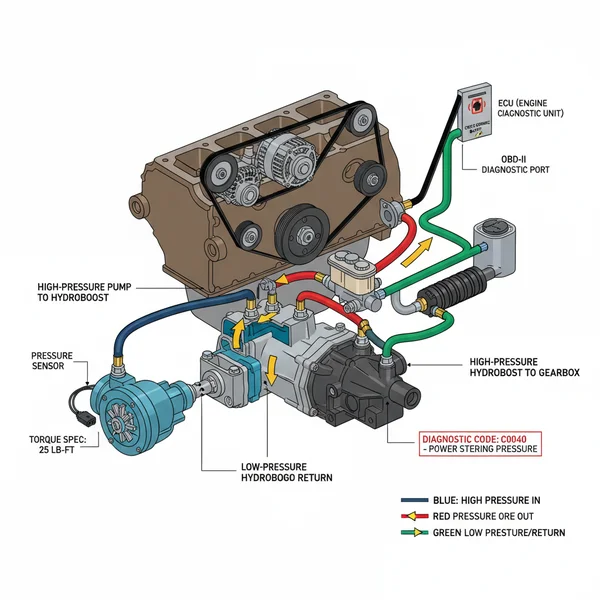

A hydroboost GM power steering hose diagram illustrates the fluid flow between the power steering pump, the hydraulic brake booster, and the steering gear. It identifies the high-pressure supply lines and low-pressure return lines critical for ensuring both steering assist and braking power function correctly in heavy-duty GM vehicles.

📌 Key Takeaways

- Maps the high-pressure and low-pressure fluid paths

- The hydroboost unit acts as the primary junction between brakes and steering

- Ensuring leak-free seals is vital for maintaining vehicle braking power

- Use the diagram to prevent crossing pressure and return lines

- Consult this when replacing a leaking hose or upgrading steering

Understanding the layout of a hydroboost system is essential for any GM truck or SUV owner who performs their own maintenance. Unlike standard vacuum-assist brakes, the GM hydroboost system uses hydraulic pressure from the power steering pump to provide braking assistance. This dual-purpose setup means that your steering and braking systems are interconnected, making a clear hydroboost gm power steering hose diagram an invaluable tool for troubleshooting leaks or replacing aging lines. In this comprehensive guide, you will learn the exact routing of these hoses, the specific functions of each component, and the technical steps required to ensure your vehicle remains safe and responsive on the road.

Understanding the Hydroboost GM Power Steering Hose Diagram

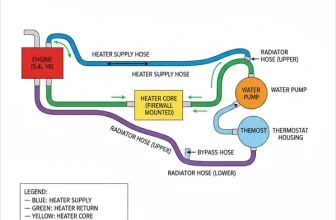

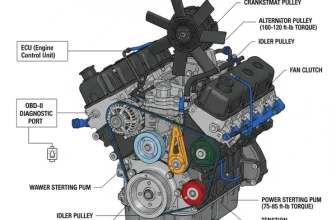

The hydroboost system is a masterpiece of hydraulic engineering, but its complexity can be daunting without a visual map. At its core, the system consists of three primary high-pressure connections and two low-pressure return paths. When looking at a standard diagram, you will notice that the power steering pump acts as the heart of the operation, pushing fluid through the accessory belt-driven pulley to create the necessary force for both the steering gear and the brake booster.

In a typical GM configuration, the high-pressure line exits the pump and travels directly to the hydroboost unit mounted on the firewall. From there, a second high-pressure line exits the booster and travels down to the steering gearbox. This “daisy-chain” configuration ensures that the braking system receives priority pressure. Finally, both the hydroboost unit and the steering gear have low-pressure return lines that lead back to the pump reservoir.

Most GM heavy-duty vehicles utilize a “T-fitting” or a dual-return reservoir. This allows the low-pressure fluid from both the steering gear and the hydroboost unit to merge before entering the pump, preventing back-pressure that could cause a stiff brake pedal or erratic steering feedback.

