Golf Cart Solenoid Wiring Diagram: Easy Connection Guide

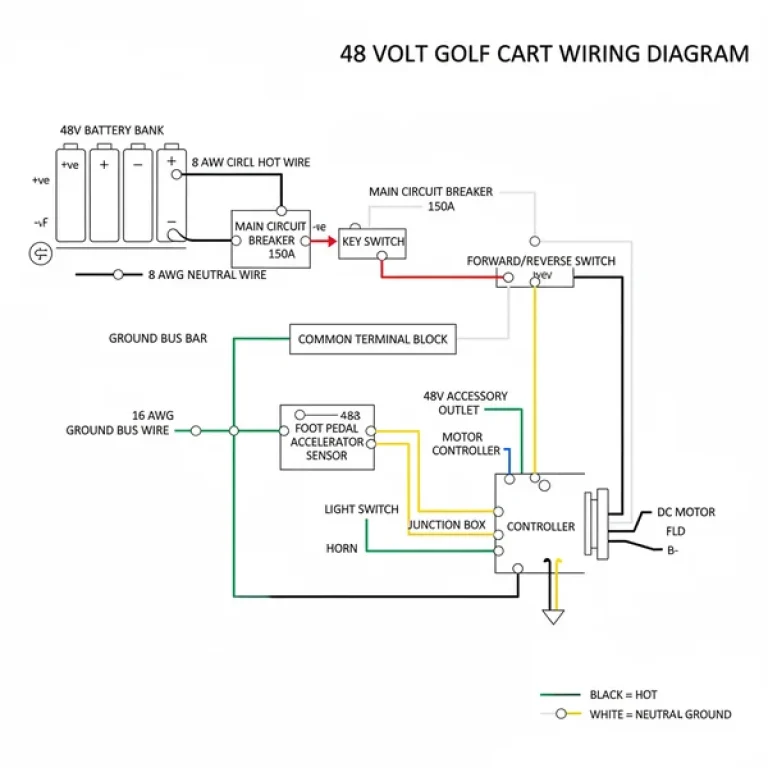

A golf cart solenoid wiring diagram illustrates how the battery, ignition, and motor controller connect to the solenoid’s terminals. It shows the high-current power path and the low-current activation circuit, ensuring the motor receives power only when the key is on and the accelerator is pressed, completing the electrical loop safely.

📌 Key Takeaways

- The diagram maps both high-current and low-current electrical paths

- Correctly identifying large vs small terminals is essential for safety

- Always disconnect the battery pack before using the wiring diagram

- Proper gauge wiring prevents overheating and potential solenoid failure

- Use this diagram for solenoid replacement or diagnosing power issues

Understanding the internal logic of your vehicle begins with a clear golf cart solenoid wiring diagram. Whether you are dealing with a sudden failure where the cart refuses to move or you are performing a routine upgrade to a high-performance controller, the solenoid is the heart of the electrical system. This electromechanical switch acts as the gatekeeper between your high-capacity battery bank and the motor, allowing a low-current signal from your key switch to trigger a high-current flow. By mastering the wiring layout, you gain the ability to diagnose “no-start” conditions, replace faulty components with confidence, and ensure your vehicle operates safely under heavy loads. This guide provides a comprehensive breakdown of the wiring architecture, component identification, and the specific steps required to ensure your cart’s electrical path is optimized for longevity and performance.

Understanding the Components of a Solenoid Diagram

A golf cart solenoid wiring diagram is essentially a map of two distinct circuits working in harmony: the “control circuit” and the “power circuit.” When you look at the diagram, you will notice the solenoid features four distinct terminals. Two are large threaded posts, and two are smaller posts, often featuring a brass screw for secure connections. The large terminals handle the high-amperage current—often 200 to 400 amps—that travels from the battery to the motor. The smaller terminals are part of the activation circuit, which typically operates at the standard system voltage of 36V or 48V but at a much lower amperage.

In a standard diagram, you will see the hot wire originating from the battery positive, moving through the key switch and the microswitch (usually located in the pedal box), and eventually reaching one of the small terminals on the solenoid. The other small terminal is connected to the ground wire, completing the loop. Within the diagram, color-coding is vital. Red lines typically indicate the high-voltage power path, while thinner lines represent the signal wires. You may also see a “traveler wire” concept in some advanced aftermarket setups where signals are routed through a direction selector or a controller interface. Understanding the gauge of these wires is critical; the power circuit requires thick 4-gauge or 6-gauge cables to prevent overheating, while the control circuit can function safely with 16-gauge or 18-gauge wire.

