7 Way Trailer Plug Diagram: Wiring and Pinout Guide

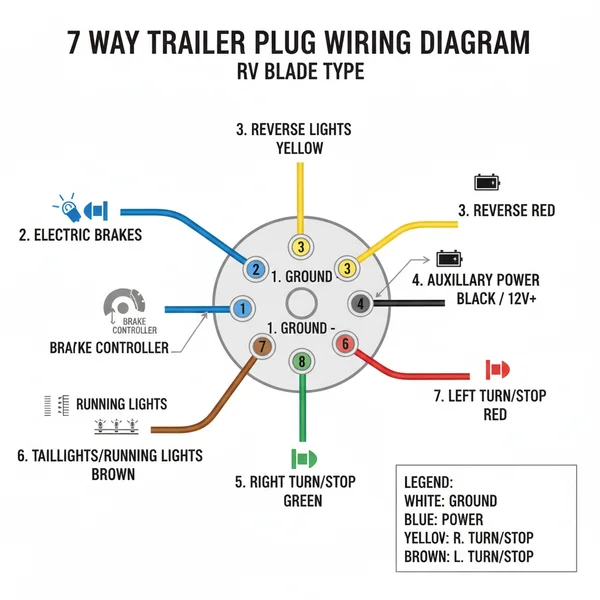

A 7 way trailer plug diagram maps the electrical connections for the standard RV blade connector. It identifies the specific pins for ground, running lights, left and right turn signals, electric brakes via a brake controller, and auxiliary power for battery charging, ensuring full functionality and safety while towing.

📌 Key Takeaways

- Identifies the standard color-coding for RV blade connectors

- Ensures the brake controller is properly integrated for safety

- Prevents electrical shorts by clarifying ground and power pins

- Facilitates troubleshooting of dead running lights or turn signals

- Essential for wiring large trailers with auxiliary power needs

Successfully navigating the world of towing requires more than just a heavy-duty hitch and a powerful engine; it requires a reliable electrical connection between your vehicle and your trailer. When you are looking for a comprehensive 7 way trailer plug diagram, you are likely tackling a project that involves more than just basic lighting. Whether you are setting up a new RV, installing a brake controller, or troubleshooting a faulty connection, understanding the layout of an RV blade connector is essential for safety and functionality. This guide provides a deep dive into the wiring standards, color-coding conventions, and installation procedures necessary to ensure your auxiliary power, electric brakes, and signal lights operate flawlessly every time you hit the road.

A 7-way trailer plug is the industry standard for trailers equipped with electric brakes and internal batteries. Unlike a simple 4-way flat connector, the 7-way system provides dedicated circuits for charging trailer batteries and operating sophisticated braking systems.

Understanding the 7 Way Trailer Plug Diagram Layout

The standard 7 way trailer plug diagram, specifically the RV blade style, is organized in a circular pattern with six blades surrounding a center pin. This design is robust and intended to handle higher current loads than smaller connectors. To read the diagram correctly, you must first determine if you are looking at the “vehicle side” (the socket) or the “trailer side” (the plug). Most diagrams illustrate the view from the face of the connector, as if you are looking directly into the pins or holes.

In a standard RV blade configuration, each pin serves a distinct purpose. The orientation is critical: the notch or “keyway” at the top of the connector serves as the 12 o’clock position. Starting from the top and moving clockwise, the pins are typically assigned to specific functions. The ground pin is usually the largest or most prominent, as it must facilitate the return path for all other electrical circuits. The auxiliary power pin provides a constant 12V charge to the trailer’s onboard battery, while the electric brake pin carries the modulated signal from your vehicle’s brake controller to the trailer’s drum or disc brakes.

While the physical layout of the pins is standardized, wire colors can sometimes vary by manufacturer. However, the industry follows a traditional color-coding scheme that helps DIYers and professionals alike. White is almost universally used for the ground. Blue is reserved for the electric brake output. Green typically handles the tail and running lights. Black is the standard for the 12V auxiliary power line. Red and Brown are used for the left and right turn signals and brake lights, respectively. The center pin, often Yellow, is most commonly used for reverse lights or an additional auxiliary circuit. Knowing these variations is the first step toward a successful installation.

Detailed Breakdown of Wire Functions and Gauges

To truly master the 7 way trailer plug diagram, you must understand the technical requirements of each circuit. Not all wires in the harness are created equal; some carry significantly more current than others.

