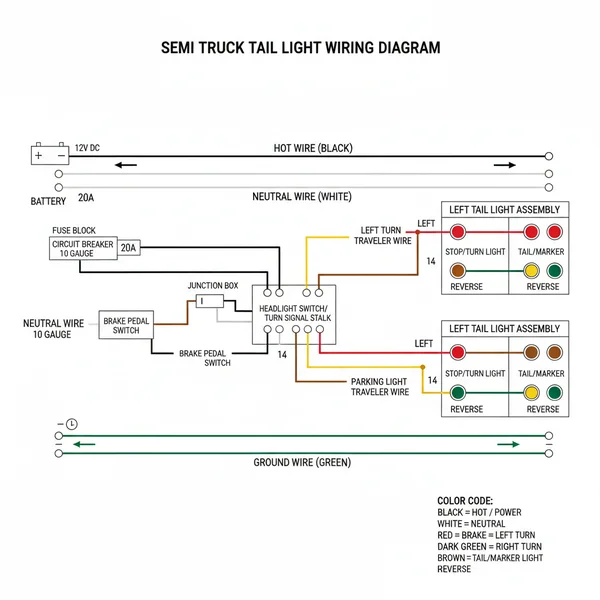

Semi Truck Tail Light Wiring Diagram: Color Coding Guide

A semi truck tail light wiring diagram illustrates how electrical current flows from the tractor to the trailer lights. It identifies the hot wire for power, the ground wire for circuit completion, and specific traveler wire paths for signals, ensuring all brake, turn, and running lights function correctly and safely.

📌 Key Takeaways

- Accurate color-coding ensures trailer-to-tractor compatibility.

- Identify the ground wire first to prevent electrical shorts.

- Ensure high-voltage components are correctly fused for safety.

- Use heat-shrink connectors to protect against weather damage.

- Refer to this diagram during DOT inspections or light failure repairs.

Understanding a semi truck tail light wiring diagram is more than just a maintenance task; it is a critical safety requirement for any driver, fleet operator, or DIY mechanic. When you are hauling a trailer that spans fifty-three feet, ensuring that your brake lights, turn signals, and markers are functioning perfectly is the difference between a safe delivery and a hazardous road incident. This guide provides a comprehensive breakdown of the electrical architecture behind your vehicle’s rear lighting system. You will learn how to identify specific circuits, understand color-coding standards, and master the installation of a 7-way connector. Whether you are troubleshooting a flickering marker light or performing a complete rewiring project, having the correct semi truck tail light wiring diagram ensures your work is technically accurate and compliant with Department of Transportation (DOT) regulations.

Deep Dive into the Semi Truck Tail Light Wiring Diagram

The core of any semi truck tail light wiring diagram is the J560 7-way plug, which serves as the primary interface between the tractor and the trailer. This standardized system ensures that regardless of the trailer brand, the electrical signals for braking and signaling remain consistent. The diagram visually maps out how power flows from the battery and alternator, through the cab switches, and eventually to the rear housing. Each circuit is designed to handle specific levels of current, and the diagram illustrates how these individual paths are shielded and routed along the chassis.

In a standard 7-way system, the center pin is typically reserved for auxiliary power, while the surrounding six pins handle ground, clearance lights, turn signals, and the stop light circuit. Always consult your specific truck’s manual, as some custom vocational trucks may use the auxiliary pin for specialized equipment like liftgates.

The visual breakdown of a professional diagram typically uses specific color coding. In most North American heavy-duty applications, the white wire serves as the ground wire, providing the return path to the battery. The black wire usually handles the marker and clearance lights, while the yellow and green wires are dedicated to the left and right turn signals, respectively. The red wire is generally assigned to the stop lights. In the context of the diagram, you will also see the common terminal where multiple ground points may converge. While residential systems use a neutral wire to complete a circuit, in the DC electrical systems of a semi truck, the ground serves this fundamental purpose. The diagram will also indicate the necessary wire gauge for each circuit, typically ranging from 10-gauge for heavy-duty ground and power lines to 14-gauge for individual signal lamps.

[DIAGRAM_PLACEHOLDER: 7-Way J560 Connector Pinout]

1. White: Ground Wire (Large Gauge)

2. Black: Marker / Clearance Lights

3. Yellow: Left Turn / Brake

4. Red: Stop Lamps / Auxiliary

5. Green: Right Turn / Brake

6. Brown: Tail / License Plate

7. Blue: Auxiliary / ABS Power

Variations can occur based on the year of the truck or specific trailer requirements. For example, older trailers might not have integrated ABS systems, whereas modern diagrams will clearly show the blue wire providing constant voltage to the ABS controller. Understanding these nuances in the diagram allows you to bridge the gap between different generations of equipment without blowing fuses or damaging sensitive electronic control modules.

Step-by-Step Guide to Interpreting and Installing Wiring

Reading a semi truck tail light wiring diagram requires a methodical approach. It is not just about connecting colors; it is about ensuring electrical integrity across a long distance. Follow these steps to correctly interpret the diagram and implement the wiring in your vehicle.

- ✓ Step 1: Identify the Main Power Source: Locate the “hot wire” on your diagram. This is the wire that carries constant voltage from the battery or the ignition-switched source. Ensure you are using the correct gauge to prevent overheating.

- ✓ Step 2: Map the Grounding Path: Every circuit needs a return. Identify the common terminal for your grounds. Unlike a traveler wire in a household 3-way switch that toggles between paths, the truck’s ground must be a solid, low-resistance connection to the chassis or the white wire in the 7-way harness.