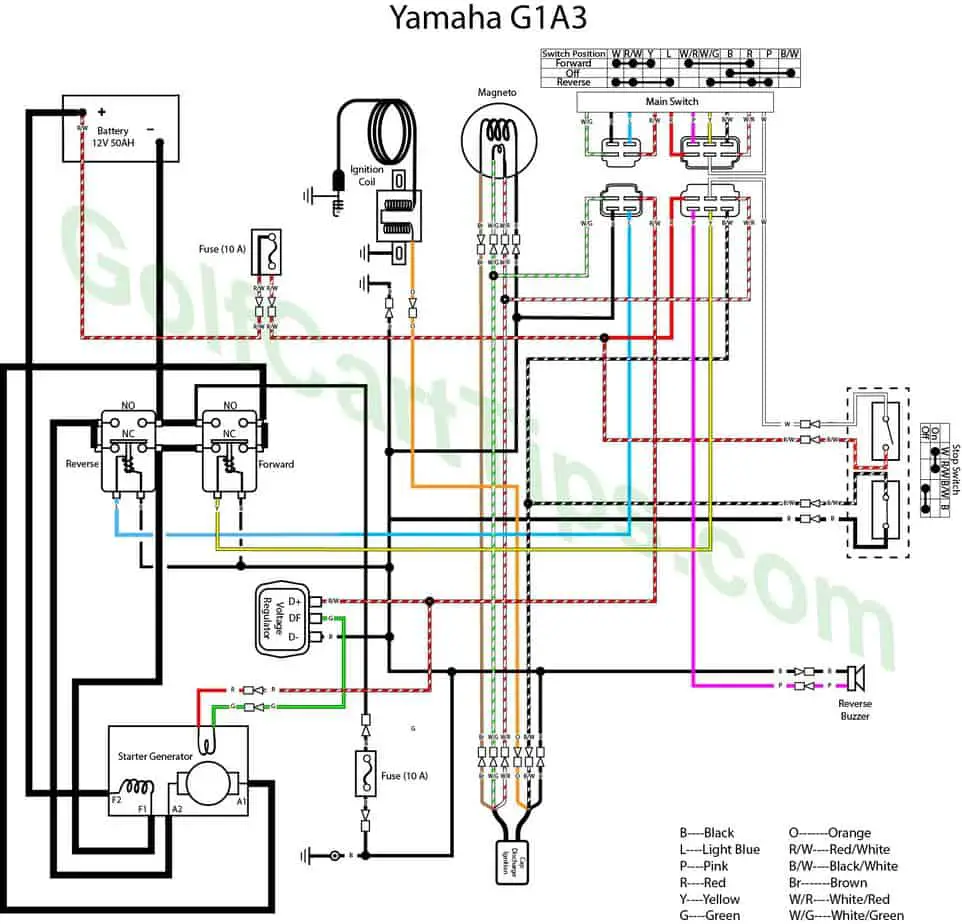

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing a 4-terminal solenoid. The two large top terminals are labeled “Battery Positive” and “Controller B+.” A resistor is shown bridged across the large terminals. The two small front terminals are labeled “Activation Input” and “System Ground.” Arrows indicate the flow of voltage from the key switch through the small brass screw terminals, while heavy-gauge lines show the main power path.]

Most modern golf cart solenoids are “constant duty,” meaning they are designed to remain engaged for long periods. Never replace a golf cart solenoid with a standard automotive starter solenoid, as those are “intermittent duty” and will burn out within minutes of use.

Step-by-Step Installation and Wiring Guide

Interpreting a golf cart solenoid wiring diagram is the first step; the second is the physical implementation. Following a systematic approach ensures that you do not cross-wire the system, which could lead to expensive controller damage or a fire hazard.

1. Preparation and Safety

Before touching any wires, switch the golf cart to “Tow” mode (if applicable) and disconnect the main positive and negative cables from the battery pack. This eliminates the risk of accidental short-circuits. Gather your tools: a 1/2-inch wrench for the large terminals and a 3/8-inch or 10mm wrench for the small brass screw terminals.

2. Identify the Common Terminal and Power Paths

Look at your diagram to identify which large terminal serves as the input from the battery. This is often connected directly to the “Main Positive” of the battery pack. The other large terminal is the output, which sends current to the “B+” terminal on your speed controller. If your diagram includes a pre-charge resistor, slide the circular eyelets of the resistor over these two large posts before attaching the heavy-gauge cables.

3. Wiring the Activation (Small) Terminals

The control circuit is non-polarized on many solenoids, but check your diagram to be sure. One small terminal will receive the hot wire coming from the ignition/pedal switch assembly. The second small terminal must be connected to the ground wire. In many EZGO and Club Car models, this ground is provided by the controller or a dedicated wire to the battery negative.

4. Installing the Diode

If your kit includes a flyback diode, it must be installed across the two small terminals. The diagram will show a stripe on one end of the diode; this stripe must point toward the hot wire side. The diode prevents voltage spikes from traveling back into the delicate electronics of your controller when the solenoid clicks off.