The ground pin (White) is the most critical component. Because every light and motor on the trailer sends its current back through this single wire, it must be of a heavy gauge, typically 10-gauge or 12-gauge. If the ground connection is weak or undersized, you may experience flickering lights, weak braking, or “phantom” electrical issues where one circuit interferes with another.

The auxiliary power wire (Black) is another high-current line. This wire is responsible for maintaining the charge in your RV or camper battery while you drive. It also powers interior lights or 12V appliances. Because it needs to carry a constant charge over a long distance, a 10-gauge wire is recommended to prevent voltage drop.

The electric brake wire (Blue) carries the signal from your aftermarket or factory brake controller. This is a modulated signal; the more pressure you apply to the brake pedal, the more voltage is sent through this wire to the trailer magnets. Safety depends entirely on the integrity of this connection. Using a 12-gauge wire ensures that the braking force is consistent and responsive.

When wiring your 7-way plug, always use “marine-grade” or “automotive-grade” multi-strand copper wire. Avoid solid-core house wiring, as the vibrations from the road will cause solid wire to fatigue and snap over time.

The lighting circuits, including running lights (Green), left turn (Red), and right turn (Brown), generally carry less current. These can safely be wired with 14-gauge or 16-gauge wire. However, if your trailer uses traditional incandescent bulbs rather than modern LEDs, the cumulative draw can be surprising, so sticking to 14-gauge is a safer bet for long-term reliability.

Step-by-Step Installation and Wiring Guide

Installing a 7-way plug requires patience and the right tools. Follow these steps to ensure a secure, weather-resistant connection that matches the 7 way trailer plug diagram exactly.

1. Gather Your Tools and Materials: You will need a high-quality 7-way RV blade plug or socket, wire strippers, a terminal crimping tool, heat shrink tubing, electrical grease (dielectric grease), and a multimeter or circuit tester.

2. Prepare the Cable: Strip back the outer jacket of the trailer wiring harness about 2 to 3 inches, being careful not to nick the insulation on the individual wires inside. Once exposed, strip approximately half an inch of insulation from the end of each colored wire.

3. Slide on the Housing: Before you start attaching wires to the terminals, slide the back shell or dust cover of the plug onto the cable. This is a common mistake that requires you to dismantle your work if forgotten.

4. Connect the Ground Wire First: Identify the terminal marked “GND” or “White” on the back of the plug. Insert the white wire into the terminal and tighten the set screw firmly. Ensuring the ground is secure first provides a safety baseline for your testing.

5. Follow the Clockwise Pattern: Referencing your 7 way trailer plug diagram, connect the remaining wires to their designated terminals. Typically, the order inside the plug will be clearly labeled with letters or color names (e.g., “B” for Blue, “BK” for Black).

Double-check your manufacturer’s specific manual. While there is a “standard” color code, some older trailers or specific brands (like some European imports) may use a different color for the auxiliary power or turn signals. Always test the vehicle-side pins with a multimeter before finalizing the trailer-side wiring.

6. Secure and Seal: Once all wires are tightened, apply a small amount of dielectric grease to the terminals. This prevents corrosion and water intrusion. Slide the housing back over the terminal assembly and tighten the cable clamp to ensure that tension is placed on the outer jacket, not the individual wires.

7. Verify the Connections: Before hitching up, use a 7-way circuit tester or a multimeter to check the vehicle’s socket. Ensure that the “12V” pin shows 12-14 volts when the engine is running and that the turn signal pins pulse when the hazards are on.

8. Final Connection: Plug the trailer into the vehicle and perform a “walk-around” test. Check the running lights, both turn signals, and have a partner check the brake lights. Finally, move the manual override on your brake controller to ensure the trailer brakes engage.

Common Issues and Troubleshooting

Even with a perfect 7 way trailer plug diagram, issues can arise due to environmental factors or wear and tear. One of the most frequent problems is “intermittent lighting,” where lights flicker or dim when the trailer hits a bump. This is almost always caused by a loose ground pin or corrosion inside the plug.

If your trailer brakes are locking up or not engaging at all, the problem usually lies in the blue wire circuit. Check for a blown fuse in the vehicle’s engine bay, or use your diagram to trace the blue wire from the plug back to the brake controller. If the brake controller shows an “NC” (No Connection) error, it means the circuit is broken somewhere between the controller and the trailer magnets.

