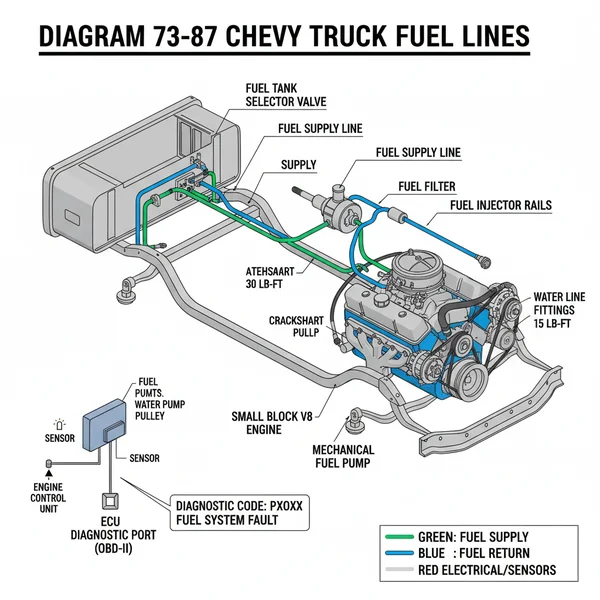

73 87 Chevy Truck Fuel Lines Diagram: Routing and Setup

A 73-87 Chevy truck fuel line diagram maps the path from the gas tanks through the selector valve to the engine. It details the routing of the main supply line and the return line, ensuring proper fuel flow and pressure for carbureted or early TBI engines while preventing leaks and vapor lock.

📌 Key Takeaways

- Illustrate the path from dual tanks to the fuel pump

- Tank selector valve for dual-tank configurations

- Ensure all rubber-to-metal connections are double-clamped

- Route lines away from the exhaust to prevent vapor lock

- During engine swaps or fuel system troubleshooting

Restoring or maintaining a classic Squarebody pickup requires a deep understanding of its plumbing, and finding an accurate diagram 73 87 chevy truck fuel lines is often the first step in a successful project. Whether you are dealing with a standard single-tank setup or the notoriously complex dual-tank selector system, having a visual roadmap prevents dangerous leaks and ensures consistent engine performance. This guide provides a detailed breakdown of the fuel delivery architecture for these iconic trucks, covering everything from the fuel tank sending units to the engine bay interface. You will learn how to identify specific lines, understand the differences between carbureted and TBI systems, and master the routing techniques necessary for a professional-grade restoration.

Understanding the Fuel Line Architecture and Components

The fuel system for Chevrolet and GMC trucks manufactured between 1973 and 1987 underwent several iterations, most notably the transition from mechanical pumps to electronic fuel injection in the final year of production. A standard diagram 73 87 chevy truck fuel lines typically illustrates three primary types of lines: the supply line, the return line, and the vapor/charcoal canister line. On most models, the supply line is the largest (3/8 inch), while the return and vapor lines are smaller (5/16 or 1/4 inch).

If your truck is equipped with dual fuel tanks, the diagram becomes significantly more complex. In this configuration, the lines from both the left and right side tanks converge at a motorized or manual selector valve mounted on the inner frame rail. From this valve, the lines are routed along the passenger-side frame rail toward the engine. For trucks built before 1987, the lines lead to a mechanical fuel pump located on the passenger side of the engine block, driven by a pushrod off the camshaft. In 1987 models, which featured Throttle Body Injection (TBI), the fuel pump is located inside the tank, and the lines lead directly to the TBI unit on top of the intake manifold.

On 1987 models, the system operates at a higher pressure (9-13 PSI) than earlier carbureted versions (4-7 PSI). Ensure your replacement hoses are rated for fuel injection if you are working on a 1987 TBI-equipped truck.

The routing path is critical for safety. The lines are generally secured to the inside of the frame rail using steel clips to protect them from road debris and exhaust heat. As the lines approach the front of the vehicle, they must navigate past the timing chain cover and underneath the accessory belt drive system. Proper clearance here is vital; if a line vibrates against a moving part or a hot coolant flow passage, it can lead to catastrophic failure.

Step-by-Step Guide to Reading and Installing Fuel Lines

Interpreting a fuel line diagram and translating it to the chassis requires patience and the right tools. Follow these steps to ensure your fuel system is routed correctly and safely.

- ✓ Step 1: Identify Your System Type – Determine if you have a single or dual tank setup. If you have a 1987 model, locate the ECU-controlled relay that triggers the in-tank pump, as this changes how you test for line blockages.

- ✓ Step 2: Map the Selector Valve – For dual tanks, the diagram will show six ports on the selector valve: two for supply (from tanks), two for return (to tanks), one main supply (to engine), and one main return (from engine). Label these before disconnecting old lines.

- ✓ Step 3: Route Along the Frame – Begin at the tanks and move forward. Use the diagram 73 87 chevy truck fuel lines to locate the exact factory clip positions. This prevents the lines from rattling or rubbing against the frame.

- ✓ Step 4: Navigate the Engine Bay – Bring the lines up near the front crossmember. Ensure the lines stay clear of the timing chain cover. On mechanical pump models, the supply line connects to the bottom “in” port of the pump.

- ✓ Step 5: Apply Proper Torque Specs – When tightening flare nuts into the fuel pump or TBI unit, use a torque spec of approximately 15-20 lb-ft. Over-tightening can crack the flare or strip the soft aluminum threads.

