluminum plank while keeping the existing linkages and motors.

- ✓ Check torque on linkage bolts every 5,000 miles to prevent sagging.

- ✓ Inspect the wire harness loom for any signs of rubbing or fraying against the frame.

- ✓ Use a plastic-safe cleaner on the end caps to prevent UV fading and cracking.

- ✓ Ensure the OBD-II or door trigger connections are seated firmly and free of moisture.

In conclusion, mastering the amp research power step parts diagram is the best way to ensure your investment lasts for the life of your vehicle. By understanding the system structure and following a disciplined maintenance routine, you can enjoy the convenience of automated entry without the headache of frequent repairs. Keep your diagram handy, stay proactive with lubrication, and always use high-quality components for any necessary repairs. This systematic approach guarantees that your power steps will reliably deploy every time you open your door, regardless of where your truck takes you.

Frequently Asked Questions

What is AMP Research Power Step parts diagram?

This specialized diagram provides a visual representation of the entire electric running board system. It details the relationship between the motor, linkage, and mounting hardware, allowing owners to understand how the mechanical structure functions. It is an essential tool for identifying specific parts needed for repairs or installation.

How do you read AMP Research Power Step parts diagram?

Start by identifying the main running board and then follow the lines to the various attachment points. Look for callouts that label the motor, wiring harness, and controller. The layout usually follows the physical configuration on the vehicle, helping you visualize where each component is installed.

What are the parts of AMP Research Power Step?

The primary parts include the electric motor, linkage assemblies (idler and drive), aluminum running board, and the electronic controller. Additionally, the system features a dedicated wiring harness, LED light kit, and various mounting brackets and hardware designed to integrate seamlessly with your specific vehicle’s chassis.

Why is the controller component important?

The controller acts as the brain of the entire configuration, receiving signals from the vehicle’s door sensors to deploy or retract the steps. It manages power distribution to the motors and ensures that the system reacts instantly. Without a functioning controller, the automated movement would fail.

What is the difference between idler and drive linkages?

The drive linkage is the component directly attached to the motor, which provides the mechanical force to move the step. In contrast, the idler linkage supports the other end of the board, maintaining the structural alignment and smooth motion without being powered by its own separate motor unit.

How do I use AMP Research Power Step parts diagram?

Use the diagram to troubleshoot mechanical failures by checking the physical alignment of the linkages against the illustrated layout. It also helps in identifying part numbers for replacement bolts or brackets. Simply match the visual component on the diagram to the physical part on your vehicle.