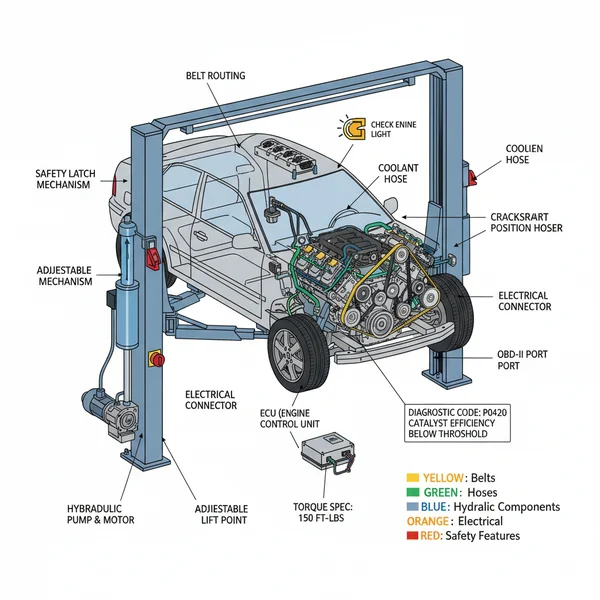

A 2 post car lift diagram illustrates the structural columns, swing arms, and hydraulic synchronization system required to elevate vehicles safely. It identifies critical lifting points and weight distribution parameters essential for maintenance tasks, ensuring stable support while you access the undercarriage or perform engine diagnostics using an OBD-II scanner.

📌 Key Takeaways

- Visualizing the balance and weight distribution for safe lifting

- Identifying the synchronization cables and hydraulic lines

- Always verify lift arm placement on vehicle hard points

- Check for floor thickness and anchor bolt torque spec

- Use the diagram for assembly, inspection, and maintenance planning

Understanding a 2 post car lift diagram is the foundational step for any automotive enthusiast or professional mechanic looking to upgrade their workspace. A detailed diagram does more than just show where the bolts go; it serves as a roadmap for structural safety, hydraulic efficiency, and mechanical synchronization. Whether you are troubleshooting a lifting imbalance or installing a brand-new unit, having a clear visual reference ensures that every component—from the heavy-duty columns to the intricate safety latches—is positioned correctly. In this guide, you will learn how to interpret a 2 post car lift diagram, identify critical internal parts, and apply this knowledge to maintain a safe and productive garage environment.

Detailed Breakdown of a 2 Post Car Lift Diagram

A comprehensive 2 post car lift diagram typically illustrates the synergy between mechanical, hydraulic, and electrical systems. The primary visual elements include the two vertical columns, which are often categorized as either symmetric or asymmetric. In a symmetric diagram, the columns face each other directly, and the arms are of equal length. In an asymmetric diagram, the columns are turned at an angle, and the arms are of different lengths to allow the vehicle to sit further back, facilitating easier door opening.

The diagram specifically highlights the carriage assembly, which is the sliding component that travels up and down the interior of the columns. Attached to these carriages are the swing arms, which utilize rubber pads to contact the vehicle’s frame. A crucial, though often overlooked, part of the diagram is the synchronization system. This usually consists of high-tension steel cables that run through the overhead crossbeam or across the floor plate. Their purpose is to ensure that both carriages rise at the exact same rate, preventing the vehicle from tilting.

Furthermore, the diagram will detail the hydraulic power unit, typically mounted on the primary column. This unit includes the motor, the oil reservoir, and the pump. You will also see the hydraulic hose routing, which directs fluid to the cylinders inside each column. Safety is represented in the diagram by the “ladder” locks—a series of mechanical notches that click into place as the lift rises. Understanding these visual cues allows you to verify that the safety pawls are engaging correctly, providing a mechanical backup to the hydraulic pressure.

[DIAGRAM_PLACEHOLDER – A detailed technical illustration showing two vertical steel columns with carriages, telescoping swing arms, overhead synchronization cables, hydraulic power unit, and mechanical safety lock intervals.]

Most modern 2 post car lift diagrams specify a minimum concrete thickness of 4 to 6 inches with a 3,000 PSI rating. Never install a lift on a surface that does not meet the manufacturer’s structural requirements indicated in the diagram.

Step-by-Step Guide to Interpreting and Using the Diagram

Reading a 2 post car lift diagram is a prerequisite for a safe installation and for performing advanced vehicle maintenance. When your vehicle displays a check engine light and you’ve pulled a diagnostic code via the OBD-II port that suggests a faulty sensor near the transmission, using the lift safely becomes your first priority. Follow these steps to master the diagram and the machine.

- ✓ Step 1: Identify the Main vs. Slave Column – The diagram will show one column with the hydraulic power unit and electrical controls. This is the “Main” column. The other is the “Slave” or “Offside” column. Correct orientation is vital for routing your power source.

- ✓ Step 2: Trace the Hydraulic Flow – Follow the lines in the diagram from the pump to the cylinders. Understanding this flow helps you identify potential leak points if the lift starts to lose pressure or fails to hold a load.

- ✓ Step 3: Locate Synchronization Cable Routes – The diagram illustrates how cables must be threaded through pulleys. Improper routing is the most common cause of “lifting jerkiness.” Ensure the cables are seated in the grooves of the pulleys exactly as shown.

