Chrysler 200 Serpentine Belt Diagram: Routing Guide

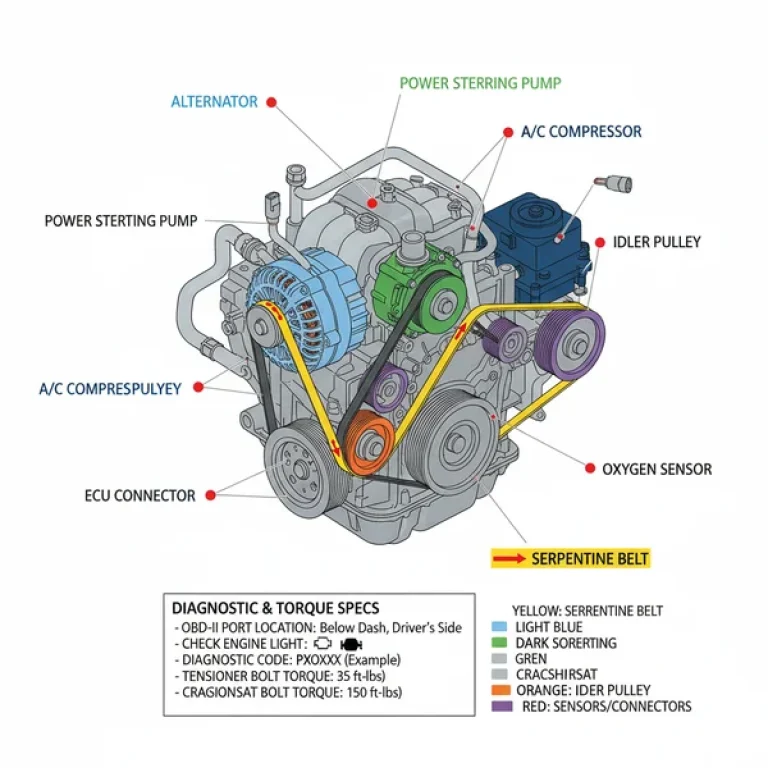

A 2012 Chrysler 200 serpentine belt diagram illustrates the specific path the belt takes around pulleys like the alternator, AC compressor, and water pump. It ensures the belt stays under proper tension. Incorrect routing can trigger a check engine light or store a diagnostic code within the ECU to alert drivers.

📌 Key Takeaways

- Ensures correct power delivery to all engine accessories

- Identifies the automatic tensioner needed for belt release

- Prevents mechanical damage from improper pulley skipping

- Verifies routing before engine startup to avoid failure

- Essential reference when the belt shows signs of wear or cracking

When you are facing a squealing engine or a sudden loss of power steering, having access to a reliable 2012 chrysler 200 serpentine belt diagram is the first step toward a successful repair. The serpentine belt, often referred to as the accessory belt, is a single, continuous belt used to drive multiple peripheral devices in your engine, such as the alternator, power steering pump, water pump, and air conditioning compressor. Because this component is vital for the operation of these systems, understanding its routing is essential for any DIY enthusiast or mechanic. In this guide, you will learn how to identify the correct routing for both the 2.4L and 3.6L engine options, the tools required for the job, and how to troubleshoot related system failures that might trigger a check engine light or diagnostic code.

Understanding the 2012 Chrysler 200 Serpentine Belt Diagram

The 2012 Chrysler 200 was manufactured with two distinct engine configurations: the 2.4L four-cylinder (World Engine) and the 3.6L Pentastar V6. Each engine utilizes a unique 2012 chrysler 200 serpentine belt diagram, meaning the routing and number of pulleys differ significantly between models.

For the 2.4L I4 engine, the layout is relatively straightforward. This configuration typically includes the crankshaft pulley (the power source), the alternator, the air conditioning compressor, a tensioner pulley, and an idler pulley. On this specific engine, the water pump is driven internally by the timing chain, so the serpentine belt focuses primarily on electrical generation and cabin comfort.

