6.7 Cummins Serpentine Belt Diagram: Routing & Installation

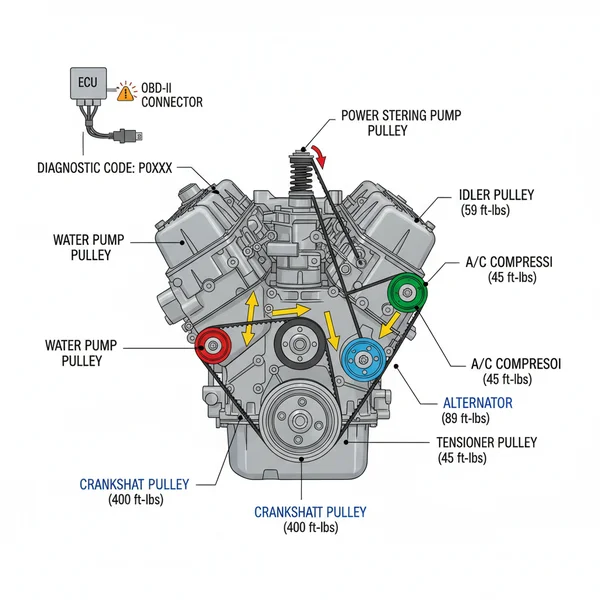

The 6.7 Cummins serpentine belt diagram illustrates the precise path the drive belt takes around the alternator, water pump, and AC compressor. Using a 1/2-inch breaker bar on the tensioner allows for easy removal. Ensure the belt ribs align perfectly with the pulleys to avoid throwing a diagnostic code or check engine light.

📌 Key Takeaways

- Provides the exact routing path to prevent engine overheating or charging failure

- The automatic belt tensioner is the most critical component for adjustment

- Always inspect pulley bearings for play or noise during belt replacement

- Keep a physical copy of the diagram in your glovebox for roadside repairs

- Use this diagram whenever the belt is removed for alternator or water pump service

Finding an accurate 2012 6.7 Cummins serpentine belt diagram is an essential first step for any truck owner looking to perform routine maintenance or emergency repairs. The 6.7-liter Cummins Turbo Diesel is a powerhouse of engineering, but its efficiency relies heavily on a complex accessory drive system. This article provides a high-fidelity breakdown of the belt routing, ensuring you understand exactly how the belt interacts with every pulley, from the alternator to the water pump. By following this guide, you will learn how to identify wear, use the correct tools for the job, and ensure your heavy-duty engine remains in peak operating condition.

Understanding the 2012 6.7 Cummins Serpentine Belt Layout

The 2012 6.7 Cummins serpentine belt diagram illustrates a single, multi-ribbed accessory belt that transfers rotational energy from the crankshaft to several critical components. Unlike older engines that used multiple V-belts, this modern serpentine system uses one continuous loop, which simplifies the engine’s front profile but makes the routing much more intricate. The diagram typically features eight distinct points of contact that the belt must navigate to function correctly.

At the heart of the system is the crankshaft pulley, which provides the driving force. From there, the belt travels to the fan hub, the water pump (critical for maintaining proper coolant flow), the air conditioning compressor, and the alternator. The alternator is monitored by the engine’s ECU to ensure the electrical system stays charged. The routing also includes two idler pulleys and a spring-loaded automatic tensioner. The tensioner is the only dynamic component in the path, designed to maintain constant pressure on the accessory belt to prevent slipping, even under high torque loads.

One important detail often noted in the diagram is the distinction between grooved pulleys and smooth pulleys. The ribbed side of the belt must always make contact with grooved pulleys (like the alternator and AC compressor), while the smooth back side of the belt typically contacts the smooth idler pulleys or the water pump on certain configurations. Understanding this “inside-out” routing is the key to preventing a premature belt failure or an expensive engine overheat.

Note: The belt begins at the large Crankshaft Pulley at the bottom, travels up to the Water Pump, wraps over the Alternator, dives under the Idler, crosses to the AC Compressor, and returns via the Tensioner.

Step-by-Step Installation and Interpretation Guide

Reading a 2012 6.7 Cummins serpentine belt diagram can be intimidating if you aren’t familiar with the engine bay’s cramped quarters. To successfully interpret the diagram and replace the belt, you need a systematic approach. Before starting, ensure the engine is completely cool to avoid burns from the radiator or cooling shroud.

The 2012 Dodge Ram 6.7 Cummins utilizes a 1/2-inch square drive interface directly on the tensioner arm. You do not need a specific socket; a long-handled breaker bar or a dedicated serpentine belt tool is usually sufficient to release the spring tension.

