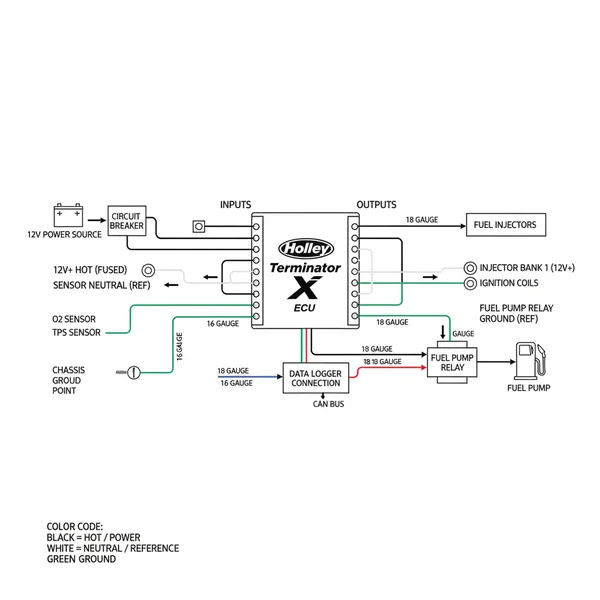

Holley Terminator X Inputs and Outputs Wiring Diagram: Mapping Guide

This wiring diagram illustrates how to configure auxiliary sensors and actuators using the J1A and J1B connectors. It identifies pinouts for PWM and digital signals, essential for controlling fans, boost, or nitrous. Proper grounding and identifying the switched 12V source ensure the ECU accurately triggers external components through the harness.

📌 Key Takeaways

- Correct pin identification prevents permanent damage to the ECU internal drivers.

- Differentiating between ground-triggered and 12V-triggered inputs is critical for sensor accuracy.

- Always use high-quality crimps for the J1A and J1B connector pins to ensure signal integrity.

- Relays are mandatory when using outputs to drive high-amperage components like fuel pumps.

- Software configuration must match the physical wiring pinout for the system to function.

Setting up a high-performance EFI system requires more than just mechanical skill; it demands a precise understanding of electrical signals and connectivity. For enthusiasts upgrading to a modern engine management system, the holley terminator x inputs and outputs wiring diagram serves as the essential roadmap for integrating cooling fans, nitrous kits, shift lights, and boost controllers. Whether you are transitioning from a carburetor or an older EFI setup, getting the wiring right the first time is the difference between a seamless first start and a frustrating afternoon of chasing electrical gremlins. In this guide, we will break down every aspect of the Holley Terminator X wiring ecosystem, ensuring you understand how to utilize every available pin to maximize your vehicle’s performance and reliability.

Decoding the Holley Terminator X Inputs and Outputs Wiring Diagram

The Holley Terminator X system utilizes two primary connectors on the ECU, typically referred to as the J1A and J1B headers. The holley terminator x inputs and outputs wiring diagram focuses heavily on the J1B connector, which houses the auxiliary wires used for custom configurations. Unlike standard residential wiring where you might look for a brass screw or a neutral wire, automotive EFI wiring is DC-based (Direct Current) and relies heavily on signal-specific colors and pin locations.

The input side of the diagram typically features four dedicated wires. These are designed to receive signals from external sensors or switches. For example, a “Ground Input” might be used to trigger a secondary fuel map when a nitrous system is activated. The output side also features four wires, which are primarily “Ground Triggers.” This means the ECU provides a path to the ground wire to complete a circuit, such as turning on a cooling fan relay.

In the diagram, you will notice that each wire is categorized by its gauge and function. Most signal wires are 20-gauge or 18-gauge, which is sufficient for low-current communication. It is important to distinguish these from the heavy-duty power wires that handle the primary battery voltage. While a household circuit might use a traveler wire to connect two switches to a common terminal, the Terminator X uses a “shared” sensor ground to provide a clean reference point for all input sensors. This prevents “electrical noise” from interfering with the delicate 5V or 12V signals passing through the ECU.