Another common sign of trouble is the “cross-talk” effect, where turning on your blinker causes the running lights to flash. This is a classic symptom of a “floating ground.” When the white ground wire fails, the electricity tries to find a path back to the vehicle through other light filaments, causing multiple circuits to activate simultaneously.

- ✓ Check for green or white crusty buildup (corrosion) on pins.

- ✓ Inspect the “jumper” or “pigtail” for cracks in the insulation.

- ✓ Ensure the vehicle’s auxiliary fuse is installed (many trucks ship from the factory with this fuse in the glovebox).

- ✓ Use a contact cleaner spray to refresh old connectors.

If you find that your vehicle-side socket is physically damaged or the lid no longer snaps shut, replace the entire unit. A loose lid allows moisture and road salt to enter, which will destroy the internal wiring in a single season.

Tips and Best Practices for Long-Term Reliability

To keep your towing setup in peak condition, maintenance is just as important as the initial installation. High-quality components are the foundation of a trouble-free experience. When purchasing a new connector, look for models with tin-plated copper terminals, as these resist corrosion much better than raw brass.

Maintenance should be performed at the start of every towing season. Use a small wire brush or a terminal cleaning tool to scuff the surfaces of the blades and pins. Applying a fresh dab of dielectric grease once a month during active use can extend the life of your plug by years. This grease doesn’t conduct electricity, but it creates a waterproof barrier that prevents oxidation.

If you frequently switch between different trailers, consider installing a “multi-tow” socket on your vehicle. These units provide both a 7-way RV blade and a 4-way flat connector in a single housing, eliminating the need for clunky adapters that can easily vibrate loose or get lost.

For those who store their trailers outdoors, the plug is often left dangling in the dirt or snow. Use a “plug dock” or a simple mounting bracket to keep the connector pointed downward and off the ground. This prevents water from pooling inside the housing. If you live in a coastal area or a region that uses heavy road salt, consider using a rubber plug cover whenever the trailer is not in use.

Finally, always carry a spare 7-way to 4-way adapter in your vehicle’s emergency kit. Even if your trailer is a 7-way, you never know when you might need to tow a friend’s smaller utility trailer or a boat. Being prepared with the right knowledge and the right tools ensures that your towing experience is safe, legal, and stress-free. By following this 7 way trailer plug diagram and installation guide, you have the foundation to handle any electrical challenge your trailer might present.

Frequently Asked Questions

What is 7 way trailer plug diagram?

A 7 way trailer plug diagram is a visual schematic that illustrates the pinout configuration for a standard RV blade-style connector. It shows where each colored wire connects to provide power for tail lights, turn signals, electric brakes, and auxiliary battery charging, ensuring your vehicle and trailer communicate electronically.

How do you read 7 way trailer plug diagram?

To read the diagram, look at the face of the connector, identifying the center pin and the six surrounding blades. The diagram will match specific wire colors—typically white for ground, blue for brakes, and black for auxiliary power—to their corresponding positions to ensure correct electrical flow and functionality.

What are the parts of 7 way trailer plug?

The main parts include the RV blade housing, seven internal metal terminals, a weather-resistant cover, and the wiring harness. These components work together to deliver signals for the turn signal, running lights, and brake controller while providing a secure ground and 12V auxiliary power for the trailer’s interior.

Why is brake controller important?

A brake controller is vital because it regulates the intensity of the trailer’s electric brakes based on the towing vehicle’s deceleration. Without a properly wired 7-way plug to transmit this signal, the trailer would rely solely on the vehicle’s brakes, leading to dangerous stopping distances and increased wear.

What is the difference between 4-pin and 7-pin plugs?

A 4-pin plug only handles basic lighting like the turn signal and running lights. In contrast, a 7-way plug adds three critical circuits: electric brakes for a brake controller, a 12V auxiliary power line for battery charging, and backup lights, making it necessary for larger RVs and trailers.

How do I use 7 way trailer plug diagram?

Use the diagram by matching the physical wires on your trailer harness to the labeled pins on the plug. Strip the wire ends, insert them into the correct terminal as shown in the diagram, and tighten the set screws. This ensures that your lights and brakes respond correctly.