- ✓ Step 6: Connect the Vapor System – Don’t ignore the vapor line. It must run to the charcoal canister in the engine bay to prevent pressure buildup in the tank and gas smells in the cab.

Always use a “flare nut” or “line wrench” when working with fuel line fittings. Standard open-end wrenches are prone to rounding off the soft metal nuts used on these vintage Chevy trucks.

Before finalizing the installation, verify that the lines do not interfere with the accessory belt or any steering components. For 1987 trucks, once the lines are connected, you may need to cycle the ignition several times to allow the ECU to prime the system and bleed out air.

Common Issues and Troubleshooting

The most frequent issue encountered with 73-87 Chevy fuel lines is the failure of the dual-tank selector valve. When this valve fails, it can cause the engine to pull fuel from one tank but return it to the other, leading to an overflow situation. Utilizing your diagram 73 87 chevy truck fuel lines, you can perform a bypass test to determine if the valve or the lines themselves are clogged.

Another common problem is vapor lock, especially in 1973-1986 models with mechanical pumps. This happens when the fuel in the lines boils due to proximity to coolant flow pipes or exhaust manifolds. If your truck stalls when hot and won’t restart until it cools, check your line routing against the factory diagram to ensure they aren’t too close to heat sources.

In 1987 models, a fuel delivery issue often triggers a check engine light. While these trucks are pre-OBD-II, they utilize an earlier diagnostic system (ALDL). You can jump the diagnostic terminals to see if a specific diagnostic code related to the fuel pump relay or lean exhaust is present. This helps determine if the issue is a physical line blockage or an electronic failure within the ECU.

Fuel leaks near the hot engine block or exhaust can cause an immediate fire. Always perform a “leak down” test by priming the system and inspecting every fitting before the first test drive.

Maintenance Tips and Best Practices

To keep your fuel system in top shape, regular maintenance is required. Because these trucks are now several decades old, the original steel lines are susceptible to internal corrosion from modern ethanol-blended fuels. Ethanol attracts moisture, which settles in the low points of the lines and causes rust.

- ✓ Replace Rubber Sections: The short sections of rubber hose connecting the hard lines to the tank and pump dry out and crack. Replace these every 5-7 years with SAE J30R9 rated hose.

- ✓ Filter Location: For carbureted trucks, ensure you have a filter before the pump and a second “stone” filter inside the carburetor inlet.

- ✓ Inspect Hardware: Ensure the torque spec on the mounting bolts for the selector valve is maintained to prevent vibration damage to the plastic housing.

- ✓ Check Engine Light Prep: On 1987 trucks, keep the ALDL connector clean. Even though it isn’t OBD-II, it is your only way to read a diagnostic code without specialized equipment.

When replacing lines, consider using NiCopp (Nickel-Copper) tubing. It is much easier to bend by hand than stainless steel or traditional galvanized steel, and it is naturally resistant to corrosion. This is particularly helpful when trying to mimic the intricate bends shown in a diagram 73 87 chevy truck fuel lines.

Finally, always ensure your fuel system is integrated properly with the rest of the engine’s vitals. For instance, if you are replacing the timing chain, it is the perfect time to inspect the mechanical fuel pump and its associated hard lines, as the pump must be removed for that job anyway. Similarly, keep fuel lines away from accessory belt pulleys to prevent friction-induced leaks. By following these guidelines and referencing a high-quality diagram, you can ensure your Chevy truck remains reliable for years to come.

Frequently Asked Questions

What is a 73 87 Chevy truck fuel lines diagram?

This diagram is a visual schematic illustrating the layout of the fuel delivery system for C10 and K10 series trucks. It shows how gasoline travels from the fuel tanks, through the frame-mounted lines, to the fuel pump and carburetor or TBI unit, highlighting specific hose sizes and connector types.

How do you read a 73 87 Chevy truck fuel lines diagram?

Begin by identifying the fuel tanks and following the lines along the frame rail. Solid lines represent metal tubing, while dashed lines often indicate rubber hoses. Pay attention to the diameter differences, as supply lines are typically larger than return lines, and note the location of the frame-mounted fuel filter.

What are the parts of 73 87 Chevy truck fuel lines?

Key components include the primary fuel supply line, the return line, and the charcoal canister vent line. On trucks with dual tanks, the fuel tank selector valve and solenoid are critical. The system also includes rubber couplers, metal flare fittings, and the mechanical or electric fuel pump depending on the year.

Why is the tank selector valve important?

The tank selector valve allows the driver to switch fuel sources between dual tanks. It is a common failure point that can lead to fuel starvation or incorrect gauge readings. Understanding its wiring and plumbing on the diagram is essential for diagnosing issues where the engine draws from only one tank.

What is the difference between supply and return lines?

The supply line is a 3/8-inch pipe that carries fuel under pressure or vacuum to the engine. The return line is a smaller 1/4-inch pipe that sends excess fuel back to the tank. While these trucks lack an OBD-II port, the return system helps maintain pressure and prevents vapor lock.

How do I use a 73 87 Chevy truck fuel lines diagram?

Use the diagram to verify that new lines follow the original factory path away from heat sources. When troubleshooting a check engine light on 1987 TBI models, the diagram helps locate the ECU-controlled components. Ensure all fittings meet the required torque spec to prevent dangerous leaks after a restoration.