Air Ride Relay Wiring Diagram: Compressor Installation Guide

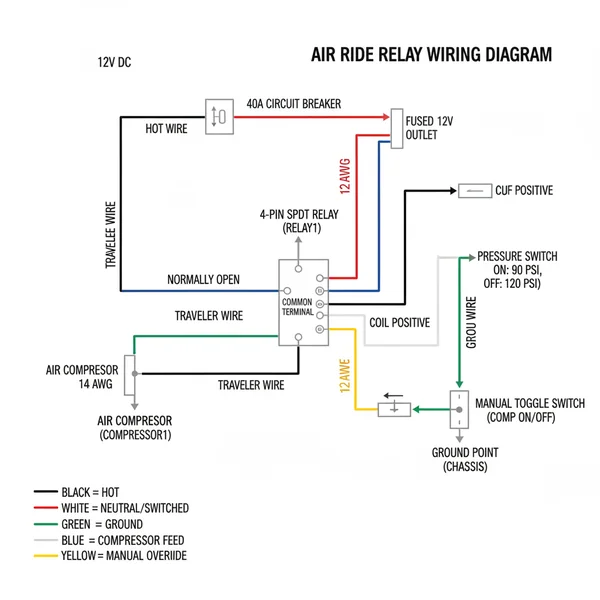

An air ride relay wiring diagram illustrates the electrical path between your battery, pressure switch, and compressor. It ensures high-current components receive power without damaging sensitive switches. By following the diagram, you can safely wire the 12V hot wire to a fused source while securing a reliable ground wire for consistent system operation.

📌 Key Takeaways

- Visualizing the high-current circuit path between battery and compressor

- Identifying relay terminals 30, 85, 86, and 87 for correct pinout

- Ensuring the main power source is protected with an appropriately rated fuse

- Maintaining clean, bare-metal ground connections for all components

- Using the diagram to prevent switch failure by isolating high amperage

If you are looking to upgrade your vehicle’s suspension system with an aftermarket compressor, understanding an air ride relay wiring diagram is the most critical step in the installation process. High-performance air compressors pull a significant amount of current, which can easily melt standard switches or damage your vehicle’s factory electrical harness if not managed correctly. This article provides a comprehensive breakdown of how to route power safely using a relay, ensuring your system operates efficiently without the risk of electrical failure. By following this technical guide, you will learn the fundamental components of air ride wiring, how to read complex schematics, and the best practices for a professional-grade installation that stands the test of time.

