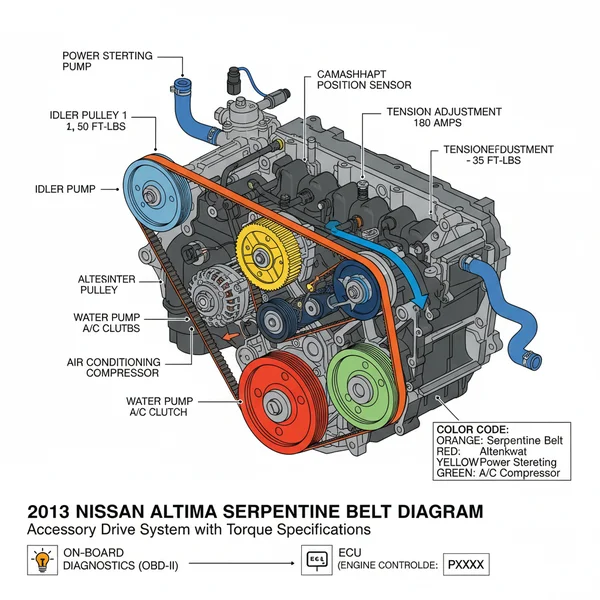

2013 Nissan Altima Serpentine Belt Diagram: Routing Guide

The 2013 Nissan Altima serpentine belt diagram illustrates the precise path the drive belt takes around the crankshaft, alternator, and A/C compressor pulleys. Controlled by an automatic tensioner, this system ensures power reaches vital components. Correct routing prevents engine overheating and ensures the charging system maintains proper battery voltage for the vehicle.

📌 Key Takeaways

- Provides the essential routing path to ensure pulleys rotate in the correct direction.

- Identifies the automatic tensioner as the primary component for releasing belt pressure.

- Prevents mechanical damage by ensuring the belt ribs seat correctly in pulley grooves.

- Helps diagnose symptoms like squealing or loss of power steering and air conditioning.

- Essential during alternator or A/C compressor replacement procedures.

Maintaining your vehicle involves more than just frequent oil changes; understanding the 2013 nissan altima serpentine belt diagram is crucial for any DIY enthusiast or owner looking to ensure long-term reliability. The serpentine belt, also known as the accessory belt, is a single, continuous loop that powers multiple peripheral devices in your engine, such as the alternator and the air conditioning compressor. Having the correct routing diagram is the difference between a successful 20-minute repair and hours of frustration. In this comprehensive guide, you will learn how to interpret the routing paths for both the 2.5L and 3.5L engine variants, identify the specialized tools required for the job, and understand how this system interacts with your vehicle’s electronic control unit and cooling system.

The 2013 Nissan Altima typically utilizes a spring-loaded automatic tensioner. This means you do not need to manually set the tension; however, the tensioner must be fully rotated to release the old belt and install the new one.

Main Diagram Description and Pulley Components

The 2013 nissan altima serpentine belt diagram is a visual map of how the belt weaves around various pulleys. While the 2.5L four-cylinder engine (QR25DE) is the most common, the 3.5L V6 (VQ35DE) follows a similar logic but with slightly different spatial orientations. In both layouts, the belt is driven by the crankshaft pulley, which is the largest pulley located at the bottom of the engine block. From there, the belt travels to the alternator, which generates electrical power for the ECU and charges the battery.

On the 2.5L engine, the routing is relatively straightforward. The belt moves from the crankshaft to the alternator, then down to the A/C compressor, and finally around the tensioner pulley. It is important to note that the water pump on this specific model is driven by the internal timing chain, not the external accessory belt. However, the belt is still vital for engine health because it powers the alternator, which provides the current necessary for the electric cooling fans to maintain proper coolant flow through the radiator.

The diagram identifies several key elements:

- ✓ Crankshaft Pulley: The primary drive source located at the base of the engine.

- ✓ Alternator Pulley: Located at the top, this provides electrical energy to the vehicle.

- ✓ A/C Compressor: Usually positioned toward the lower front of the engine bay.

- ✓ Automatic Tensioner: A spring-loaded arm with a pulley that maintains constant pressure on the belt.

In the visual diagram, the smooth side of the belt always contacts the smooth idler or tensioner pulleys, while the ribbed side of the belt must perfectly seat into the grooves of the drive pulleys (crankshaft, alternator, and A/C). If you notice the belt is not sitting flush in these grooves during your inspection, it indicates a misalignment or an incorrect belt size.

Step-by-Step Guide to Interpretation and Installation

Replacing or inspecting the belt using the 2013 nissan altima serpentine belt diagram requires a systematic approach. Before you begin, ensure the engine is completely cool to the touch to avoid burns from the engine block or the radiator.

Always disconnect the negative battery terminal before working near the accessory belt. If the engine or cooling fans were to start unexpectedly, it could cause severe injury.

Step 1: Preparation and Access

Park the vehicle on a level surface and engage the parking brake. For the 2013 Altima, access to the tensioner is best achieved through the passenger-side wheel well. Loosen the lug nuts on the front passenger wheel, jack up the car, and secure it on jack stands. Remove the wheel and the plastic splash guard held in by push-pins to reveal the lower pulleys.

Step 2: Map the Existing Routing

Before removing the old belt, compare your physical engine layout to the 2013 nissan altima serpentine belt diagram. Take a photo of the current belt path with your phone. Even though you have a diagram, a real-world reference of your specific engine can be a lifesaver if you get confused midway through the process.

Step 3: Locate the Tensioner

Identify the automatic tensioner pulley. On the 2.5L engine, it is located between the alternator and the crankshaft. It will have a 14mm bolt head in the center of the pulley or a dedicated lug on the tensioner arm.