_

| Pin | Color | Function |

|——-|—————|————-|

| A1 | White | Input 1 |

| A2 | White/Black | Input 2 |

| A3 | White/Red | Input 3 |

| A4 | White/Green | Input 4 |

| B1 | Gray/Red | Output 1 |

| B2 | Gray/Black | Output 2 |

| B3 | Gray/White | Output 3 |

| B4 | Gray/Green | Output 4 |

|_|

(Note: Always verify with your specific harness ID)

Step-by-Step Installation Guide

Properly executing the holley terminator x inputs and outputs wiring diagram requires a methodical approach. Follow these steps to ensure your I/O pins are configured correctly and safely.

Step 1: Planning Your Map

Before touching a wire stripper, list every accessory you want the ECU to control. Common inputs include AC request, trans-brake release, or a valet mode switch. Common outputs include cooling fans, fuel pumps, or boost solenoids. Assign each of these to a specific pin on the J1B connector.

Step 2: Disconnecting the Power

Safety is paramount. Ensure the vehicle battery is disconnected. Since the ECU is sensitive to voltage spikes, never attempt to pin or unpin the connector while the system is energized.

Step 3: Preparing the Wires

Identify the specific input or output wire in the harness. If you are adding a new wire to a blank cavity, ensure you are using the correct gauge wire—typically 18 or 20 AWG for signals. Use a high-quality wire stripper to remove exactly 1/4 inch of insulation. Do not nick the copper strands, as this creates resistance and potential failure points.

Step 4: Understanding Grounding vs. Hot Wire Triggers

In residential electrical work, you deal with a hot wire and a neutral wire. In the Holley ecosystem, most outputs are “Pull to Ground.” This means you will connect one side of your device (like a relay coil) to a constant 12V source and the other side to the ECU output wire. When the ECU wants to “turn on” the device, it completes the path to the ground wire.

Step 5: Pinning the Connector

If you are adding pins to the J1B connector, use a dedicated crimping tool. A “loose” connection at the common terminal of the ECU connector will cause intermittent signal loss. Once the pin is crimped, slide it into the back of the connector until you hear a distinct “click.” Gently tug the wire to ensure it is locked in place.

Step 6: Routing and Shielding

Route your I/O wires away from high-noise components like spark plug wires or the alternator. Use loom or heat shrink to protect the wires from heat and abrasion. If you are running a signal wire through the firewall, use a rubber grommet to prevent the metal edge from cutting into the insulation.

Step 7: Software Configuration

The physical wiring is only half the battle. You must open the Holley software on your laptop or 3.5-inch touchscreen. Navigate to the “Inputs/Outputs” section and define each pin. For an input, tell the ECU if it is looking for a “Ground” or a “12V” signal. For an output, define the conditions (e.g., “Turn on Fan 1 when Coolant Temp > 190°F”).

Most Holley Terminator X outputs are rated for a maximum of 2 Amps. If you are powering a device that draws more current, such as a cooling fan or a high-pressure fuel pump, you MUST use the ECU output to trigger a relay rather than powering the device directly.

Common Issues and Troubleshooting

Even with a perfect holley terminator x inputs and outputs wiring diagram, issues can arise during the initial setup. The most common problem is “Electrical Noise” or EMI. Because the ECU operates on very low voltage signals, high-voltage components like the ignition system can “leak” interference into the I/O wires.

If an input is flickering on and off in the software data log, check your grounding. Unlike a house where a neutral wire carries current back to the panel, an EFI system requires a “Star Ground” configuration. All major grounds should return to the battery or a central engine block location. If you have used a chassis ground that is corroded, the ECU may see a floating voltage, leading to erratic behavior.

Another frequent issue is incorrect pin mapping. If you have wired a fan to Output 1 but configured Output 2 in the software, nothing will happen. Always use the “Status” screen in the Holley software to manually trigger outputs during testing. This allows you to verify the circuit is complete without needing the engine to reach operating temperature.

