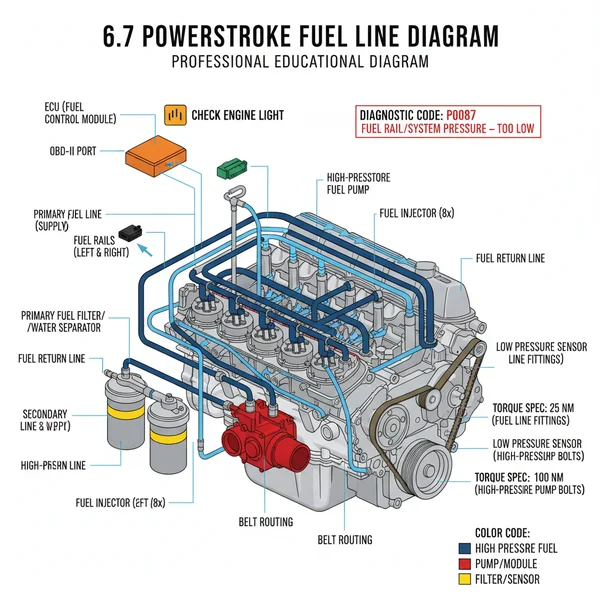

A 6.7 Powerstroke fuel line diagram illustrates the flow from the tank to the DFCM, high-pressure pump, and injectors. It helps locate leaks causing a check engine light or diagnostic code. Proper identification ensures correct fuel pressure management via the ECU and prevents catastrophic contamination while ensuring every fitting meets its torque spec.

📌 Key Takeaways

- Visually mapping the high-pressure and return fuel paths correctly

- Identifying the CP4 high-pressure pump and piezo injectors

- Checking for leaks at quick-connect fittings and primary filters

- Tracing fuel starvation issues to solve diagnostic codes

- Ensuring correct routing to prevent heat damage or vibration wear

Understanding the 6.7 powerstroke fuel line diagram is essential for maintaining the performance and longevity of your Ford Super Duty truck. This guide provides a comprehensive breakdown of the fuel delivery system, from the tank to the injectors. You will learn how to identify specific fuel lines, locate the primary and secondary filters, and understand the high-pressure rail configuration. Whether you are troubleshooting a leak or replacing a failed pump, this article equips you with the technical knowledge to navigate the complex fuel architecture of the 6.7L engine safely and effectively, ensuring your diesel engine remains reliable under heavy loads.

The 6.7 Powerstroke uses a dual-stage fuel system. The low-pressure side operates at approximately 55-70 PSI, while the high-pressure side can reach over 29,000 PSI. Never crack a high-pressure line while the engine is running.

Understanding the 6.7 Powerstroke Fuel Line Diagram Components

The 6.7 Powerstroke fuel line diagram is split into two distinct sections: the low-pressure supply system and the high-pressure injection system. The journey begins at the fuel tank, where the lift pump sends fuel through the frame-mounted Diesel Fuel Conditioning Module (DFCM). On the diagram, you will see a series of blue or green lines representing the supply side. These lines run along the driver-side frame rail, passing the transmission area where they are often secured by heavy-duty clips to prevent vibration damage near the accessory belt and transmission housing.

Once the fuel reaches the engine bay, it enters the secondary fuel filter located on top of the engine. From here, the diagram shows a transition to the high-pressure pump, known as the CP4.2. This pump is the heart of the system. The high-pressure lines, usually represented in red or thick black lines on technical schematics, connect the pump to the two fuel rails. Unlike the rubber or nylon low-pressure lines, these are constructed of high-grade stainless steel to withstand extreme force. The diagram also illustrates the return circuit, which carries unused fuel back to the tank. This return path is critical for cooling the injectors and the pump, as it integrates with the coolant flow system through a fuel-to-coolant heat exchanger in some model variations.

Visualizing the layout helps identify the “return manifold,” a common point of confusion for beginners. This manifold collects return fuel from all eight injectors. If you notice a leak near the back of the engine, the diagram will help you distinguish between a high-pressure rail leak and a low-pressure return line failure. Identifying these components correctly is the first step toward a successful repair or modification.

[DIAGRAM_PLACEHOLDER: 6.7 Powerstroke Fuel System Layout – Illustrating Tank, DFCM, Secondary Filter, CP4 Pump, High-Pressure Rails, and Return Lines]

Step-by-Step Guide to Interpreting and Using the Diagram

Interpreting a complex automotive schematic requires a systematic approach. Follow these steps to use the fuel line diagram for diagnostics or component replacement.

- 1. Identify the Direction of Flow: Start at the fuel tank on the diagram. Follow the line to the DFCM (Primary Filter). Fuel flows from the tank, through the filter, and toward the engine. Understanding the flow direction is vital when diagnosing a “no-start” condition, as it tells you where to check for fuel pressure first.

- 2. Locate the Low-Pressure Test Port: Most 6.7 Powerstroke engines feature a Schrader valve or a specific port on the secondary filter housing. Use your diagram to find this location. This is where you would hook up a manual gauge to verify if the lift pump is delivering the required 55+ PSI to the engine.

- 3. Map the CP4 High-Pressure Pump: The pump is located in the “valley” of the engine, driven by the gear train. While it is not driven by a timing chain, its timing is still synchronized with the engine’s rotation. The diagram will show two high-pressure outlets leading to the left and right fuel rails.