The components usually follow a specific color-coding in professional service manuals: high-pressure lines are often depicted in red or solid bold lines, while return lines are shown in blue or dashed lines. Variations do exist between heavy-duty (HD) models and half-ton trucks, primarily in the length of the hoses and the inclusion of an external fluid cooler. If your vehicle is equipped with a tow package, the return line may route through a small radiator-like heat exchanger located near the coolant flow path of the main radiator to keep hydraulic temperatures stable under load.

[DIAGRAM_PLACEHOLDER: A detailed schematic showing the Power Steering Pump connected via a high-pressure hose to the Hydroboost Unit. A second high-pressure hose connects the Hydroboost Unit to the Steering Gear Box. Two low-pressure return hoses are shown exiting both the Hydroboost and Gear Box, merging at a T-junction or dual-inlet reservoir on the pump.]

Step-By-Step Installation and Routing Guide

Replacing or installing hoses based on a hydroboost gm power steering hose diagram requires precision. Because these lines operate under extreme pressure, a small error in routing can lead to a catastrophic failure or an engine bay fire if fluid sprays onto a hot exhaust manifold.

Required Tools and Materials:

- ✓ Set of Flare Nut Wrenches (16mm and 18mm are common)

- ✓ Drain pan and lint-free shop towels

- ✓ High-quality GM-approved Power Steering Fluid

- ✓ New O-rings or Teflon seals (usually included with new hoses)

- ✓ Torque wrench for final tightening

Installation Steps:

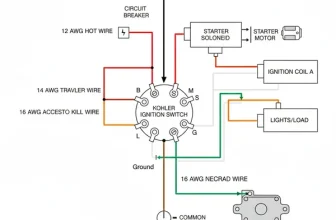

1. Preparation and Safety: Ensure the engine is cool. Disconnect the battery as a precaution. Place a drain pan under the power steering pump and steering gear. Clean the fittings on the pump, booster, and gear thoroughly with brake cleaner to prevent debris from entering the hydraulic system.

2. Identify Hose Ports: Using your diagram, identify the pressure port (usually the larger fitting) and the return port on the hydroboost unit. On the pump, the high-pressure outlet is typically a threaded fitting, while the return is a simple rubber hose pushed onto a metal nipple.

3. Remove Old Lines: Use your flare nut wrenches to break loose the high-pressure fittings. These can be quite stubborn; if they don’t budge, avoid using excessive force that might round the nut. A penetrate catalyst can help. Remove the low-pressure return lines by loosening the constant-tension clamps.

4. Install New Hoses: Route the new hoses following the exact path of the originals. Be mindful of the timing chain cover and accessory belt; hoses must be secured in their factory clips to avoid contact with moving parts or high-heat areas.

5. Sealing and Torque: Replace all O-rings. Thread the fittings by hand first to avoid cross-threading. Once finger-tight, use a wrench to snug them down. The general torque spec for these fittings is approximately 20-25 lb-ft, though you should check your specific service manual.

6. Fluid Fill and Initial Bleed: Fill the reservoir with fresh fluid. With the engine off and the front wheels off the ground, turn the steering wheel lock-to-lock 20 times. This pushes air out of the gearbox. Check fluid levels frequently.

7. System Pressurization: Start the engine briefly (5-10 seconds) and shut it off. Check for leaks. Repeat this until the fluid level remains steady.

8. Final Air Purge: With the engine running, pump the brakes several times and turn the steering wheel. If the fluid is foamy, air is still present. Allow the vehicle to sit for an hour to let bubbles dissipate, then repeat the process.

Never use ATF (Automatic Transmission Fluid) in a GM hydroboost system unless the owner’s manual specifically authorizes it. Incorrect fluid can swell the internal seals of the booster, leading to “brake drag” where the brakes stay applied even after you release the pedal.

Common Issues and Troubleshooting

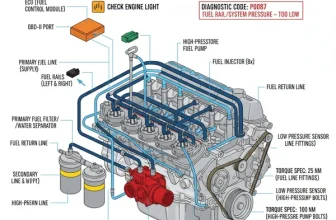

Even with a perfect hydroboost gm power steering hose diagram, issues can arise. The most frequent problem is a “whining” noise from the pump, which usually indicates air trapped in the lines or a restriction in the return path. If you notice a check engine light or an OBD-II diagnostic code related to engine idle stability, it could be the power steering pressure switch failing, which tells the ECU to bump up the idle when steering loads are high.