- Prepare the Work Area: Open the hood and locate the emissions sticker, which often contains a small version of the routing diagram. If yours is missing or illegible, use the diagram provided in this article. Disconnect the negative battery cables to ensure the engine cannot be turned over while your hands are near the pulleys.

- Release the Tensioner: Locate the automatic tensioner between the alternator and the crankshaft. Insert your 1/2-inch drive breaker bar into the square hole on the tensioner arm. Rotate the arm clockwise (towards the driver’s side) to compress the internal spring. This will create slack in the belt.

- Remove the Old Belt: While holding the tensioner in the compressed position, slip the belt off the topmost pulley (usually the alternator or upper idler). Slowly release the tensioner arm—do not let it snap back, as this can crack the casting. Carefully thread the belt around the cooling fan and remove it from the engine bay.

- Inspect the Pulley Components: With the belt removed, spin each pulley by hand. They should spin smoothly without noise or “wobble.” Check the water pump for leaks to ensure consistent coolant flow. If the tensioner feels gritty or the idler pulley has play, replace them now. A seized pulley will destroy a brand-new belt in seconds.

- Route the New Belt: Start by looping the belt around the crankshaft pulley at the bottom. Work your way up, following the 2012 6.7 Cummins serpentine belt diagram precisely. Use one hand to hold the belt against the pulleys while the other hand guides it through the narrow gaps. Save the smooth idler pulley or the alternator for the final step.

- Final Seating: Rotate the tensioner arm clockwise again and slide the belt over the final pulley. Ensure the ribs of the belt are perfectly centered in the grooves of every pulley. If the belt is even half a rib off, it will shred upon engine start.

- Verification: Double-check the routing against the diagram one last time. Release the tensioner and remove your tools. Reconnect the batteries and start the engine for a few seconds to let the belt seat itself.

Never attempt to route the belt while the engine is running. Furthermore, if you are replacing the tensioner assembly itself, ensure you use the correct torque spec for the mounting bolt (typically 32-40 ft-lbs) to avoid stripping the threads in the engine block.

Troubleshooting Common Belt and Pulley Issues

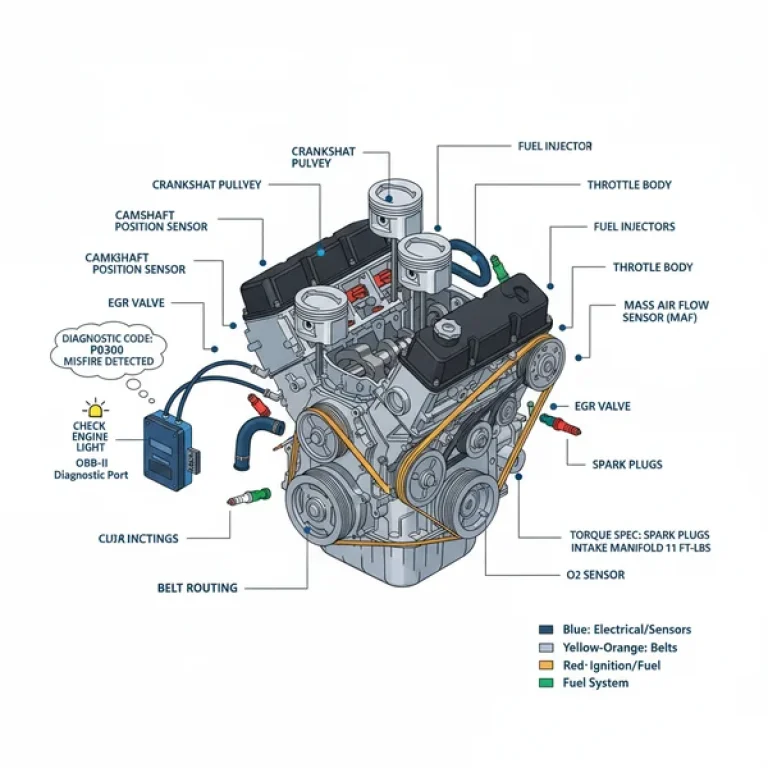

A failure in the accessory drive system often manifests through sounds or dashboard warnings. Because the 2012 6.7 Cummins is highly integrated with the ECU, a slipping or broken belt can trigger a check engine light or a specific diagnostic code. For instance, if the belt slips on the alternator, the ECU may detect a low voltage condition and throw a P0562 code.