Detailed Breakdown of the Air Ride Relay Wiring Diagram

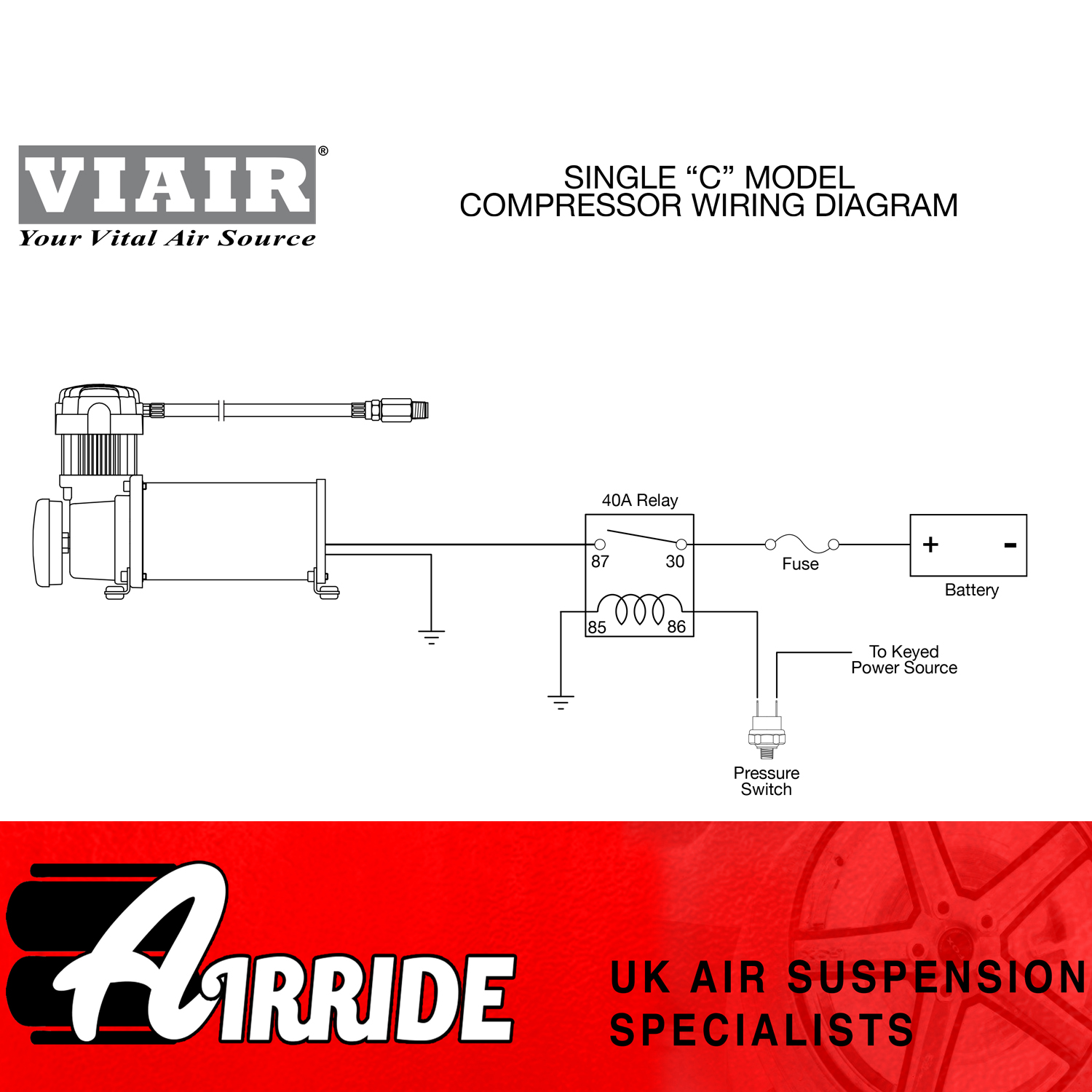

An air ride relay wiring diagram serves as a visual map for connecting your battery, pressure switch, compressor, and ground. At the heart of this system is the automotive relay—typically a 4-pin or 5-pin device rated for 30 to 40 amps. The diagram illustrates how a low-current signal (the trigger) tells a high-current circuit to close, allowing electricity to flow from the battery directly to the compressor.

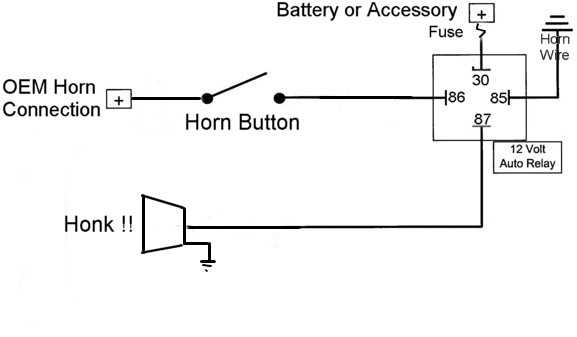

The core components of the diagram include the relay pins, which are numbered according to international standards. Pin 30 is generally the entry point for the high-current hot wire coming from your battery. Pin 87 serves as the exit point, sending that high-current voltage directly to the compressor motor. Pin 85 and Pin 86 represent the coil circuit. One of these pins connects to a ground wire, while the other receives a signal from your pressure switch or manual dash switch. This signal wire is sometimes referred to as a traveler wire because it carries the command across the vehicle’s chassis to the relay.

Visualizing the diagram also involves understanding the role of the pressure switch. In many setups, the pressure switch features a common terminal and a secondary terminal often identified by a brass screw. When the air tank pressure drops below a certain level (e.g., 110 PSI), the switch closes, completing the circuit to the relay coil. This activates the magnetic field inside the relay, snapping the internal contact shut and powering the compressor. The diagram also accounts for the gauge of the wire; high-current paths require a thicker 10-gauge or 8-gauge wire, whereas the signal wires can function perfectly with a thinner 16-gauge or 18-gauge wire.

Most air ride systems utilize a 12V DC circuit. While the term “neutral wire” is common in household AC wiring, in automotive DC applications, we focus on the “negative” or “ground” side of the circuit to complete the loop back to the battery.

Step-by-Step Installation and Wiring Guide

Interpreting an air ride relay wiring diagram and translating it into a physical installation requires a methodical approach. Before you begin, gather the necessary tools: a high-quality wire stripper, a terminal crimping tool, a digital multimeter, and heat-shrink tubing for weatherproofing. Ensure you have the correct gauge of wire; using a wire that is too thin for the compressor’s amperage draw is a major fire hazard.

- ✓ Step 1: Disconnect the vehicle battery to prevent accidental shorts during the wiring process.

- ✓ Step 2: Mount the relay in a dry location, preferably near the battery or the compressor to minimize wire length.

- ✓ Step 3: Run a heavy-gauge hot wire from the positive battery terminal to Pin 30 on the relay, installing an in-line fuse within 12 inches of the battery.

- ✓ Step 4: Connect Pin 87 of the relay to the positive lead of the air compressor.

- ✓ Step 5: Wire the pressure switch by connecting one side to a switched ignition source and the other side (the traveler wire) to Pin 86 on the relay.

