belt routing 6.0 vortec serpentine belt diagram: Proper Setup

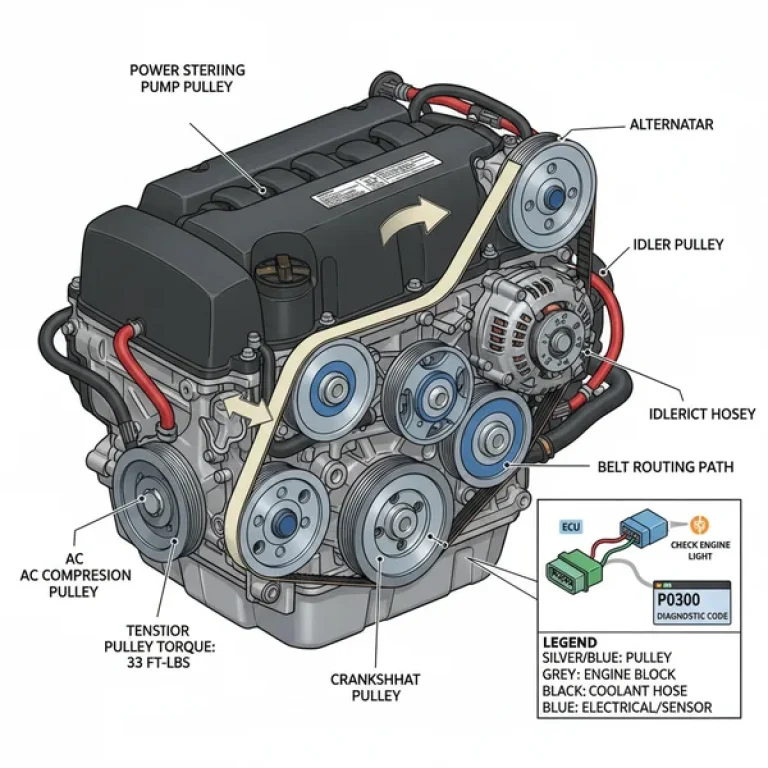

The 6.0 Vortec serpentine belt routing involves threading the belt around the crankshaft, alternator, power steering pump, water pump, and idler pulleys. Use a 1/2-inch breaker bar on the tensioner to release pressure. Ensure the ribs align perfectly with the grooves to avoid a diagnostic code or triggering the check engine light.

📌 Key Takeaways

- Ensures critical engine accessories like the alternator and water pump function correctly.

- The spring-loaded tensioner is the most important component to identify for installation.

- Always disconnect the battery and ensure the engine is cool before touching pulleys.

- Inspect the belt for glazing while the ECU monitors sensor data for performance.

- Use this diagram when replacing a worn belt or if you hear a loud squealing noise.

Finding an accurate belt routing 6.0 vortec serpentine belt diagram is an essential first step for any DIY mechanic or truck owner looking to perform routine maintenance. The 6.0-liter Vortec engine, a staple of the GM LS-based engine family, relies heavily on a single accessory belt to power vital systems like the alternator, power steering pump, and water pump. If this belt slips or snaps, your vehicle will quickly lose power and risk overheating. By understanding the specific path the belt takes around various pulleys, you can ensure your engine operates efficiently and avoid costly roadside breakdowns. In this guide, you will learn the exact routing sequence, the tools required for the job, and how to identify when other internal components might be failing.

Understanding the 6.0 Vortec Serpentine Belt Layout

The serpentine belt on a 6.0 Vortec engine is designed to wrap around several key components in a specific “serpentine” fashion to maximize surface contact and grip. Unlike older engines that used multiple V-belts, this modern accessory belt system uses a single, long ribbed belt for the main accessories. However, it is important to note that many 6.0 Vortec configurations utilize a two-belt system: a primary belt for most accessories and a smaller, secondary belt dedicated solely to the A/C compressor located lower on the passenger side of the block.