- ✓ Step 3: Prepare the Connector Housing: Open your 7-way plug. You will see several terminals, often secured with a brass screw. These brass connectors offer excellent conductivity and resistance to corrosion, which is vital for exterior automotive applications.

- ✓ Step 4: Strip and Tin the Wires: Using a high-quality wire stripper, remove approximately half an inch of insulation from each wire. If you have a soldering iron, “tinning” the ends of the wires can prevent individual strands from fraying when you tighten the brass screw.

- ✓ Step 5: Connect According to the Diagram: Match the wire colors to the corresponding pins on the J560 plug. Insert the stripped wire into the terminal and tighten the brass screw firmly. Ensure no stray strands of the hot wire are touching the ground or adjacent terminals, as this will cause a short circuit.

- ✓ Step 6: Test Voltage and Continuity: Before sealing the plug, use a multimeter to check the voltage at each pin while an assistant operates the lights in the cab. You should see approximately 12.6 to 14.2 volts depending on whether the engine is running.

- ✓ Step 7: Weatherproof the Connections: Apply dielectric grease to the terminals and use heat-shrink tubing on any splices. This prevents moisture from entering the system, which is the primary cause of electrical failure in semi trucks.

Never replace a fuse with one of a higher rating than specified in the diagram. If a 15-amp fuse keeps blowing, it indicates a short circuit in the hot wire or a faulty component. Using a larger fuse can cause the wire to overheat and potentially start a fire.

To successfully complete this project, you will need a few essential tools: a digital multimeter, wire strippers, a crimping tool, heat shrink tubing, and a set of screwdrivers for the brass screw terminals. Pay close attention to the wire gauge; using a wire that is too thin for the required voltage will result in “dim” lights because the wire itself acts as a resistor, consuming power before it reaches the bulb.

Common Issues & Troubleshooting

Even with a perfect semi truck tail light wiring diagram, issues can arise due to the harsh environments these vehicles operate in. The most frequent problem is a “lost ground.” Since the ground wire is the neutral wire equivalent that completes the circuit, any break in this line will cause all lights on the trailer to act erratically—often glowing dimly or flashing when they shouldn’t. If you notice your turn signals are making the marker lights blink, you likely have a feedback issue caused by a poor common terminal connection.

Another common issue is corrosion at the plug. Road salt and moisture can bridge the gap between the hot wire and the ground, creating a parasitic draw that drains the battery. Use your diagram to identify which pin corresponds to the malfunctioning light and check the voltage directly at that pin. If you have power at the plug but not at the tail light, the “traveler wire” (the long run of wire through the chassis) likely has a break or a rub-through point. The diagram helps you isolate which specific color wire to trace along the frame rails, saving hours of aimless searching.

Tips & Best Practices for Electrical Maintenance

Longevity in truck wiring is achieved through preventative measures. One of the best pro tips is to always use “marine grade” or “tinned” copper wire when replacing sections of the harness. This type of wire resists the “green rot” or oxidation that travels under the insulation of standard copper wire. When using your semi truck tail light wiring diagram for a new installation, always leave a “service loop”—a small extra coil of wire near the connectors. This allows for future repairs without having to stretch the wire or replace the entire run.

When connecting wires to a brass screw terminal, always wrap the wire clockwise around the screw. As you tighten the screw, the motion will pull the wire tighter into the terminal rather than pushing it out.

Regularly inspect the junction box where the main harness splits to the individual tail lights. Ensure that the wire gauge remains consistent and that all connections are tight. If you are looking to save costs, consider upgrading to LED tail lights. LEDs draw significantly less current, which reduces the load on your hot wire and reduces the chance of voltage drops across long trailer lengths. Furthermore, LEDs are more resilient to the vibrations common in heavy-duty trucking. By keeping a printed copy of your semi truck tail light wiring diagram in the glove box, you ensure that you are prepared for roadside repairs, keeping your vehicle compliant and your journey safe.

Frequently Asked Questions

What is semi truck tail light wiring diagram?

A semi truck tail light wiring diagram is a visual schematic used to map the electrical connections between a truck’s power source and its rear lighting system. It displays the paths for the hot wire, turn signals, and brake lights, ensuring technicians can correctly wire the 7-way plug.

How do you read semi truck tail light wiring diagram?

To read the diagram, start at the common terminal or power source and follow each colored line to its designated light fixture. Look for symbols representing the neutral wire and ground wire, and ensure the traveler wire path for switching signals matches the specific pin configuration of your trailer.

What are the parts of semi truck tail light wiring?

Key parts include the 7-way connector plug, the hot wire providing 12V power, and the ground wire for stability. It also features traveler wire connections for blinkers, a neutral wire equivalent for return paths, and various fuses or relays that protect the circuit from overheating or electrical surges.

Why is ground wire important?

The ground wire is critical because it provides a safe return path for electrical current to the chassis or battery. Without a solid ground, lights may flicker, dim, or fail completely. It prevents dangerous electrical buildup and ensures that the hot wire does not cause a short circuit.

What is the difference between traveler wire and hot wire?

A hot wire provides constant or primary power from the battery to the circuit, while a traveler wire acts as a bridge between switches, such as those for turn signals or specialized lighting setups. The hot wire energizes the system, whereas the traveler wire directs that energy selectively.

How do I use semi truck tail light wiring diagram?

Use the diagram to identify which wire color corresponds to specific functions like left turn or brake. Match the wires on your vehicle to the common terminal on the plug. This guide helps you troubleshoot intermittent light failures by tracing connections from the power source to the individual bulb.