Step 4: Release Belt Tension

Using a long-handled 14mm wrench or a specialized serpentine belt tool, rotate the tensioner clockwise (toward the front of the car). This compresses the internal spring and creates slack in the belt. Carefully slide the belt off the uppermost pulley (usually the alternator) first.

Step 5: Inspect the Pulleys

With the belt removed, spin each pulley by hand. They should spin smoothly without any grinding noises or lateral “wobble.” If the tensioner pulley feels gritty, now is the time to replace the tensioner assembly. Ensure the grooves in the crankshaft and A/C compressor are free of debris or old rubber chunks.

Step 6: Route the New Belt

Referencing the diagram, begin threading the new accessory belt starting from the bottom. Loop it around the crankshaft pulley first, then the A/C compressor. Work your way up toward the alternator. The last pulley you should attempt to loop is the tensioner or the alternator, as these provide the best leverage points.

Step 7: Final Tensioning and Seating

Rotate the tensioner once more to create enough slack to slip the belt over the final pulley. Once the belt is in place, slowly release the tensioner. Double-check that the ribs of the belt are perfectly centered in every grooved pulley. If the belt is off by even one groove, it will shred within minutes of starting the engine.

Step 8: Testing

Reinstall the splash guard and the wheel. Lower the vehicle and reconnect the battery. Start the engine and observe the belt for a few minutes. Listen for any chirping or squealing, which could indicate a pulley misalignment or a defective tensioner.

If you are working alone, use a small spring clamp to hold the belt against the crankshaft pulley while you route the upper sections. This prevents the belt from falling off the bottom pulleys while you are reaching from the top.

Common Issues and Troubleshooting

A failing serpentine belt system can manifest in several ways that affect the drivability of your Nissan Altima. One of the most common symptoms is a loud squealing noise, especially during cold starts or when making sharp turns. This often indicates the belt is slipping or the tensioner has lost its spring force.

Because the belt drives the alternator, a failure can lead to electronic issues. If the belt slips significantly, the alternator may not provide a steady voltage, causing the ECU to register a fault. This might trigger a check engine light or a battery warning light on your dashboard. Using an OBD-II scanner can help you identify a specific diagnostic code related to low system voltage (such as P0562), which points directly to the charging system and the accessory belt.

Visual signs of failure include cracking on the ribbed side of the belt, fraying at the edges, or “glazing,” where the belt surface appears shiny and hard. If you see any of these signs, replace the belt immediately to avoid being stranded. Unlike the timing chain, which is designed to last the life of the engine, the serpentine belt is a wear item that generally requires replacement every 60,000 to 100,000 miles.

Tips and Best Practices for Maintenance

To get the most out of your 2013 Nissan Altima, always opt for high-quality EPDM (Ethylene Propylene Diene Monomer) belts. These modern materials do not crack as easily as older neoprene belts but instead lose thickness in the ribs. You can use a belt wear gauge to check if the grooves have become too deep, which prevents the belt from gripping the pulleys effectively.

When replacing the belt, it is often a “best practice” to replace the tensioner assembly simultaneously, especially if your Altima has over 100,000 miles. The internal spring in the tensioner can weaken over time, leading to vibrations that can damage the alternator bearings. When installing a new tensioner, ensure you follow the correct torque spec for the mounting bolts (usually around 18-22 ft-lbs for this model) to prevent the bolts from backing out due to engine vibration.

Finally, keep a copy of the 2013 nissan altima serpentine belt diagram in your glovebox or saved on your phone. In an emergency road-side situation, having the routing information readily available can save you an expensive tow bill. Regular inspection of the belt and its surrounding components ensures that your coolant flow remains consistent and your ECU receives the stable power it needs to keep your Altima running smoothly for years to come.

Frequently Asked Questions

What is 2013 Nissan Altima serpentine belt diagram?

This diagram is a visual schematic showing the specific path the accessory drive belt follows around various engine pulleys. It identifies the crankshaft, alternator, A/C compressor, and tensioner locations. Following this map is critical during replacement to ensure the belt drives every component in the correct rotational direction for proper function.

How do you read 2013 Nissan Altima serpentine belt diagram?

Start by identifying the largest pulley, which is the crankshaft, then follow the line as it loops around accessory pulleys. Solid lines represent the ribbed side of the belt touching grooved pulleys, while paths where the belt’s back touches a pulley indicate a smooth idler or tensioner wheel surface.

What are the parts of 2013 Nissan Altima serpentine system?

The system consists of the crankshaft pulley, which provides power, the alternator for charging, the A/C compressor for cooling, and the water pump on some configurations. The automatic tensioner maintains constant pressure, while the belt itself transfers mechanical energy. If these fail, the ECU may record a diagnostic code.

Why is the serpentine belt important?

The serpentine belt powers every major accessory in your engine. If it snaps, the alternator stops charging, potentially causing the ECU to trigger a check engine light or OBD-II diagnostic code. Without it, the water pump may fail to circulate coolant, leading to immediate engine overheating and severe internal damage.

What is the difference between a serpentine belt and a timing belt?

A serpentine belt is located on the outside of the engine and powers accessories like the alternator and A/C. A timing belt is internal, synchronizing the crankshaft and camshaft. While a broken serpentine belt causes accessory failure and possible check engine lights, a broken timing belt often results in catastrophic engine destruction.

How do I use 2013 Nissan Altima serpentine belt diagram?

Use the diagram as a reference before removing the old belt by sketching or photographing the current setup. During installation, thread the new belt according to the diagram’s path, leaving the tensioner for the final step. This ensures the belt is not twisted and is properly seated in every pulley.