5. Securing Connections and Testing

Tighten all nuts firmly but avoid over-torquing, as the internal contacts of the solenoid can be twisted and damaged. Ensure that the neutral wire or ground path is clean and free of corrosion. Once everything is secure, reconnect the battery cables, switch the cart to “Run,” and turn the key. You should hear a distinct “click” when the pedal is pressed, indicating the solenoid is engaging.

Always use a digital multimeter to verify the voltage of your battery pack before installation. Connecting a 36V solenoid to a 48V battery pack will result in immediate component failure and potential injury.

Common Issues and Troubleshooting

Even with a perfect golf cart solenoid wiring diagram, issues can arise due to component fatigue or poor connections. The most common symptom of a solenoid failure is the cart not moving despite the batteries being fully charged.

If you hear a click but the cart doesn’t move, the internal copper discs (the common terminal contact point) may be pitted or burnt. You can verify this by using a voltmeter to check the voltage on both large posts while the solenoid is engaged. They should show the same voltage. If one post shows 48V and the other shows 0V while clicked, the solenoid is faulty.

If there is no click at all, the issue lies in the control circuit. Refer back to your diagram and trace the hot wire from the key switch to the small brass screw terminal. Use your meter to see if power is reaching that terminal when the pedal is depressed. If power is present but there is no click, check the ground wire. Without a solid path to the negative terminal, the coil cannot magnetize to pull the internal plunger down.

- ✓ Welded Contacts: The cart moves as soon as the key is turned, without pressing the pedal.

- ✓ Intermittent Clicking: Often caused by a loose traveler wire or a corroded brass screw connection.

- ✓ Thermal Failure: The solenoid works when cold but fails after 10 minutes of driving.

Tips and Best Practices for Maintenance

To ensure your solenoid and wiring remain in peak condition, regular maintenance is required. The environment under a golf cart seat is often subject to moisture and acidic vapors from the batteries, which can lead to rapid corrosion.

Apply a thin layer of dielectric grease to all terminal connections after tightening. This creates a moisture-proof barrier that prevents oxidation and ensures the voltage remains consistent across the circuit.

Always match the solenoid amperage rating to your controller’s output. If you have upgraded to a 500-amp controller but are still using a stock 200-amp solenoid, the solenoid will become a bottleneck, overheating and eventually failing. Investing in a heavy-duty solenoid with silver-alloy contacts is a cost-effective way to improve the reliability of your cart.

When replacing wires, always use the correct gauge. For the main power lines, 4-gauge copper wire is the industry standard for 36V and 48V systems. Using a wire that is too thin increases resistance, which drops the voltage reaching the motor and generates heat. Check the tightness of the brass screw terminals every six months, as vibration from driving can loosen these smaller connections, leading to “ghost” issues where the cart intermittently refuses to start.

Finally, always keep a copy of your specific golf cart solenoid wiring diagram in your glove box or saved on your phone. Having a reference for which wire goes to the common terminal versus the activation posts can save you hours of frustration when performing field repairs or troubleshooting on the fly. By following these guidelines and maintaining a clean, high-voltage path, you ensure that your golf cart remains a reliable mode of transportation for years to come.

Frequently Asked Questions

What is a golf cart solenoid wiring diagram?

A golf cart solenoid wiring diagram is a technical schematic that visualizes the electrical connections between the batteries, key switch, and motor. It highlights the paths for both high-voltage power and low-voltage activation signals, allowing users to safely install, replace, or troubleshoot the solenoid, which acts as the cart’s primary power relay.

How do you read a golf cart solenoid wiring diagram?

Reading this diagram requires identifying the two large terminals for high-current battery power and the two small terminals for the activation circuit. Follow the lines to see where the traveler wire connects to the ignition and how the ground wire completes the loop, ensuring you understand the flow of electricity before making physical connections.

What are the parts of a golf cart solenoid?

The main parts include the two large high-current terminals, two small activation terminals, and the internal contactor coil. The diagram also shows the hot wire coming from the battery pack, the common terminal for power distribution, and the mounting bracket which often acts as a structural support during the installation process.

Why is the common terminal important?

The common terminal is vital because it serves as the primary connection point where high-current power enters or exits the solenoid. Ensuring this connection is tight and clean prevents electrical resistance, which can lead to overheating, melted components, or a failure of the golf cart to move when the accelerator is depressed.

What is the difference between a hot wire and a neutral wire?

In this DC system, the hot wire carries the positive voltage required to activate the solenoid coil, while the neutral wire or ground provides the return path to the battery. Understanding this difference is crucial for preventing short circuits and ensuring the electromagnetic coil inside the solenoid triggers the high-power contacts correctly.

How do I use a golf cart solenoid wiring diagram?

Use the diagram as a visual reference by comparing the physical wires on your golf cart to the symbols on the page. Use it to verify that the traveler wire is in the right position and that all connections to the common terminal are secure, preventing errors during a solenoid replacement or upgrade.