- 4. Observe the Return Line Junctions: Look for the lines labeled “Return” or “Drain Back.” These lines are often lighter in construction. On the 6.7, the return lines use quick-connect plastic fittings that are notorious for becoming brittle over time. The diagram shows how these lines merge before heading back to the frame rail.

- 5. Match the Diagram to the Physical Hardware: Before loosening any bolts, match the visual representation on the diagram to the actual hoses under the hood. Look for the color-coded clips (usually blue for supply and gray for return) to ensure you are disconnecting the correct circuit.

- 6. Verify Torque Specifications: When reassembling high-pressure lines, refer to the torque spec provided in your service manual (typically 22-25 lb-ft for injector lines). The diagram often includes these values in the notes for critical connections to prevent leaks or flared-end damage.

The high-pressure fuel system remains pressurized even after the engine is turned off. Wait at least 10 minutes after shutdown before opening any high-pressure lines to allow the ECU to bleed off residual pressure through the return circuit.

Common Issues & Troubleshooting

The fuel system on the 6.7 Powerstroke is robust but has specific failure points that a diagram can help you isolate. One of the most common issues is the “P0087” diagnostic code, which indicates low fuel rail pressure. By using the diagram, you can systematically check the lift pump at the frame, the secondary filter on the engine, and finally the high-pressure pump.

If you see a check engine light, use an OBD-II scanner to pull codes. If the codes point toward fuel delivery, the diagram helps you locate the Volume Control Valve (VCV) and Pressure Control Valve (PCV). These electronic components are controlled by the ECU to manage rail pressure. Another frequent problem is “air in the lines,” which often occurs after a filter change. The diagram illustrates the path the air must take to be purged through the return system. If the truck fails to start, tracing the lines can reveal if a quick-connect fitting has a cracked O-ring, allowing air to enter the suction side of the system.

Tips & Best Practices for Maintenance

Maintaining the fuel system of your 6.7 Powerstroke is far cheaper than replacing a set of injectors or a high-pressure pump. Follow these industry best practices to keep your fuel lines and components in top shape:

- ✓ Filter Intervals: Replace both the primary (frame-mounted) and secondary (engine-mounted) filters every 15,000 to 22,500 miles. Always use OEM filters, as aftermarket versions often have inferior micron ratings.

- ✓ Water Separation: Drain the water separator on the DFCM monthly. Water is the primary enemy of the CP4 pump and can lead to internal corrosion and catastrophic failure.

- ✓ Inspect for Rubbing: Periodically check fuel lines where they pass near the accessory belt or sharp engine brackets. Vibration can cause lines to chafe, leading to difficult-to-find pinhole leaks.

- ✓ Lubricate O-Rings: When installing new lines or filters, use a small amount of clean diesel fuel or clean engine oil to lubricate the O-rings. This prevents tearing during installation.

If you are performing major work, consider installing a “Disaster Prevention Kit.” This modifies the fuel line routing so that if the high-pressure pump fails, the debris is sent back to the tank rather than through the expensive injectors and rails.

In conclusion, mastering the 6.7 powerstroke fuel line diagram allows you to take control of your vehicle’s maintenance. By understanding the flow from the tank to the high-pressure rails, you can accurately diagnose issues, perform safe repairs, and avoid the high costs associated with dealership service departments. Always prioritize cleanliness and safety when working on these precision components to ensure your Powerstroke continues to deliver the torque and reliability you depend on.

Frequently Asked Questions

What is 6.7 Powerstroke fuel line diagram?

A 6.7 Powerstroke fuel line diagram is a visual map showing how diesel flows from the tank to the engine. It details the primary and secondary filtration systems, high-pressure rails, and return lines. Mechanics use it to identify leaks or blockages that trigger a check engine light and store a diagnostic code.

How do you read 6.7 Powerstroke fuel line diagram?

Reading the diagram involves following the flow arrows from the fuel tank through the lift pump. Pay attention to color-coding or line weights that distinguish high-pressure rails from low-pressure return lines. Cross-reference the diagram with the ECU sensor locations to understand how the system monitors pressure and volume effectively.

What are the parts of 6.7 Powerstroke fuel line?

Key parts include the Diesel Fuel Conditioning Module, secondary fuel filter, CP4 high-pressure pump, fuel rails, and injectors. The system also features various sensors and valves that communicate with the ECU. Understanding these components is vital for troubleshooting a specific diagnostic code related to low fuel rail pressure or volume.

Why is the fuel pressure sensor important?

The fuel pressure sensor is critical because it monitors real-time pressure within the high-pressure rail. This data is sent to the ECU to adjust pump output and injector timing. If the sensor fails, it often triggers a check engine light and may put the truck into a reduced power mode.

What is the difference between supply and return lines?

Supply lines carry pressurized diesel from the tank toward the combustion chamber, while return lines send excess fuel back to the tank to cool the system. High-pressure supply lines require a specific torque spec for fittings to prevent leaks. Return lines operate under much lower pressure but are equally vital.

How do I use 6.7 Powerstroke fuel line diagram?

Use the diagram to isolate specific sections of the fuel system during a diagnostic process. When you retrieve a diagnostic code using an OBD-II scanner, the diagram helps you locate the exact hose, sensor, or fitting responsible. It is an essential tool for ensuring lines are routed without kinks.