In contrast, the 3.6L V6 Pentastar engine features a more complex routing. The belt must navigate around the crankshaft, alternator, water pump, A/C compressor, and power steering pump, while being managed by both an automatic tensioner and an idler pulley. Unlike the smaller engine, the 3.6L relies on the serpentine belt to maintain coolant flow. If this belt snaps, the water pump stops turning immediately, leading to a rapid rise in engine temperature.

Visualizing these components requires looking at the “ribbed” versus “smooth” sides of the belt. Pulleys with grooves or ribs always interface with the ribbed side of the belt, while smooth idler pulleys or the backside of the tensioner typically interface with the flat, smooth side of the belt.

Visual representation showing the clockwise and counter-clockwise loops around the alternator, A/C compressor, and tensioner.

Always verify your engine type before beginning work. The 2.4L belt is shorter and follows a five-point path, while the 3.6L belt is longer and follows a seven-point path. Mixing up these diagrams can lead to incorrect tension and component damage.

Step-By-Step Installation and Interpretation Guide

Replacing a belt using the 2012 chrysler 200 serpentine belt diagram requires patience and the right leverage. Because the engine bay in the Chrysler 200 is somewhat cramped, especially in the V6 models, following these steps in order will save you time and prevent injury.

Required Tools and Materials

- ✓ Serpentine belt tool or a long-handle 3/8-inch drive ratchet

- ✓ 15mm or 16mm socket (depending on the tensioner bolt head)

- ✓ Replacement EPDM serpentine belt

- ✓ Flashlight and mechanics gloves

The Replacement Process

1. Safety First: Ensure the engine is completely cool. Disconnect the negative battery terminal. This is a crucial safety step to prevent the engine from accidentally cranking and to protect the ECU from voltage spikes while working near the alternator.

2. Locate the Tensioner: Identify the automatic tensioner pulley. On the 2.4L, it is located toward the middle-front of the engine block. On the 3.6L, it is positioned lower down. The tensioner is a spring-loaded arm designed to keep the belt tight.

3. Release Belt Tension: Place your long-handle ratchet or serpentine tool onto the tensioner’s center bolt. Rotate the tensioner (usually clockwise for the 2012 Chrysler 200) to compress the internal spring. This will create slack in the belt.

4. Remove the Old Belt: While holding the tensioner in the “released” position, slide the belt off the uppermost pulley (usually the alternator). Slowly release the tensioner arm back to its resting position. You can now pull the old belt out of the engine bay.

5. Inspect Pulleys: Before installing the new belt, spin each pulley by hand. They should spin freely without grinding noises or lateral “wobble.” If a pulley is seized, the new belt will snap almost immediately.

6. Route the New Belt: Using your 2012 chrysler 200 serpentine belt diagram, begin looping the new belt around the lower pulleys first (crankshaft and A/C compressor). Work your way up, leaving the tensioner or the alternator for the last step. Ensure the ribs of the belt are perfectly seated in the grooves of the pulleys.

7. Apply Tension: Rotate the tensioner arm once more to create the necessary clearance. Slide the final loop of the belt over the last pulley. Double-check that the belt hasn’t slipped off any of the lower pulleys during this process.

8. Final Check: Slowly release the tensioner so it applies pressure to the belt. Inspect the entire path one last time to ensure the belt is centered. Reconnect the battery and start the engine for a brief moment to ensure the belt tracks properly.

Never place your fingers between the belt and the pulley. If the tensioner tool slips, the spring force is strong enough to cause severe injury. Always handle the belt from the sections between the pulleys.