When looking at the belt routing 6.0 vortec serpentine belt diagram, you will notice several distinct circles representing the pulleys. The largest pulley at the bottom center is the crankshaft pulley (harmonic balancer), which provides the rotational force for the entire system. Moving clockwise from the top, you generally encounter the alternator (top driver’s side), the power steering pump (middle driver’s side), and the water pump (large center pulley). The tensioner pulley and the idler pulley are smooth-faced components that do not “drive” an accessory but instead provide the necessary tension and directional guidance to keep the belt seated.

[DIAGRAM_PLACEHOLDER: 6.0 Vortec Serpentine Belt Routing Path]

(Visualizing the path: Crankshaft -> Water Pump -> Alternator -> Idler -> Power Steering -> Tensioner -> Back to Crankshaft)

The water pump on the 6.0 Vortec is particularly important as it regulates coolant flow throughout the engine block and heads. Because the belt drives this pump, a failed belt means an immediate stop to coolant circulation, leading to rapid temperature spikes. The diagram also highlights the difference between ribbed pulleys and smooth pulleys. Ribbed pulleys interface with the grooved side of the belt, while smooth pulleys (like the idler and tensioner) usually interface with the flat back side of the belt.

Most 6.0 Vortec engines found in heavy-duty trucks use a separate, smaller belt for the A/C compressor. This belt is located behind the main serpentine belt and must be removed first if you are performing a full overhaul of the front engine accessories.

Step-by-Step Installation and Routing Guide

Replacing your belt using a belt routing 6.0 vortec serpentine belt diagram is a straightforward process if you follow a logical sequence. Before starting, ensure the engine is completely cool to avoid burns from the radiator or water pump housing.

- ✓ 1/2-inch drive breaker bar or a dedicated serpentine belt tool

- ✓ A new high-quality EPDM serpentine belt

- ✓ Flashlight and a clean rag

- ✓ Safety glasses and gloves

Step 1: Locate the Tensioner

Open the hood and locate the automatic belt tensioner. On the 6.0 Vortec, this is typically located on the passenger side of the engine, slightly above the water pump. It features a pulley attached to a spring-loaded arm with a square 1/2-inch drive hole or a hexagonal bolt head in the center.

Step 2: Release Belt Tension

Insert your breaker bar or belt tool into the tensioner. Rotate the tool clockwise (toward the driver’s side) to compress the spring and release the tension on the belt. While holding the tensioner in this position, use your other hand to slide the belt off the uppermost pulley, which is usually the alternator.

Step 3: Remove the Old Belt

Slowly release the tensioner arm back to its resting position. Carefully thread the old belt out from around the fan blades (if equipped with a mechanical fan) and away from the remaining pulleys. This is an excellent time to inspect the pulleys for play or “wobble,” which could indicate a failing bearing.

Step 4: Clean the Pulley Grooves

Use a clean rag or a soft wire brush to remove any rubber deposits or debris from the grooves of the crankshaft, alternator, and power steering pulleys. Clean pulleys ensure the new belt seats perfectly and prevents premature wear or squealing.

Step 5: Route the New Belt

Begin routing the new belt according to your belt routing 6.0 vortec serpentine belt diagram. It is often easiest to start at the bottom with the crankshaft pulley, then work your way up to the power steering pump and water pump. Ensure the ribs of the belt align perfectly with the grooves on the pulleys. Leave the smooth idler pulley or the alternator for the final step.

Step 6: Apply Tension and Seat

Once the belt is routed around every pulley except one, rotate the tensioner again using your tool. Slide the belt over the final pulley. Double-check that the belt is centered on every single pulley. If the belt is even half a rib off-center, it will shred within minutes of starting the engine.

Never place your fingers between the belt and the pulley while the tensioner is being held back. If the tool slips, the tensioner can snap back with enough force to cause serious injury.

Common Troubleshooting and Accessory Issues

While the belt itself is a common wear item, its failure often points to deeper issues within the engine’s accessory drive. If your belt has snapped or is frequently slipping, it may trigger a check engine light on your dashboard. When this happens, using an OBD-II scanner can reveal a diagnostic code related to charging system failure or engine overheating.