Never connect a 12V hot wire directly to an ECU output pin configured for ground-triggering without a load (like a relay) in between. Doing so will create a short circuit that can permanently damage the ECU’s internal drivers.

Tips and Best Practices for EFI Wiring

To ensure your installation lasts the life of the vehicle, follow these professional-level tips. First, prioritize the quality of your connections. While a traveler wire in a home might be secured under a brass screw, automotive wires are subject to vibration and moisture. Always use heat-shrink butt connectors or, preferably, soldered joints covered with adhesive-lined heat shrink.

- ✓ Use Correct Wire Gauge: Use 18-gauge wire for most I/O tasks. It is thick enough to be durable but thin enough to pin easily into the J1B connector.

- ✓ Label Everything: Use a label maker or masking tape to identify every wire. Six months from now, you won’t remember which white/green wire goes to the AC kick-up.

- ✓ Avoid T-Taps: Never use “vampire” or T-tap connectors. They cut into the wire strands and are notorious for causing intermittent voltage drops.

- ✓ Consolidate Grounds: Use a dedicated terminal strip for your sensor grounds to keep the engine bay organized.

When selecting components, stick with high-quality relays and sensors. A cheap relay can fail in the “closed” position, draining your battery or over-speeding a pump. Look for relays with built-in flyback diodes, which prevent voltage spikes from traveling back up the ground wire and hitting the ECU when the magnetic field in the relay coil collapses.

Finally, always keep a digital copy of your specific holley terminator x inputs and outputs wiring diagram on your phone. Whether you are at the track or in your garage, having quick access to the pinout definitions will save you hours of guesswork when adding new features or diagnosing a sensor failure.

When testing your outputs, use a Multimeter set to ‘Continuity.’ Check from the output pin to the ground wire. This confirms the ECU is successfully switching the circuit internally before you hook up expensive accessories.

In conclusion, mastering the holley terminator x inputs and outputs wiring diagram is about precision and patience. By understanding the relationship between voltage, gauge, and grounding, you transform your ECU from a simple fuel controller into a comprehensive vehicle management system. Take your time, double-check your pin locations, and enjoy the added functionality that a properly wired Holley system provides.

Frequently Asked Questions

What is Holley Terminator X inputs and outputs wiring diagram?

This diagram is a visual map showing how to connect external accessories to the ECU. It details the specific pins on the main harness used for signal inputs and pulse-width modulated outputs. It ensures users correctly route the ground wire and signal lines to manage engine functions like cooling fans or stages of nitrous.

How do you read Holley Terminator X inputs and outputs wiring diagram?

Start by identifying the connector labels, typically J1A and J1B. Look for the pin numbers corresponding to specific wire colors. The diagram shows where the hot wire connects to power and how various sensors return signals to the common terminal on the ECU, allowing for precise data monitoring and component activation.

What are the parts of Holley Terminator X inputs and outputs?

The system consists of digital inputs, analog inputs, and various types of outputs. Key parts include the J1A/B connectors, the multi-pin harness, and the internal ECU drivers. External parts often involve relays where a hot wire provides power and the ECU provides a ground trigger to complete the accessory circuit.

Why is the ground wire important in this diagram?

The ground wire serves as the primary return path for electrical current and signal reference. In automotive EFI systems, a poor ground can cause electromagnetic interference or ‘noise,’ leading to sensor errors. Unlike home AC systems that use a neutral wire, DC automotive systems rely entirely on a solid chassis ground.

What is the difference between a hot wire and a signal wire?

A hot wire carries 12V battery or switched power to a device or the ECU. In contrast, a signal wire carries low-voltage data from a sensor. When wiring a relay, the hot wire connects to a common terminal to supply current, while the signal wire tells the ECU when to trigger.

How do I use Holley Terminator X inputs and outputs wiring diagram?

Use the diagram to plan your accessory expansion. If installing a dual-stage switch, you might treat the toggle connection like a traveler wire to switch between different ECU maps. Follow the diagram to pin the connector correctly, then verify the settings in the Holley software to match your physical wiring.