Common symptoms include a high-pitched squeal, which usually indicates a glazed belt or a failing tensioner that can no longer maintain the proper load. If you notice a “chirping” sound at idle, it is often a sign of pulley misalignment or a bearing beginning to fail in the AC compressor or water pump. Using an OBD-II scanner can help confirm if the charging system or engine temperature is fluctuating due to belt performance.

The diagram is a vital troubleshooting tool because it helps you identify which component is driven by which side of the belt. If you see heavy wear on the back (smooth side) of the belt, you should focus your inspection on the water pump and idler pulleys. If the grooved side is fraying, the crankshaft, alternator, or AC compressor pulleys likely have debris or alignment issues. While the Cummins uses a timing chain internally for engine synchronization, the external belt is solely responsible for the “life support” systems of the vehicle.

Pro Tips for Maintaining the 6.7 Cummins Accessory Drive

To get the most mileage out of your 2012 6.7 Cummins serpentine belt, maintenance should be proactive rather than reactive. Most professional mechanics recommend inspecting the belt every 30,000 miles and replacing it every 100,000 miles, or sooner if cracking is visible.

When replacing the belt, always clean the pulley grooves with a stiff nylon brush and some brake cleaner. Accumulated rubber dust and road grime can cause even a brand-new belt to squeak or slip.

Consider these best practices to ensure longevity:

- ✓ Buy Quality: Stick with OEM Cummins/Mopar belts or high-end aftermarket options like Gates FleetRunner or Dayco Gold Label. These are designed to handle the high heat and torque of the 6.7-liter diesel.

- ✓ The Tensioner Rule: A common industry standard is to replace the tensioner every time you replace the belt. The internal spring loses its temper over time, and a weak tensioner is the leading cause of “premature belt death.”

- ✓ Carry a Spare: Because the 2012 6.7 Cummins serpentine belt diagram is so specific, finding a replacement at a small-town parts store in the middle of a trip can be difficult. Keep your old belt (if it isn’t shredded) behind the seat as an emergency backup.

- ✓ Check for Fluid Leaks: Diesel fuel and engine oil will quickly degrade the rubber compounds in a serpentine belt. If you have a leak near the front of the engine, fix it immediately to protect the accessory drive.

By keeping a printed copy of the 2012 6.7 Cummins serpentine belt diagram in your glove box and performing regular inspections, you can avoid the frustration of a roadside breakdown. Whether you are dealing with a check engine light related to charging or simply performing milestone maintenance, understanding this system is key to the legendary reliability of the Cummins engine. Proper tension, clean pulleys, and the correct routing will keep your truck on the road and performing at its best for hundreds of thousands of miles.

Frequently Asked Questions

What is a 6.7 Cummins serpentine belt diagram?

A 6.7 Cummins serpentine belt diagram is a visual schematic that illustrates the specific path a single, continuous belt takes to power engine accessories. It identifies the orientation around the crankshaft, alternator, power steering pump, and tensioner, ensuring all components rotate in the correct direction for optimal engine performance.

How do you read a 6.7 Cummins serpentine belt diagram?

To read the diagram, identify the crankshaft pulley as the starting point and follow the lines indicating the belt’s path. Smooth pulleys typically contact the back of the belt, while ribbed pulleys mesh with the belt’s grooves. Arrows often indicate the direction of rotation and tensioner movement for replacement.

What are the parts of a 6.7 Cummins drive system?

The system includes the crankshaft pulley, which provides power, the alternator for electrical charging, and the water pump for cooling. It also features an AC compressor, power steering pump, idler pulleys, and an automatic tensioner. Each part must be properly aligned to prevent the belt from slipping or snapping.

Why is the tensioner torque spec important?

The tensioner torque spec is vital because over-tightening can strip threads in the engine block, while under-tightening may lead to the tensioner vibrating loose. Maintaining the correct torque ensures the pulley remains square to the belt, preventing premature wear, belt squeal, and potential damage to the front gear housing.

What is the difference between a slipping belt and a failed tensioner?

A slipping belt usually produces a high-pitched squeal, often triggered by moisture or glaze, and might trigger a check engine light. A failed tensioner often causes the belt to vibrate excessively or walk off the pulleys. A diagnostic code related to low voltage might appear if the alternator loses speed.

How do I use a 6.7 Cummins serpentine belt diagram?

Use the diagram as a reference before removing the old belt to ensure you understand the routing. During installation, use it to verify the belt is seated in every groove of the ribbed pulleys. This prevents mechanical interference and ensures the ECU receives consistent data from the engine’s various sensors.