The ECU (Engine Control Unit) monitors the alternator’s output voltage. If the belt is slipping, the alternator cannot maintain the required voltage, causing the ECU to store a code and illuminate the battery light. Furthermore, if the belt stops driving the water pump, the engine’s temperature sensors will detect a rapid rise in heat, potentially putting the vehicle into “limp mode” to protect the internal components.

If you hear a high-pitched chirping sound that disappears when you spray a small amount of water on the belt, the issue is likely belt alignment or wear. If the noise persists or sounds like a metallic grind, a pulley bearing is likely failing.

Another area to watch is the timing chain. While the serpentine belt is external, the timing chain is internal and keeps the camshaft and crankshaft synchronized. On high-mileage 6.0 Vortec engines, excessive vibration from a worn harmonic balancer (crankshaft pulley) can theoretically put unnecessary stress on the front of the crank. Always ensure your harmonic balancer is in good condition when replacing your accessory belt.

Maintenance Tips and Best Practices

To get the most out of your 6.0 Vortec engine, proactive maintenance of the accessory drive system is vital. Most manufacturers recommend inspecting the serpentine belt every 30,000 miles and replacing it every 60,000 to 100,000 miles, depending on environmental conditions. Heat and road salt can accelerate the degradation of the rubber compounds.

When replacing components, always adhere to the proper torque spec for pulley bolts. For example, the idler pulley bolt and the tensioner mounting bolts usually require specific torque settings to prevent them from vibrating loose. Over-tightening can damage the threads in the aluminum engine block or accessory brackets, while under-tightening can lead to catastrophic failure while driving.

In terms of cost-saving, it is often more economical to replace the tensioner and the idler pulley at the same time as the belt. These components contain bearings that have the same service life as the belt itself. If the tensioner’s internal spring weakens, it won’t provide enough pressure to keep the belt tight, leading to slipping and reduced performance of the power steering and charging systems.

Finally, always choose a high-quality replacement belt. Look for belts made of EPDM (Ethylene Propylene Diene Monomer), as they do not crack like older chloroprene belts. Instead, EPDM belts lose material over time—similar to a tire tread—which can be measured with a belt wear gauge. By keeping a belt routing 6.0 vortec serpentine belt diagram in your glove box or saved on your phone, you are always prepared for an emergency repair, ensuring your Vortec engine stays on the road for hundreds of thousands of miles.

Frequently Asked Questions

What is belt routing 6.0 vortec serpentine belt diagram?

The belt routing 6.0 vortec serpentine belt diagram is a visual map showing the path a single belt takes around engine accessories. It ensures components like the water pump and alternator rotate correctly. Without it, you might misroute the belt, causing overheating or electrical failure in your GM truck.

How do you read belt routing 6.0 vortec serpentine belt diagram?

Reading this diagram involves following the continuous line representing the belt around various circles, which represent the pulleys. Solid lines usually indicate the grooved side of the belt, while smooth paths represent the flat back side. Pay close attention to arrows indicating the direction of engine rotation for accuracy.

What are the parts of 6.0 Vortec belt system?

The parts of the 6.0 Vortec belt system include the crankshaft pulley, alternator, power steering pump, water pump, and idler pulley. Many 6.0 engines also feature a separate, smaller belt for the air conditioning compressor located lower on the block, which requires its own specific and separate routing path.

Why is the tensioner important?

The tensioner is vital because it maintains the specific torque spec required to keep the belt tight during engine operation. A failing tensioner can cause the belt to slip or snap, potentially triggering a diagnostic code or a check engine light on your dashboard via the vehicle’s ECU monitoring.

What is the difference between the main and AC belt?

The primary difference is the function and size. The main serpentine belt drives most critical accessories like the alternator and water pump. The AC belt is typically a smaller, secondary belt dedicated solely to the compressor. Replacing both simultaneously is often recommended during standard engine maintenance or repair procedures.

How do I use belt routing 6.0 vortec serpentine belt diagram?

Use this diagram as a reference guide while threading the new belt through the engine bay. Start at the bottom crankshaft pulley and work upward, leaving the tensioner for the final step. Double-check the alignment with an OBD-II scanner if any performance issues arise after the belt installation.