- ✓ Step 6: Connect Pin 85 of the relay to a clean, unpainted metal surface on the chassis to establish a solid ground wire connection.

- ✓ Step 7: Ground the compressor motor itself to the chassis using the same gauge wire as the power lead.

- ✓ Step 8: Reconnect the battery and test the system with a multimeter to ensure the correct voltage is reaching the compressor when the switch is activated.

When working with the pressure switch, look for the common terminal. This is where the incoming power from your ignition source typically enters. The “traveler wire” then exits the switch and heads to the relay. If your pressure switch uses screw terminals, ensure the wire is wrapped securely around the brass screw before tightening to prevent vibration from loosening the connection over time.

Never bypass the relay and connect a compressor directly to a toggle switch. The high amperage will burn out the switch contacts almost instantly, potentially causing a fire under your dashboard.

Common Issues & Troubleshooting

Even with a perfect air ride relay wiring diagram, issues can arise during or after installation. The most common problem users encounter is the compressor failing to turn on. This is often traced back to a poor ground wire connection. In automotive electrical systems, the chassis acts as the return path for current. If the spot where you grounded your relay or compressor is covered in paint or rust, the circuit will remain open. Use a multimeter to check for continuity between your ground point and the negative battery terminal.

Another frequent issue is a blown fuse. This usually indicates that the wire gauge used was too small, causing excessive heat and resistance, or that the compressor is drawing more amperage than the fuse’s rating. Check the voltage at Pin 30 and Pin 87 while the compressor is trying to run. If you see a significant drop in voltage, your power supply wire is likely inadequate. Finally, if the compressor runs continuously and won’t shut off, the pressure switch or the relay itself may have “welded” its internal contacts together due to an electrical surge.

Tips & Best Practices for Air Ride Wiring

To ensure the longevity of your air suspension system, follow these professional best practices. First, always use marine-grade or automotive-grade multi-strand copper wire. Avoid solid-core house wire, as it is brittle and will crack under the constant vibration of a moving vehicle. When making connections, use heat-shrink butt connectors rather than standard plastic ones. These provide a watertight seal that prevents corrosion, which is the number one killer of air ride electronics.

Label both ends of every wire, especially the traveler wire and the hot wire. If you ever need to troubleshoot the system in the future, having labeled wires will save you hours of tracing lines through the vehicle’s carpet and trim.

Maintenance is also key. Periodically check the brass screw terminals on your pressure switch and the pins on your relay for signs of heat discoloration. If the plastic around a pin looks melted, it is a sign of high resistance, and the component should be replaced immediately. For cost-saving, you can buy relays in bulk, but never compromise on the quality of your fuse holder. A high-quality, weather-resistant fuse holder is your primary defense against catastrophic electrical failure.

In summary, a properly implemented air ride relay wiring diagram is the difference between a reliable suspension system and a dangerous electrical hazard. By understanding how the hot wire provides power, how the traveler wire signals the relay, and how the ground wire completes the circuit, you can confidently install or repair your air ride system. Always prioritize safety by using the correct gauge wire and ensuring every connection is secure and protected from the elements. With these steps, your air ride system will provide years of smooth, adjustable performance.

Frequently Asked Questions

What is air ride relay wiring diagram?

An air ride relay wiring diagram is a schematic showing how to connect an air compressor to a power source using a relay. It outlines the specific pin connections for the battery, ground, and pressure switch, ensuring the high-amperage compressor runs safely without melting the control switches or damaging the vehicle’s electrical system.

How do you read air ride relay wiring diagram?

To read the diagram, identify the relay pins usually labeled 30, 85, 86, and 87. Trace the lines from the battery to terminal 30 and from terminal 87 to the compressor. Locate the trigger signal from the pressure switch and the necessary chassis ground points for circuit completion and safety.

What are the parts of air ride relay?

The main parts include the electromagnetic coil, the common terminal, and the internal contact points. Externally, you will find four or five pins: the high-power input, the switched output to the compressor, the ground wire connection, and the signal input that activates the internal magnetic switch mechanism when pressure drops.

Why is ground wire important?

The ground wire is critical because it completes the electrical circuit, allowing current to flow back to the battery. Without a solid ground on both the relay and the compressor, the system will face high resistance, leading to overheating, intermittent operation, or total failure of the air suspension system’s mechanical components.

What is the difference between traveler wire and common terminal?

In specialized air ride manifold setups, a traveler wire may carry signals between different switch positions or valves, whereas the common terminal acts as the primary connection point for incoming power or ground. Understanding these ensures the relay triggers only when the system reaches specific pressure thresholds or receives a manual command.

How do I use air ride relay wiring diagram?

Use the diagram as a blueprint during installation to map out cable routing and wire sizing. Match the physical wire colors and gauges to the diagram’s specifications. It helps you identify where to place the inline fuse on the hot wire and how to bridge the pressure switch for automatic operation.