Common Issues & Troubleshooting

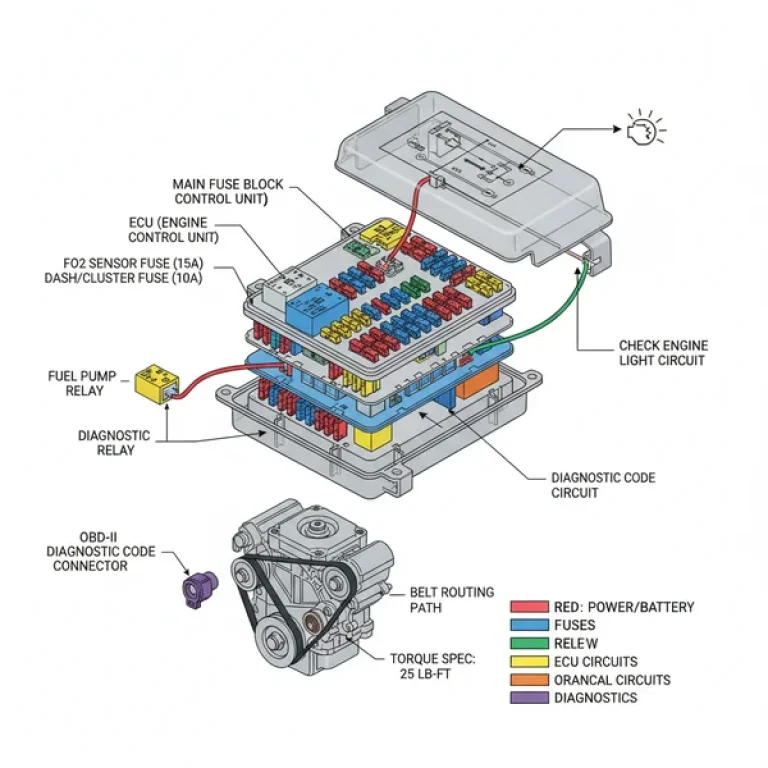

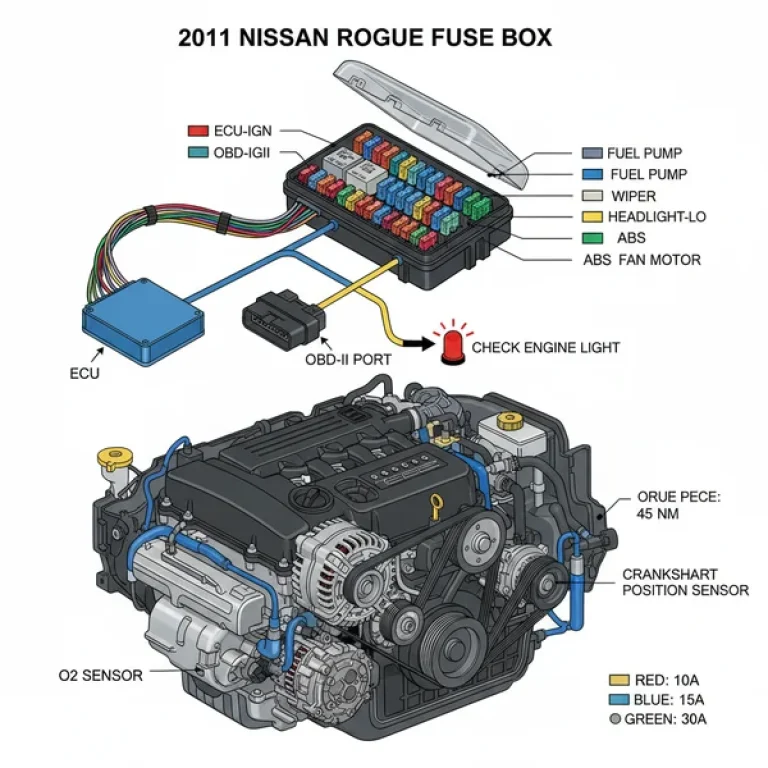

A failing serpentine belt on a 2012 Chrysler 200 often manifests through audible and electrical symptoms. The most common sign is a high-pitched squeal, which usually indicates a glazed belt or a failing tensioner. If the belt is slipping, the alternator may not provide consistent power, causing the ECU (Engine Control Unit) to detect a low voltage state.

When the ECU detects irregular voltage, it may trigger a check engine light and store a diagnostic code such as P0562 (System Voltage Low). If you use an OBD-II scanner and see this code, don’t immediately assume the alternator is dead; check the condition and tension of the serpentine belt first.

Another critical issue involves the 3.6L engine’s water pump. Since the belt drives the pump, a broken belt stops coolant flow. If you notice your temperature gauge rising rapidly, pull over immediately. Driving without coolant flow can cause catastrophic engine failure, even if the timing chain is still intact and the engine is technically “running.”