- ✓ Step 4: Verify Arm Restraint Systems – Look for the gear-like mechanisms at the base of the swing arms in the diagram. These are the arm restraints that lock the arms in place once the lift begins to rise, preventing the vehicle from shifting.

- ✓ Step 5: Reference the Anchor Bolt Layout – The base plate diagram will show the exact torque spec for the anchor bolts. Typically, these require a high torque (around 100-150 ft-lbs) to ensure the columns do not sway under the weight of a heavy SUV or truck.

- ✓ Step 6: Plan the Service Access – Use the diagram to visualize where the vehicle’s center of gravity will sit. This is crucial when you need to access the accessory belt or timing chain at the front of the engine, or when you are tracing coolant flow issues along the undercarriage.

Always lower the lift onto the mechanical safety locks before working under the vehicle. Never rely solely on the hydraulic pressure shown in the diagram to hold the load during a repair.

Common Issues & Troubleshooting

Even with a perfect 2 post car lift diagram, mechanical wear and tear can lead to operational hurdles. One of the most frequent issues is an “uneven lift,” where one arm rises faster than the other. By referencing the diagram’s cable synchronization section, you can usually determine that one cable has stretched or a pulley has become misaligned. Tightening the equalizer cables to the manufacturer’s specifications often resolves this.

Another common problem is hydraulic “drifting,” where the lift slowly descends after being raised. The diagram will point you toward the check valve in the power unit or the seals in the hydraulic cylinders. If you notice a “spongy” feeling when operating the lift, there is likely air trapped in the hydraulic lines. The diagram’s plumbing layout will help you locate the bleeder screws on top of the cylinders to purge the air.

Lastly, electrical failures can occur. If the motor refuses to turn over, use the wiring schematic in your diagram to check the limit switch (usually located at the top of the lift) and the contactor in the control box. A faulty limit switch will prevent the lift from rising to avoid crushing the vehicle against the overhead beam.

Tips & Best Practices for Maintenance

To keep your lift operating according to the standards set in your 2 post car lift diagram, regular maintenance is non-negotiable. Treat your lift with the same precision you apply to a complex engine repair. For instance, just as you would use a specific torque spec for head bolts when replacing a timing chain, you must regularly check the torque on your lift’s floor anchors to ensure they haven’t vibrated loose over time.

Lubricate the inside of the columns where the carriage slide blocks travel every three months. Use a high-quality white lithium grease to reduce friction and prevent premature wear on the slide blocks, ensuring a smooth ascent.

When the car is elevated, it provides the perfect opportunity to perform comprehensive inspections that are difficult on the ground. Use the extra clearance to inspect the accessory belt for fraying or to check the radiator hoses for consistent coolant flow. If you are diagnosing a complex electrical issue near the ECU, having the car at eye level allows you to inspect wiring harnesses for heat damage or rodent interference that might trigger a mysterious check engine light.

For cost-saving and longevity, always keep the hydraulic fluid clean. Contaminated fluid is the leading cause of pump failure. Check the reservoir levels monthly and replace the fluid every two years. Finally, always keep a physical copy of your 2 post car lift diagram laminated and mounted near the power unit. This ensures that any person operating the lift has immediate access to safety information and component locations, fostering a culture of safety and professionalism in your shop.

By following these guidelines and maintaining a deep understanding of your 2 post car lift diagram, you ensure that your equipment remains a reliable partner in your automotive journeys. Whether you are chasing a diagnostic code or performing a full frame-off restoration, a well-maintained lift is your most valuable tool.

Frequently Asked Questions

What is 2 post car lift diagram?

A 2 post car lift diagram is a technical schematic showing the assembly of columns, carriages, and lifting arms. It outlines how hydraulic pressure and mechanical locks work together to suspend a vehicle. These diagrams are vital for ensuring correct installation and identifying specific maintenance points for safe shop operation.

How do you read 2 post car lift diagram?

Reading the diagram requires identifying the primary power unit and how it feeds hydraulic fluid to both cylinders. Look for the synchronization cable paths that ensure the carriages rise evenly. Detailed schematics will also show the locking mechanism locations and the specific anchor points required for floor mounting.

What are the parts of 2 post car lift?

The primary parts include two vertical columns, a hydraulic power unit, and four adjustable swing arms. Internal components like synchronization cables, pulleys, and locking latches are crucial for safety. The diagram also highlights the carriage assemblies that move along the columns to lift the vehicle off the ground.

Why is the synchronization system important?

The synchronization system ensures that both carriages lift the vehicle at exactly the same rate. Without this balance, the vehicle could tilt dangerously, leading to structural failure or a fall. Proper alignment shown in the diagram prevents mechanical strain and ensures a level surface for sensitive underbody repairs.

What is the difference between symmetric and asymmetric lifts?

Symmetric lifts have columns directly facing each other with arms of equal length, while asymmetric lifts have angled columns and uneven arm lengths. Asymmetric designs allow for better door clearance, making it easier to access the interior for ECU diagnostics or addressing a persistent check engine light while lifted.

How do I use 2 post car lift diagram?

Use the diagram as a roadmap for initial installation, routine safety inspections, and identifying replacement parts. It helps technicians locate grease points and verify that every bolt meets the required torque spec. Referring to the schematic ensures that the lift remains reliable for long-term professional automotive service.