A “spongy” brake pedal in a hydroboost system often points to a failing nitrogen accumulator (the gold or blue cylinder on the side of the booster). However, if you see fluid dripping from the weep hole where the master cylinder meets the booster, your internal seals are blown, and a hose replacement will not fix the issue. Use the diagram to ensure you haven’t swapped the pressure and return lines at the booster, as this will result in a rock-hard pedal and potential pump damage.

Pro Tips and Best Practices

Maintenance of the hydroboost system is often overlooked compared to oil changes or timing chain inspections, but it is just as vital. For long-term reliability, consider the following expert advice:

When replacing hoses, always install a magnetic inline filter on the low-pressure return line. This captures microscopic metal shavings from the steering gear before they can reach the pump and the sensitive valves inside the hydroboost unit.

To save costs in the long run, invest in high-pressure hoses with “swivel” ends. These allow for easier installation in tight engine bays and prevent the hose from kinking during engine torque movements. Additionally, if you live in a rust-prone area, coat the metal ends of your hoses with a thin layer of dielectric grease or rust inhibitor to prevent the fittings from seizing into the aluminum booster housing.

Regularly check the condition of your accessory belt. Since the hydroboost system relies entirely on the pump’s rotation, a slipping belt will result in a sudden loss of both steering and braking assistance—a dangerous scenario at any speed. By following a correct hydroboost gm power steering hose diagram and adhering to these maintenance standards, you ensure that your GM vehicle remains a reliable powerhouse for years to come.

Step-by-Step Guide to Understanding the Hydroboost Gm Power Steering Hose Diagram: Routing Guide

Identify the power steering pump as the primary fluid source in the diagram.

Locate the high-pressure hose connecting the pump directly to the hydroboost inlet.

Understand how fluid moves from the hydroboost outlet to the steering gear input.

Connect the low-pressure return lines from both the booster and gear back to the reservoir.

Verify that all fittings are tightened to the specific manufacturer torque spec.

Complete the repair by scanning for any diagnostic code that may remain active.

Frequently Asked Questions

What is hydroboost gm power steering hose diagram?

This diagram is a visual map showing how hydraulic fluid travels from the pump to the brake booster and steering box. It helps technicians identify specific hoses, such as the pressure line from the pump to the booster, ensuring every connection follows the correct flow for optimal safety and performance.

How do you read hydroboost gm power steering hose diagram?

Begin at the power steering pump and follow the pressure lines to the hydroboost unit. Use the diagram to trace the lines from the booster to the steering gear and the return lines leading back to the reservoir, checking for proper orientation and secure hose clamping points throughout the system.

What are the parts of hydroboost gm power steering hose diagram?

Key parts include the power steering pump, the hydroboost unit, the steering gear, and various high-pressure and low-pressure hoses. The system also interacts indirectly with the ECU; though hydraulic, modern sensors might trigger a check engine light if power levels drop, requiring an OBD-II scanner check for any errors.

Why is torque spec important?

Maintaining the correct torque spec for hose fittings is critical to prevent leaks and system failure. Over-tightening can damage threads, while under-tightening leads to fluid loss. Proper torque ensures a secure seal in the high-pressure environment of the hydroboost system, keeping the brakes and steering responsive and reliable.

What is the difference between hydroboost and vacuum systems?

Vacuum boosters rely on engine air pressure, while hydroboost systems use hydraulic pressure from the power steering pump. Hydroboost provides significantly more braking force, making it ideal for diesel engines or heavy trucks where vacuum levels are insufficient to provide consistent brake assist and steering power under heavy loads.

How do I use hydroboost gm power steering hose diagram?

Use the diagram to identify which line is leaking or needs replacement. If a diagnostic code appears on your OBD-II scanner related to pressure sensors, the diagram helps locate the physical component. Always cross-reference the diagram during reassembly to ensure all lines are routed without kinks or interference.