If your belt is making a “chirping” noise that disappears when you spray a small amount of water on it, the issue is likely a misaligned pulley. If the noise gets louder, the belt itself is likely worn out and needs replacement.

Tips & Best Practices for Longevity

To ensure your 2012 Chrysler 200 remains reliable, proactive maintenance is better than reactive repair. Most serpentine belts are designed to last between 60,000 and 100,000 miles, but heat and environmental factors can shorten this lifespan.

First, always opt for high-quality EPDM (Ethylene Propylene Diene Monomer) belts. Unlike older neoprene belts, EPDM does not typically crack with age. Instead, the grooves simply wear deeper, much like a tire tread. You can use a belt wear gauge to check if the grooves have become too wide, which reduces the surface area contact and leads to slipping.

Second, when replacing the belt, consider the “kit” approach. Since the labor to reach the belt is the hardest part, many mechanics recommend replacing the automatic tensioner and idler pulley at the same time. A new belt on a worn tensioner will likely fail prematurely because the weakened spring cannot maintain the required torque spec for the accessory drive system.

Finally, keep a printed copy of the 2012 chrysler 200 serpentine belt diagram in your glovebox. In the event of a roadside failure, having the diagram handy can turn a potential tow-truck situation into a quick parking-lot fix. Regular inspections during oil changes—looking for fraying, oil contamination, or “pilling” in the grooves—will help you catch issues before they result in a diagnostic code or a stranded vehicle. By following these guidelines and using the correct diagram, you ensure your Chrysler 200 continues to operate smoothly for years to come.

Step-by-Step Guide to Understanding the Chrysler 200 Serpentine Belt Diagram: Routing Guide

Identify the belt routing – Start with identifying the specific path by referencing the diagram found under the hood or in the service manual.

Locate the tensioner – Locate the spring-loaded tensioner pulley and determine the direction needed to rotate it to release the belt tension.

Understand how to release – Understand how to apply a wrench or breaker bar to the tensioner to create slack and carefully slide the belt off.

Connect the new belt – Connect the new belt by looping it around the crankshaft first, then follow the diagram for all other accessory pulleys.

Verify that belt seats – Verify that the belt is perfectly aligned within all pulley grooves to prevent jumping or shredding during vehicle operation.

Complete the installation – Complete the process by releasing the tensioner and checking for a stored diagnostic code or check engine light using OBD-II.

Frequently Asked Questions

What is a Chrysler 200 serpentine belt diagram?

A serpentine belt diagram is a visual map showing how the drive belt wraps around various engine pulleys. It is crucial for ensuring that components like the alternator and power steering pump rotate in the correct direction. Without this guide, you risk improper installation, leading to mechanical failure.

How do you read a Chrysler 200 serpentine belt diagram?

To read the diagram, identify the crankshaft pulley as the starting point. Follow the line to each accessory, noting whether the belt goes over or under the pulley. Pay close attention to the tensioner pulley, which is used to create slack during installation or removal of the belt.

What are the parts of the serpentine belt system?

The system consists of the crankshaft pulley, which provides power, and accessory pulleys for the alternator, AC compressor, and water pump. An automatic tensioner maintains the required pressure, while idler pulleys guide the belt. Failure in any part may cause the ECU to register a specific diagnostic code.

Why is the automatic tensioner important?

The automatic tensioner is vital because it maintains a consistent torque spec on the belt, preventing slippage or excessive wear. If the tensioner fails, the belt may squeal or snap, potentially causing the engine to overheat and triggering a check engine light via the vehicle’s OBD-II system.

What is the difference between a serpentine belt and a V-belt?

A serpentine belt is a single, long, flat belt with multiple grooves that powers all engine accessories simultaneously. In contrast, older V-belt systems use multiple individual belts for different components. Serpentine systems are more efficient but require a precise routing diagram for maintenance and troubleshooting purposes.

How do I use this serpentine belt diagram?

Use the diagram by matching the pulley layout under your hood to the illustration. Before removing the old belt, verify the path. Use a breaker bar on the tensioner to release pressure, then thread the new belt following the diagram, ensuring it sits flush in every groove.